Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

273results about How to "Uniform air distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

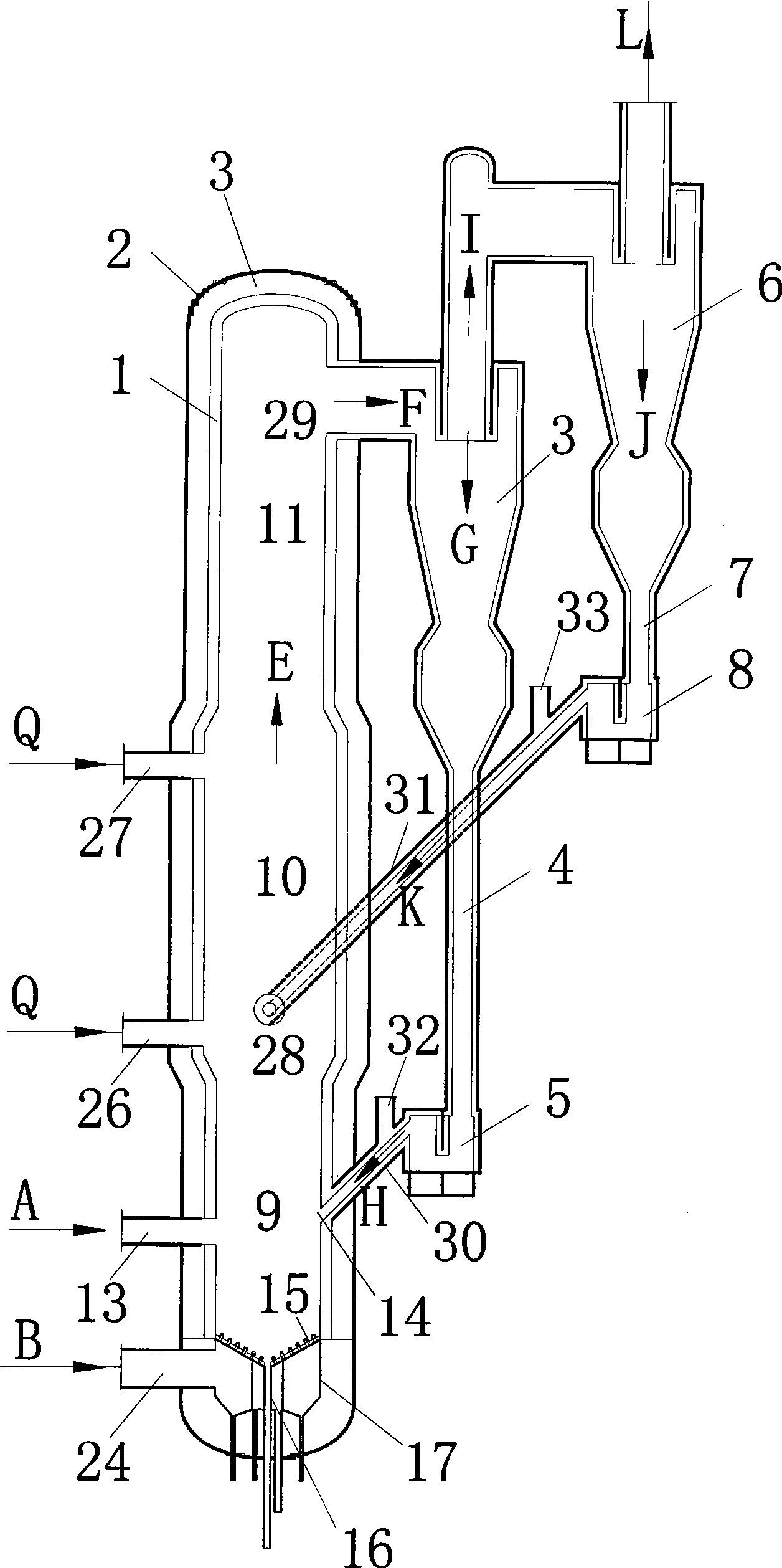

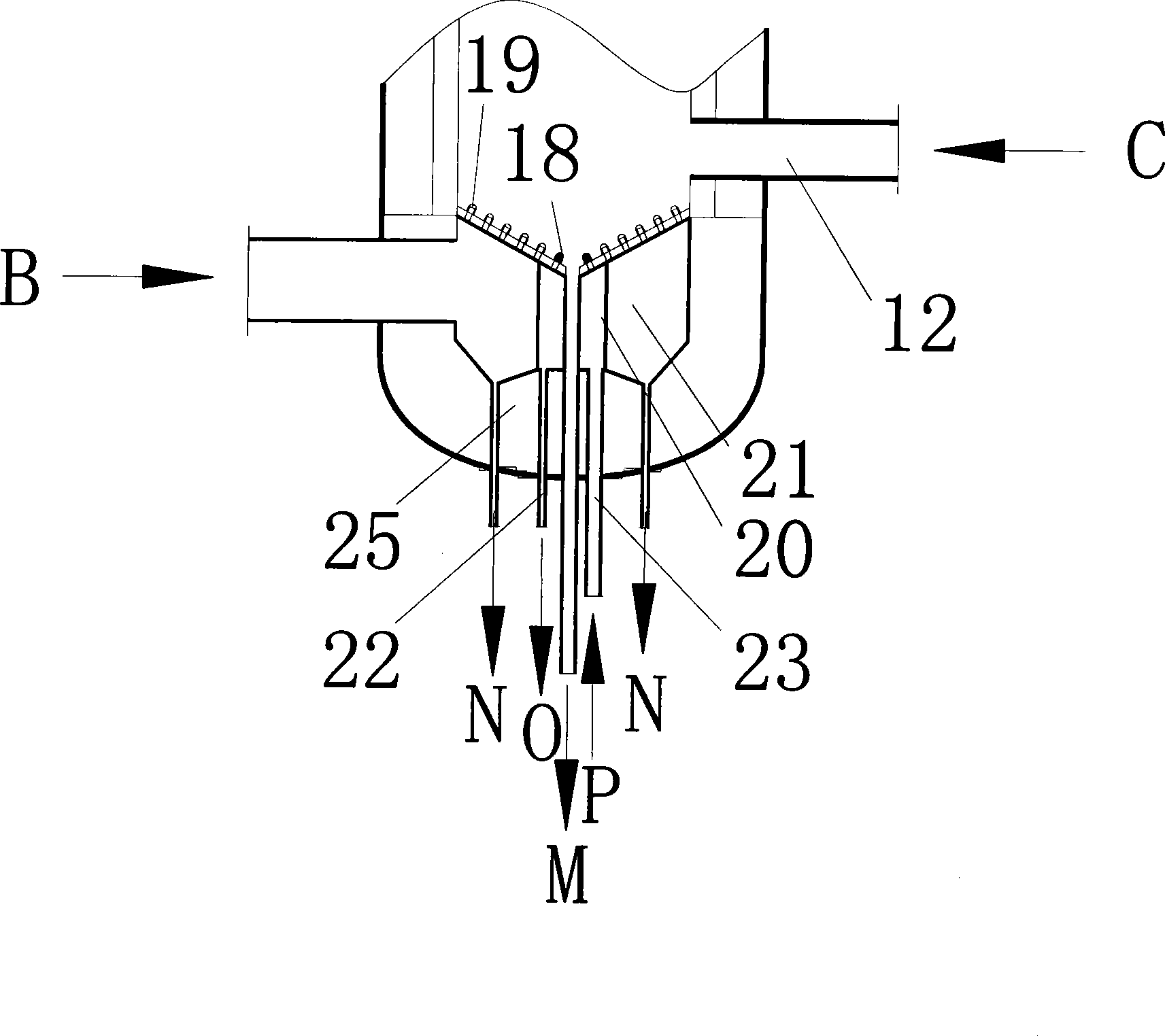

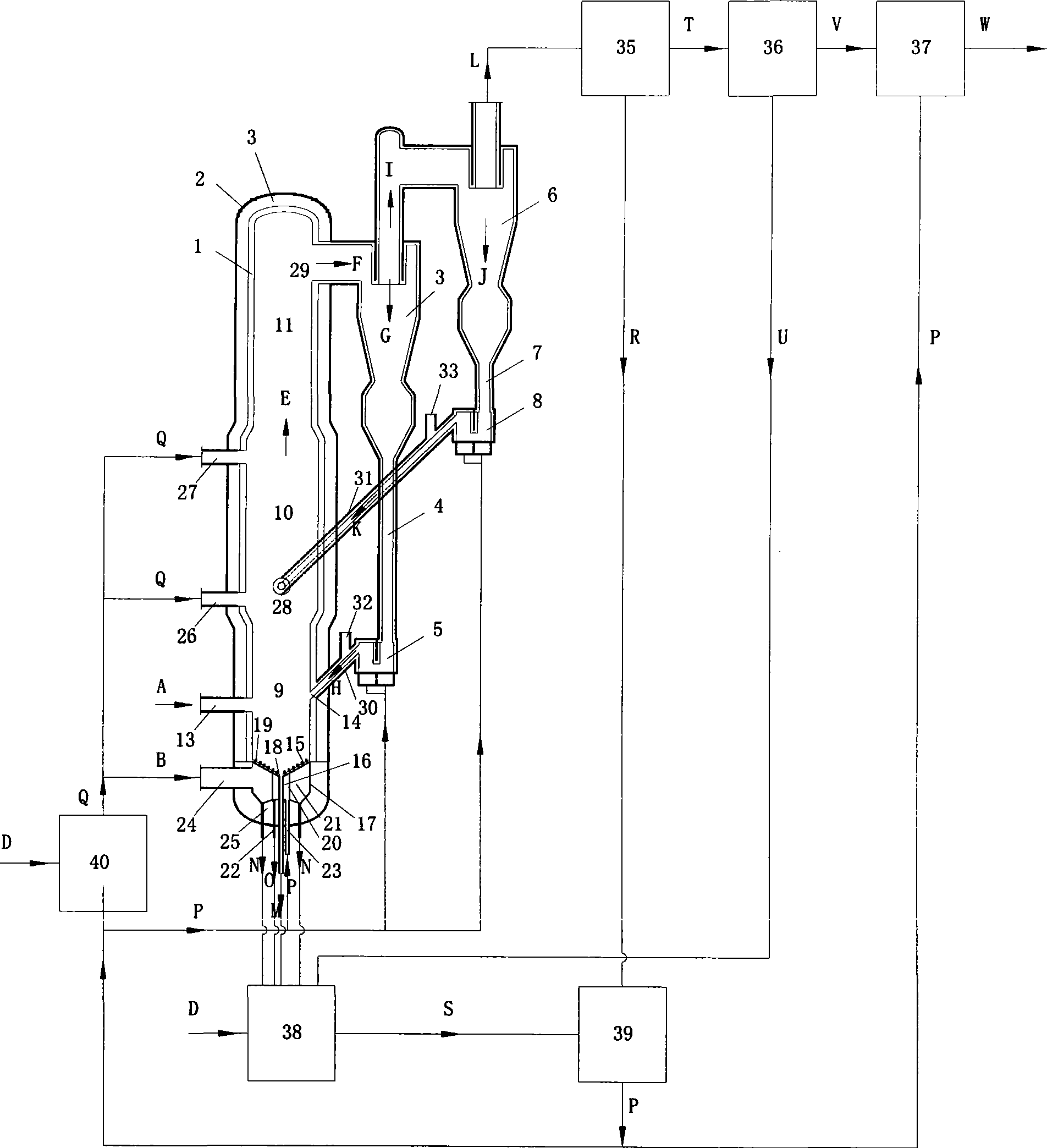

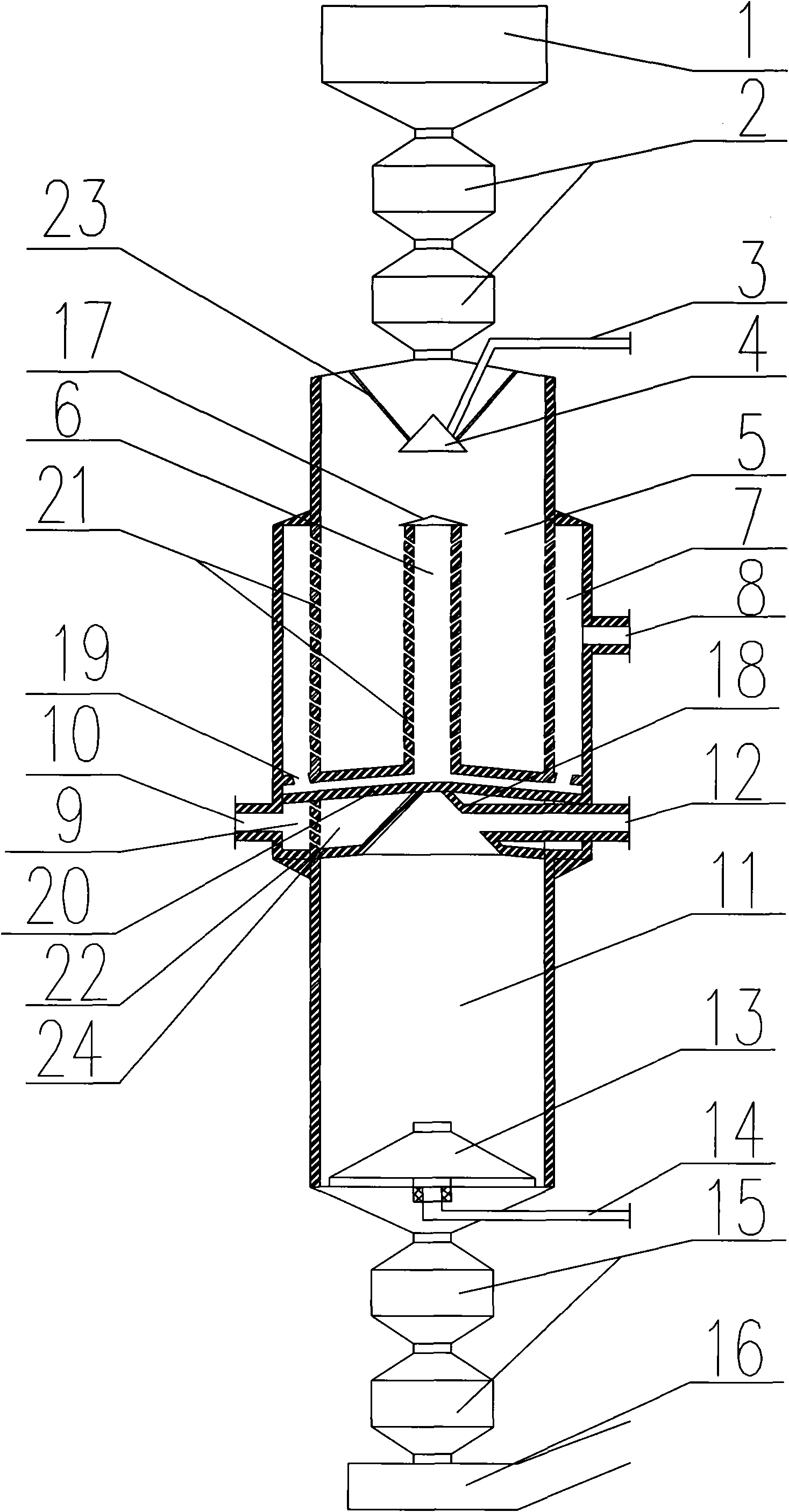

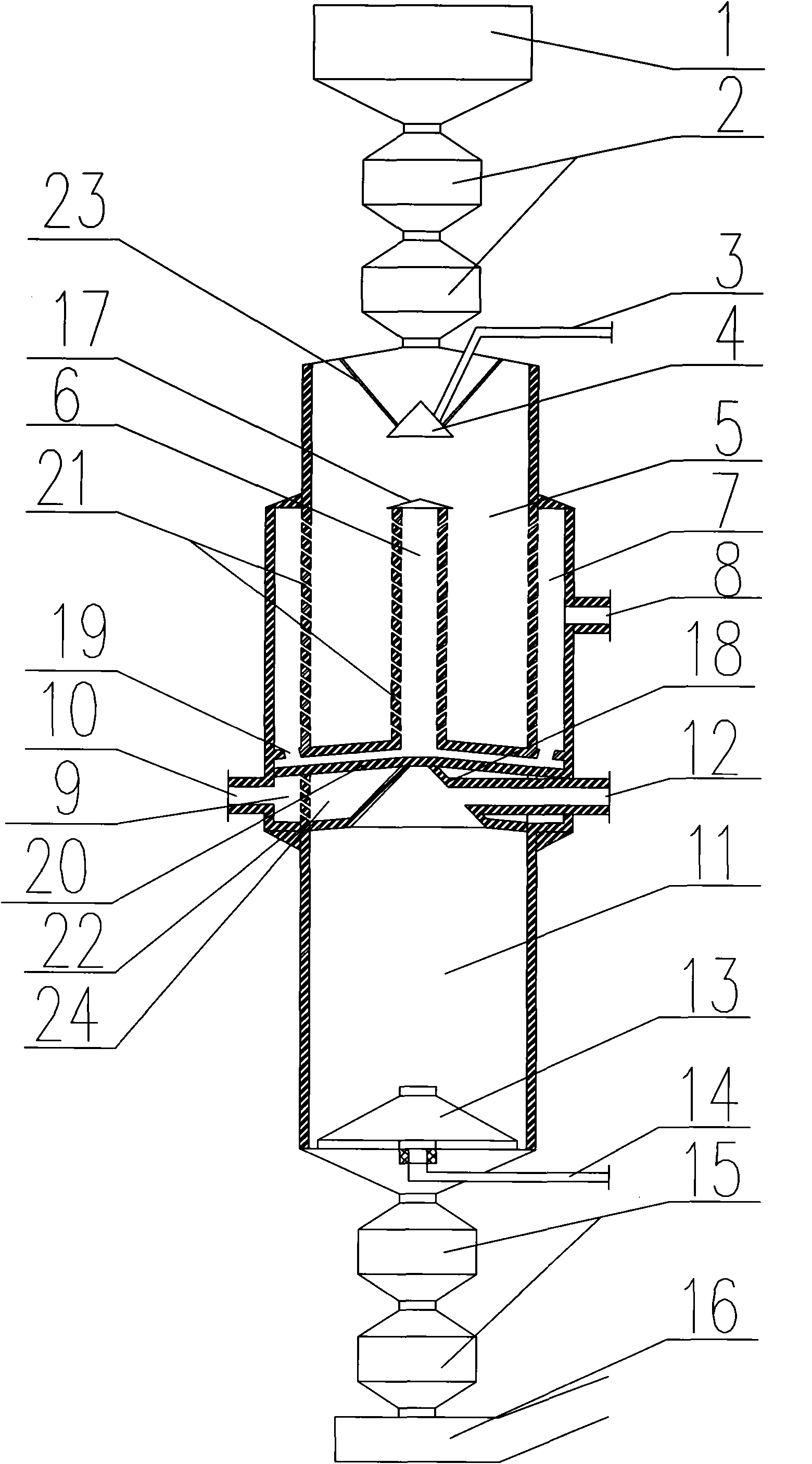

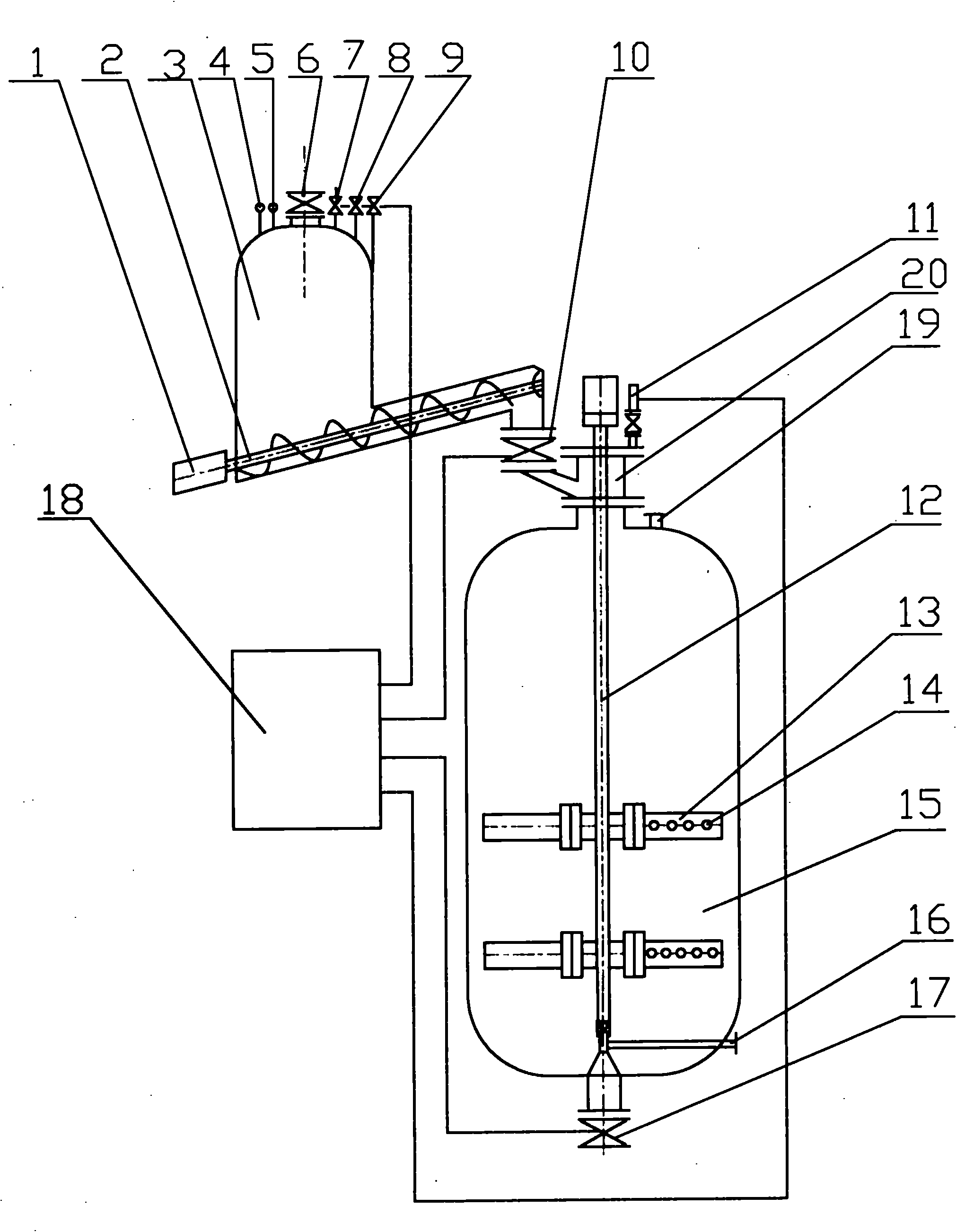

High-density pressurized fluidized bed coal gasification apparatus and method

ActiveCN101372635AGood amplification performance of flow dynamic characteristicsImprove carbon conversionCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringTransformation ratio

