Waste cracking furnace with low energy consumption

A cracking furnace, low energy consumption technology, applied in the direction of incinerator, combustion ignition, combustion method, etc., can solve the problems that affect the popularization and application, inconvenient ignition, a large amount of smoke, etc., and achieve the effect of improving the reaction effect and simple structure

Inactive Publication Date: 2010-08-25

黄广禧

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, in the waste treatment process, incinerators are often used, and cracking furnaces are also used to treat waste. The cracking furnaces used in the existing waste treatment process do not have a reaction zone balance device, which cannot maintain a relatively stable pressure in the reaction zone, making cracking It is difficult for the furnace to continuously and stably produce combustible gas, and cannot avoid the generation of smoke, nor can it shield the harmful molecules released by the cracked substances

The cracking furnace cannot solve the problem of exporting the generated gas-liquid mixture well, so that the cracking furnace cannot be fully burned, and a large amount of flue gas is generated, which pollutes the environment

The current cracking furnace adopts manual ignition, and uses an open flame, which is inconvenient, unsafe, and uneven ignition

The gas distribution device designed on the cracking furnace is unreasonable, and the gas distribution effect is not ideal

Uneven ignition and unreasonable gas distribution directly affect the reaction effect of the cracking furnace

These defects of the cracking furnace directly affect its stable operation and also affect its popularization and application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

