Combined biological deodorization integrated equipment and processing method of odorous gas

A biological deodorization and composite technology, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of water level drop, treatment effect reduction, and hindering the upward flow of gas, so as to achieve uniform gas distribution and keep gas smooth flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

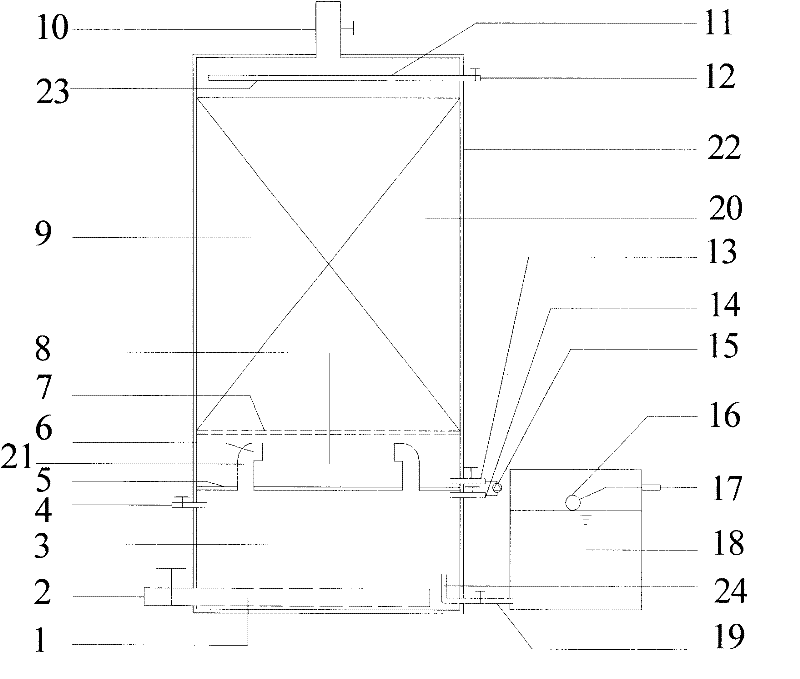

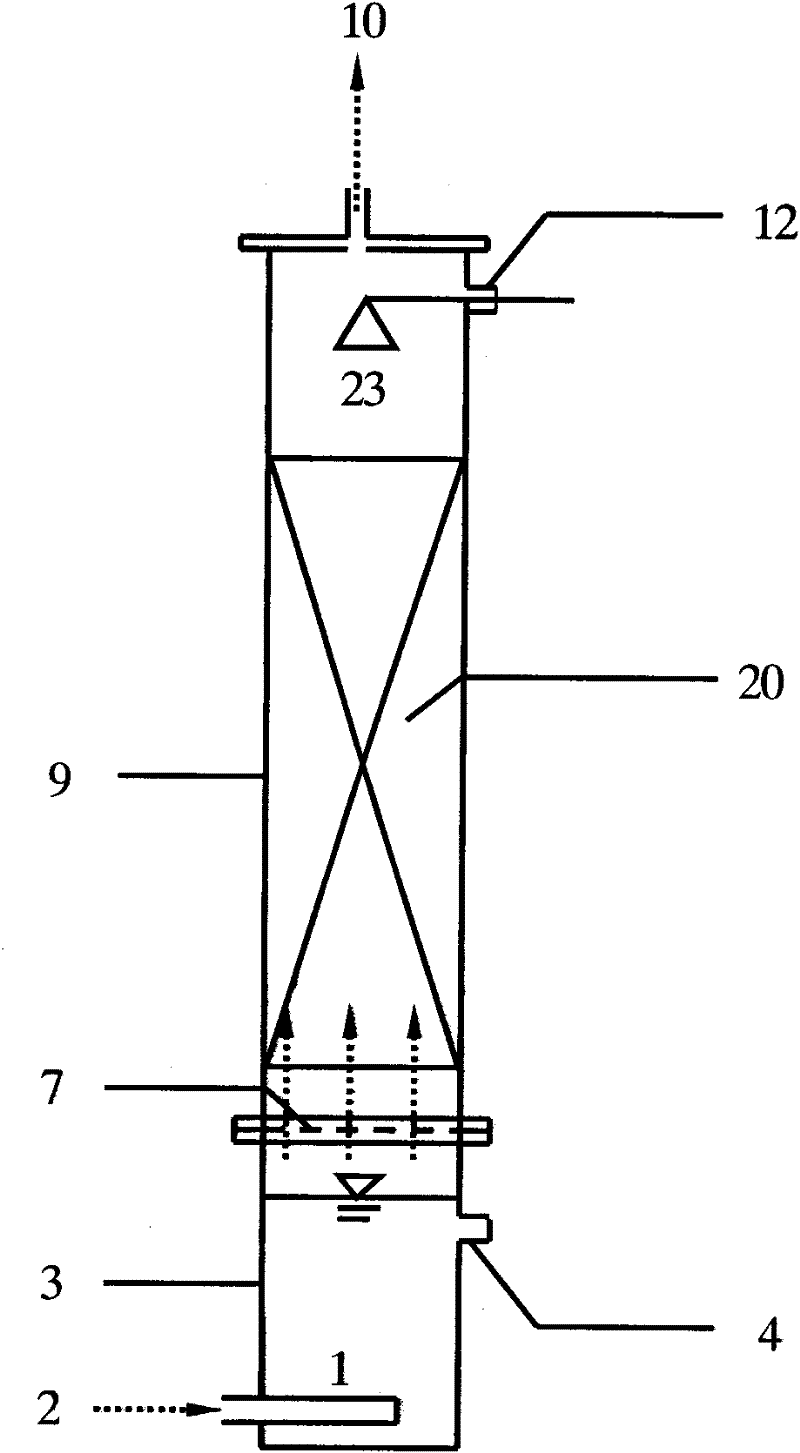

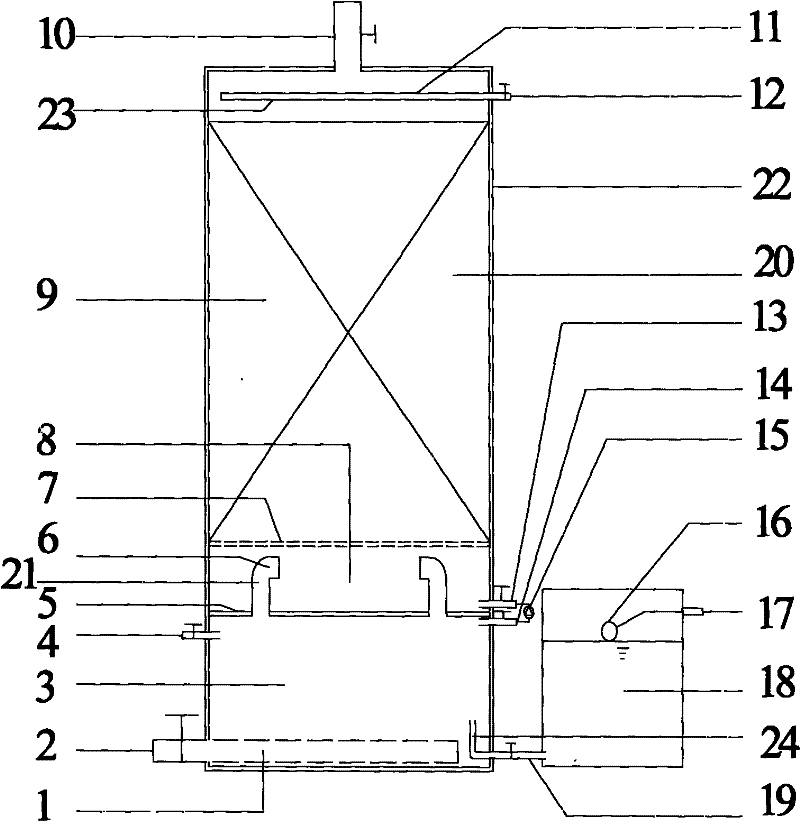

[0043] See figure 1 . The composite biological deodorization integrated equipment 22 made of plastic board has a length, width and height of 0.80m, 0.70m and 1.80m respectively, and a total volume of 1.01m 3 ; It includes a suspended bioreaction zone 3 for accommodating a solution in which bacteria and microorganisms are suspended, a fixed bioreaction zone 9 for accommodating fillers attached to fungal microorganisms, a liquid collection zone 8 and a liquid level control zone 18 .

[0044] In the inner cavity of the compound biological deodorization integrated equipment 22, there are a perforated plate 7 with a plurality of holes (the diameter of which is 3-50mm) and a partition plate 5 with holes. The perforated plate 7 with multiple holes and the partition plate 5 with holes divide the inner cavity of the composite biological deodorization integrated equipment into the suspended biological The reaction zone 3, the fixed biological reaction zone 9 for accommodating the fil...

Embodiment 2

[0054] See figure 1 . The composite biological deodorization integrated equipment 22 made of plastic boards has a length, width and height of 6.0m, 3.0m and 3.0m respectively, and an effective volume of 54m 3 . The equipment structure and the waste gas treatment method are the same as in Example 1.

[0055] The above-mentioned compound biological deodorization integrated equipment 22 is used for odor gas treatment. Operating at room temperature, the suspended biological reaction zone is filled with dilute activated sludge, filled with inorganic fillers such as gravel, ceramsite or activated carbon; or organic fillers such as bark, wood chips, compost or resin.

[0056] The mixed odor containing hydrogen sulfide and ammonia enters the composite biological deodorization integrated equipment 22 from the air inlet 2, and the residence time is 1-3mins. The intake concentrations of hydrogen sulfide and ammonia are respectively: 4.86mg / m 3 and 0.325mg / m 3 , the outlet concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com