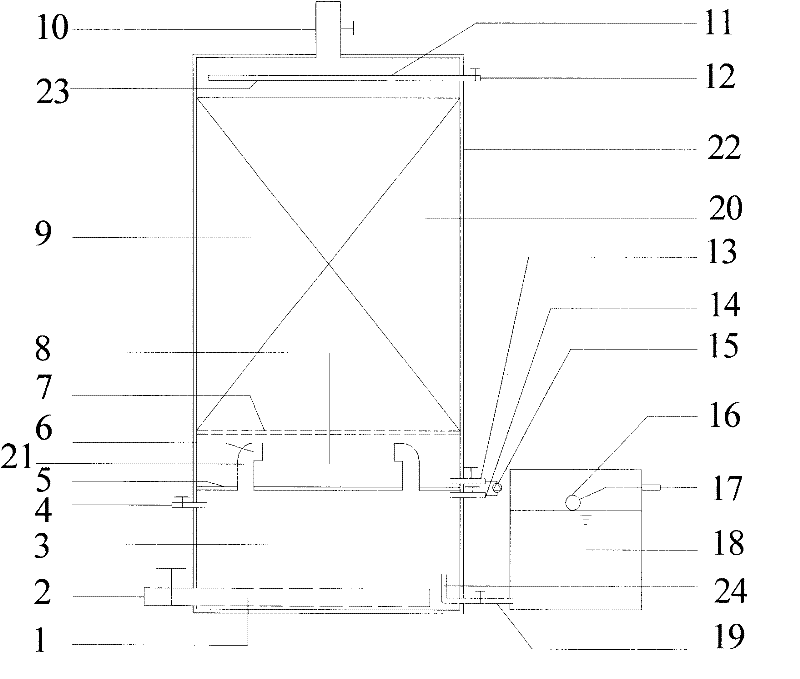

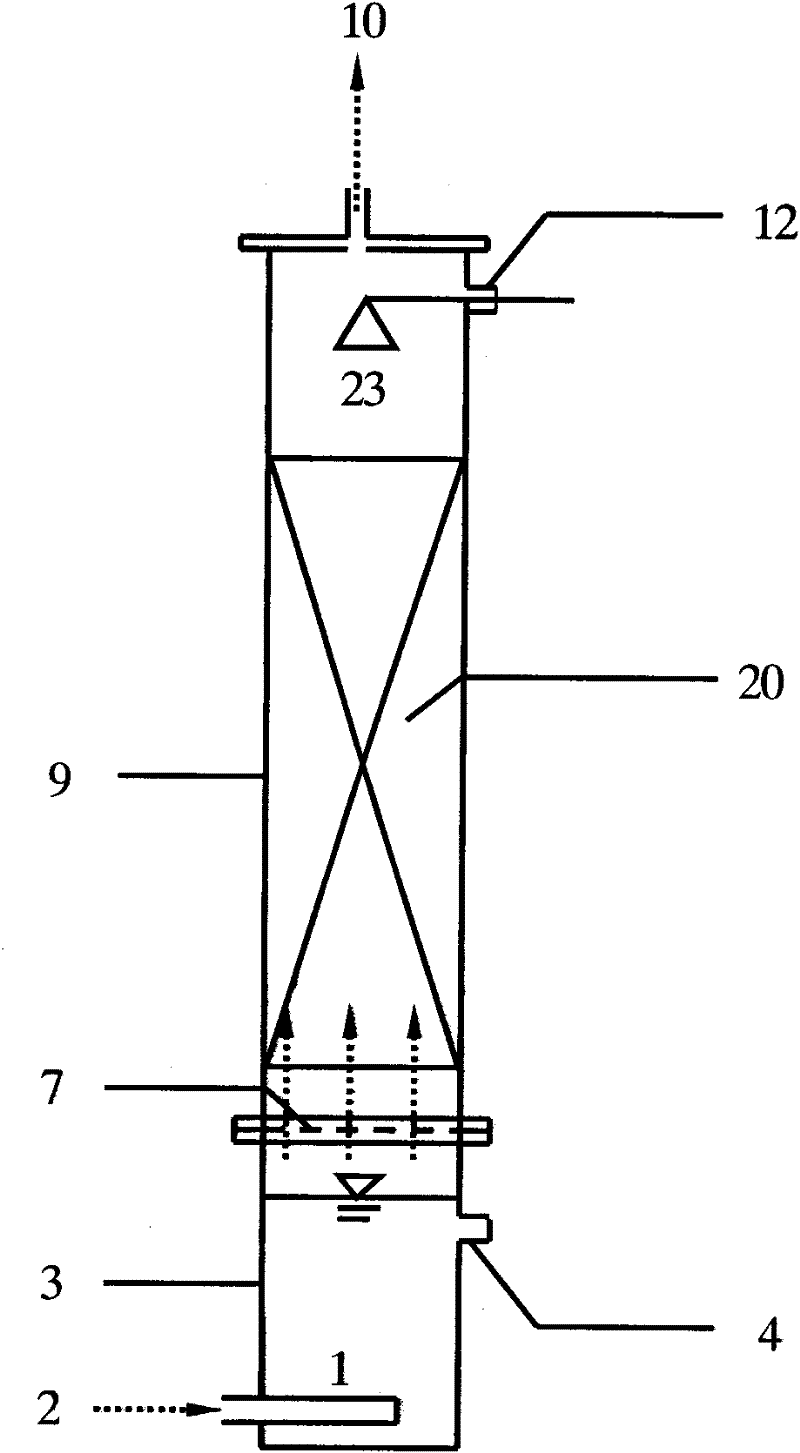

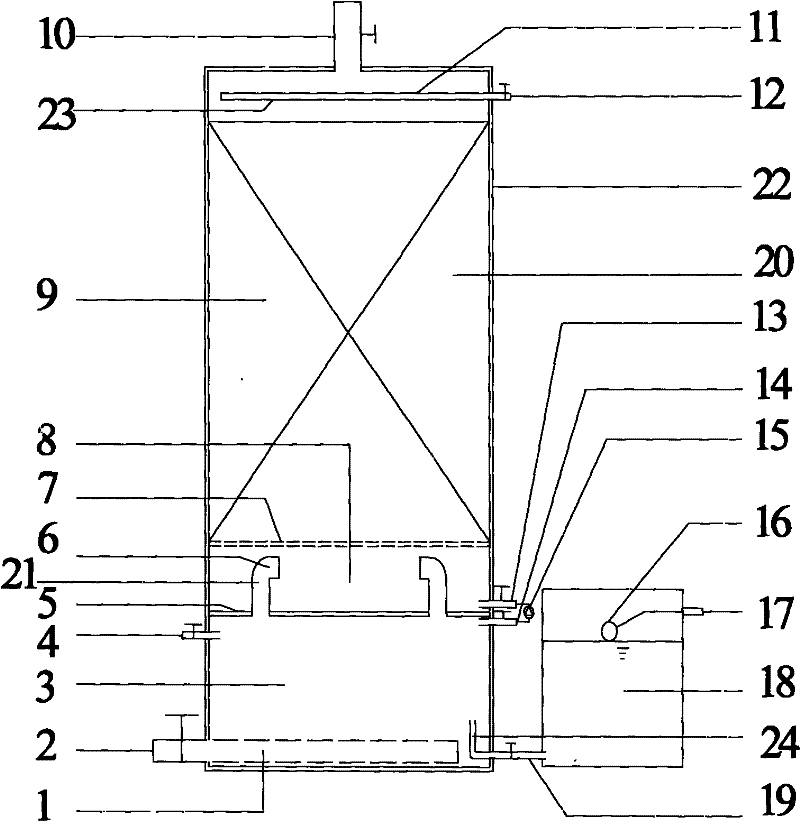

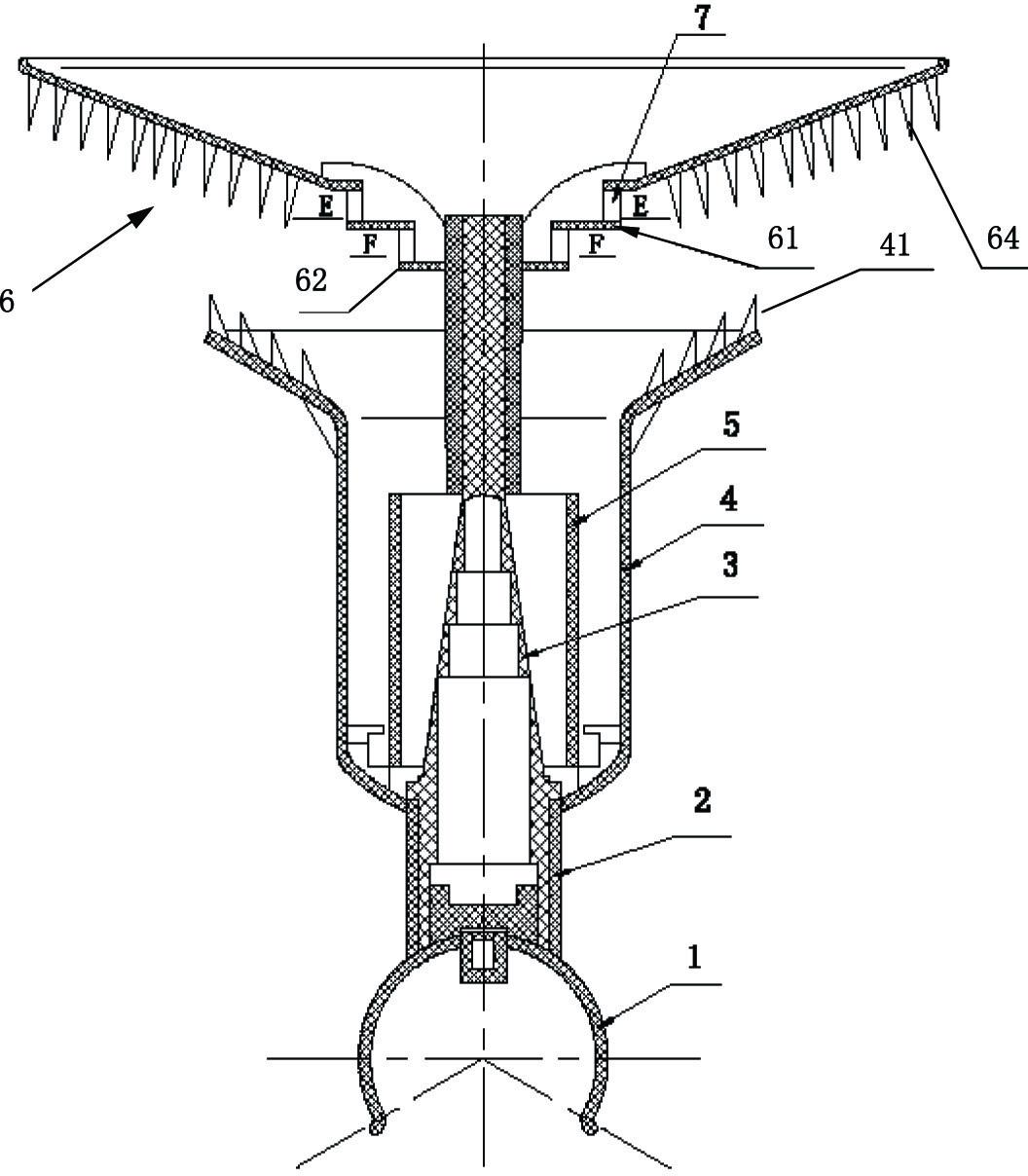

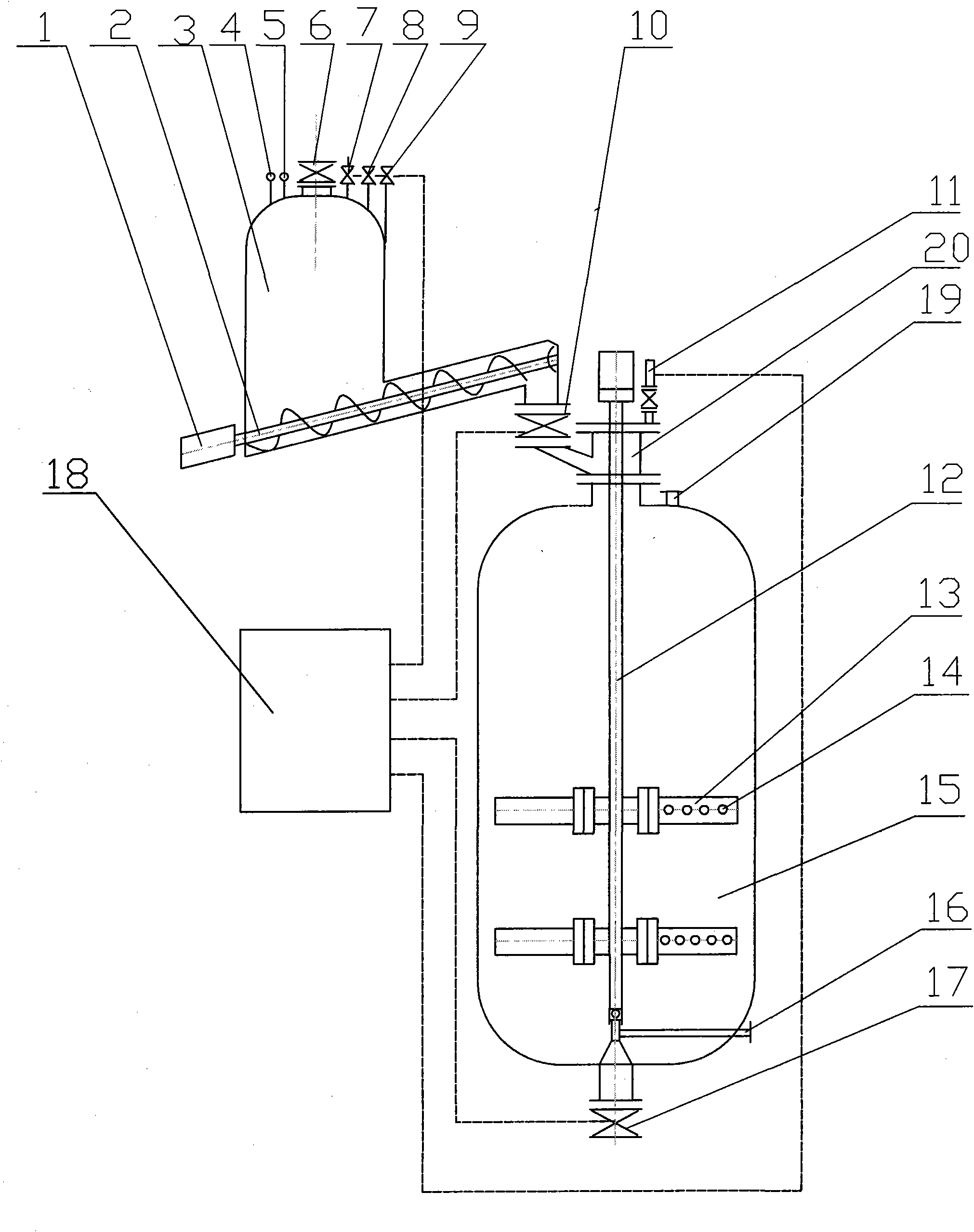

A high-density pressurized fluid bed coal gasification device and a method relate to a gasification device and a method which are especially suitable for the efficient treatment of the high-sulfur, high-ash and high ash fusion point coal with high reserve volume in China and have the advantages of broad coal type adaptability, high carbon transformation ratio in the gasification process, high heat value of coal gas, low investment and excellent environment-friendly performance. A gasification reactor (1) is arranged in a pressure shell (2) and is divided into a dense-phase turbulent flow fluidizing section (9), a high-density core-annulus flow section (10) and a density rapid flow section (11) from bottom to top, and according to the gasification character of the goal with high sulfur, high ash and high ash fusion point, flow states with different features are adopted for pressurizing and sectionalized gasification from bottom to top and the pressure for gasification is 1.0-2.5MPa.

Owner:SOUTHEAST UNIV

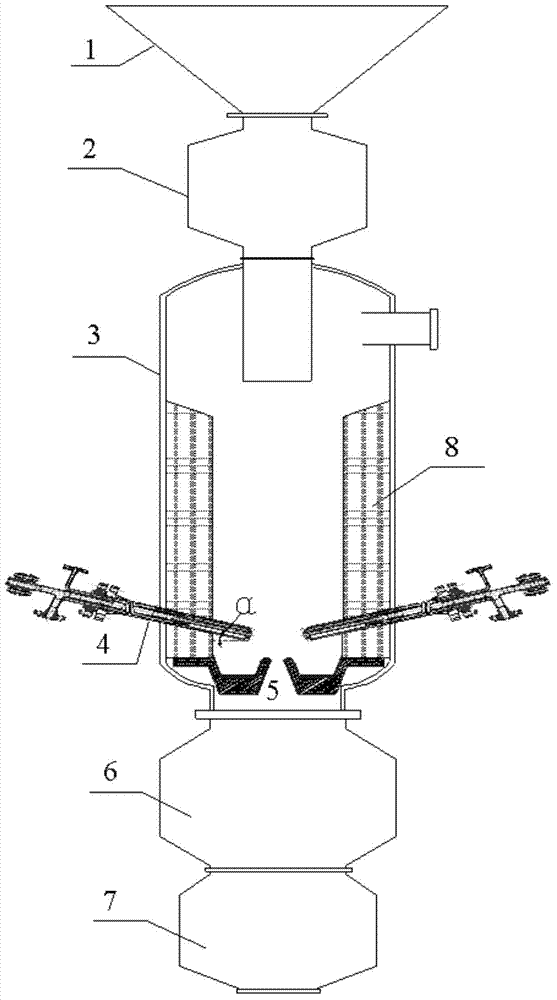

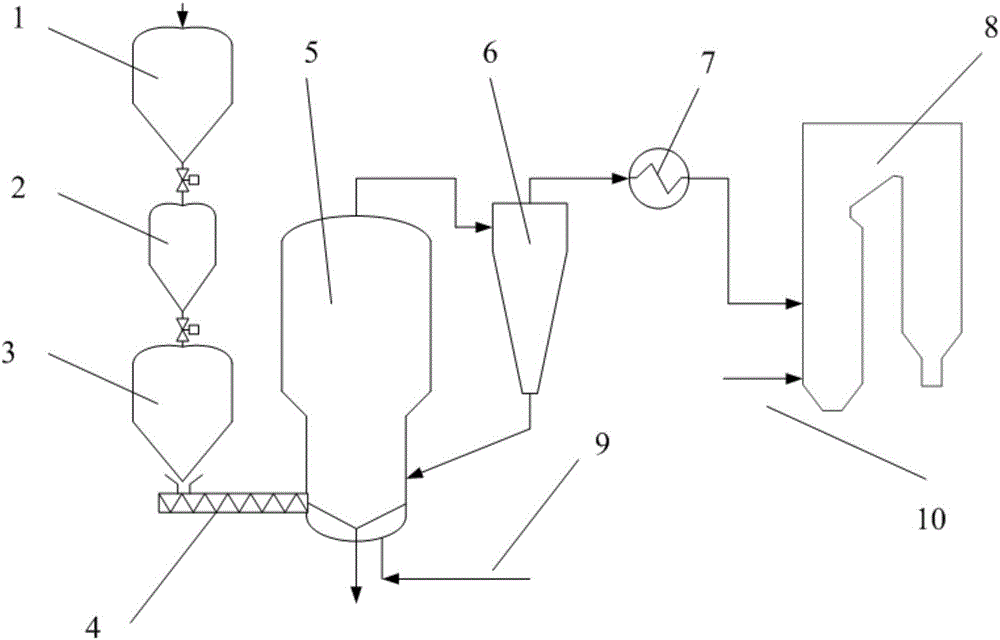

Liquid continuous slag-removal fixed bed gasification furnace and gasification method thereof

ActiveCN104327881AExtended service lifeAvoid overall overheatingHydrogenGasification processes detailsFixed bedQuenching

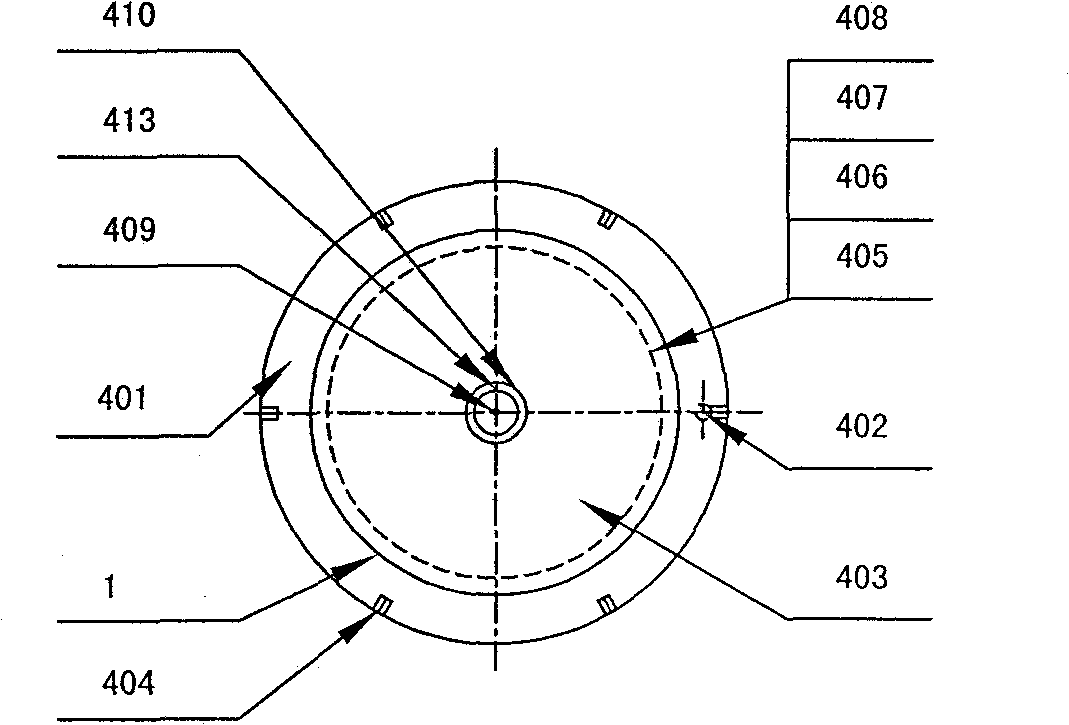

The invention relates to a liquid continuous slag-removal fixed bed gasification furnace and a gasification method thereof, the liquid continuous slag-removal fixed bed gasification furnace is characterized in that: the liquid continuous slag-removal fixed bed gasification furnace from top to bottom in turn comprises a raw material bin, a material lock hopper, a furnace body, a plurality of gasification agent nozzles, a slag-removal device, a molten slag quenching chamber and a slag lock; the raw material bin is funnel-shaped, the lower end of the raw material bin is in fastening connection with the upper end of the raw material lock hopper; the raw material lock hopper is in fastening connection with an upper end port of the furnace body, the upper part of the furnace body is provided with a crude gas outlet, the furnace body inner wall located below the crude gas outlet is provided with a layer of furnace lining; the plurality of gasification agent nozzles are in fastening connection with the lower part of the furnace body and are arranged uniformly along the circumferential direction of the furnace body, the outlet of each gasification agent nozzle passes through the furnace body furnace wall and the furnace lining and extends into the furnace body; the slag-removal device is installed in the furnace body located below the furnace lining, the lower end of the furnace body is in fastening connection with the upper end of the molten slag quenching chamber, and the lower end of the molten slag quenching chamber is in fastening connection with the upper end of the slag lock. The gasification agent nozzles adopt a single channel structure only conveying a gasifying agent, the service life of the gasification agent nozzles is improved, and an overflow type slag pool can effectively ensure the smooth slag removal, and improves the operation efficiency of the fixed bed molten slag gasification furnace.

Owner:CCTEG CHINA COAL RES INST

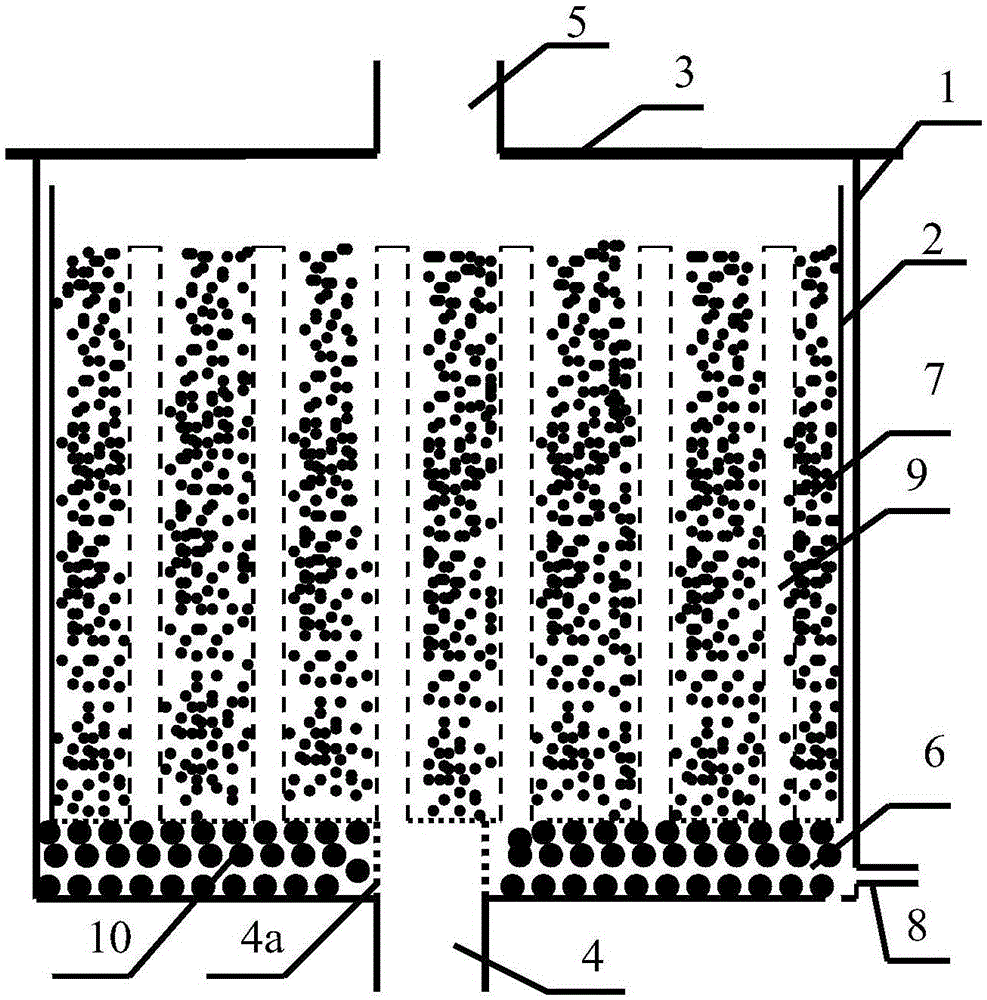

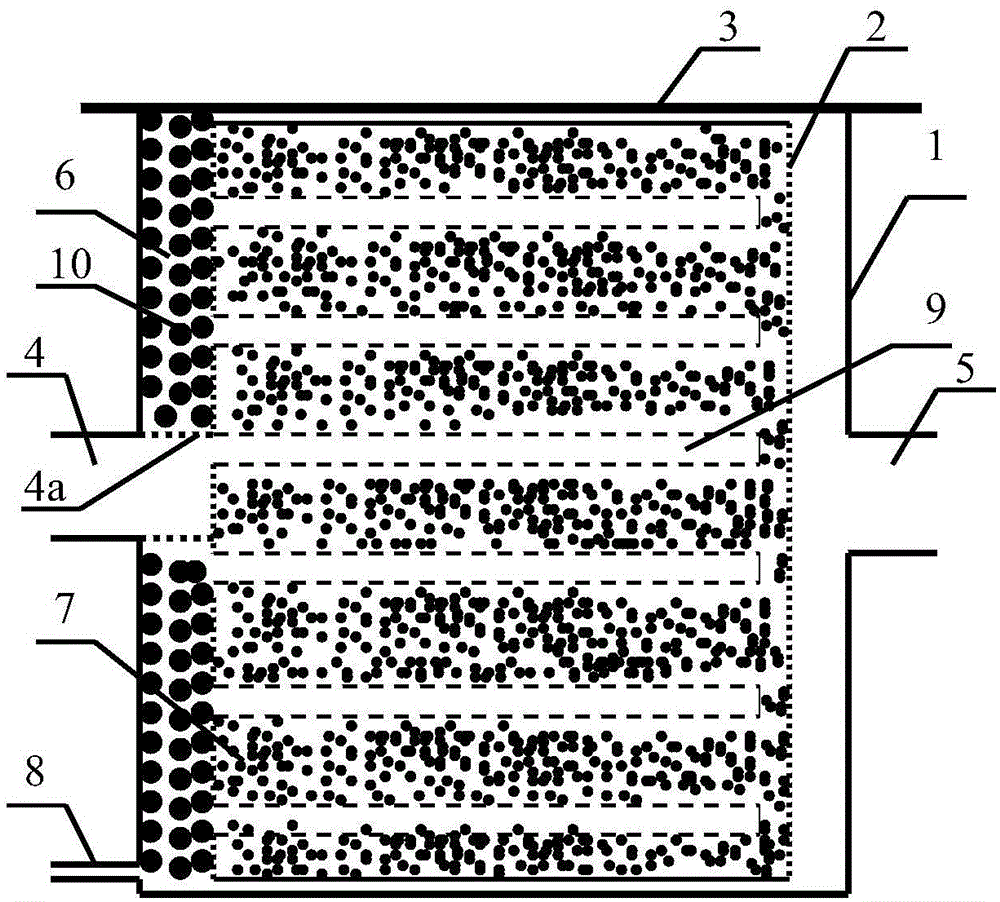

Three dimension electrode reaction unit

InactiveCN105461024ABroad-spectrumIncrease useDispersed particle separationWater/sewage treatment using germicide/oligodynamic-processSiphonTreatment effect

