Self-variable-resistance blast cap

An air cap and resistance technology is applied in the field of circulating fluidized bed boilers, which can solve the problems of low-load material fluidization uniformity and oxygen peroxidation contradiction, and achieve the effect of solving the peroxidation contradiction, reducing fan energy consumption, and improving boiler efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

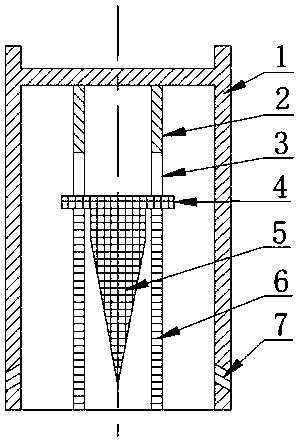

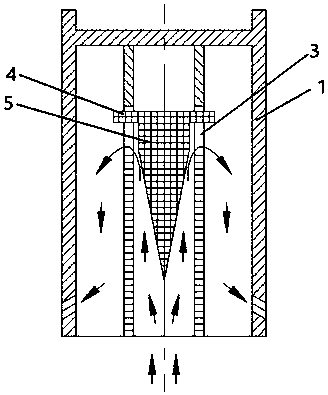

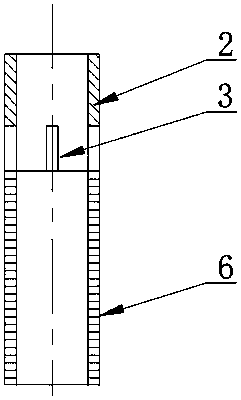

[0019] Such as Figure 1 to Figure 3 As shown, a self-variable resistance wind cap provided by the present invention includes a wind cap outer cover 1, a limit tube 2, a limit hole 3, a movable rod 4, a movable block 5, a core tube base 6, and a wind cap hole 7, wherein the core tube One end of the base 6 is connected to the air distribution plate; the other end is connected to the limiting tube 2; the core tube base 6, the limiting tube 2 and the hood cover 1 are connected.

[0020] The limiting tube 2 is in contact with the top of the hood cover 1 .

[0021] A plurality of limiting holes 3 are opened on the side wall of the end of the limiting tube 2 connected with the core tube base 6 along its circumferential direction; the limiting holes 3 are opened along the axial direction of the limiting tube 2 .

[0022] Such as Figure 4 As shown, a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com