Rotational flow shearing bubble aerator

A bubble aerator and swirl technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., to achieve the effect of suitable bubble size, uniform air distribution and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

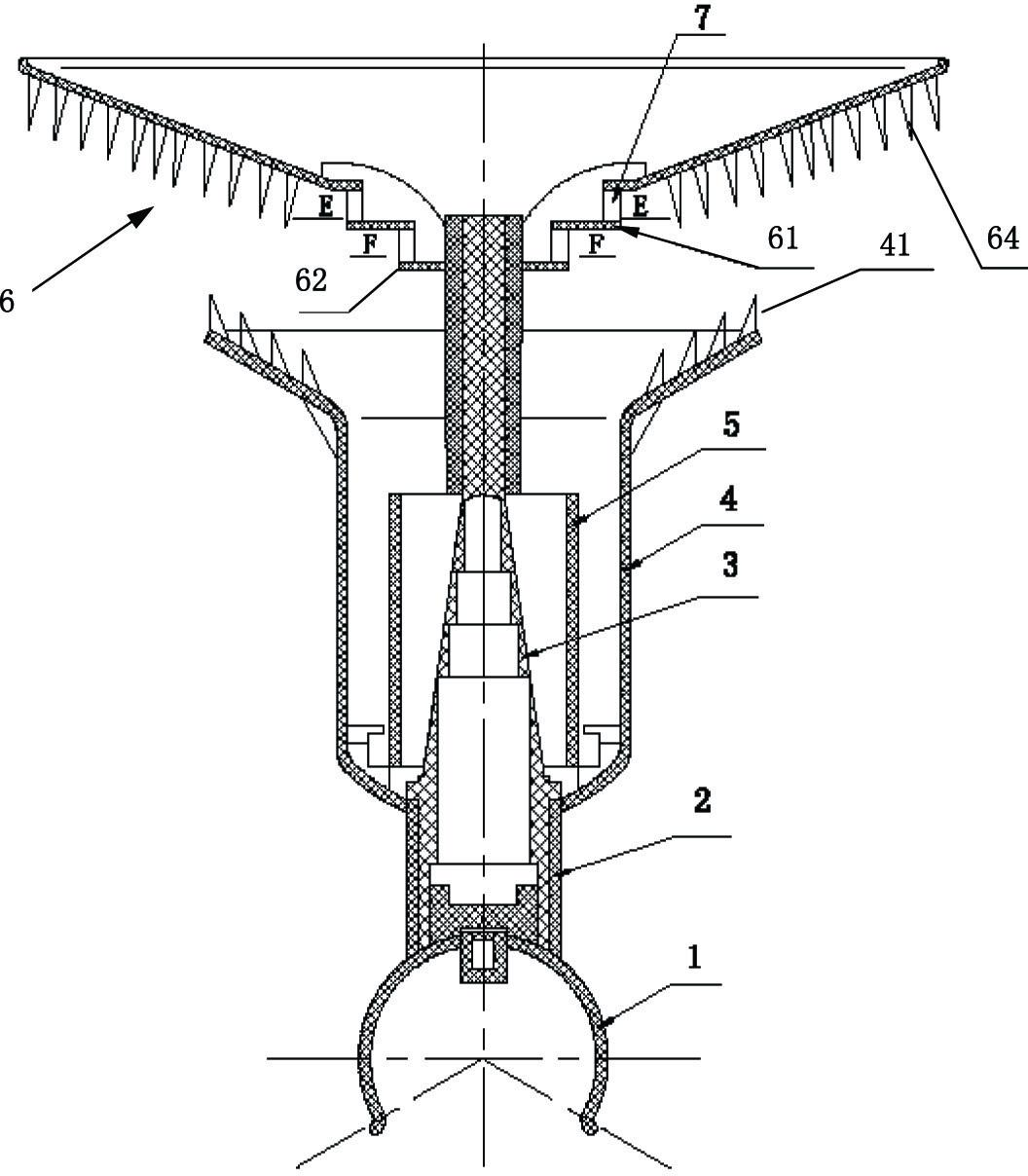

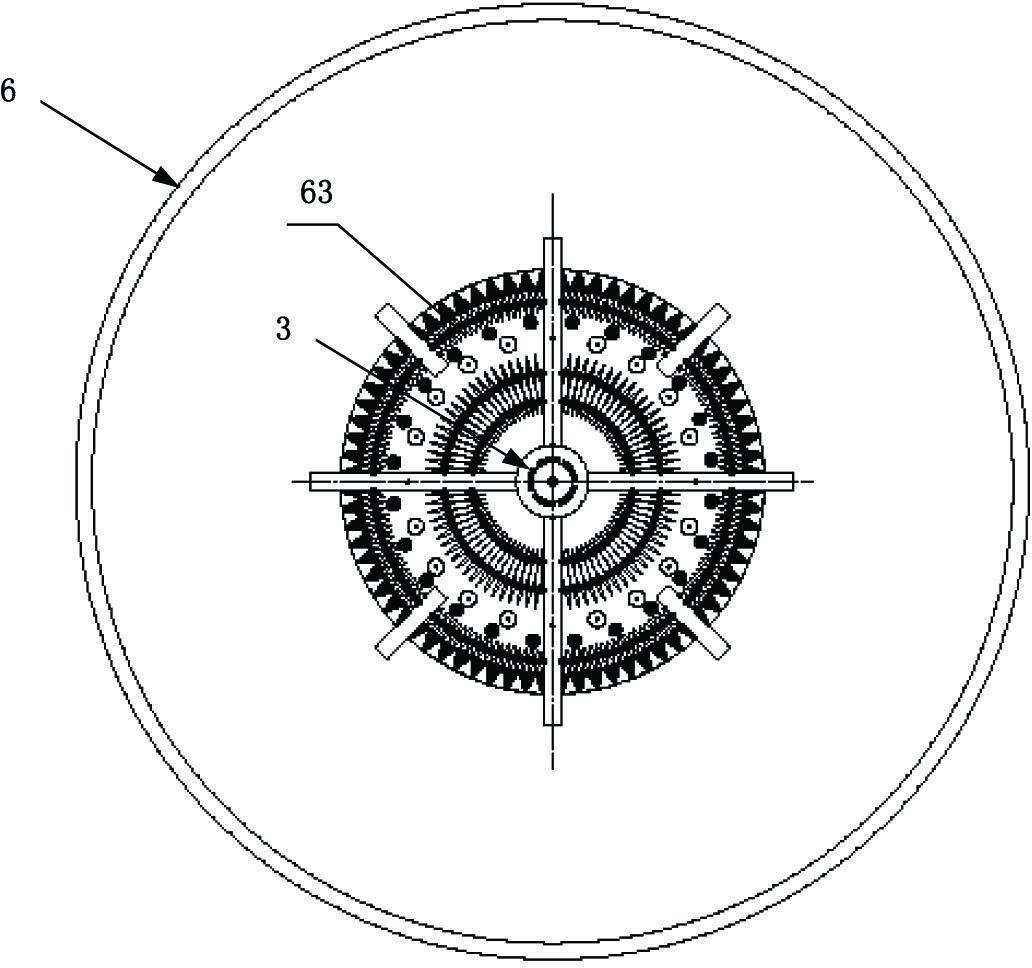

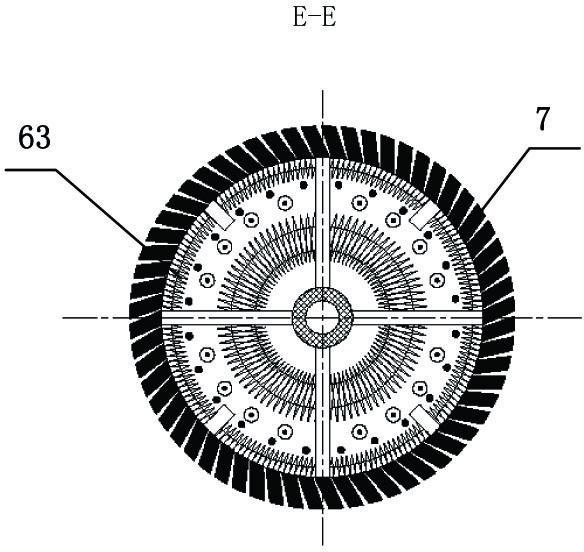

[0018] Depend on Figures 1 to 6 It can be seen that the present invention includes an air inlet base 1 , a one-way valve 2 , a gas distributor 3 , an outer reaction cylinder 4 , an inner reaction cylinder 5 , and a shear bubble diffusion plate 6 . The one-way valve 2 is arranged on the air intake base 1, one side is connected with the air intake base 1, and the other side is connected with the reaction outer cylinder 4; the gas distributor 3 is arranged in the one-way valve 2 and the reaction outer cylinder 4, and its The bottom is connected to the air inlet base 1 (threaded connection or tight-fitting socket can be used), and the upper part is connected to the shear bubble diffusion plate 6 (socketed or threaded connection can be used); the periphery of the gas distributor 3 is connected to the reaction outer cylinder 4 The reaction inner cylinder 5 is arranged in between.

[0019] continue to see figure 1 , several teeth 41 are provided on the diffusion port at the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com