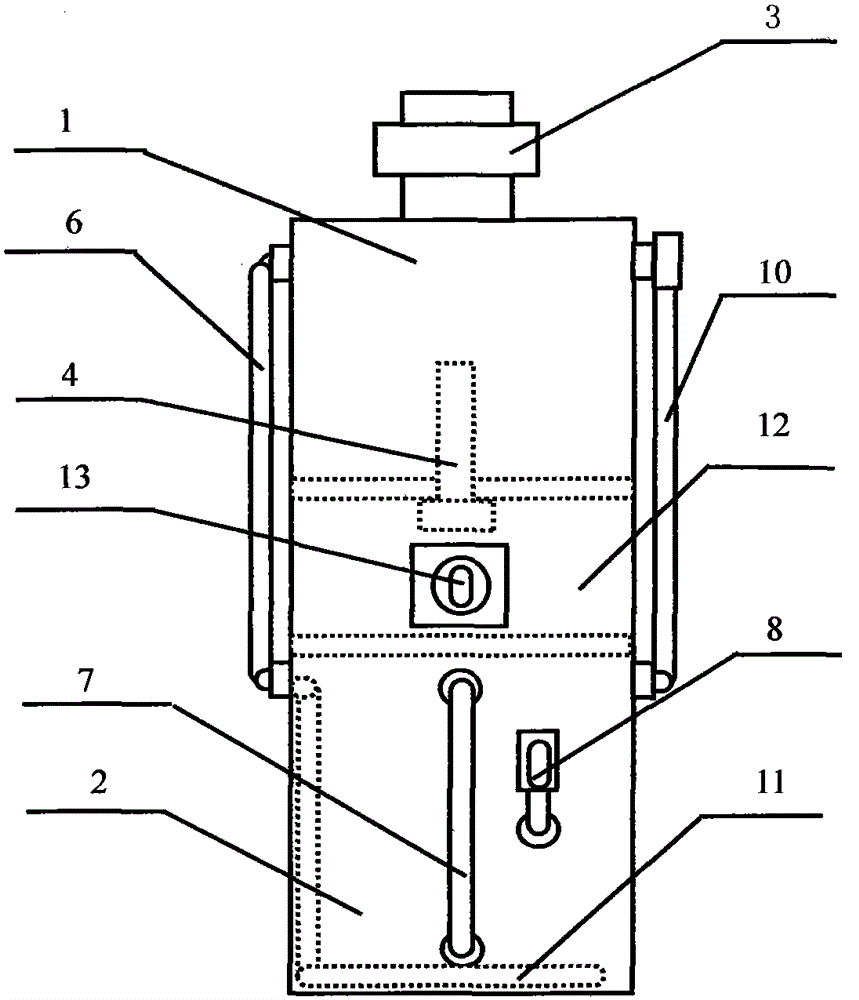

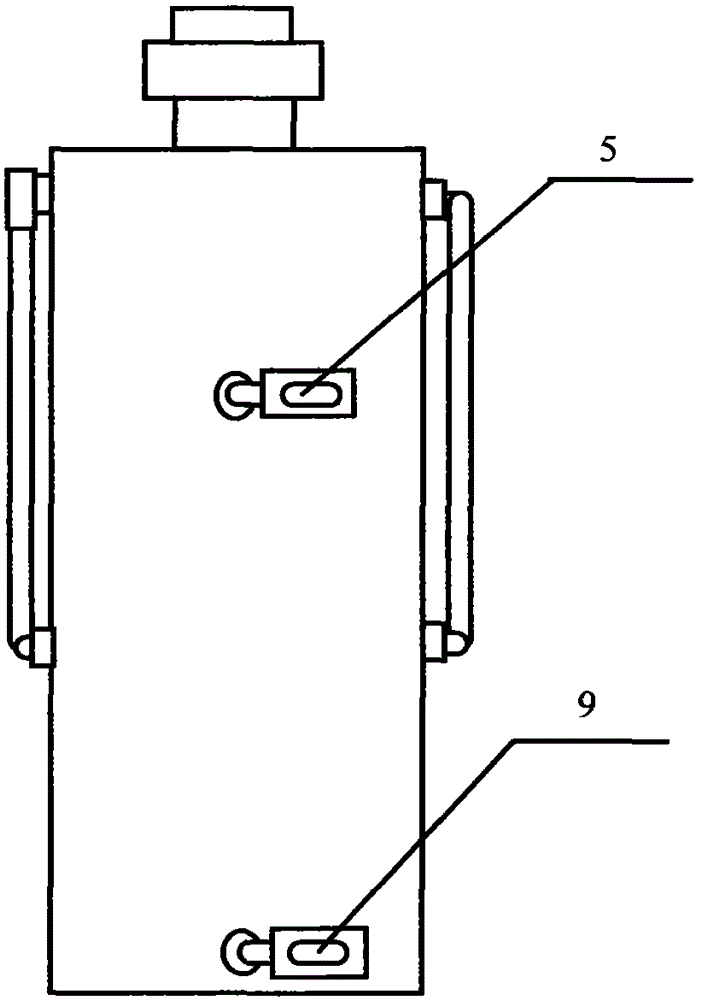

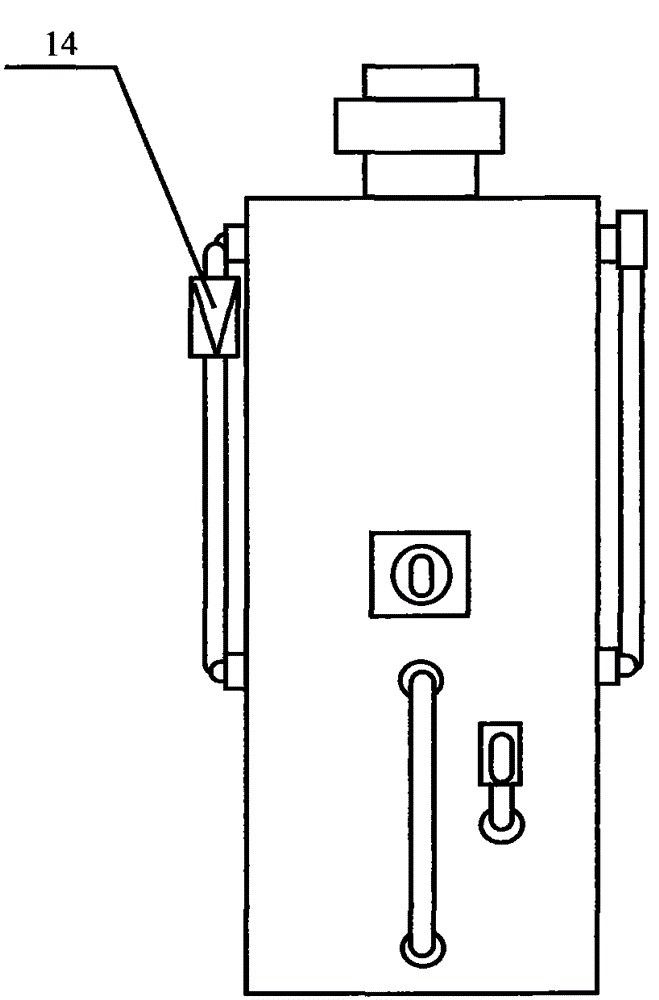

The invention discloses a three dimension electrode reaction unit, which is characterized in that short flow of wastewater is avoided by arranging plate-type main electrodes placed in a parallel staggered manner, insulation baskets with holes and particle electrodes filled therein, aerator pipes, insulation frames of which the surfaces have fine wire screens, support pins and tees, so that the wastewater is more uniformly mixed and the retention time is simultaneously reduced; the aeration is more uniform, the degree of mixedness of the wastewater is deepened, and the mass transfer efficiency is greatly improved; the partitioning design of the particle electrodes can omit a discharge opening of a traditional device, so that loading and unloading of the particle electrodes are more convenient and cleaner, and the partitioning design of the particle electrodes also can block a short-circuit current difficult to overcome in a traditional three dimension electrode reaction unit, and economy, green and high efficiency are realized; a gas-liquid mixture can be removed while mixing and effluent discharging are performed; the occurrence of a siphon problem can be avoided; the height of the wastewater can be controlled through the length of a discharging tube, thus a basic parameter, namely the filling amount of the particle electrodes, is controlled, and a better treatment effect is further obtained.

Owner:湖北金日生态能源股份有限公司

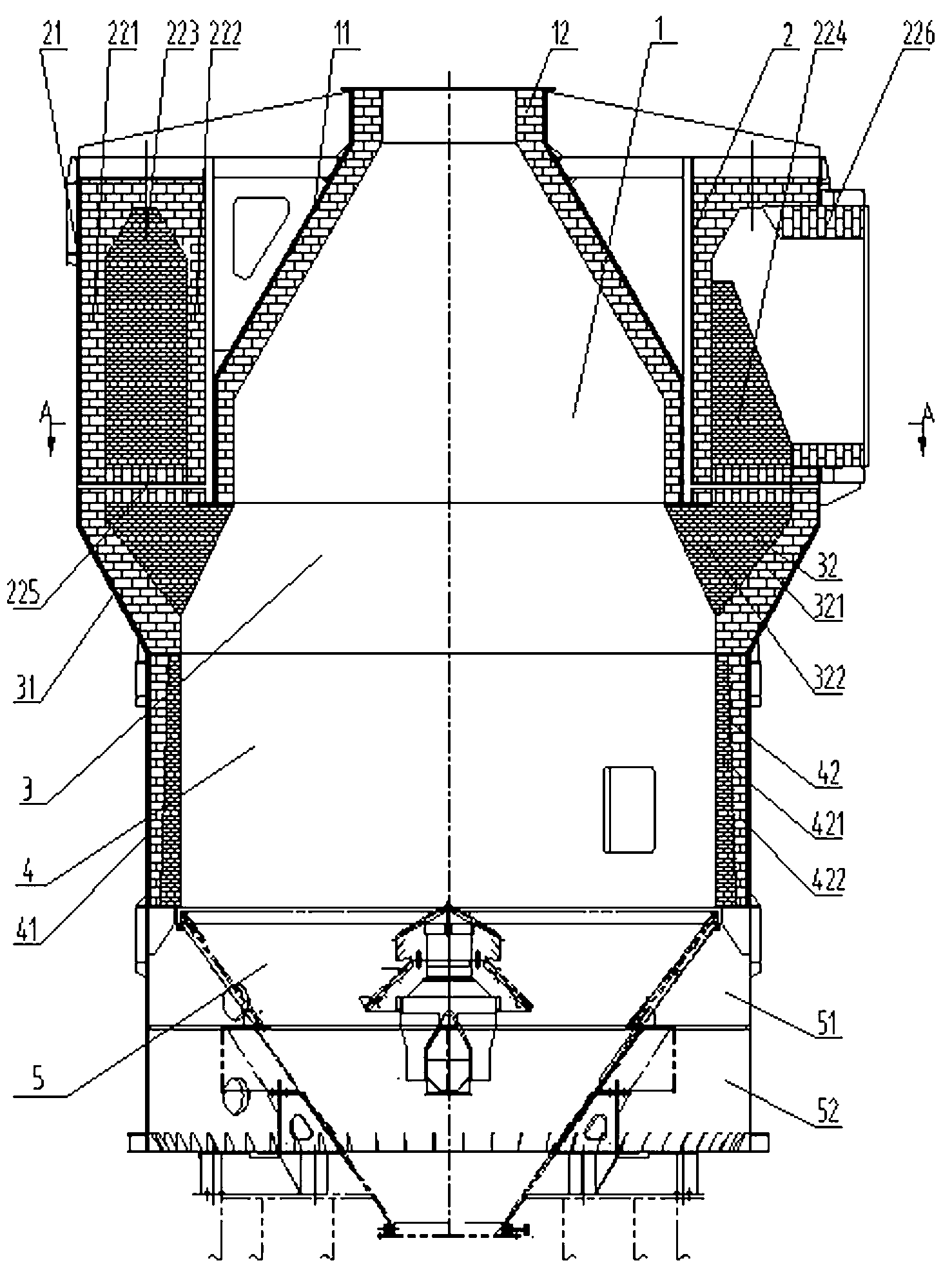

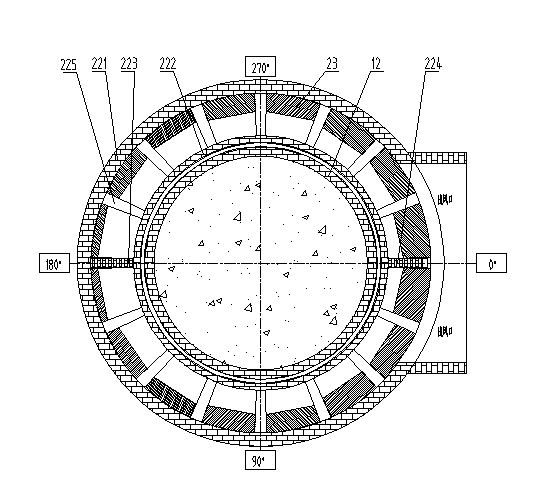

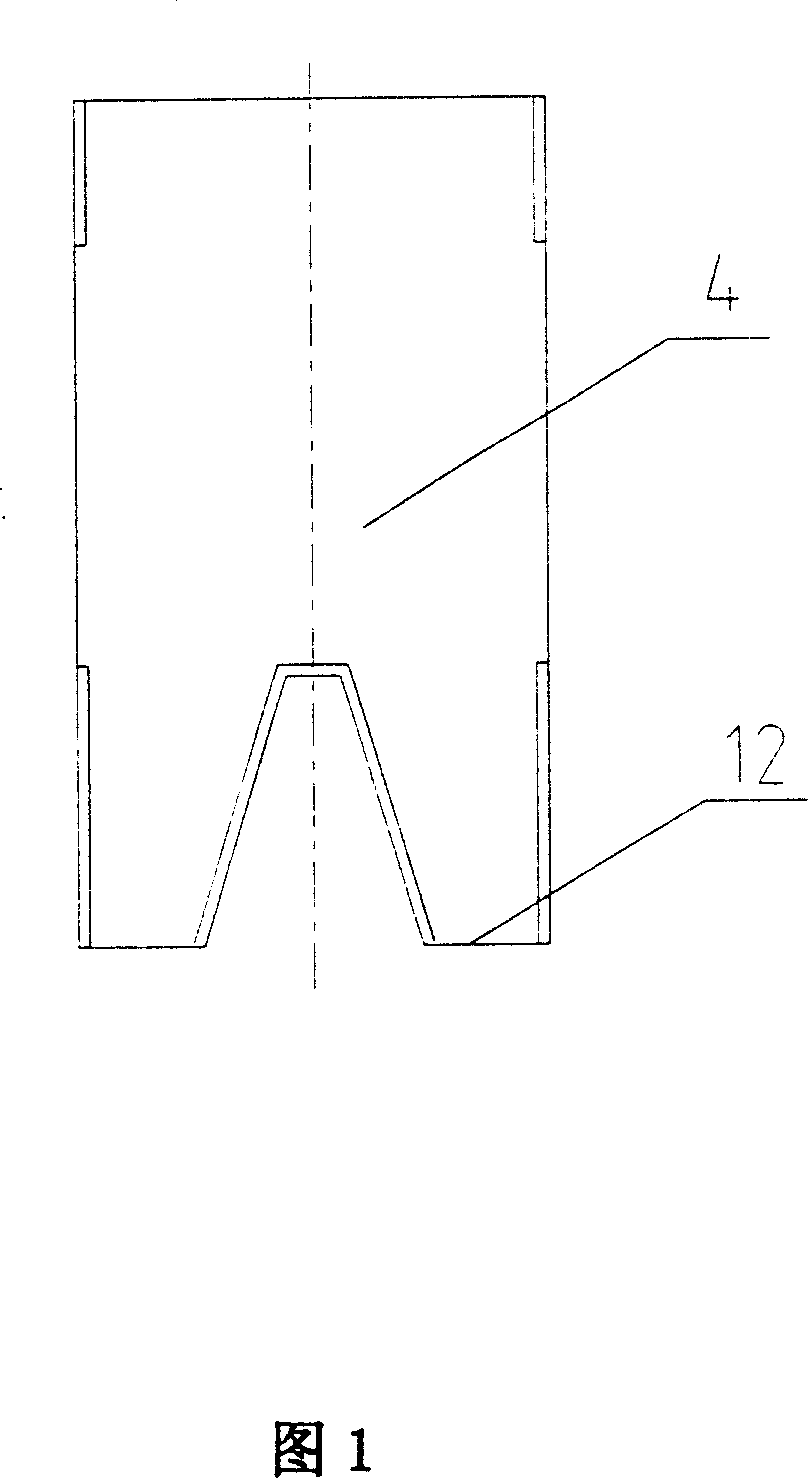

Sintered ore cooling furnace

ActiveCN103234361AAvoid volatilitySimple structureIncreasing energy efficiencyHandling discharged materialCounter flowMaterial distribution

The invention discloses a sintered ore cooling furnace device. The device is composed of a pre-storage area, an annular air flue area, a chute area, a cooling area and an air chamber. High-temperature sintered ores are continuously and evenly distributed into a cooling furnace for cooling through a charging port above the pre-storage area by a material distribution device, high-temperature sintered ores are subjected to counter-flow heat exchange with low-temperature air blown from the bottom of the furnace in the cooling area of the cooling furnace, sintered ores are cooled to below 180 DEG C, low-temperature ores are discharged by a discharging device, the low-temperature air is heated to about 600 DEG C through counter-flow heat exchange and enters a waste heat recycling system through an air outlet, and hot air and hot sintered ores are effectively sealed inside the cooling furnace in the whole process. By the aid of the device, on the premise that the quality of sintered ores is guaranteed or improved and the return fine rate is reduced, the efficiency of recycling of waste heat of sintered ores is improved to the maximum extent.

Owner:中信重工工程技术有限责任公司

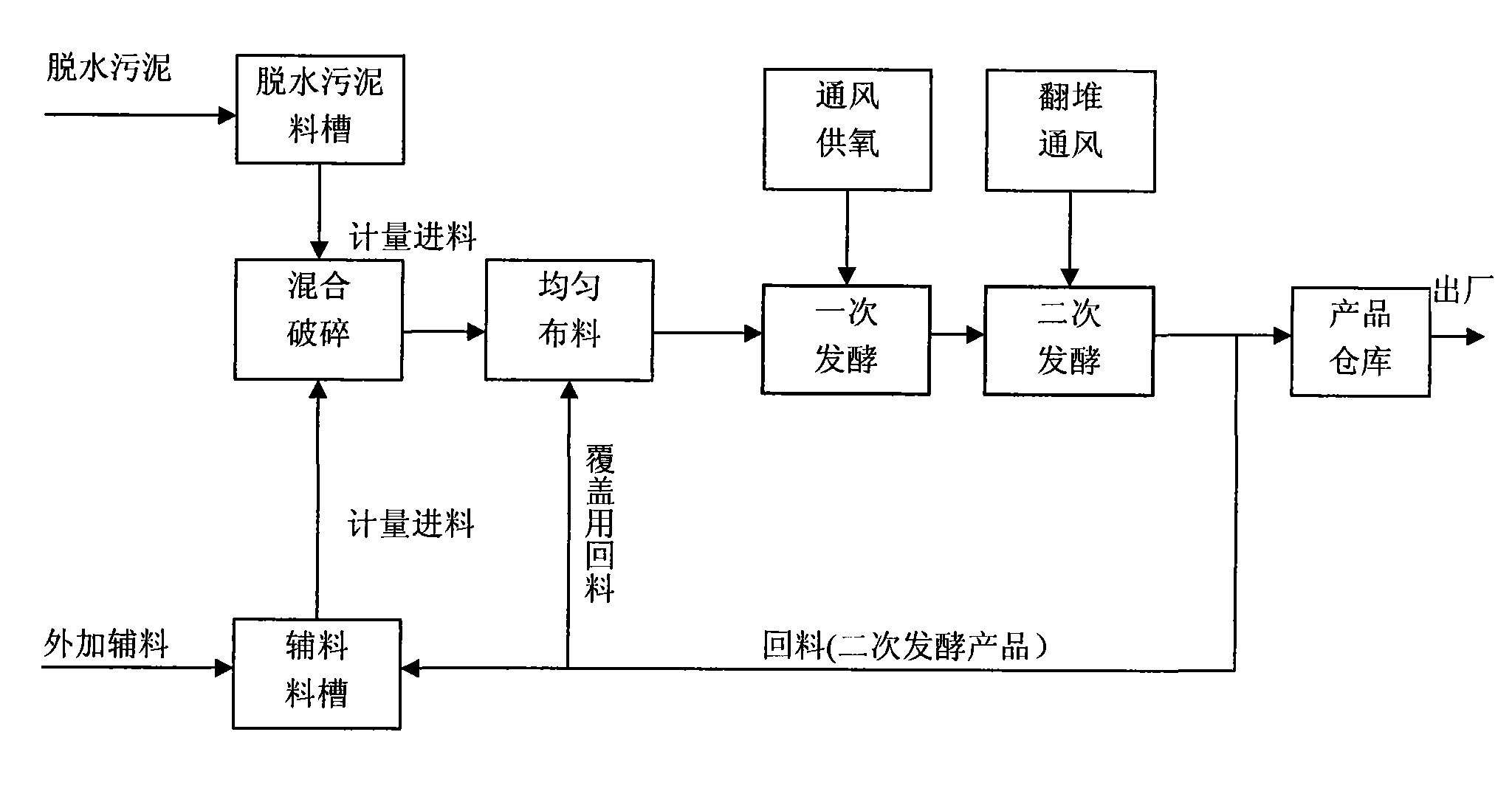

High-temperature aerobic fermentation process for sludge with low energy consumption and no pollution

InactiveCN101618977AAvoid pollutionPromote fermentationBio-organic fraction processingClimate change adaptationReduction treatmentIndustrial waste water

The invention discloses a high-temperature aerobic fermentation process for sludge with low energy consumption and no pollution, and relates to the technology for aerobic fermentation treatment on dewatered sludge. The process is used for decontamination, stabilization and reduction treatment of town sewage sludge, sewage sludge, organic industrial wastewater sludge and organic sludge. In the process, the dewatered sludge and auxiliary materials are mixed, the mixture is crushed into composting particles with the diameter less than or equal to 20mm, the composting particles are evenly distributed into a pile with the height of 2m by a spreader, and the pile is covered by fermented decaying products to effectively reduce the odor emitted by the composting. A fermentation bin with two combined or separated bins is provided with a ventilation and oxygen supply system which is detachable, is easy to clear, prevents blockage and has even gas distribution, and a pile turning device inside; and the oxygen concentration, fermentation temperature, water ratio of the pile in the fermentation bin are controlled, so that sludge fermented products meet national standard. The process facilitates air supply and aerobic fermentation of the pile due to small diameter of the composting particles and the loose pile, has thorough fermentation of the particles of the sludge mixture, improves the quality of the sludge fermented products, makes the sludge fermented products meet the decontamination, stabilization and reduction index requirements specified by the national standard, and greatly saves electric energy consumption and reduces operating cost.

Owner:城市污染控制国家工程研究中心 +2

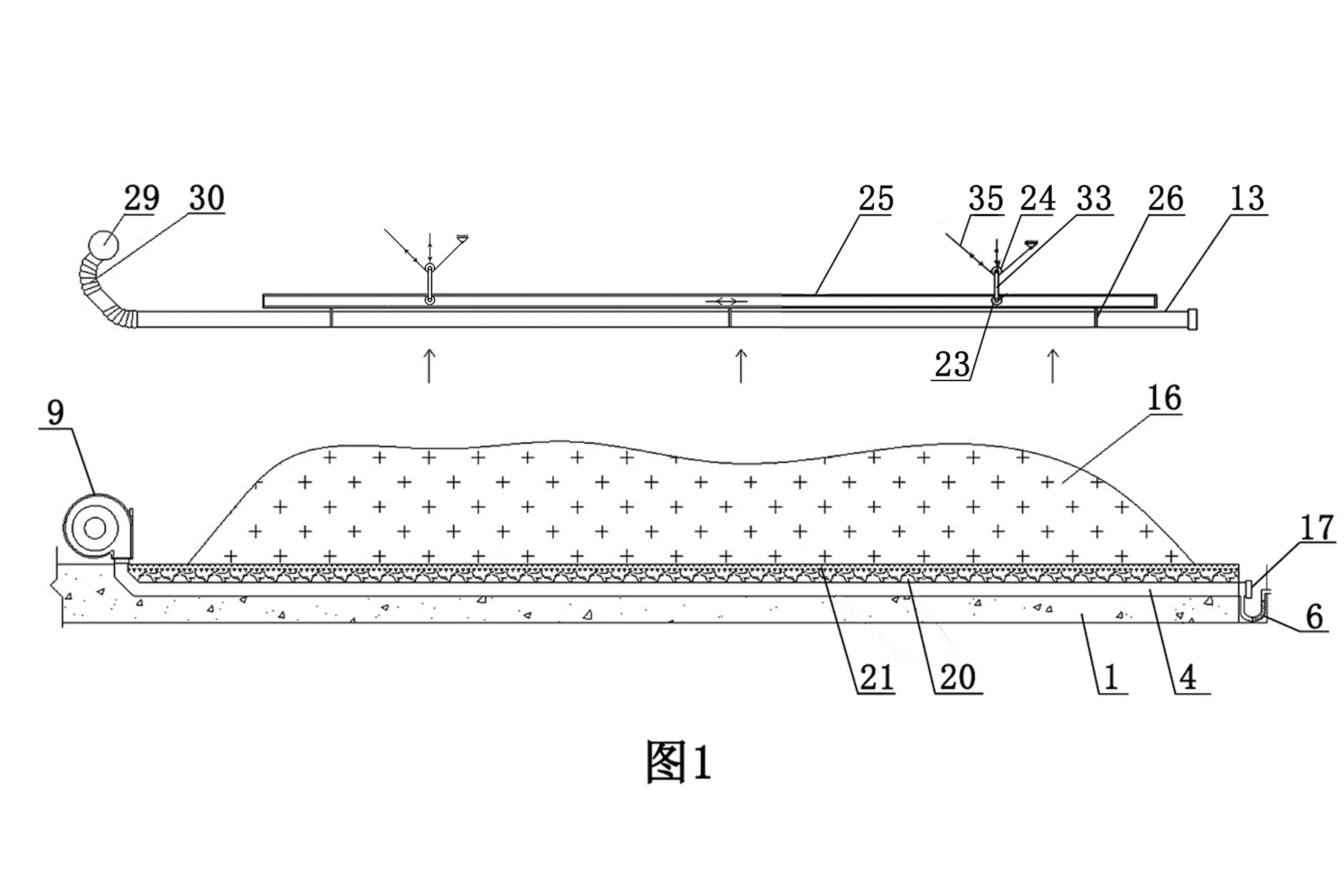

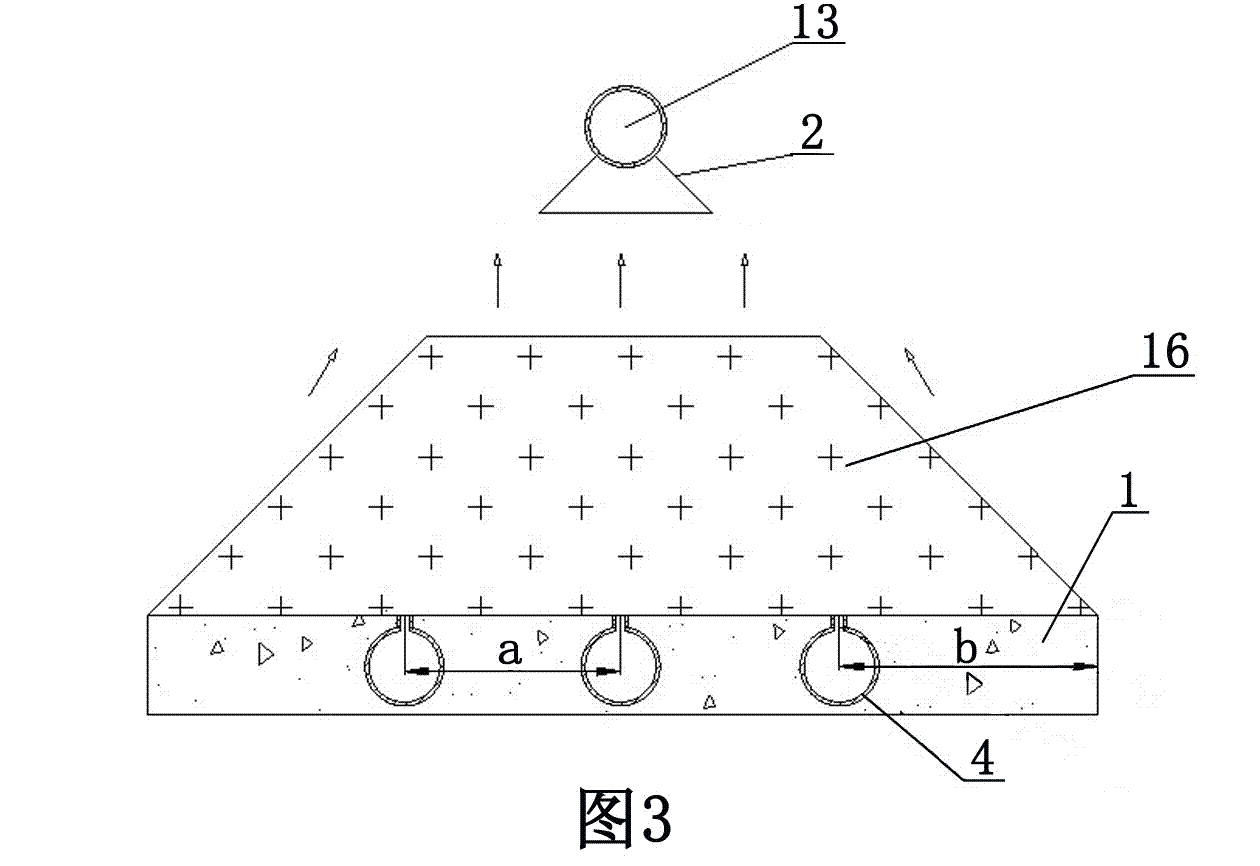

System and method for ventilating stacks and collecting exhaust gases and percolate of compost

ActiveCN101817701AReduce the amount of civil worksUniform air distributionBio-organic fraction processingOrganic fertiliser preparationSystem structureCompost

The invention discloses a system and a method for ventilating stacks and collecting exhaust gases and percolate of compost. At least one air tube is laid in a base at the bottom of each stack along a length direction of the stack; grooves are reserved on the bases above vents of the air tubes; ventilation protecting layers are laid in the grooves above the vents; one end of each air tube is connected with a main air tube connected with a blower, while the other end is sealed with a pipe closer; a percolate outlet is downwards reserved at the closed end of each air tube; cleaning grooves are reserved on the peripheries of the pipe closers and the percolate outlets; percolate buffering and discharging devices connected with the percolate outlets are arranged in the cleaning grooves; an exhaust pipeline is arranged above each stack along the length direction; exhaust openings are distributed at the bottom of the exhaust pipeline; and each exhaust pipeline is connected with a main exhausttube. The system and the method have the advantages of greatly reducing the quantity of civil engineering at the same time of ensuring relatively better oxygenation state in the whole composting body, and simultaneously realizing the directed and highly-efficient collection of the exhaust gases produced in a composting process; and the system has a simpler structure and is convenient to operate.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