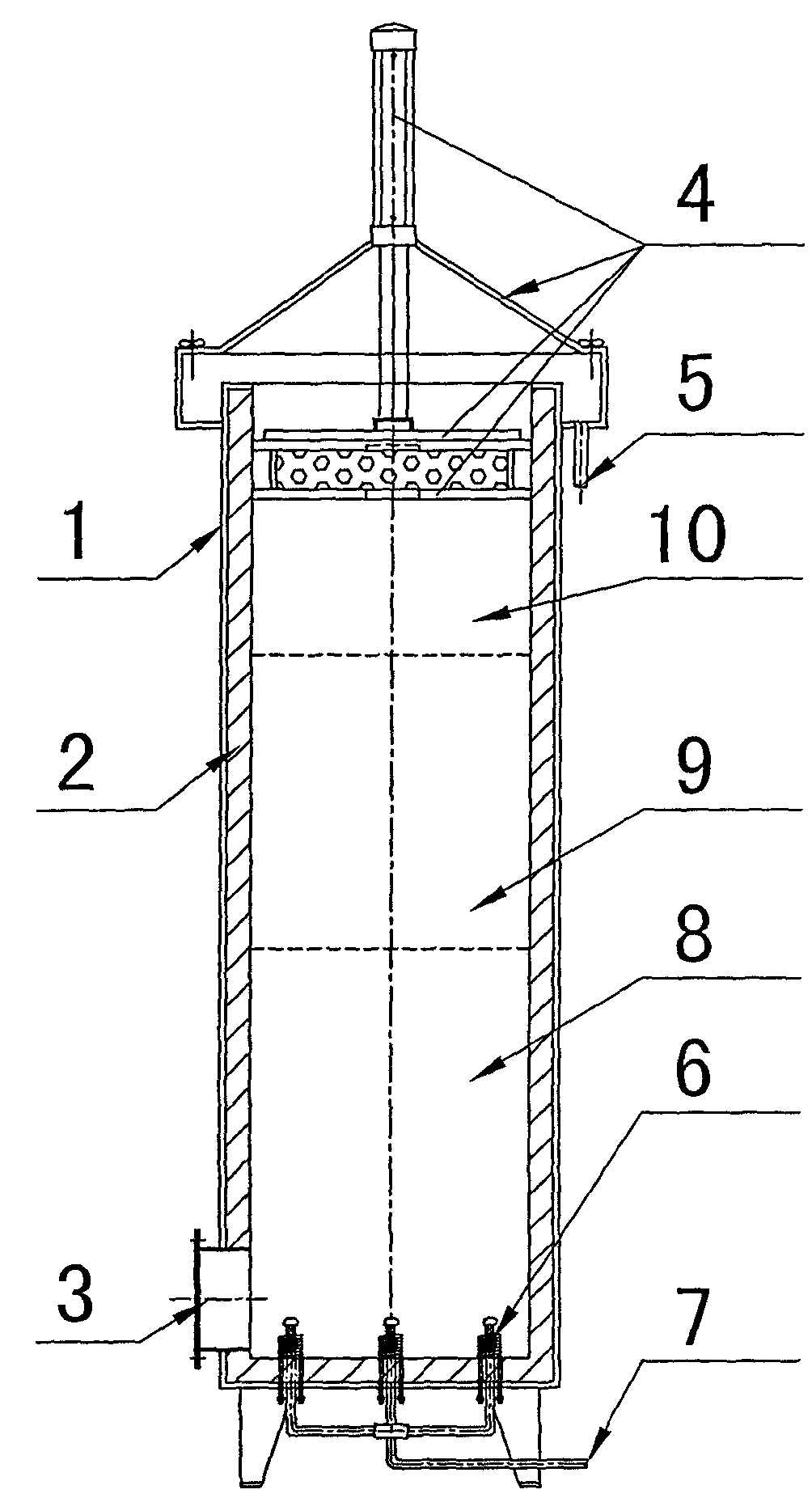

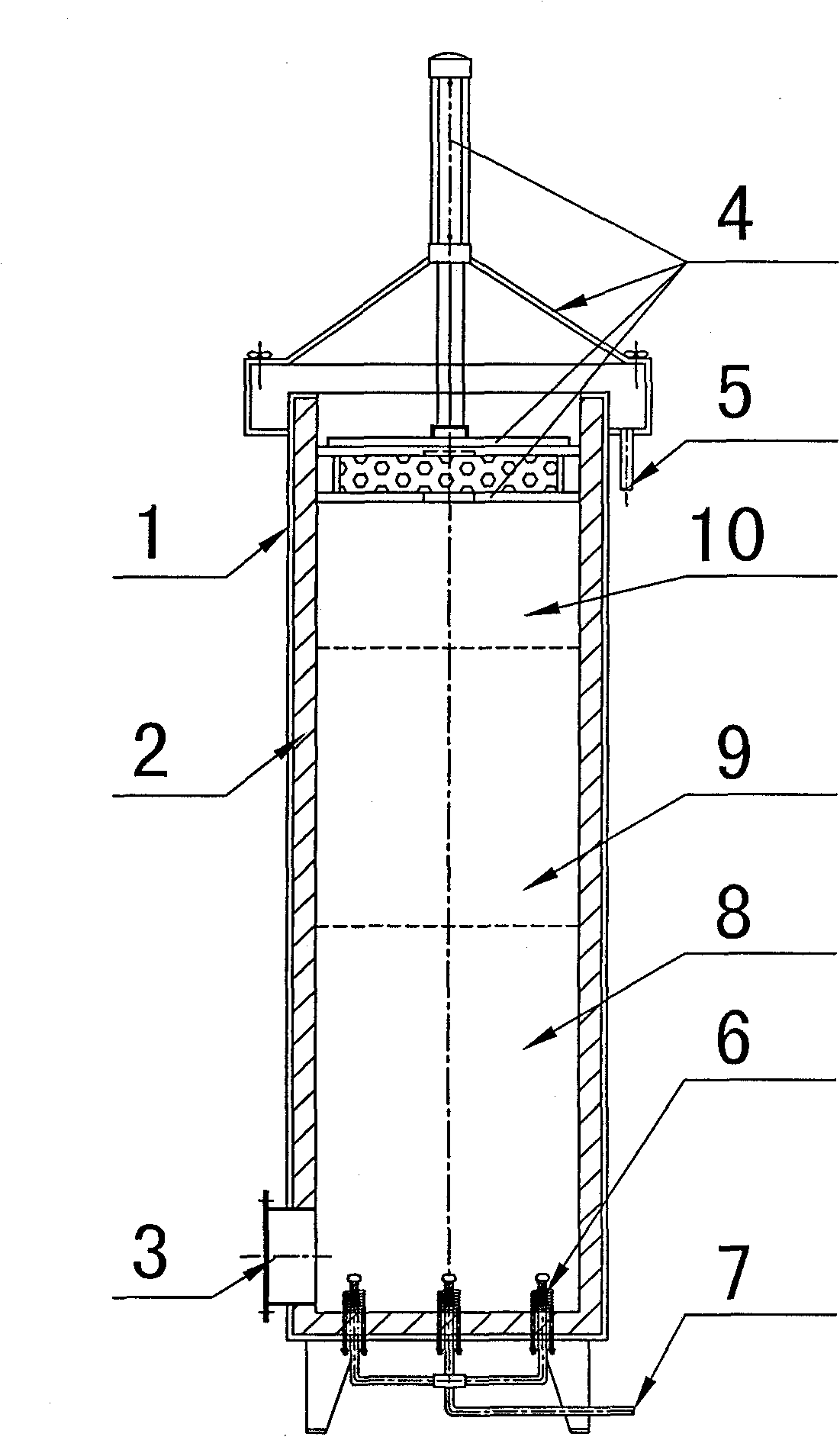

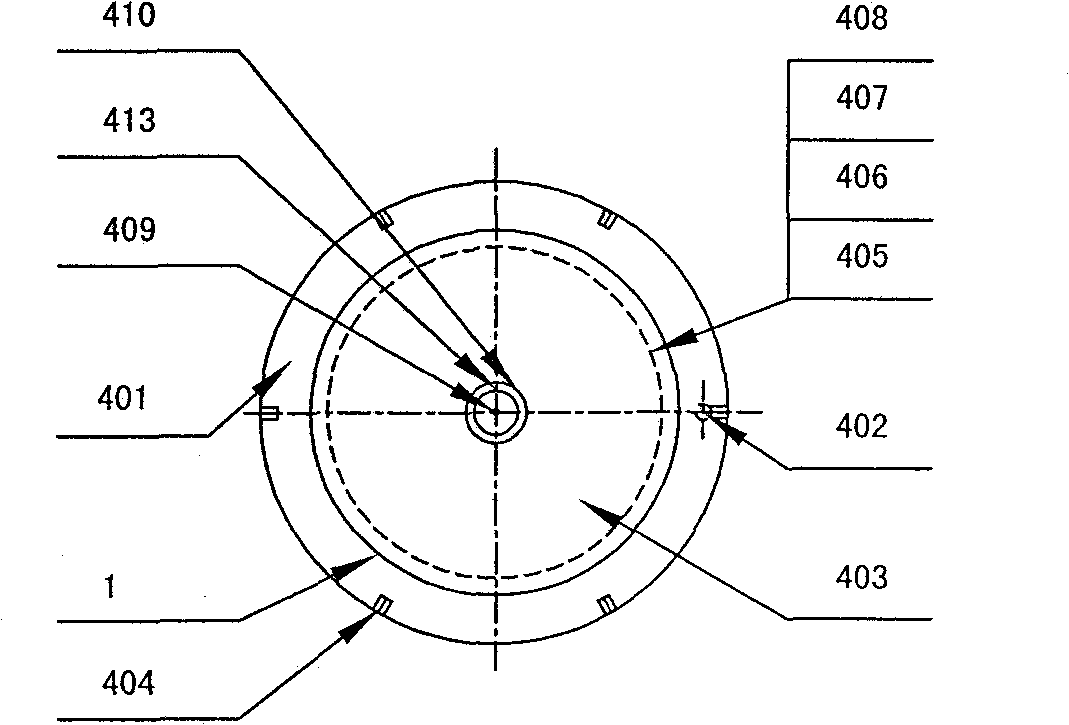

The invention relates to a waste cracking furnace with low energy consumption, which belongs to the field of waste processors and comprises a furnace body, a permanent magnetic material layer, a carbon mixture outlet, a balance and gas-liquid collection device, a gas-liquid mixture outlet, an oxygen supply and automatic ignition device and an air inlet. The balance and gas-liquid collection device is arranged at the top of the furnace body, the oxygen supply and ignition device is arranged on a base plate of the furnace body, the permanent magnetic material layer is arranged in the furnace body and tightly attached to furnace body, and the balance and gas-liquid collection device comprises a gas-liquid collection passage, a gas-liquid collection pipeline, a closed cover, a sealing ring, a top pressure layer, a piston, a gas cylinder, a lower air inlet and an upper air inlet, and the oxygen supply and ignition device comprises an oxygen supply, an oxygen supply pipeline, an air distributor, an air main pipe and a heating wire ignition device. The invention has simple structure, can keep the relatively stable pressure of a cracking furnace reaction region, realizes the automatic power ignition and the even bottom gas distribution of the cracking furnace and improves the reaction effect of the cracking furnace.

Description

Low energy consumption garbage pyrolysis furnace technical field The low-energy-consumption garbage cracking furnace of the invention belongs to the field of garbage treatment devices, and in particular relates to a low-energy-consumption garbage cracking furnace. Background technique At present, in the waste treatment process, incinerators are often used, and cracking furnaces are also used to treat waste. The cracking furnaces used in the existing waste treatment process do not have a reaction zone balance device, which cannot maintain a relatively stable pressure in the reaction zone, making cracking It is difficult for the furnace to continuously and stably produce combustible gas, and cannot avoid the generation of smoke, nor can it shield the harmful molecules released by the cracked substances. The cracking furnace cannot well solve the export problem of the generated gas-liquid mixture, which makes the cracking furnace unable to fully burn, produces a large amount ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23G5/027F23G5/44F23Q7/04

Inventor 黄广禧刘平李高奇

Owner 黄广禧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com