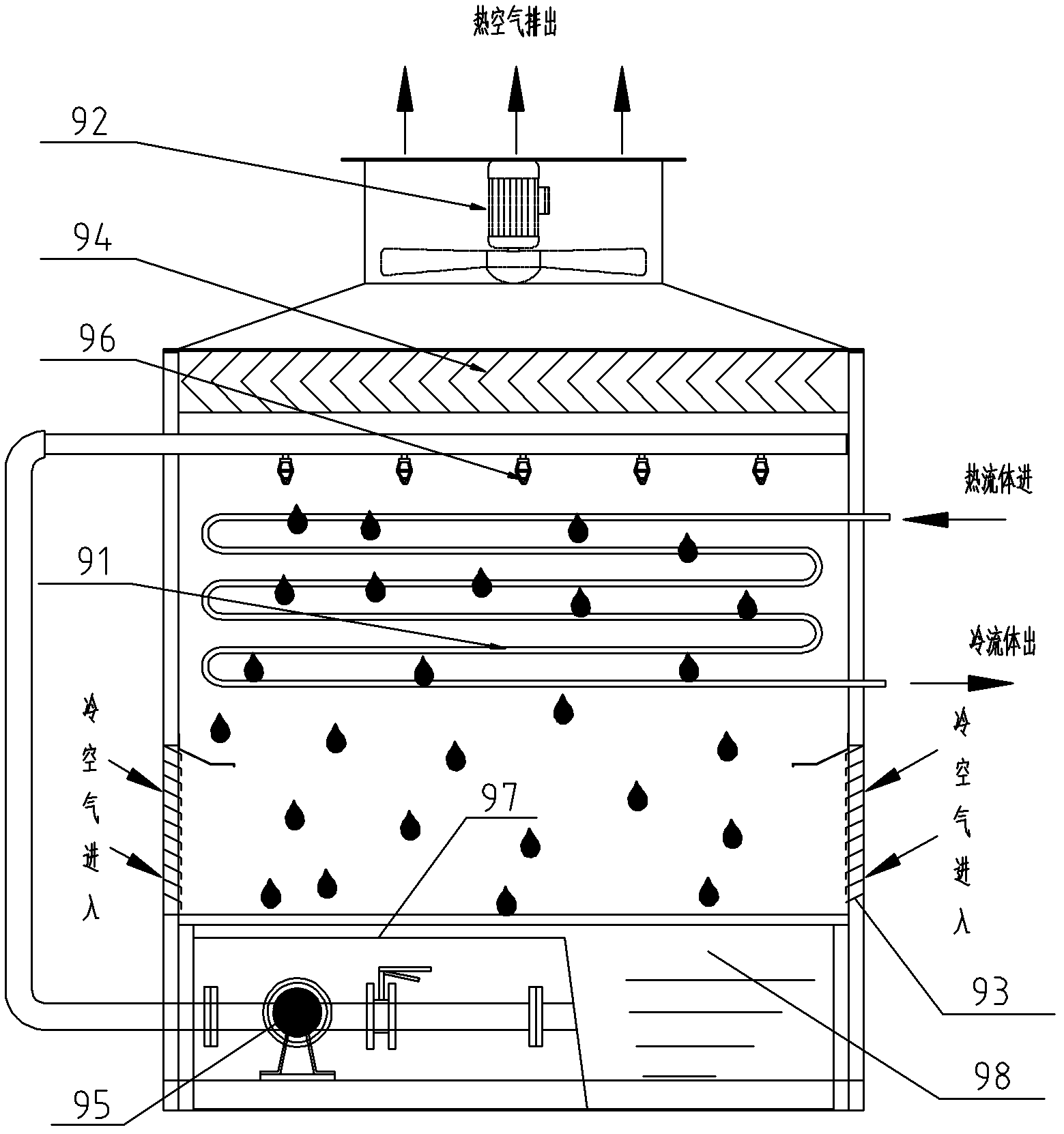

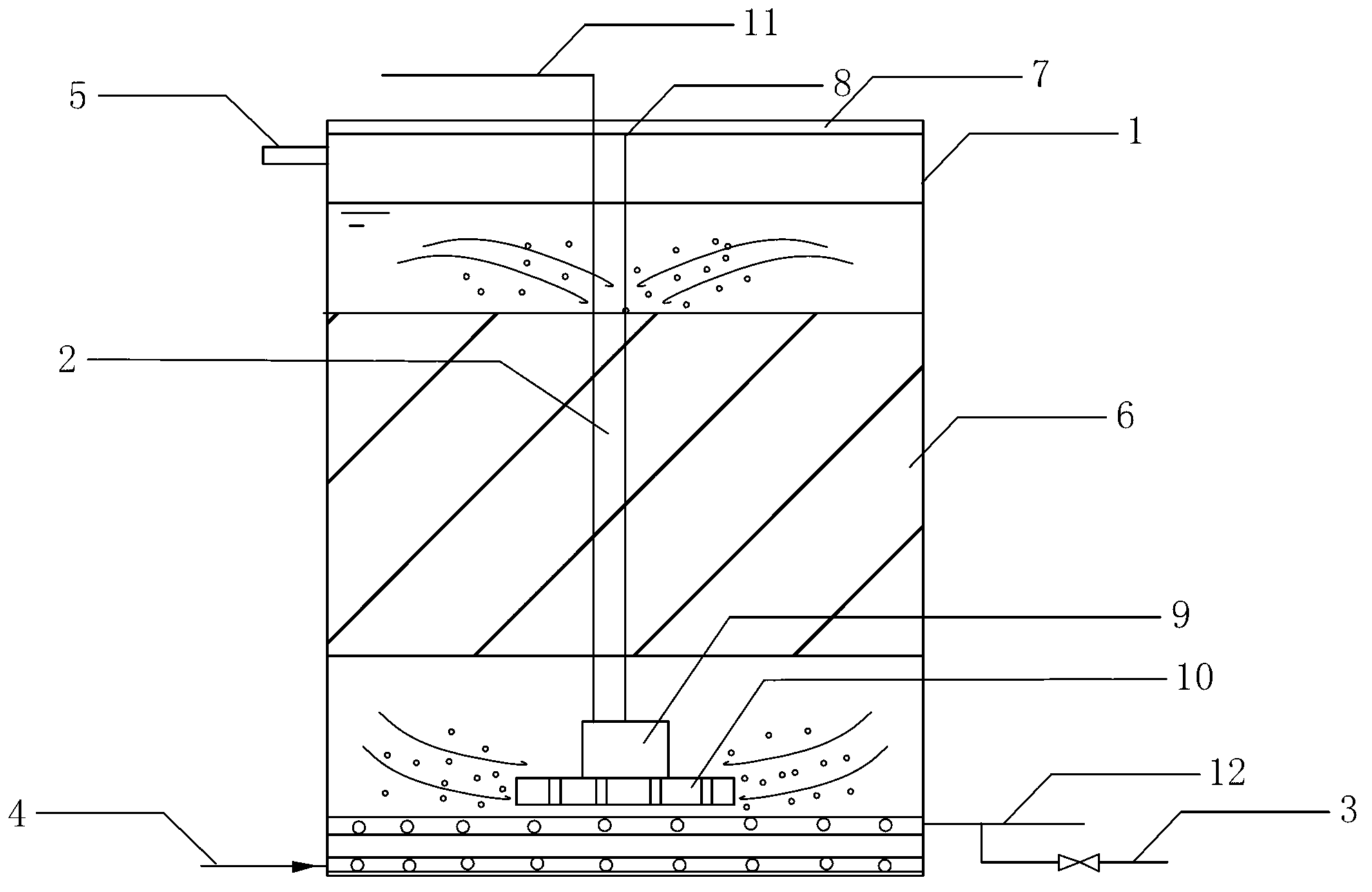

Bottom air admission type closed cooling tower

The invention provides a bottom air admission type closed cooling tower, which comprises a fan, a water collector, a spray pipe, a heat exchange tube assembly, a water tank and a spray pump, the fan is arranged on the top in a closed cooling tower shell, the water collector is arranged under the fan, the spray pipe is arranged under the water collector, the heat exchange tube assembly is arrangedunder the spray pipe, the water tank is arranged on the bottom in the closed cooling tower shell, and the spray pump is arranged outside the water tank and respectively communicates with the water tank and the spray pipe; the bottom air admission type closed cooling tower also comprises a plurality of water guide louvers, the water guide louvers are arranged on the bottom of the cooling tower, and moreover, an air inlet is arranged between each two neighboring water guide louvers. When the bottom air admission type closed cooling tower is used, air distribution is more uniform, the heat exchange efficiency is effectively increased, moreover, the arrangement of a group of towers is more benefited, and more project land is saved. When a large-water quantity project is treated, the multi-rowtube assembly arranged under the single fan can effectively solve the problem of large water quantity, more structural part cost is saved, and the bottom air admission type closed cooling tower is convenient to maintain.

Owner:BEIJING LANG BO KE TECH DEV COMPANYLIMITED +1

Multilayer gas distribution full circulation carbonization furnace

ActiveCN101928582ASmall spray radiusHeating evenlyCoke oven safety devicesDirect heating destructive distillationHeat carrierSlag

The invention discloses a multilayer gas distribution full circulation carbonization furnace which comprises a furnace body, a discharge system and a slag discharge system, wherein the discharge system is arranged on the top of the furnace body, the slag discharge system is arranged at the bottom of the furnace body, the furnace body is divided into a carbonization section at the upper part and ageneration section at the lower part by an arched leg arranged at the middle part of the furnace body, a carbonization product outlet is arranged at the upper part of the carbonization section, an air supply system is arranged at the lower part of the generation section, a gas seal section which is communicated with a gas-seal gas inlet is arranged between the carbonization section and the generation section, and an annular gas distribution chamber which is communicated with an inner cavity of the carbonization section through a gas distribution hole and also communicated with a circulation gas inlet is arranged outside the carbonization section, a center gas collection cavity is arranged in the carbonization section, the upper end of the center gas collection cavity is closed, the lower end of the center gas collection cavity is communicated with the circulation gas inlet, a gas distribution hole is arranged at the middle part of the center gas collection cavity, and a generation gasoutlet is arranged at the upper part of the generation section. The invention has the advantages of small heat carrier jet radius, more uniform gas distribution and heating, high heating and oil production efficiency, and the like, can fundamentally avoid the oil firing phenomenon, makes up a blank of the kind of carbonization furnaces and is worthy of popularization and application.

Owner:中国寰球工程有限公司辽宁分公司 +1

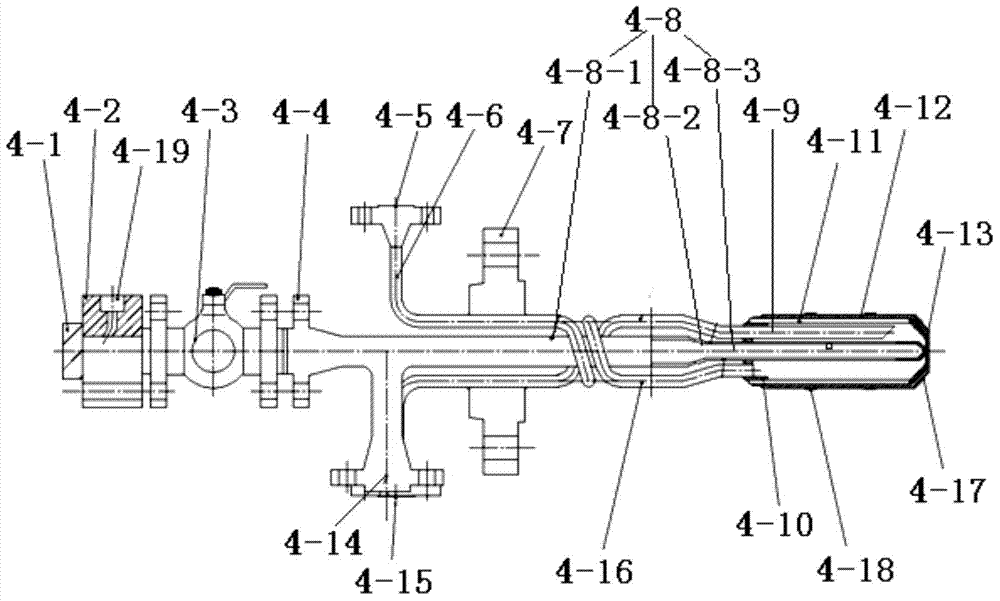

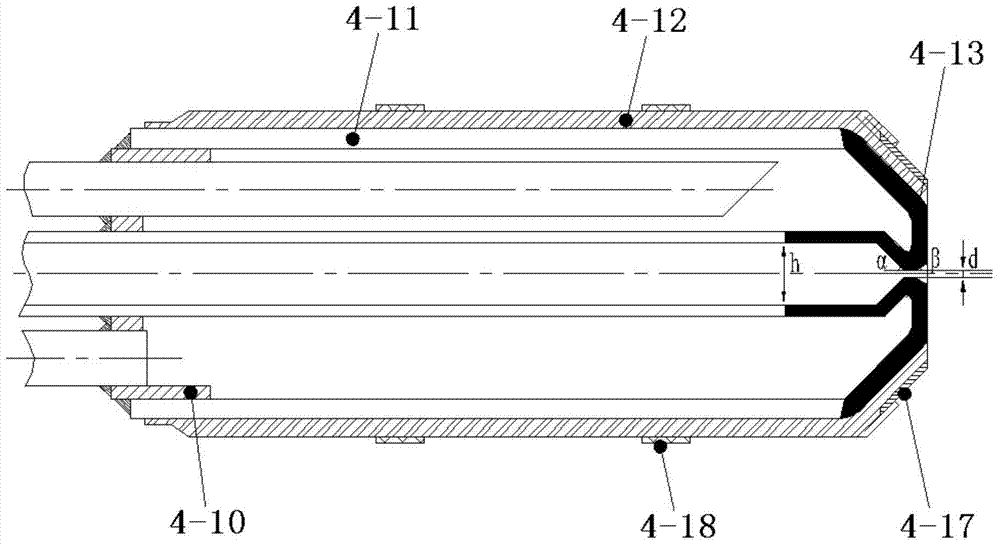

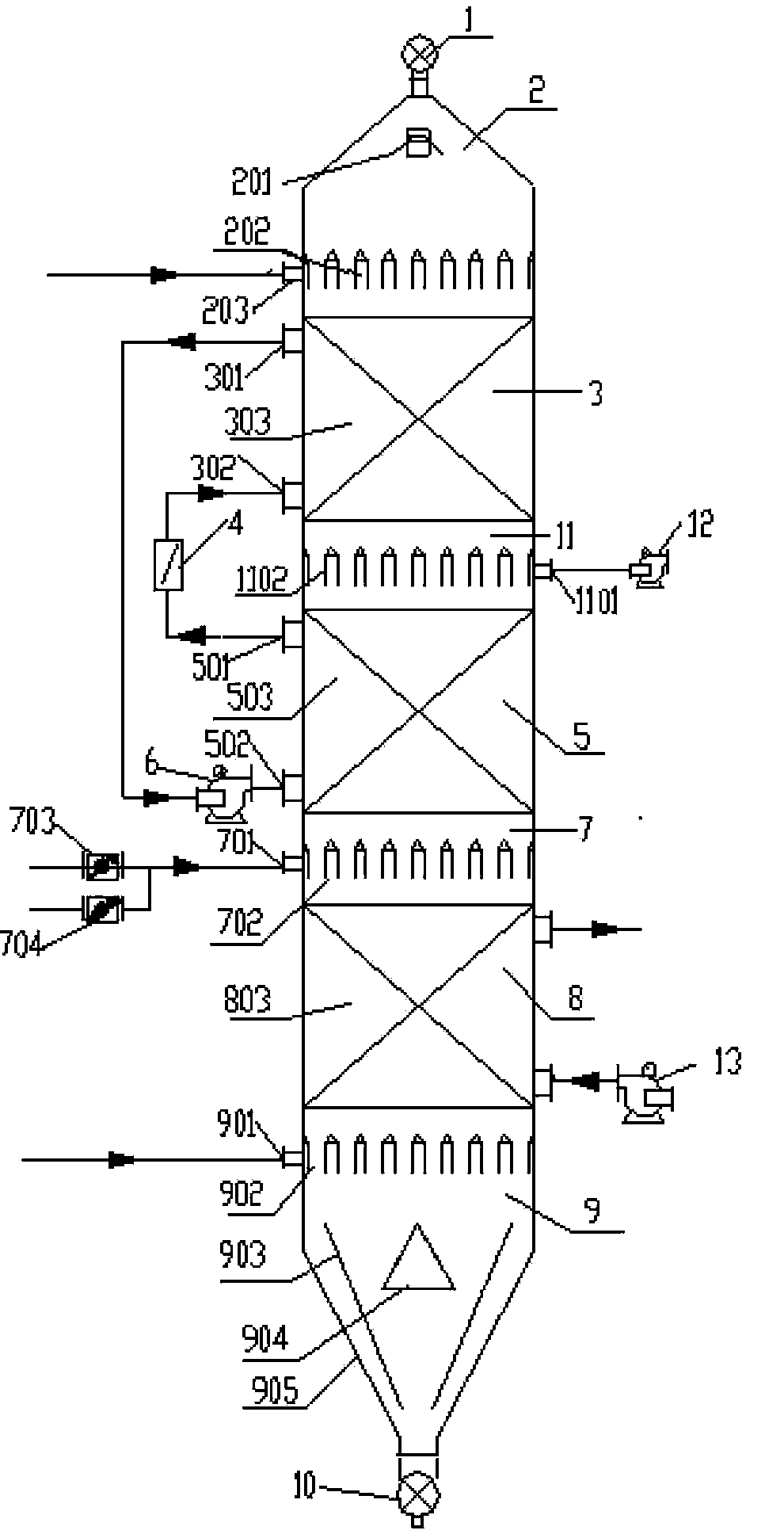

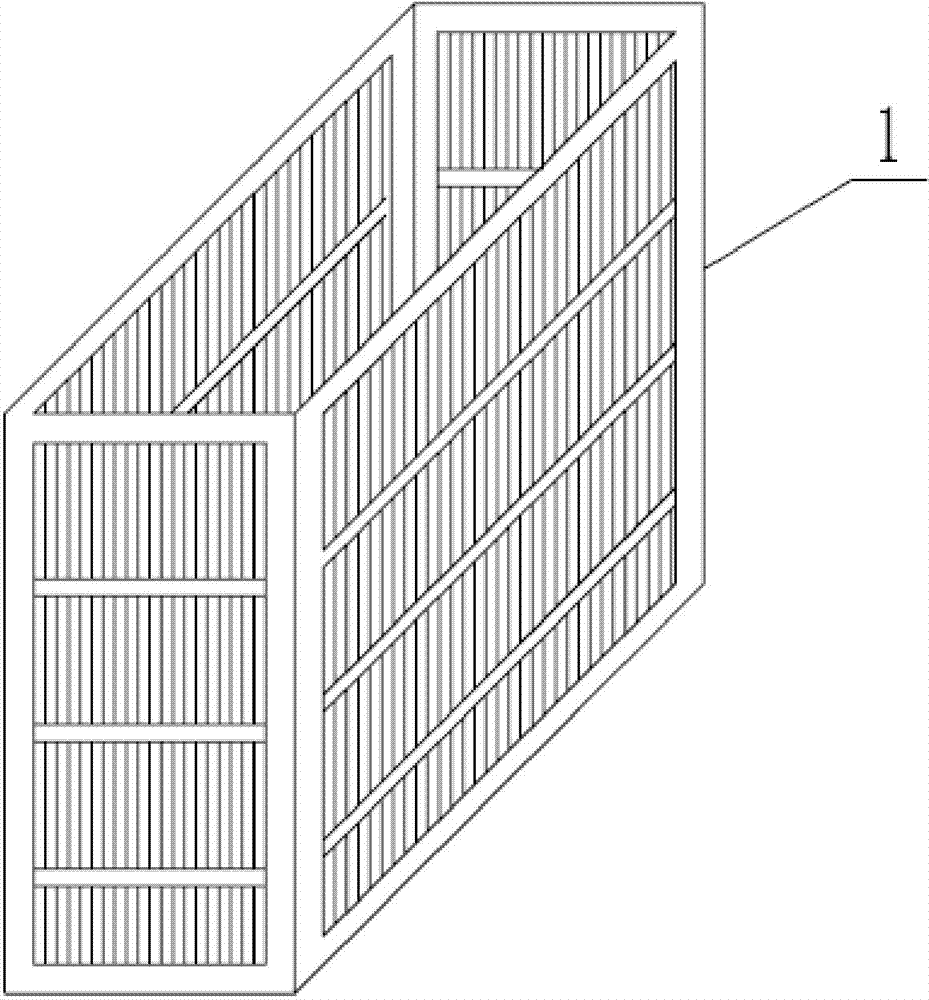

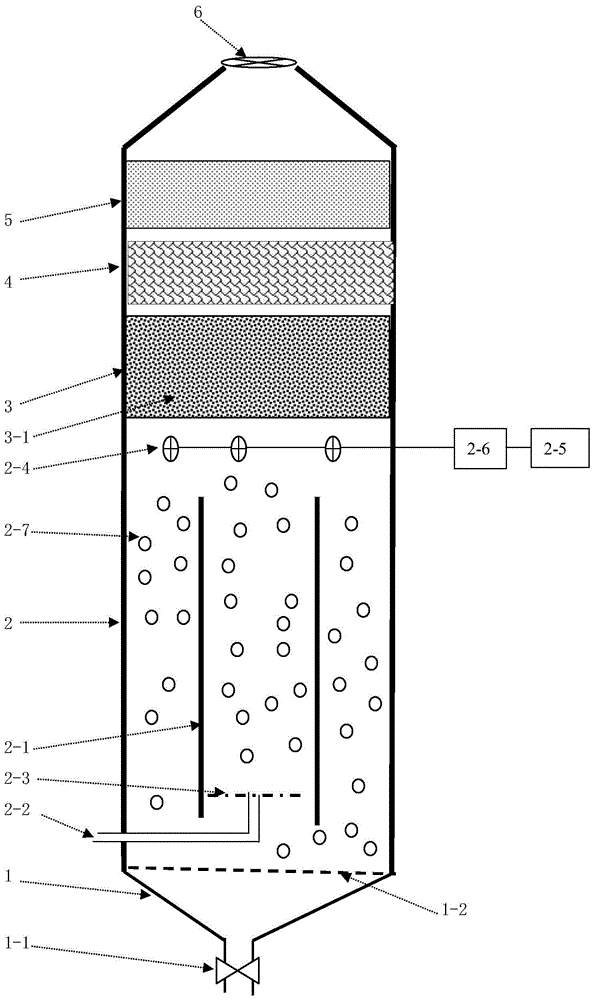

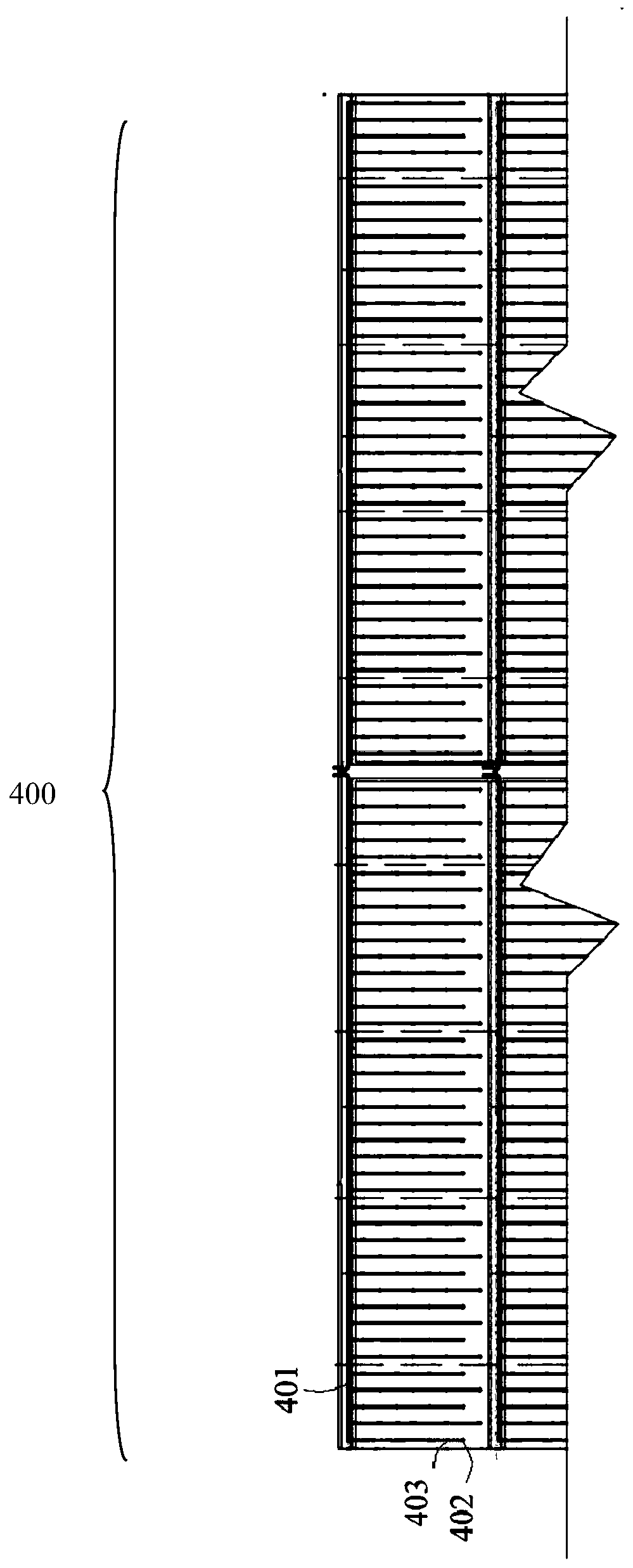

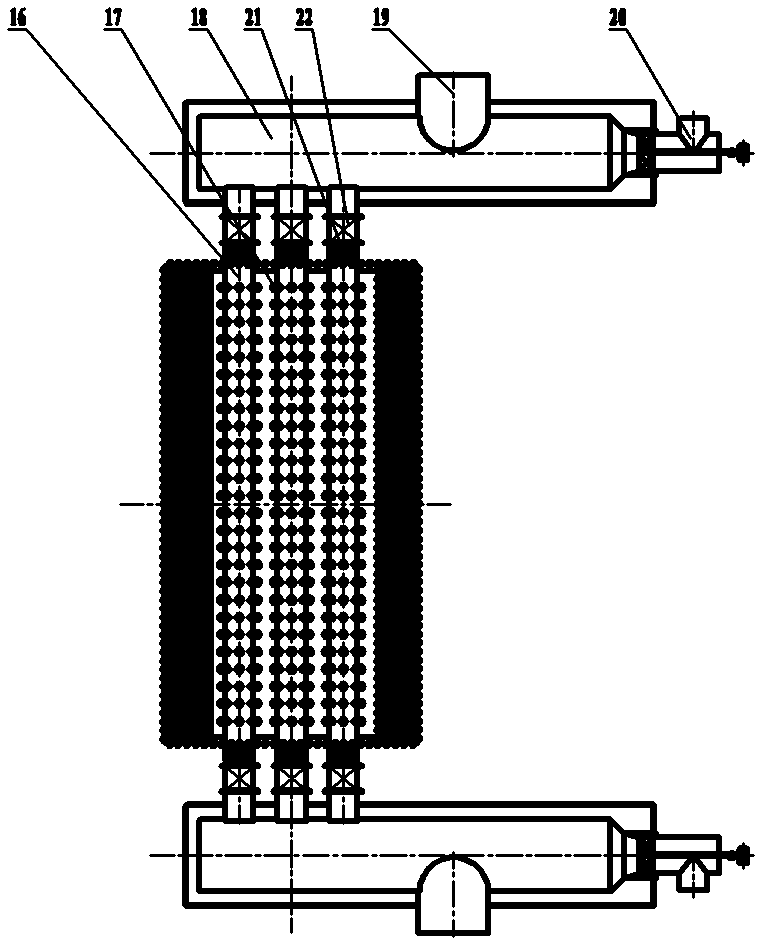

Regenerative device and method for desulfurized and denitrified active coke

ActiveCN103418360ARealize online modificationImprove the effect of desulfurization and denitrificationOther chemical processesDispersed particle separationBlocked valvesProcess engineering

The invention discloses a regenerative device and method for desulfurized and denitrified active coke. The regenerative device comprises a regenerative reactor, wherein the regenerative reactor is composed by the connection of an inlet blocking valve, a feeding bin, a heating bin, a regenerative bin, a precooling bin, a cooling bin, a discharging bin, and an outlet blocking valve in sequence; a heating heat exchanger component is arranged in the heating bin; a precooling heat exchanger component is arranged in the precooling bin; a cooling heat exchanger component is arranged in the cooling bin; a nitrogen carrying bin for inletting ammonia nitrogen gas to improve the desulfurization and denitrification performances of regenerated active coke during regeneration process is arranged between the precooling bin and the cooling bin. The regenerative method adopts the regenerative device to conduct the regeneration of the active coke. According to the invention, more reasonable utilization of energy can be realized in the regeneration process to allow the desulfurization and denitrification performance of the regenerated active coke to obtain further improvement; on-line modification can be conducted on the active coke through the nitrogen carrying bin to keep high desulfurization and denitrification performance of the active coke.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

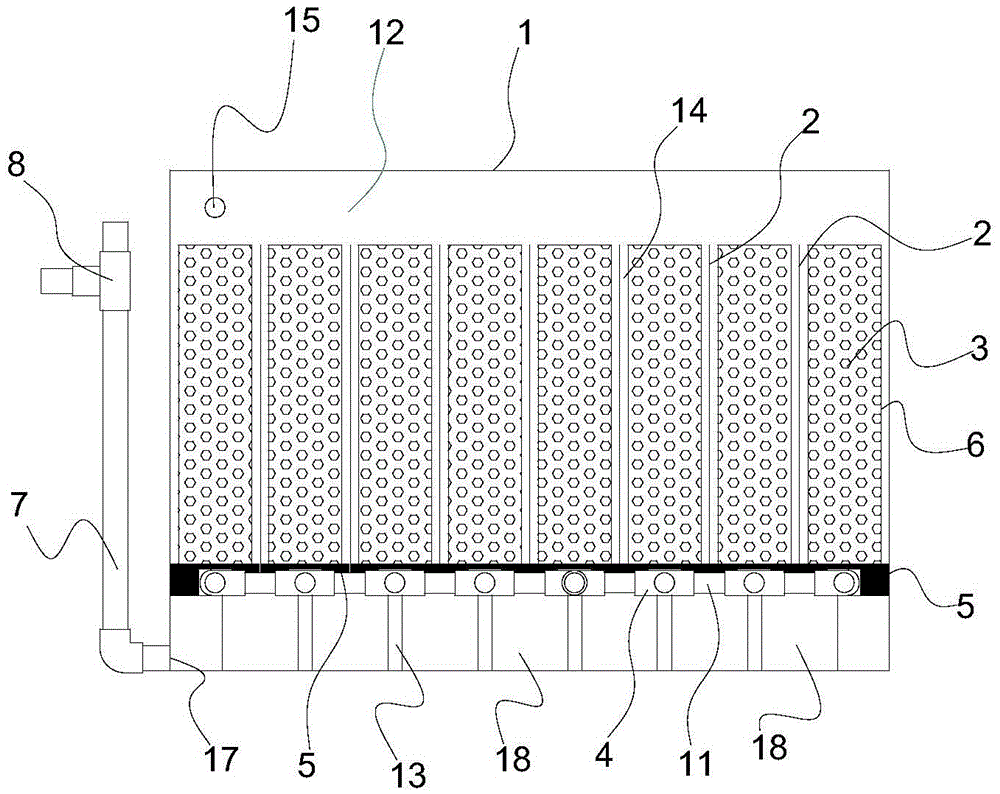

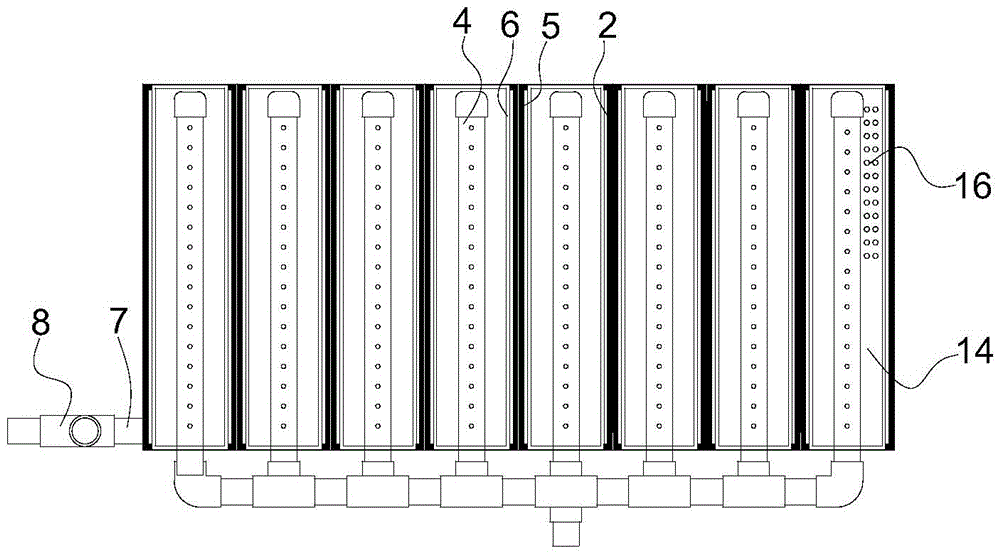

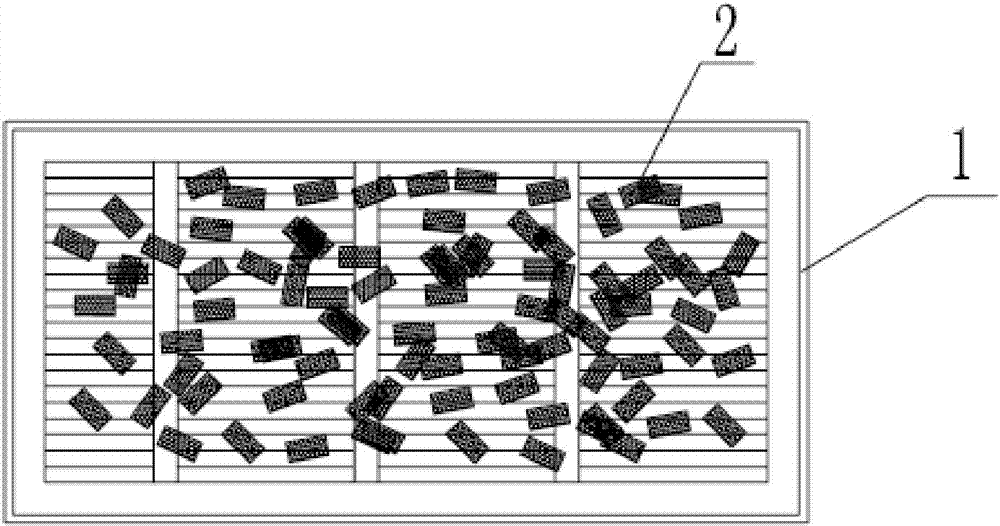

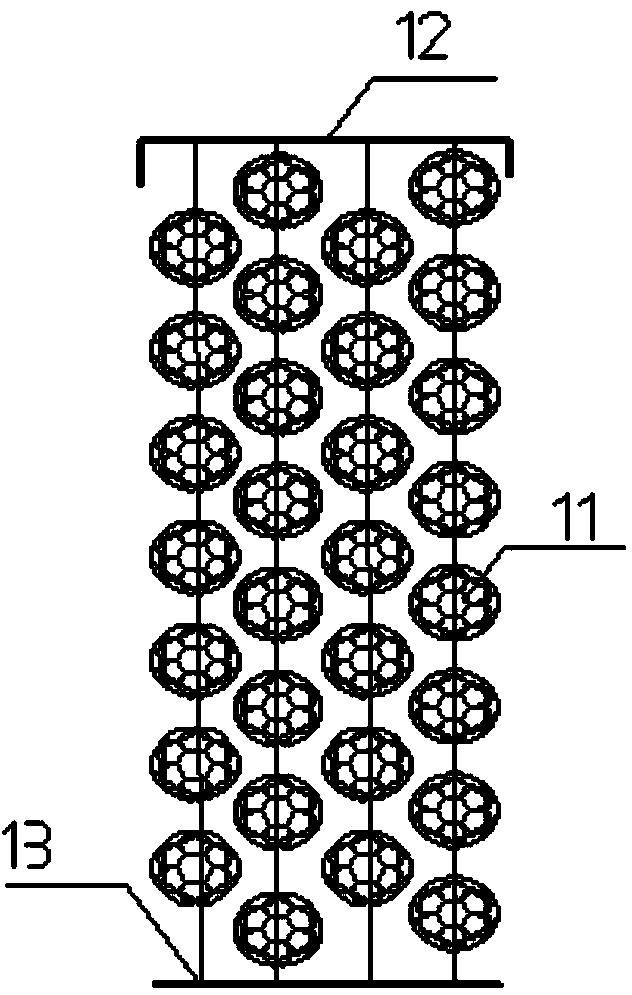

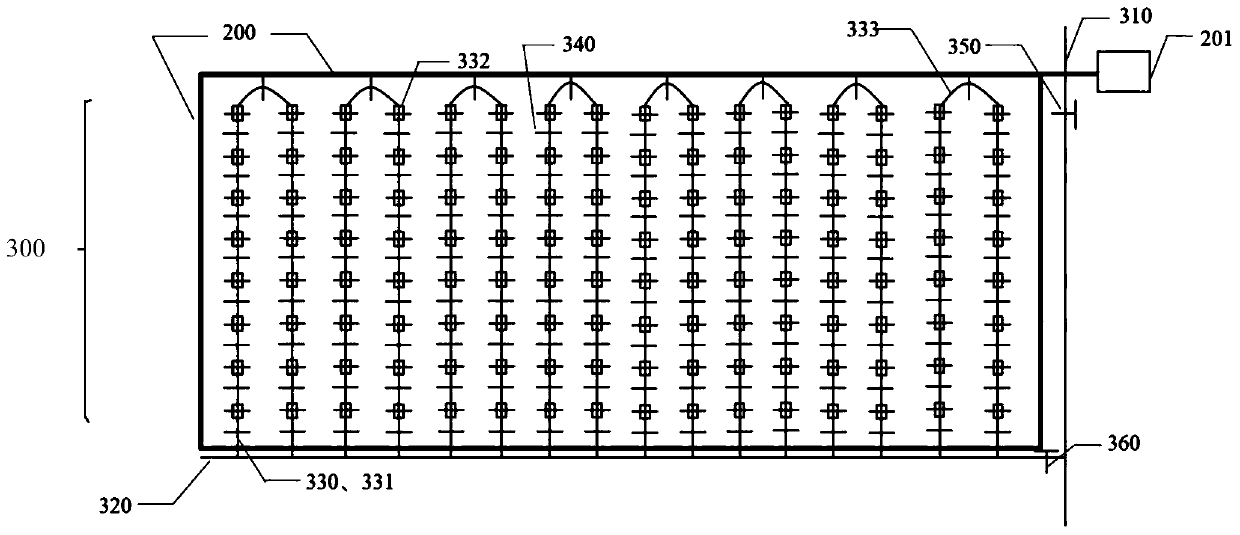

Net cage type biological carrier, immobilized microbiological treatment sewage device and application of immobilized microbiological treatment sewage device

ActiveCN104724817AAvoid short flowPrevent floatingTreatment using aerobic processesTreatment with anaerobic digestion processesHigh concentrationWater flow

The invention discloses a net cage type biological carrier, an immobilized microbiological treatment sewage device and application of the immobilized microbiological treatment sewage device. The net cage type biological carrier comprises a net cage and biological stuffing filled in the net cage, wherein the net cage is in the shape of a rectangle without a top cover, and a hollow-out mesh holes are formed in the side surface and bottom surface of the net cage. The immobilized microbiological treatment sewage device comprises a sewage treatment tank, a perforated mud discharge tube, a perforated aeration tube, a plurality of lower supporting beams and a sealing net, wherein a plurality of the net cage type biological carriers are stacked in the sewage treatment tank and arranged above the lower supporting beams. The net cage type biological carrier disclosed by the invention is large in specific surface area, low in accumulation, caking and blockage possibility, good in gas-water permeability, and convenient to mount and maintain. The immobilized microbiological treatment sewage device is good in gas-water flow state, conductive to bringing mass transfer effect into play, large in biological load amount, good in treatment effect and suitable for high-concentration degradation-resistant sewage treatment and advanced sewage treatment.

Owner:北京三泰正方生物环境科技发展有限公司

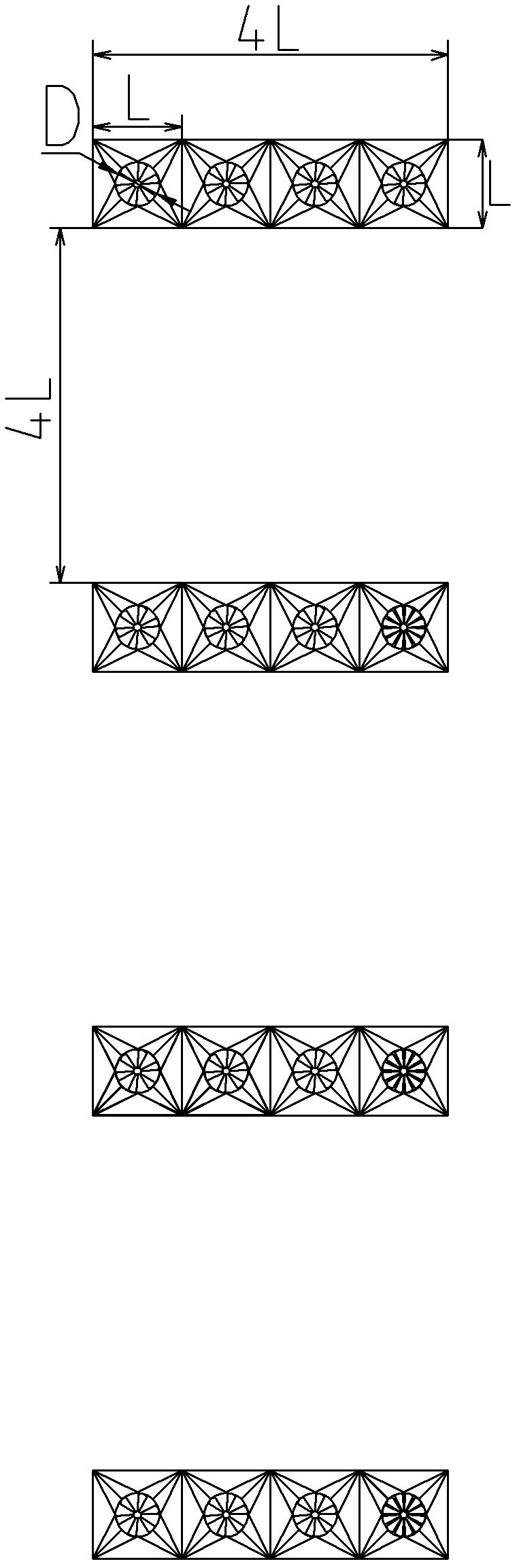

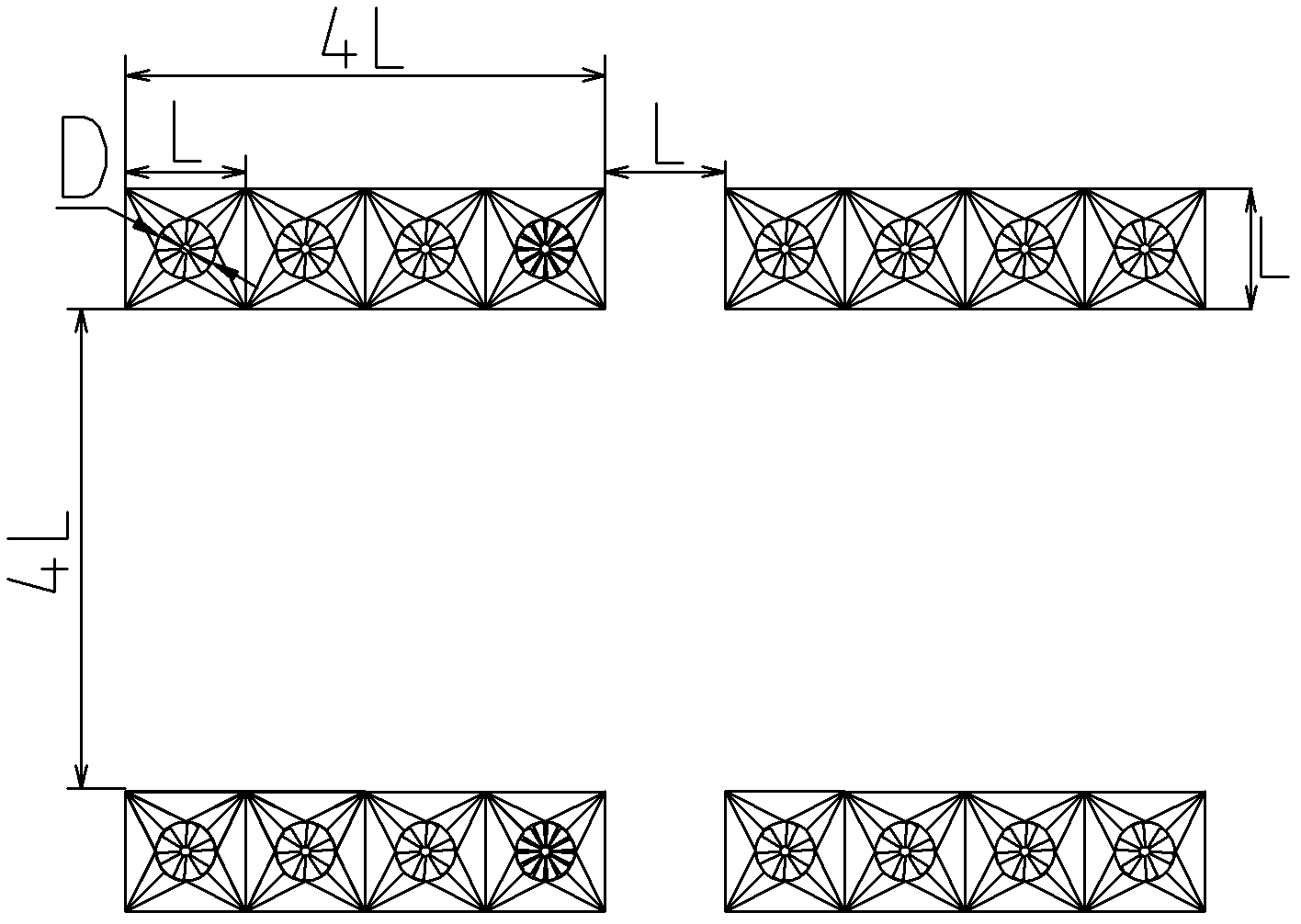

Arranging method of layered fluidization air distribution plate of fluidized bed boiler

ActiveCN1948831AImprove mixing conditionsRealize large-scaleFluidized bed combustionApparatus for fluidised bed combustionAir volumeCombustion

The invention adopts a multi-layer arrangement method of a fluidized-bed boiler bottom air-feeding plates and the integral hearth bottom consists of three independent air-feeding plates. One air-feeding plate is disposed in the lowerest part of the hearth and on the above air-feeding plate are overlaid the other air-feeding plates, so as to realize the step charging, the step air-supply and the fractional combustion of the recirculating fluidized-bed boiler. By regulating the blast volume and the fuel flow of each air-feeding plate, the uniform combustion and air-supply of the boiler can be realizer.

Owner:SHANGHAI BOILER WORKS

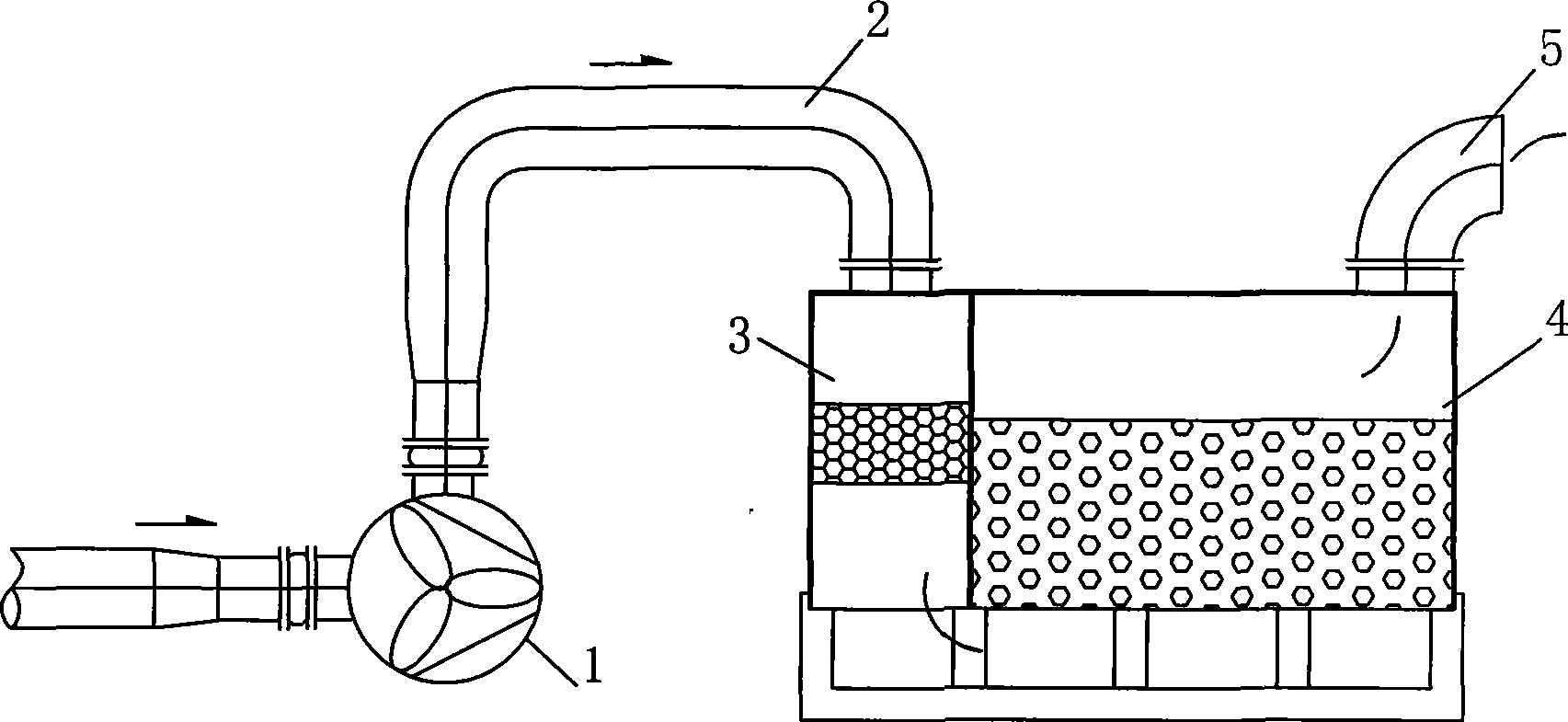

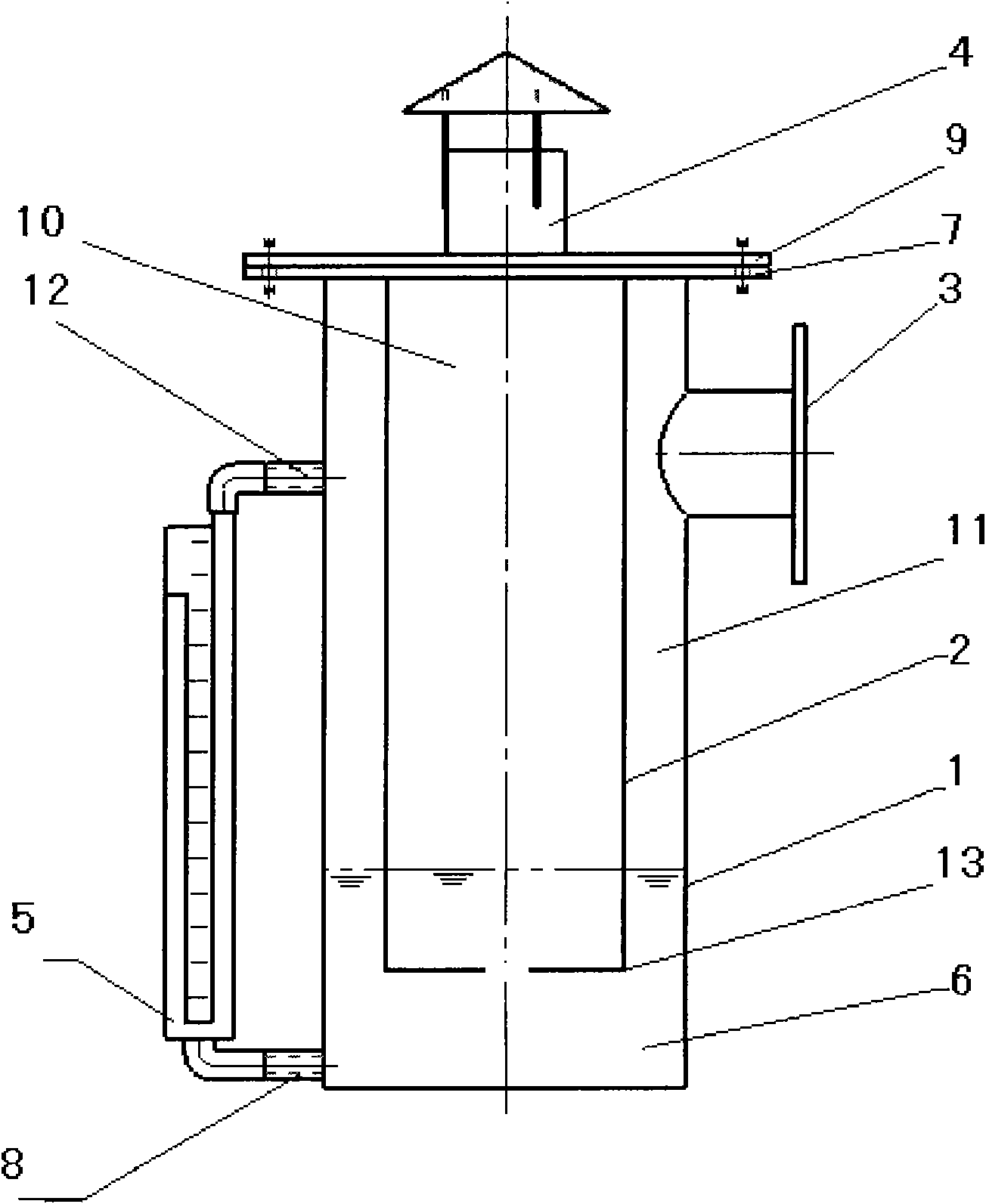

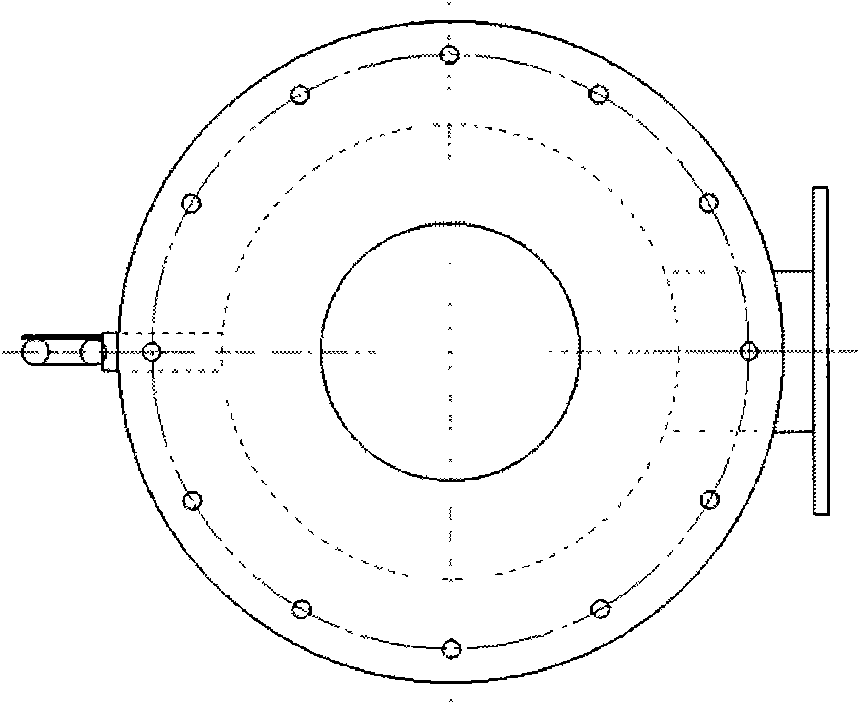

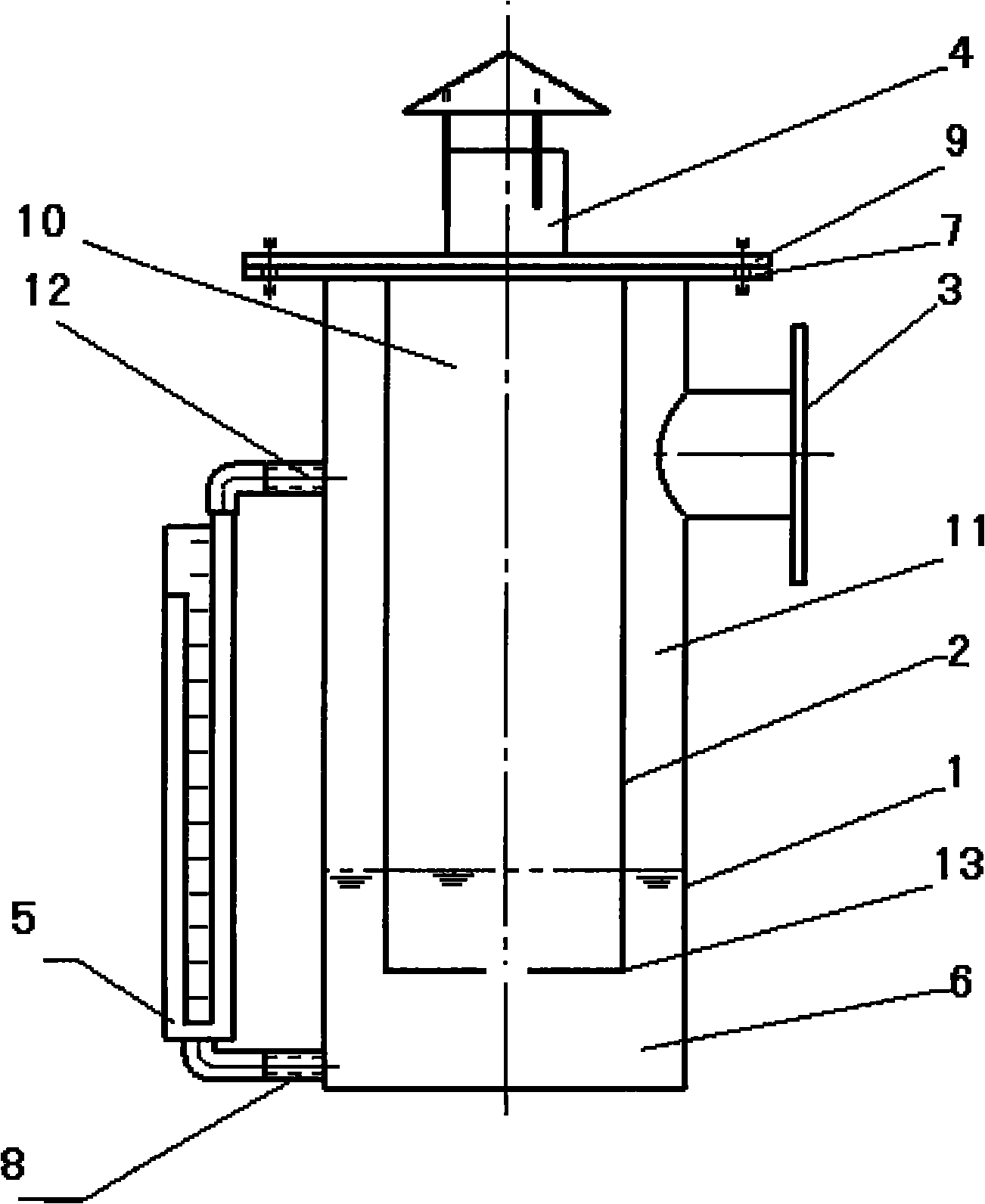

Biological filter deodorizing device

ActiveCN101543725AReduce volumeImprove removal efficiencyDispersed particle separationDeodrantsProduct gasCentrifugal fan

The invention provides a biological filter deodorizing device, which comprises an air inlet pipe, a biological filter tower, a centrifugal fan and an air discharge chimney. The device is characterized in that: the biological filter tower adopts a double-tower structure of circular inner and outer towers; the inside of the tower is filled with inorganic-organic mixed fillers; the upper part of the inner tower is provided with a ring-shaped air distribution channel; the upper part of the outer tower is provided with a ring-shaped air collection channel; the circumferences of the air distribution channel and the air collection channel are evenly provided with slotted type air outlets; the inner tower and the outer tower are communicated with each other by a lower part space; the air inlet pipe is communicated with an air inlet of the biological filter tower and the ring-shaped air distribution channel on the upper part of the inner tower; and an air inlet of the centrifugal fan is communicated with an air outlet of the biological filter tower and the ring-shaped air collection channel on the upper part of the outer tower, and an air outlet of the centrifugal fan is communicated with the air discharge chimney. The centrifugal fan pumps the biological filter tower, and a negative pressure is formed, thereby solving the problem of uneven air distribution and easy leakage of air existing in the prior device. The device also has the advantages of high removal rate, no secondary pollution, simple structure and convenient maintenance and management.

Owner:广东新环环保产业集团有限公司

Integral positive/negative pressure protector

InactiveCN102399682AEasy to adjust the ratioLiquidGas production bioreactorsBoiling pointEngineering

The invention discloses an integral positive / negative pressure protector composed of an outer cylinder, an inner cylinder, a pressure balancing pipe, an evacuating pipe, a liquidometer, and sealed liquid. The outer cylinder and the inner cylinder are connected through a flange. The evacuating pipe communicates with the inner cylinder. The pressure balancing pipe communicates with the outer cylinder. The sealed liquid is non-compressible. The sealed liquid is Newton fluid with a boiling point no lower than 80 DEG C and a melting point no higher than -40 DEG C. According to the invention, positive and negative pressure protecting functions are integrated, such that defects of traditional technologies of increased investment, tedious management and large land occupation caused by independent positive and negative pressure protectors are avoided. The protector provided by the invention is advantaged in stable operation. The protector can provide effective and reliable protections for containers.

Owner:LIAONING BEIFANG ENVIRONMENTAL PROTECTION

Biological soil filtering body deodorizing device

InactiveCN1935329AImprove performanceLow investment costDispersed particle separationDeodrantsVegetationBrick

The present invention provides a biological soil filter body deodorization equipment. It includes a blower fan, and is characterized by that said blower fan is connected with soil filter bed includes soil hard-layer of bottom portion, peripheral brick wall and active soil filter layer whose interior is filled up with air-permeable soil medium; between the soil hard layer and active soil filter layer a gas distribution layer is set, in the gas distribution layer the gas distribution tube with gas distribution holes is set, said gas distribution tube is connected with the above-mentioned humidifier; on the upper surface of active soil filter layer the vegetation can be planted.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

Combined biological deodorization integrated equipment and processing method of odorous gas

InactiveCN102188898AUniform air distributionEfficient collectionDispersed particle separationAir quality improvementButt jointProduct gas

The invention relates to combined biological deodorization integrated equipment and a processing method of odorous gas. According to the invention, a liquid collecting zone is added between a floated biological reaction zone and a fixed biological reaction zone of an upward flow biological odorous gas processing device of the combined biological odorous gas processing equipment; a top part of the floated biological reaction zone has a butt joint with the liquid collecting zone; a separator is arranged between the floated biological reaction zone and the liquid collecting zone; a side wall of the liquid collecting zone is provided with water outlets, and the top part of the liquid collecting zone has a butt joint with the fixed biological reaction zone; a perforated plate is arranged between the liquid collecting zone and the fixed biological reaction zone; more than two vent pipes, which are arranged in the inner liquid collecting zone, communicate with the floated biological reaction zone; a liquid level control zone is added on the outer floated biological reaction zone; and a side wall of the liquid level control zone is provided with the vent pipes. The equipment not only reserves advantages of the combined biological odorous gas processing equipment, but also has a uniform gas distribution, can effectively collect liquids and control the liquid level, and allows spraying and gas processing to be carried out simultaneously.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

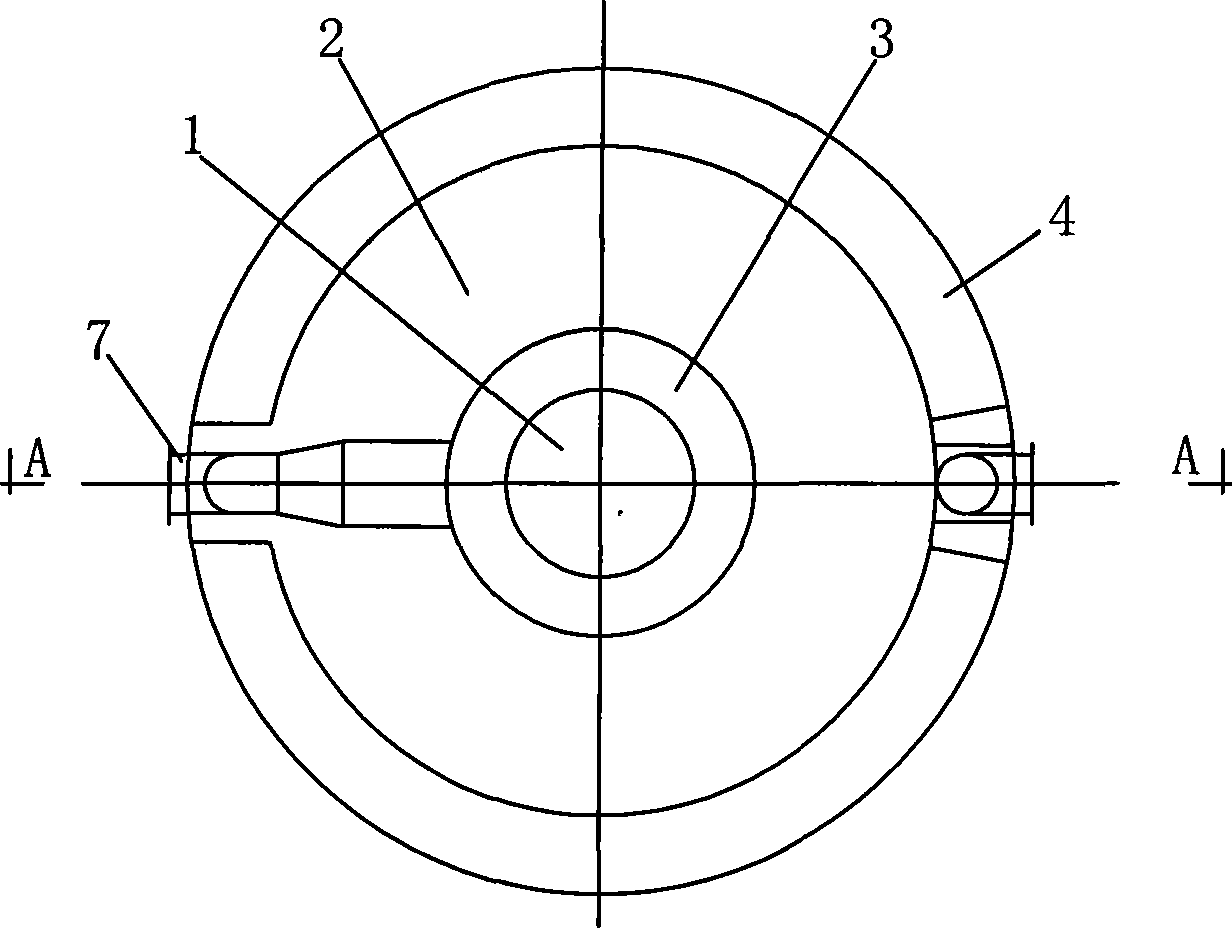

Rotational flow shearing bubble aerator

InactiveCN102139951ALarge diameterReduce sizeSustainable biological treatmentBiological water/sewage treatmentEngineeringDistributor

The invention relates to a rotational flow shearing bubble aerator comprising an air inlet base, a one-way valve, an air distributor, a reaction outer barrel, a reaction inner barrel and a shearing bubble diffusion disc, wherein the one-way valve is arranged on the air inlet base, one surface of the one-way valve is connected with the air inlet base, and the other surface is connected with the reaction outer barrel; the air distributor is arranged in the one-way valve and the reaction outer barrel, the bottom of the air distributor is connected with the air inlet base, and the upper part is connected with the shearing bubble diffusion disc; the reaction inner barrel is arranged between the periphery of the air distributor and the reaction outer barrel; the bottom of the shearing bubble diffusion disc is provided with a first-stage rotational flow step and a second-stage rotational flow step; and the first-stage rotational flow step and the second-stage rotational flow step are provided with teeth. A broken bubble principle of a macropore (relative to a micropore) slit high-speed injecting air distribution and shearing bubble diffusion combined action is adopted in the invention, thus bubbles with more appropriate size are obtained and distributed more uniformly.

Owner:POWERCHINA ZHONGNAN ENG +1

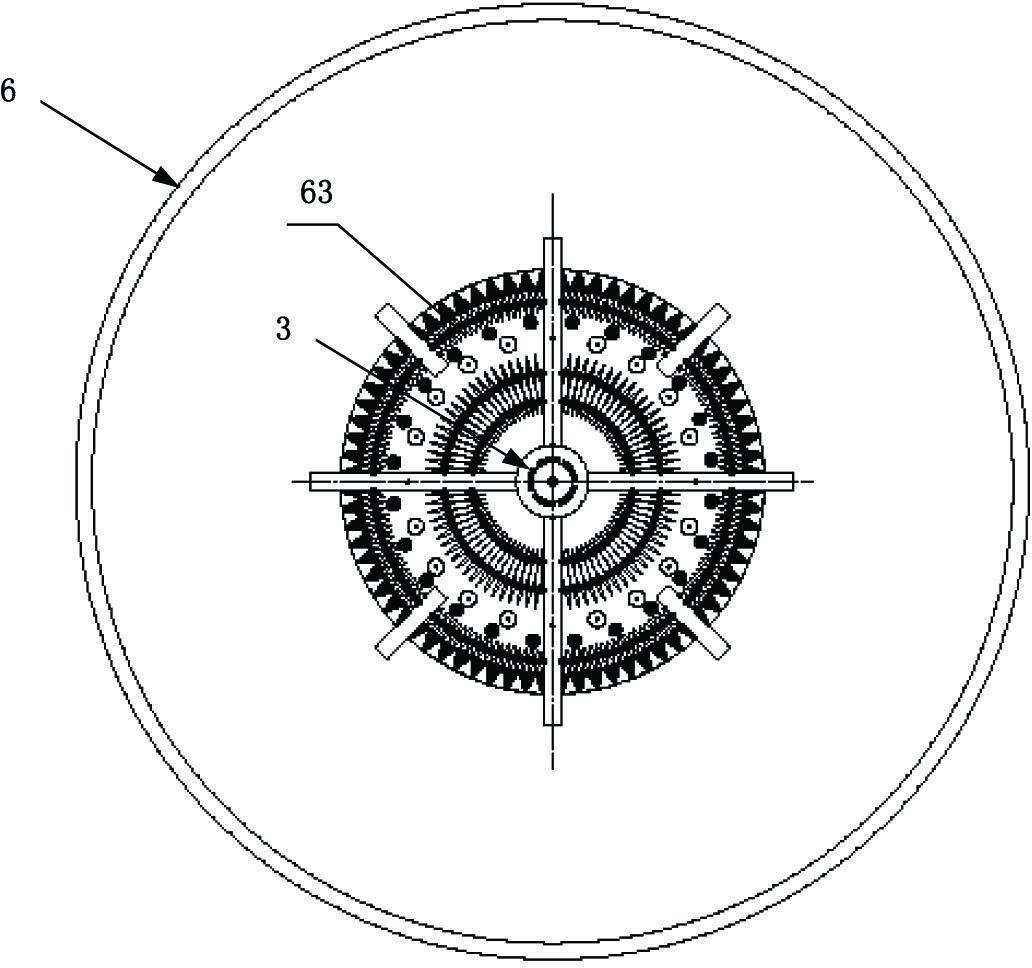

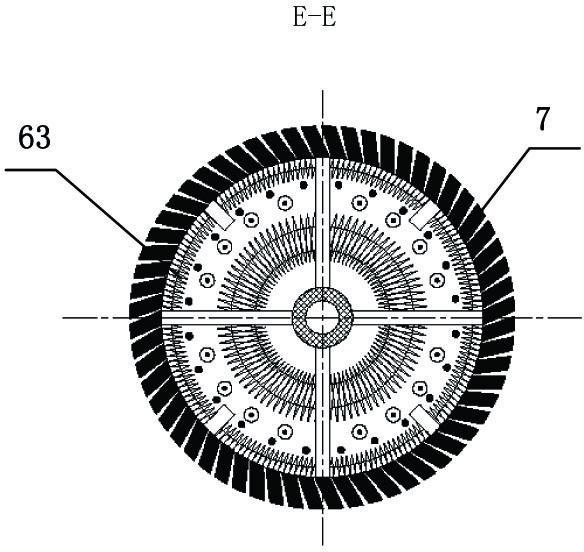

Chemical vapor deposition furnace

ActiveCN107779843AFull cracking and volatilizationAvoid cloggingChemical vapor deposition coatingChemical vapor depositionCarbon source

The invention discloses a chemical vapor deposition furnace. The chemical vapor deposition furnace comprises a furnace body and a gas inlet device arranged at the bottom of the furnace body, wherein the gas inlet device comprises a main gas inlet pipeline, a gas distribution device and a heater; the main gas inlet pipeline is communicated with the gas distribution device; the gas distribution device is communicated with a furnace chamber in the furnace body; the gas distribution device is used for uniformly distributing a gas flow into the furnace chamber; the heater is arranged at the outer part of the gas distribution device; the heater is used for heating the gas distribution device. According to the chemical vapor deposition furnace disclosed by the invention, carbon source gas entersfrom the main gas inlet pipeline and is dispersed into the furnace chamber through the gas distribution device; the gas distribution device can be used for uniformly distributing gas in a bottom spaceof the furnace chamber and buffering the speed of the gas flow, so that the gas flow can sufficiently react with a product at the bottom of the furnace chamber; the heater is arranged on the gas distribution device and can be used for pre-heating the entered carbon source gas so that the carbon source gas is sufficiently cracked and volatilized at the bottom of the furnace chamber; the product atthe bottom is subjected to deposition reaction so that a whole deposition effect of the product is improved.

Owner:ADVANCED FOR MATERIALS & EQUIP

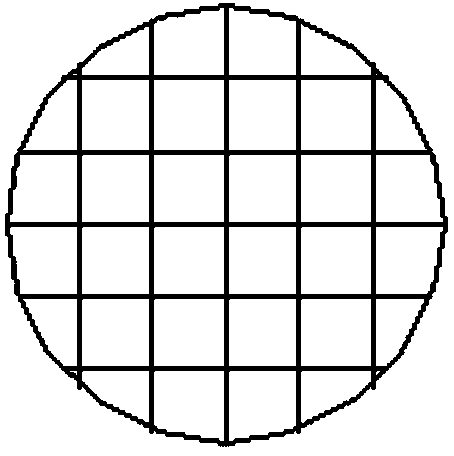

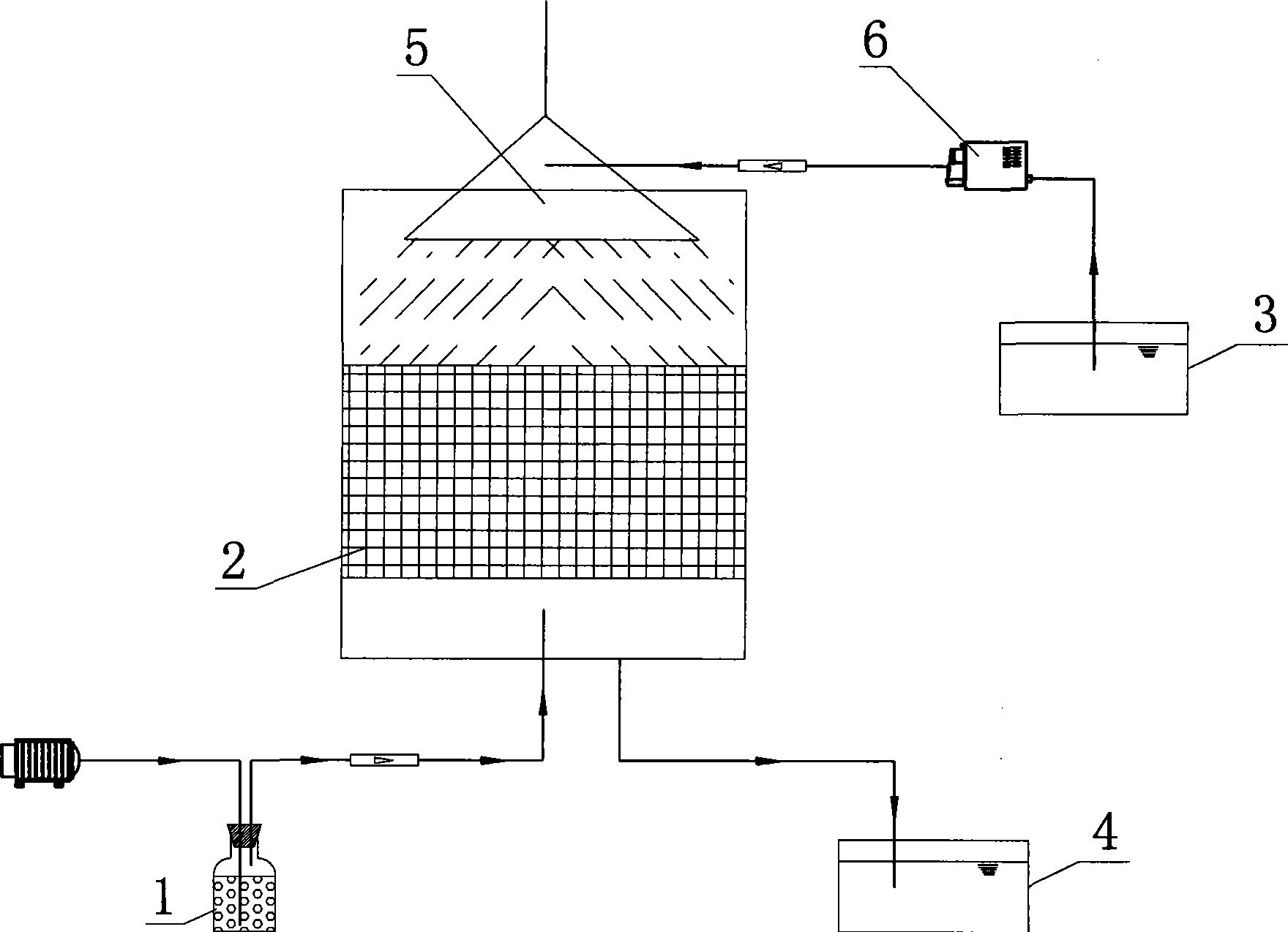

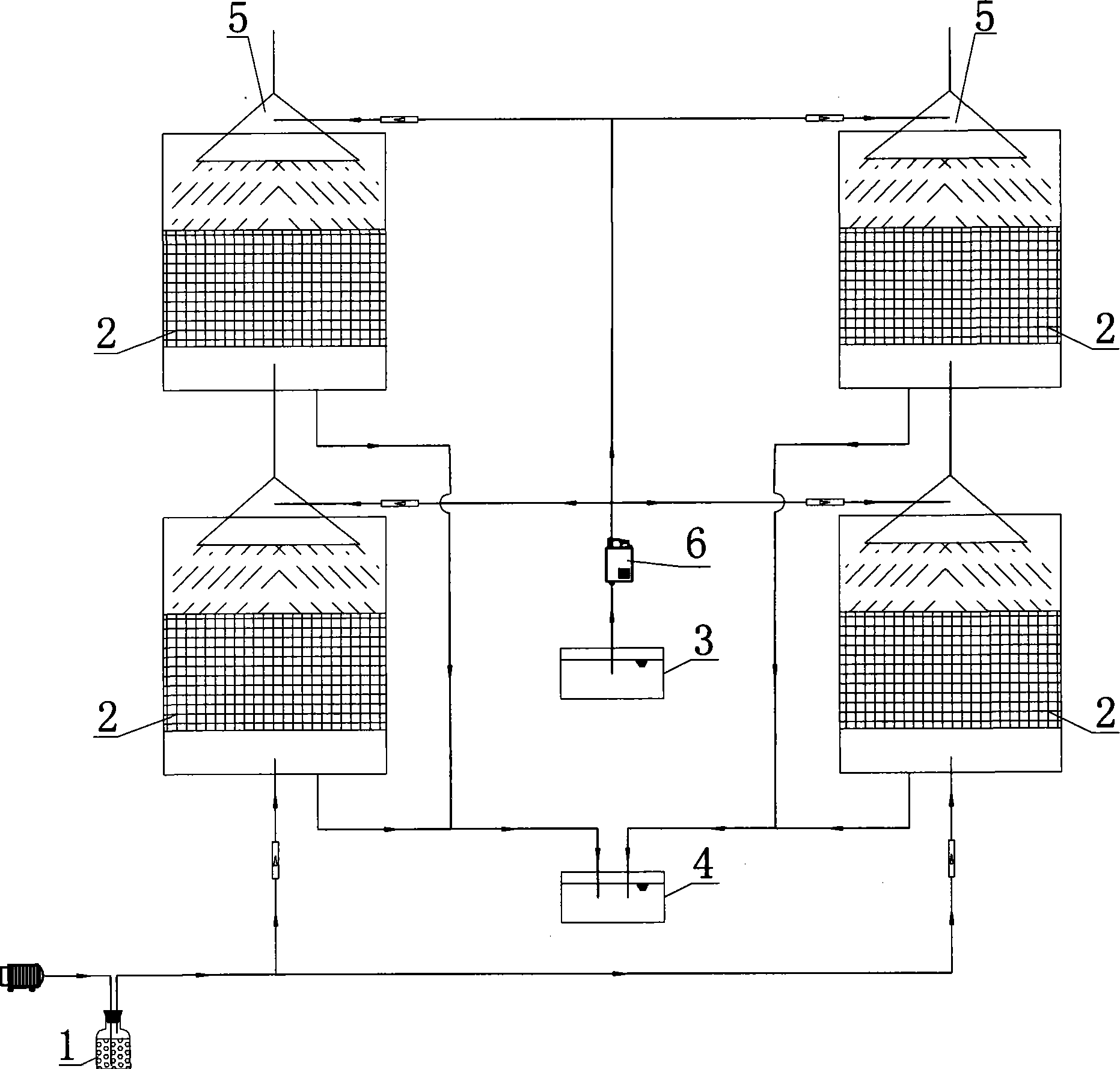

Sewage treatment device based on 3D printing biological stuffing

ActiveCN104045170AEasy to attachUniform air distributionSustainable biological treatmentBiological water/sewage treatmentAutomatic controlMesh grid

The invention discloses a sewage treatment device based on 3D printing biological stuffing, and belongs to the field of water pollution government devices. The device comprises a barrel body, a stirring device, an aeration device and stuffing and the device further comprises a water bath machine and a water bath machine water inlet pump, wherein the two ends of the water bath machine are respectively connected with a water bath layer water inlet tube and a water bath layer water outlet tube; a water bath layer water inlet pump is arranged between the water bath machine and the water bath layer water inlet tube; the stuffing is vertically suspended between upper gridding and lower gridding; adjacent two rows of stuffing are arranged in a staggered manner at upper and lower layers, and the spacing between the adjacent two rows of the stuffing is equal; the lower gridding is matched with the inner edge of an inner cavity; the upper gridding is matched with the outer edge of the inner cavity. The device disclosed by the invention is high in stuffing film-suspending rate, high in sewage treatment load, capable of realizing automatic control and suitable for sewage treatment for domestic sewage such as household sewage, housing estate sewage or plant sewage and similar water quality, and is not blocked.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Discharge gas surface biofiltration scouring method and device

InactiveCN101249382AShort stayHigh volume load rateDispersed particle separationAir quality improvementLiquid wasteVolumetric Mass Density

The invention provides a method for filtrating and purifying organisms on the surface of exhaust gas and a device thereof. The method comprises the steps that: (1) a biofiltration dielectric layer is provided: a multihole synthetic filler thin layer with the thickness ranging from 0.02m to 0.2m is used as the biofiltration dielectric layer so that microbes such as bacteria or fungi and so on are attached to and grow on the biofiltration dielectric layer; the filter media is made of the material with the porosity ranging from 90 percent to 98 percent, the aperture ranging from 1mm to 10mm, the opening rate more than 95%, the tensile strength more than 5000Pa, the compressive strength more than 1000Pa, the stacking density ranging from 20kg / m<3> to 600kg / m<3>, and the specific area ranging from 100m<2> / m<3> to 1000m<2> / m<3>; (2) exhaust gas is filtered: the exhaust gas to be purified passes through the biofiltration dielectric layer at the lower flow speed ranging from 0.005 m / s to 0.05m / s and stops on the biofiltration dielectric layer for one to twenty seconds. The device comprises an exhaust gas humidification cell, a biofiltration dielectric layer, a nutrient solution supply cell, a liquid waste disposal cell, a nutrient solution spray header and a control cell. The method and the device provided by the invention have the advantages of uniform distribution of gas, small pressure drop, small height of bed, high cubage and load, large handling capacity, low running cost, stable performance during long running and so on.

Owner:HUNAN UNIV

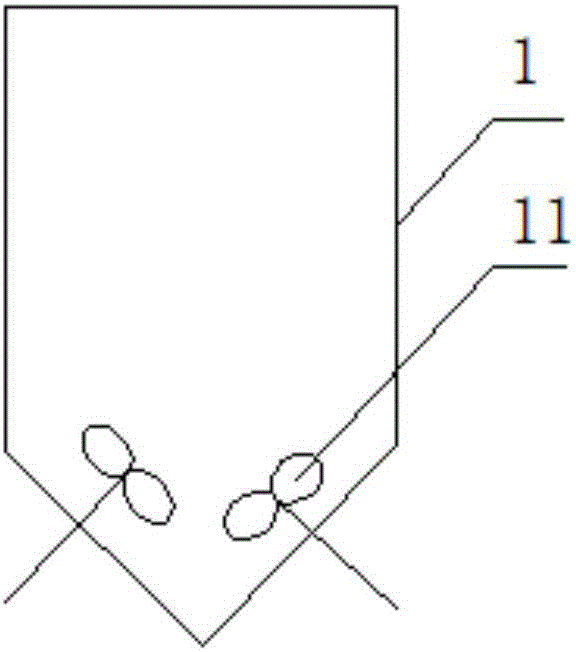

Low-concentration organic exhaust gas fluidization tower

ActiveCN105727733ALow running costSimple structureDispersed particle separationAir quality improvementActivated carbonSludge

The invention relates to a low-concentration organic exhaust gas fluidization tower. A muddy water zone, a fluidization zone, an adsorption oxidation zone, a dehumidification zone, an activated carbon adsorption zone and an exhaust fan are arranged from bottom to top of the tower in turn; the muddy water zone is designed as a tapered structure and is used for collecting the muddy water from the upper part; a draining valve is arranged at the bottom of the tapered structure; the draining valve is connected with a sludge thickener on the outer side of the tower; a fluidization drum is arranged in the fluidization zone; the fluidization drum has a cylindrical structure and is located at the center of the fluidization zone; the lower end opening of the fluidization drum is located at the bottom of the fluidization zone while the upper end opening is located on the upper part of the fluidization zone; a gas inlet pipe and a gas distributing pipe are arranged at the lower end of the fluidization drum; the gas distributing pipe is arranged in the shape of a concentric circle; the adsorption oxidation zone is located on the upper part of the fluidization zone; the dehumidification zone is arranged on the upper part of the adsorption oxidation zone; and the activated carbon adsorption zone is arranged on the upper part of the dehumidification zone.

Owner:上海博士高工贸有限公司

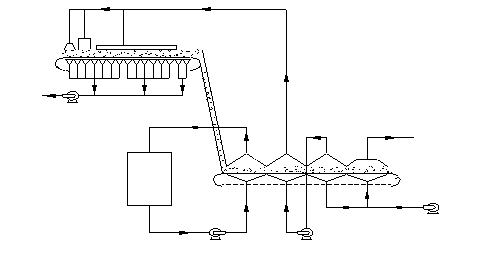

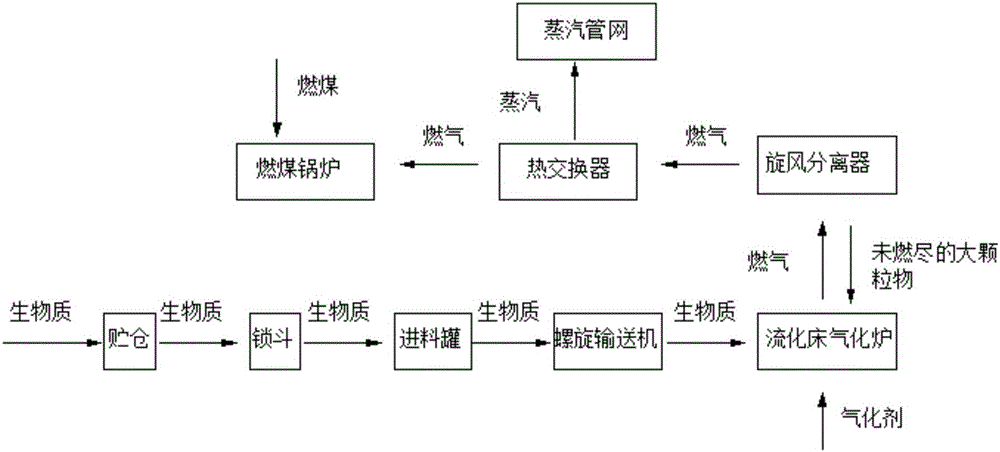

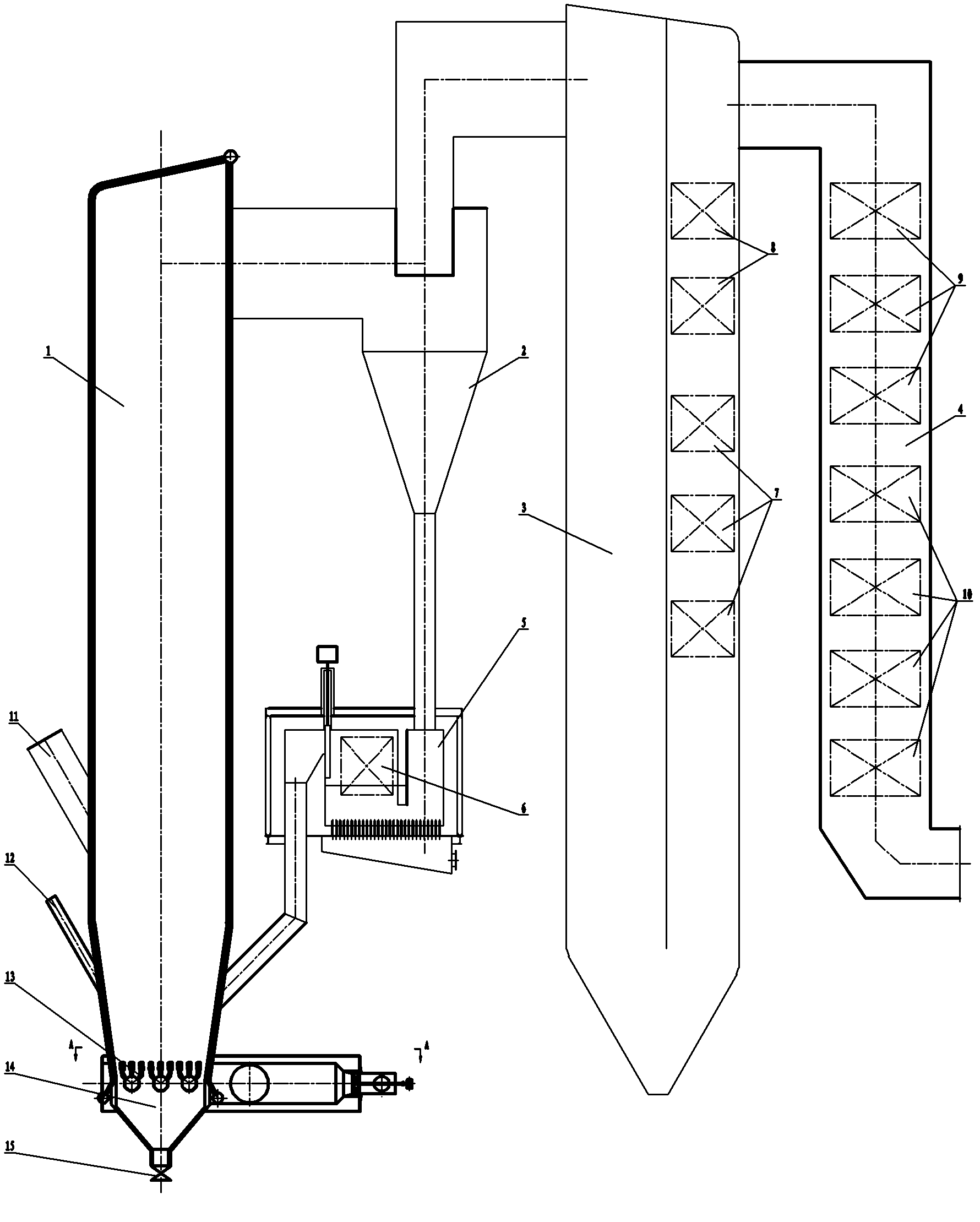

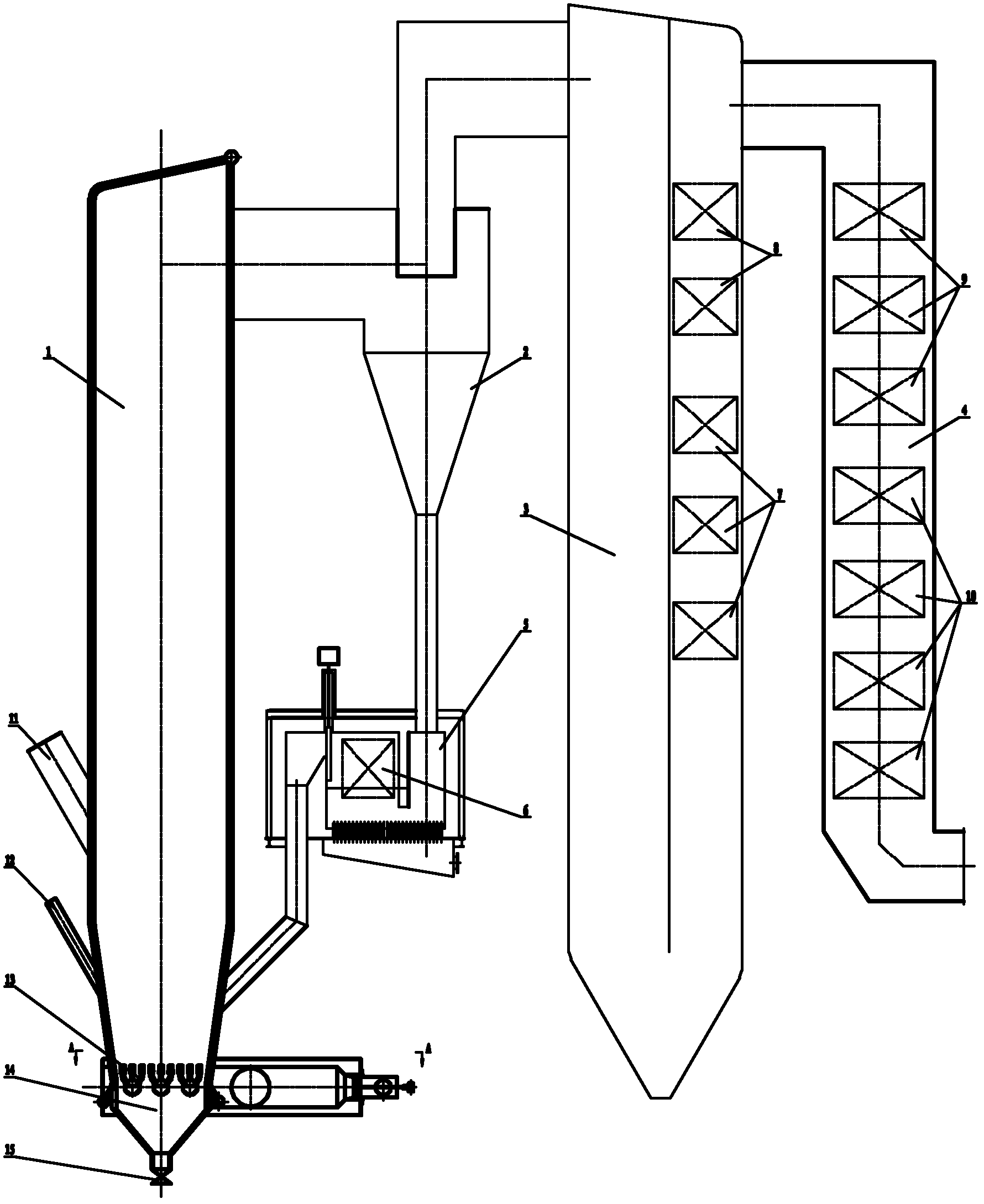

Biomass gasification power-generation process

InactiveCN106244246AHigh strengthImprove gasification efficiencyGasifier feeding meansGasification processes detailsParticulatesFood consumption

The invention discloses a biomass gasification power-generation process. The biomass gasification power-generation process comprises the following steps of step (I), pressurizing biomass granules until the gauge pressure is 0.1-4.0Mpa, then discharging materials to a charging tank, then conveying the discharged materials to a fluidized-bed gasifier, and performing a gasification reaction with a gasification agent so as to obtain fuel gas for standby application; step II, performing cyclone dust removal on the fuel gas prepared in step (I) through a cyclone separator, performing separation to obtain large particles which are not burn-out, and returning the large particles to the fluidized-bed gasifier for gasifying once again; and step (III), cooling the flue gas which is subjected to dust removal by the cyclone separator to 300-700 DEG C through a heat exchanger, and enabling the cooled flue gas to be led into a coal boiler to be subjected to mixed combustion with the coal for power generation. According to the biomass gasification power-generation process disclosed by the invention, the biomass granules are sent to a large-scale coal boiler through the fuel gas generated by gasification to be subjected to combined combustion with the coal for power generation, so that the coal consumption required for power generation is reduced, the amount of CO2 generated during combustion is reduced, greenhouse effects caused by CO2 can be alleviated, and emission of NOX by power plants is reduced.

Owner:武汉高斯生态能源技术有限公司

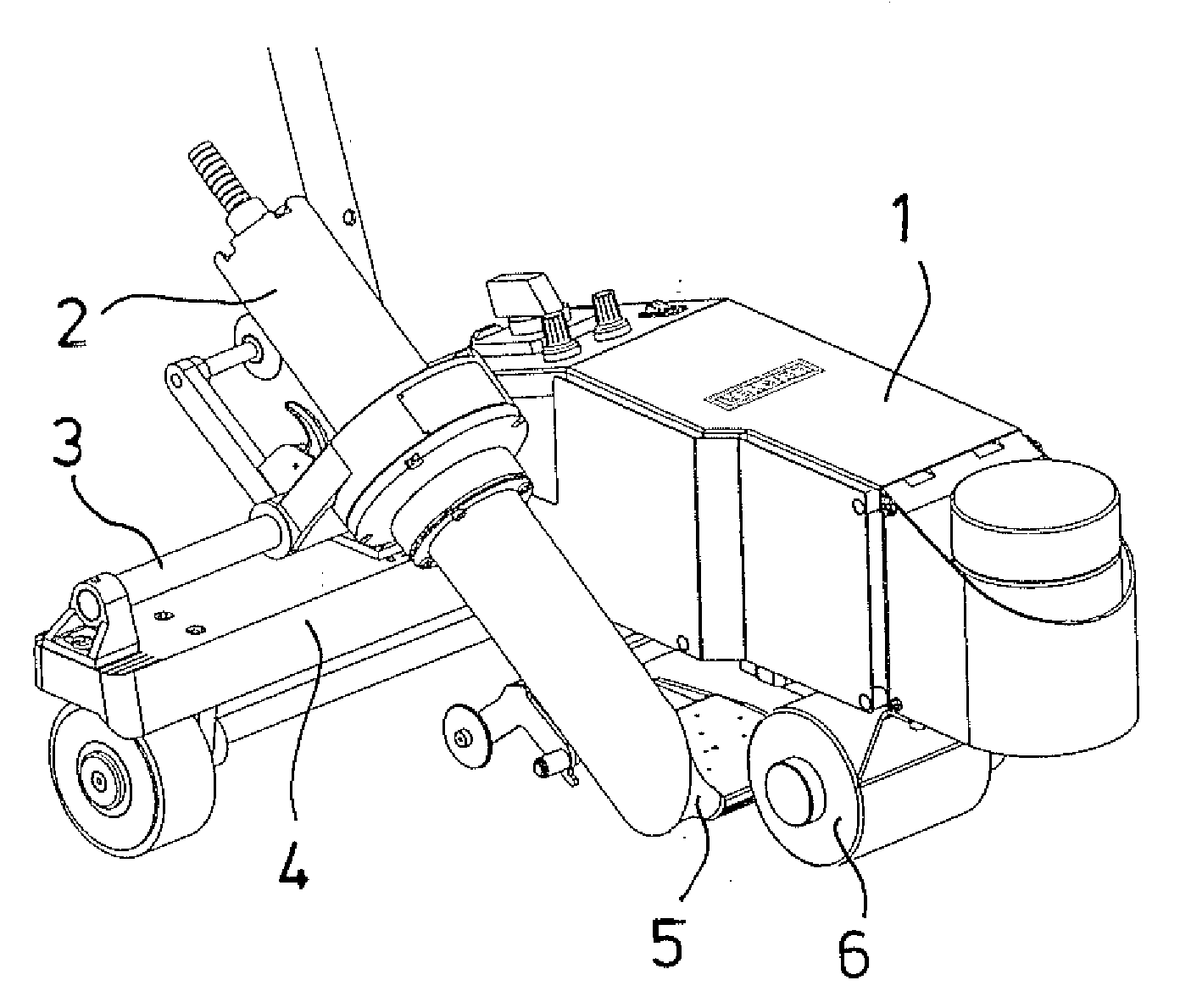

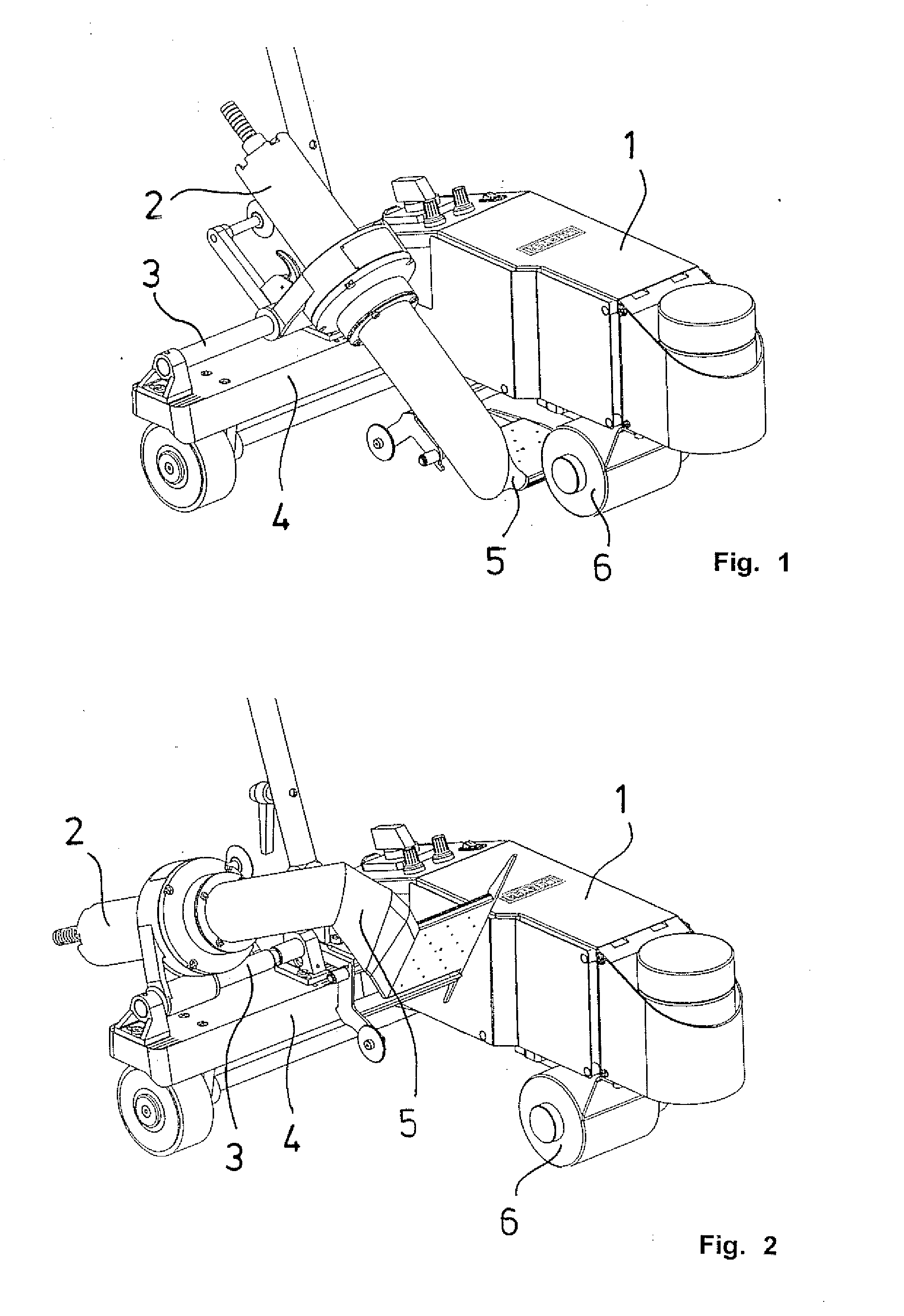

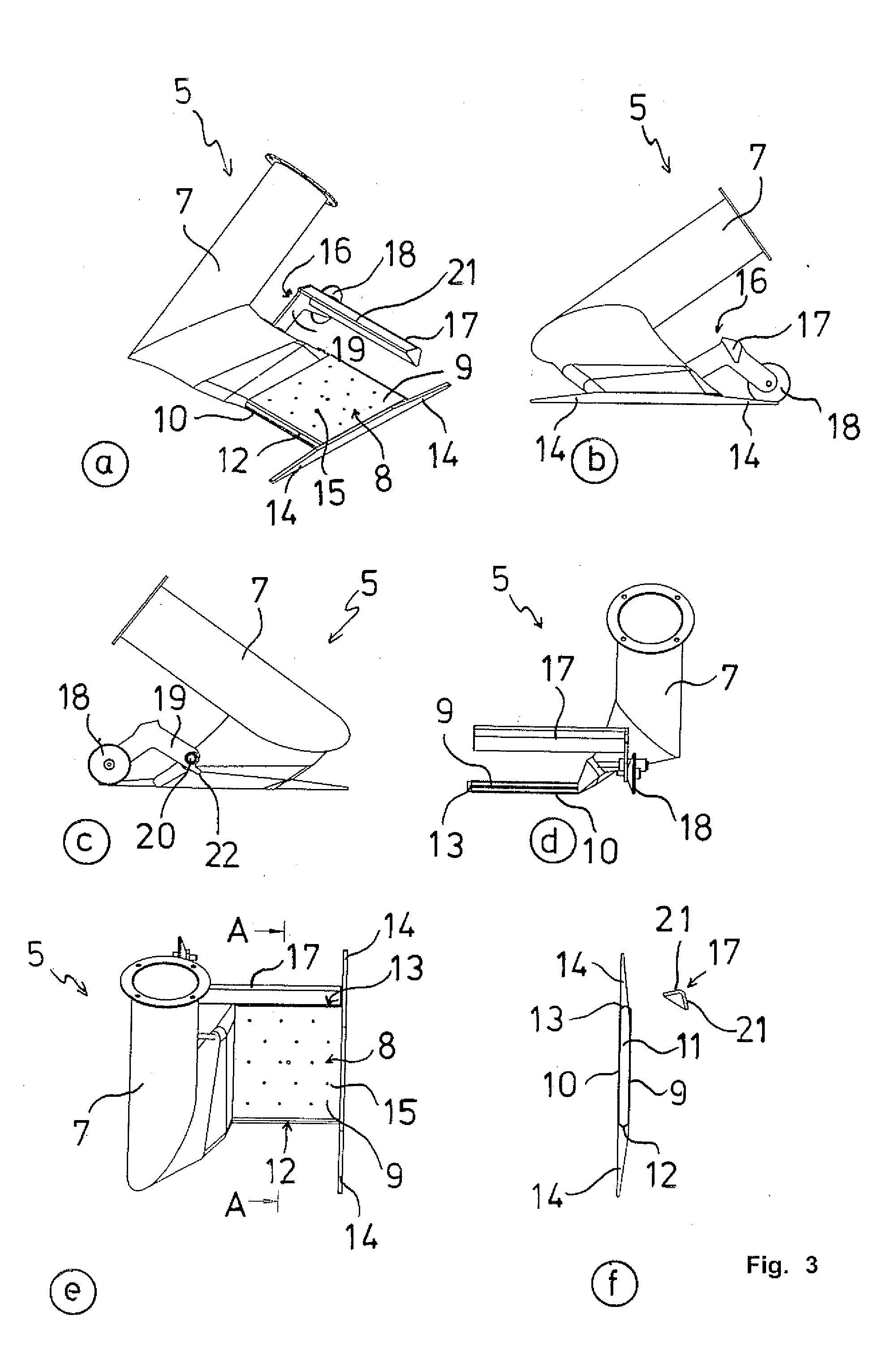

Hot air nozzle

A hot air welding nozzle for a hot air welding device for welding overlapping webs of sealing material, in particular webs of bitumen. The hot air welding nozzle includes a connection for a hot air supply, a top and a bottom heat plate forming an air space, and at least one rear outlet between the top and bottom heat plate on a facing side that is oriented in a direction opposite to the moving direction of the hot air welding device, with at least one front outlet relative to the moving direction of the hot air welding device, and with air guides that extend beyond the facing sides of the heat plates, at least on the inner side, i.e. the side facing away from the connection for a hot air supply. With the hot air welding nozzle designed as proposed by the invention, and / or a hot air welding device of appropriate design, it is now possible to weld webs of sealing material, in particular webs of sealing material made of bitumen, considerably faster due to the long pre-heating zone.

Owner:LEISTER TECHNOLOGIES

Household waste inventory heterotopic aerobiotic strengthening stabilization system and method

ActiveCN111570467AControl moisture contentEvenly distributed waterSolid waste disposalSpecial buildingCapillary waterMechanical engineering

The invention discloses a household waste inventory heterotopic aerobiotic strengthening stabilization system and method, and belongs to the technical field of environment protection. The system comprise the following units that a parallel gallery unit, a drainage and air distribution unit, cover films and a capillary water distribution unit, wherein the parallel gallery unit is located on a dug object placement site and composed of N longitudinal partition walls and transverse partition walls perpendicular to the longitudinal partition walls, the transverse partition walls and the longitudinal partition walls form unit galleries of which the two ends are provided with outlets, and the N longitudinal partition walls and the transverse partition walls form 2(N-1) unit galleries to form theparallel gallery unit; the drainage and air distribution unit is arranged on the terrace of the unit galleries; the cover films are arranged at the tops of the unit galleries and can be folded or unfolded; and the capillary water distribution unit is arranged above the parallel gallery unit. By adopting the aerobiotic strengthening stabilization system, the stabilization cycle can be effectively shortened, the target that waste inventory dug objects are quickly and stably pre-processed within one week is achieved, and the follow-up sorting efficiency and the resource utilization technology efficiency are improved.

Owner:NANJING UNIV +1

Novel diving jet-type biological aerated filter

InactiveCN103011390AImprove gas-liquid mixing effectUniform air distributionTreatment using aerobic processesSustainable biological treatmentOxygen utilization rateMicrobiological growth

The invention discloses a novel diving jet-type biological aerated filter, comprising a biological filter, wherein a filter filler part and a filter material layer are arranged in the biological filter; a water inlet tube is arranged at the upper end of the biological filter, and a water outlet tube is arranged at the lower end of the biological filter; a bridge is installed at the top end of the biological filter; a diving jet-type aerator which is fixed via a hoisting chain is installed on the bridge; and the main machine of the diving jet-type aerator is installed below the filter filler part. Via the mode aforementioned, the novel diving jet-type biological aerated filter disclosed by the invention is capable of effectively improving gas-liquid mixing effect, realizing uniform gas distribution, increasing oxygen utilization rate, creating an environment suitable for growth of microbes which are used for oxygenolysis of organic matters, improving effluent treatment effect, and saving space and construction cost.

Owner:SUZHOU RES INST OF TONGJI UNIV

Continuous hydrolysis kettle converted from furfural intermittent hydrolysis kettle

InactiveCN102039111AUniform air distributionOrganic chemistryChemical/physical/physico-chemical stationary reactorsComputer control systemEngineering

The invention relates to a continuous hydrolysis kettle converted from a furfural intermittent hydrolysis kettle. An intermittent pressure preheating feeding device, a material level monitoring device, an intermittent deslagging amount and time control device and a computer control system for continuously discharging furfural are added to complete the converting process of the furfural hydrolysis kettle from intermittent to continuity.

Owner:武建民

Vertical carbon-dioxide generator for greenhouse

ActiveCN105009994APromote absorptionReduce the temperatureGreenhouse cultivationHorticulture methodsWater dischargeGreenhouse

The invention relates to a gas generating device, in particular to a vertical carbon-dioxide generator for a greenhouse with the purpose of solving the technical difficulty that carbon dioxide generators in the same kind are high in energy loss. The vertical carbon-dioxide generator comprises a thermal decomposition reactor and an ammonia absorber. The top end of the thermal decomposition reactor is provided with a feeding sealing cover. The bottom of the thermal decomposition reactor is provided with a heater. The side wall of the thermal decomposition reactor is provided with a waste discharge valve and a mixed gas pipe. The mixed gas pipe and the ammonia absorber are communicated. The side wall of the ammonia absorber is provided with a liquid level pipe, a water-adding valve, an ammonia water discharge valve and a carbon-dioxide exhaust pipe. The interior of the ammonia absorber is provided with a millipore filter communicated with the mixed gas pipe.The vertical carbon-dioxide generator for the greenhouse has following beneficial effects: by heating ammonium bicarbonate, carbon dioxide is produced and gas is produced at high speed; by means of a pressure adjusting system, uniform gas distribution at long distance can be achieved; the problem that a technical product in the same kind may have energy dissipation due to the need of air pump pressurization is solved; the vertical carbon-dioxide generator is adapted for greenhouses with all specifications; and carbon dioxide can be supplemented to multiple greenhouses in a unified way at the same time.

Owner:丁盛生

Purification device and method for strongly acidic components in exhaust gas

ActiveCN105107369AEliminate airway blockageIncrease responsivenessDispersed particle separationExhaust gasChemical engineering

The invention discloses a purification device and method for strongly acidic components in exhaust gas. The purification device is characterized by comprising a reactor shell, an active material filling container arranged in the reactor shell and a bearing layer arranged between the reactor shell and the active material filling container. The top of the reactor shell is sealed through a sealing cover plate. The reactor shell is provided with a gas inlet, a gas outlet and a liquid outlet. A gas guide pipe is inserted into the active material filling container. According to the purification device, the exhaust gas containing the strongly acidic components is distributed through the bearing layer, enters the gas guide pipe and then enters the active material filling container through gas holes distributed in the gas guide pipe to make contact with an active material, the strongly acidic components are reacted with the active material to form salt, and purified exhaust gas is exhausted through an exhaust pipe.

Owner:HEFEI UNIV OF TECH

Waste cracking furnace with low energy consumption

InactiveCN101813317AGuaranteed uptimeImprove responseIncandescent ignitionIncinerator apparatusGas cylinderEngineering

The invention relates to a waste cracking furnace with low energy consumption, which belongs to the field of waste processors and comprises a furnace body, a permanent magnetic material layer, a carbon mixture outlet, a balance and gas-liquid collection device, a gas-liquid mixture outlet, an oxygen supply and automatic ignition device and an air inlet. The balance and gas-liquid collection device is arranged at the top of the furnace body, the oxygen supply and ignition device is arranged on a base plate of the furnace body, the permanent magnetic material layer is arranged in the furnace body and tightly attached to furnace body, and the balance and gas-liquid collection device comprises a gas-liquid collection passage, a gas-liquid collection pipeline, a closed cover, a sealing ring, a top pressure layer, a piston, a gas cylinder, a lower air inlet and an upper air inlet, and the oxygen supply and ignition device comprises an oxygen supply, an oxygen supply pipeline, an air distributor, an air main pipe and a heating wire ignition device. The invention has simple structure, can keep the relatively stable pressure of a cracking furnace reaction region, realizes the automatic power ignition and the even bottom gas distribution of the cracking furnace and improves the reaction effect of the cracking furnace.

Owner:黄广禧

Circulating fluid bed waste incineration boiler with open-type furnace chamber

InactiveCN102305406AEasy to wrapLong continuous running timeIncinerator apparatusCooling chamberSuperheater

The invention relates to a circulating fluid bed waste incineration boiler with an open-type furnace chamber. The circulating fluid bed waste incineration boiler comprises the open-type furnace chamber, a cyclone separator, a cooling chamber and a tail convection flue which are connected with one another in turn, wherein the lower end of the cyclone separator is connected with an external heat exchanger, and the other end of the external heat exchanger is connected with the open-type furnace chamber; a high-temperature over-heater is arranged in the external heat exchanger; a plurality of air distribution tubes are arranged on the same horizontal plane equidistantly to form an open-type air distribution plate which is arranged at the bottom of the open-type furnace chamber; an ash hopper is connected below the open-type air distribution plate; a fuel ash valve is arranged below the ash hopper; the open-type air distribution plate separates the upper part of the open-type furnace chamber and the ash hopper; and the open-type air distribution plate consists of the plurality of air distribution tubes. The circulating fluid bed waste incineration boiler can successfully discharge materials which can be easily wound on an air cap, or large-particle or even blocky materials such as iron wires, iron nails and the like in wastes, can uniformly distribute air, is difficult to coke and clinker, and fulfills the aims of prolonging the continuous operation time of the waste incineration boiler and saving energy resources.

Owner:WUXI TAIHU BOILER

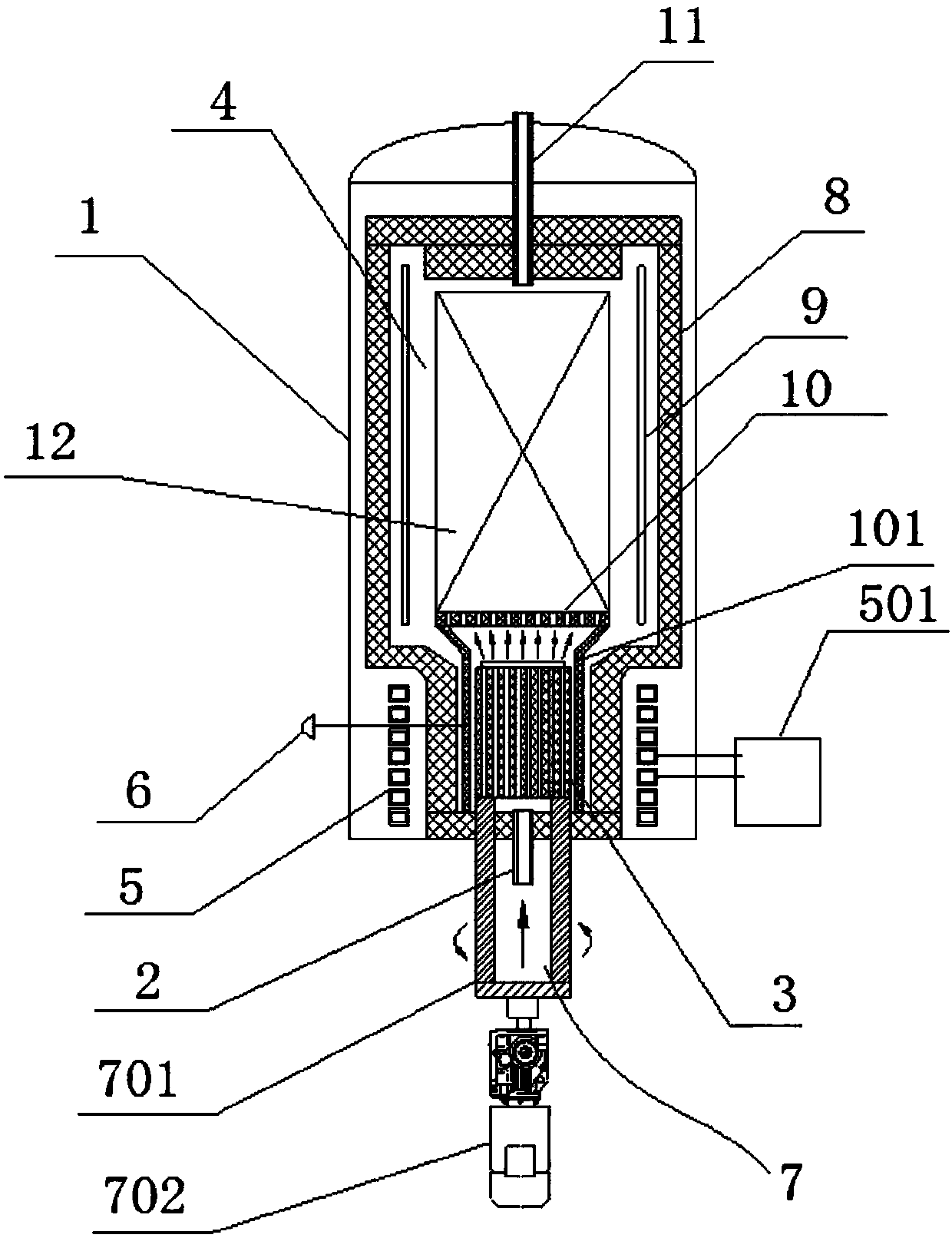

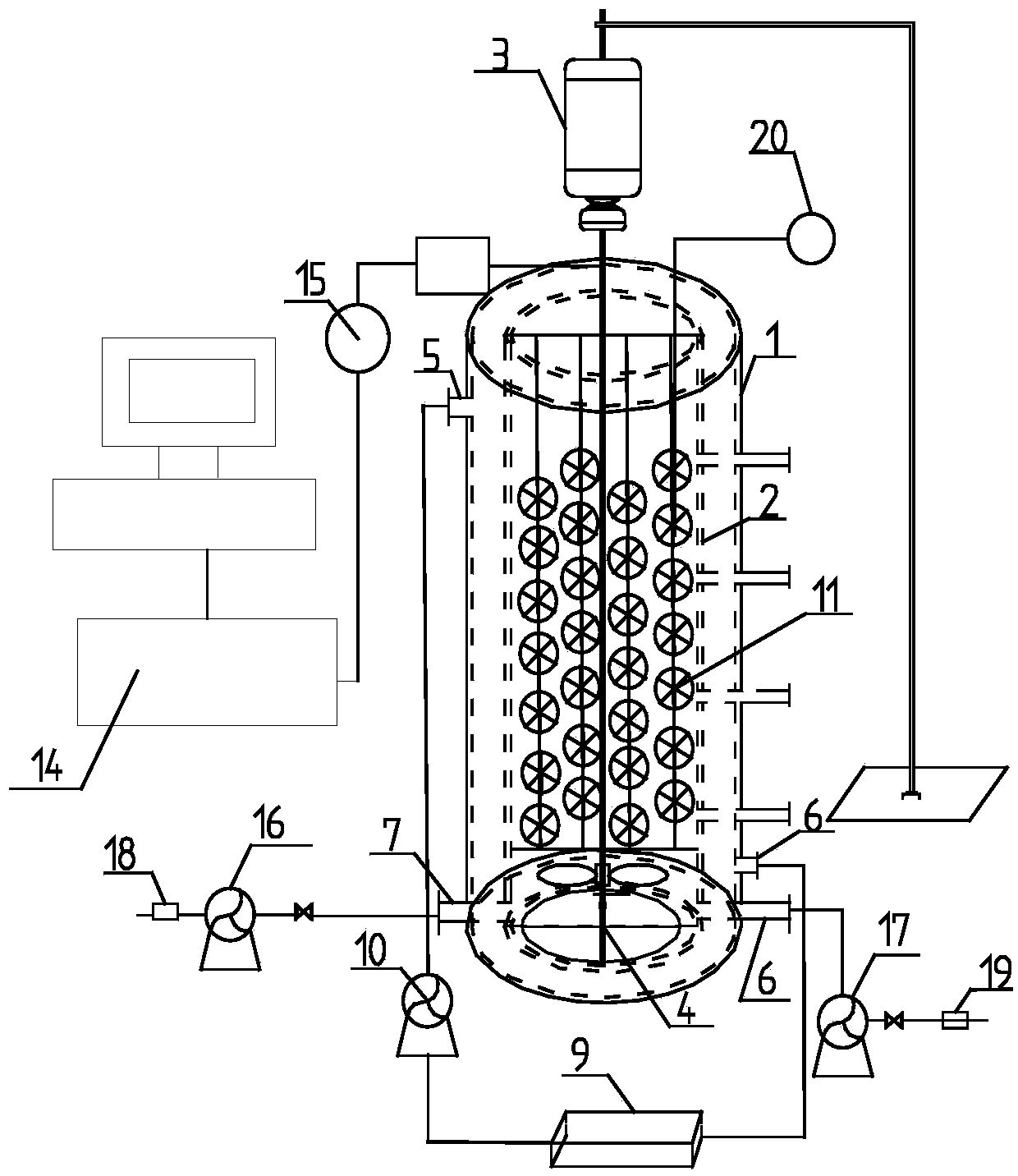

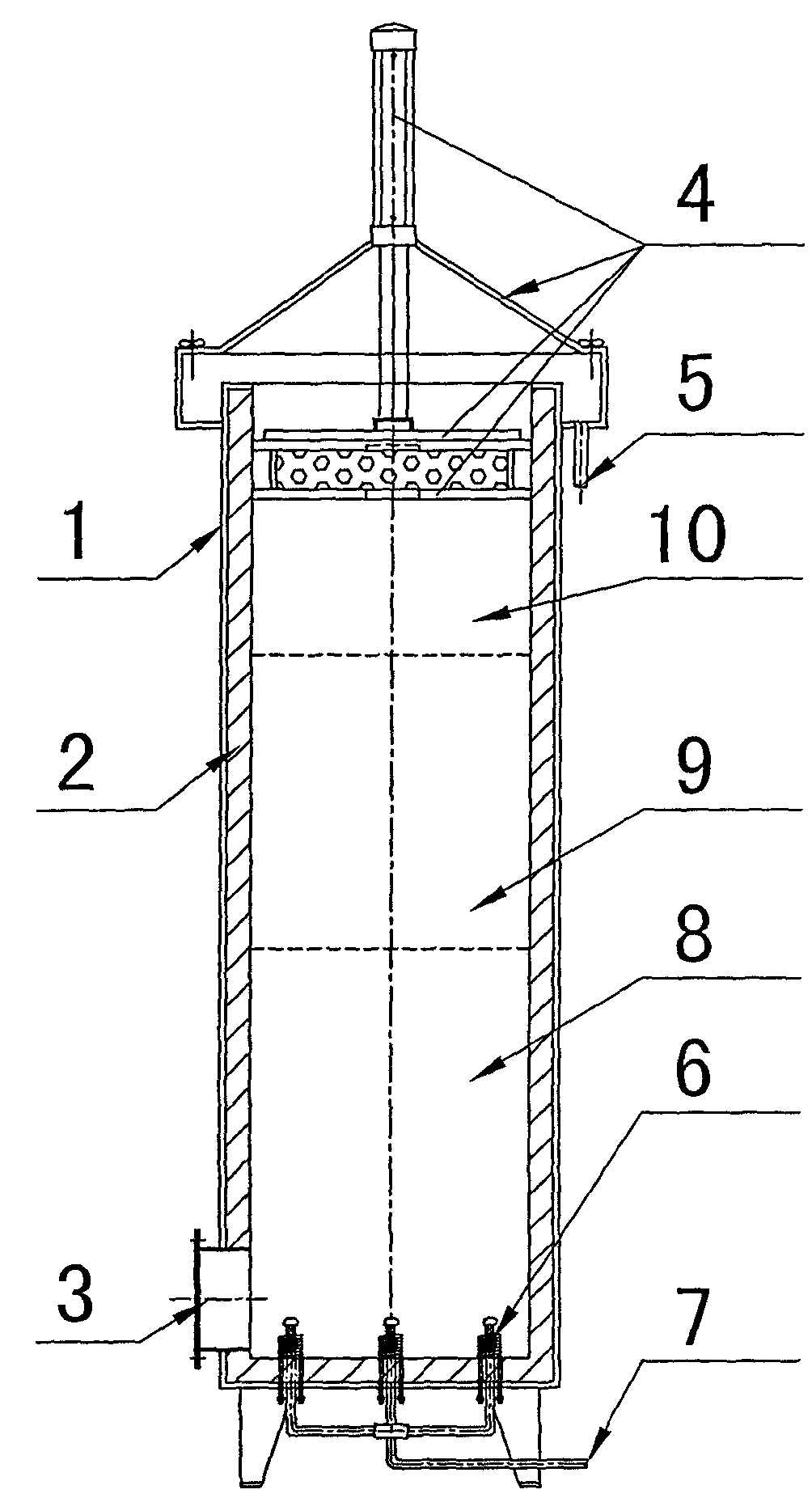

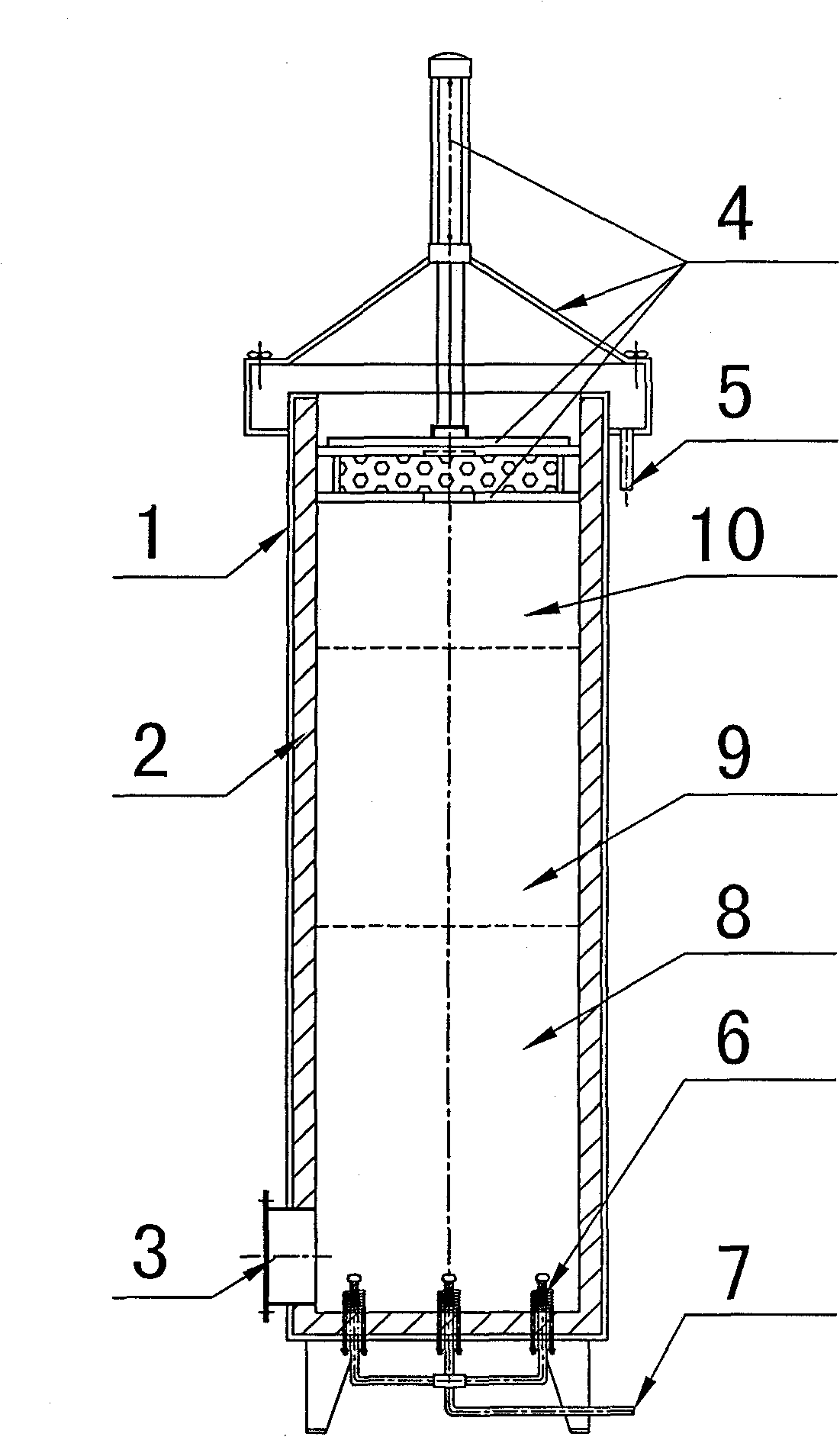

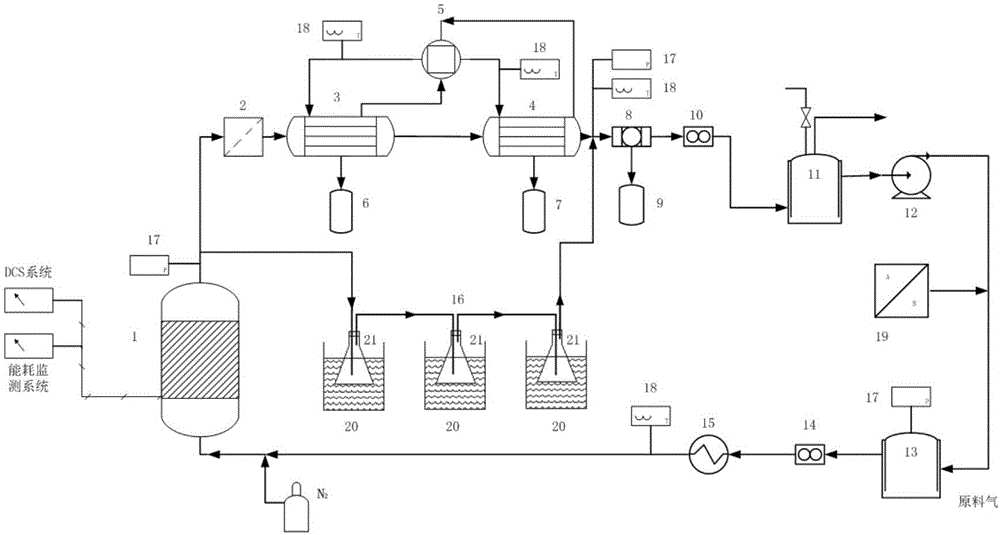

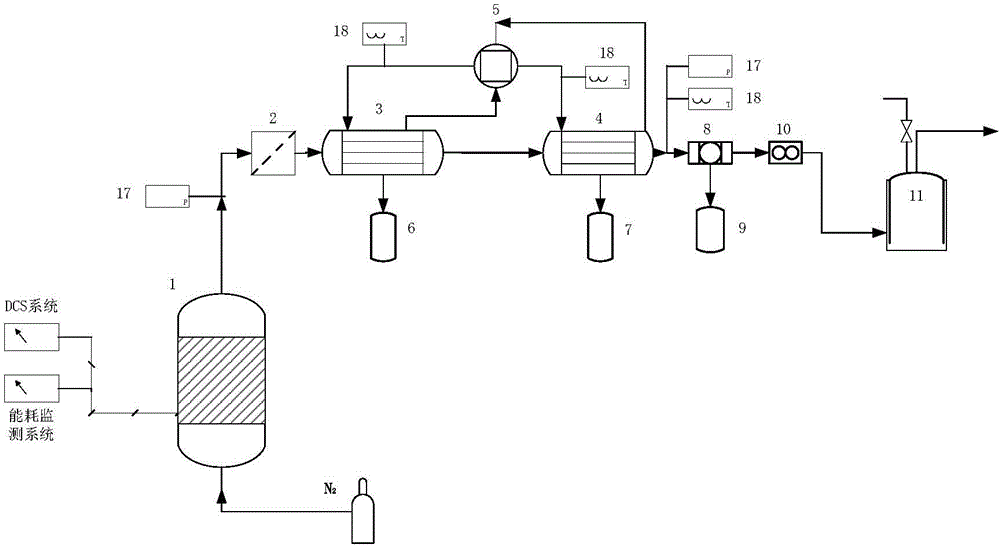

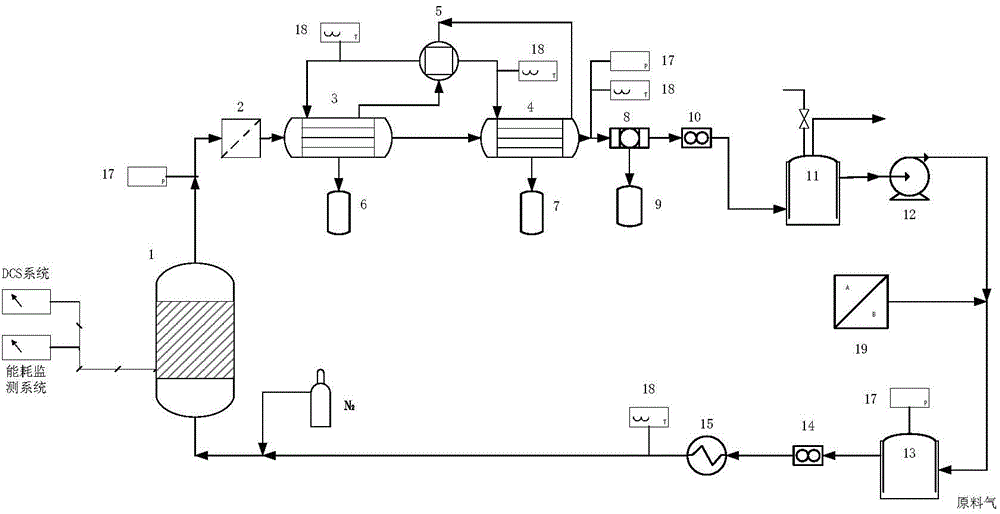

Multifunctional carbon-containing substance pyrolysis evaluation device and method

ActiveCN104155326AUniform air distributionHigh thermal efficiencyMaterial heat developmentSludgeCarbonization

The invention provides a multifunctional carbon-containing substance pyrolysis evaluation device which comprises a reactor (1), a condensing unit or a dust content testing device (16), a gas oil-water separator (8), a liquid storage tank (9) of the separator, a first gas flow meter (10), a gas storage tank (11) and a forced gas circulation device, wherein the reactor (1), the condensing unit or the dust content testing device (16), the gas oil-water separator (8), the first gas flow meter (10) and the gas storage tank (11) are sequentially communicated with one another; a liquid outlet of the gas oil-water separator (8) is connected with the liquid storage tank (9) of the separator. The multifunctional carbon-containing substance pyrolysis evaluation device can be used for carrying out multiple evaluation tests such as low temperature carbonization, forced-convection heat transfer, hydropyrolysis and dust content measurement as well as quantitative analysis on different types of carbon-containing substances such as coal, biomass, garbage, waste tires, waste organic matters and organic sludge. The invention also provides a multifunctional carbon-containing substance pyrolysis evaluation method.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com