High-temperature aerobic fermentation process for sludge with low energy consumption and no pollution

An aerobic fermentation, non-polluting technology, used in sewage/sludge fertilizer, sludge treatment, biological sludge treatment, etc., can solve the problems of stabilization, incomplete harmlessness, low operating energy consumption, environmental pollution, etc. , to avoid odor pollution and ground pollution, high oxygen utilization rate, uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

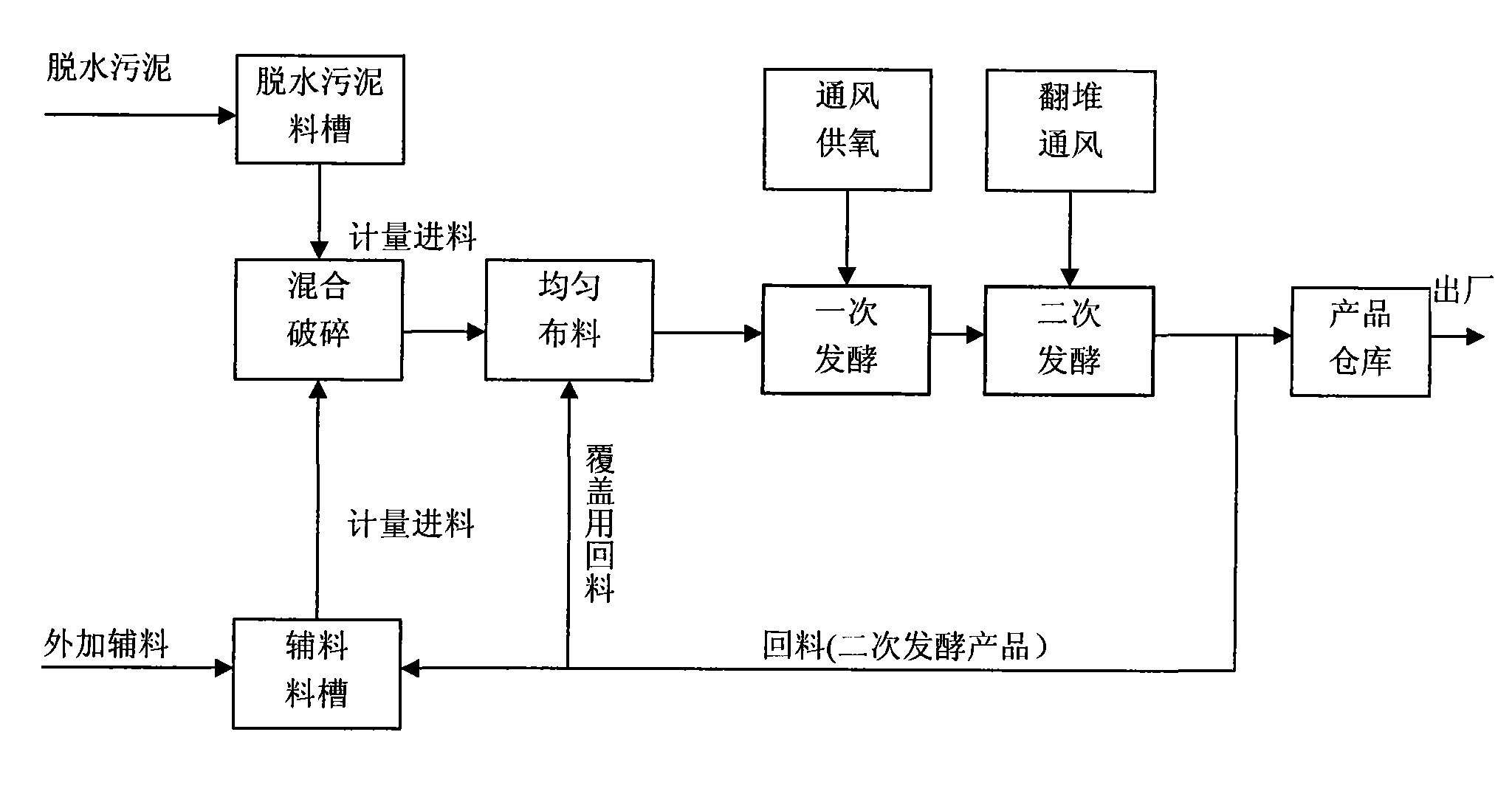

[0013] The dewatered sludge and auxiliary materials of the sewage plant with a moisture content of 80% enter the sludge trough and the auxiliary material chute respectively, and enter the mixing crusher quantitatively at a ratio of 1:1 for mixing and crushing. When the process is initially started, additional sawdust auxiliary materials are added , to adjust the water content of the sludge, after the process is in normal operation, the fermented product of the process of the present invention is used as an auxiliary material. After the mixture is mixed and crushed into pile particles smaller than 20mm, the pile particles are evenly distributed into the two-combined fermentation bin by the distributor. The smell of stockpiles. Through the detachable, easy-to-clean, and anti-clogging ventilation and oxygen supply system installed in the warehouse, the wind pressure is 0.5kPa, so that the stack can be fully supplied with oxygen and keep the entire warehouse in an aerobic state. ...

Embodiment 2

[0015] The dewatered sludge and auxiliary materials of the sewage plant with a moisture content of 80% enter the sludge trough and auxiliary material chute respectively, and enter the mixing crusher in a certain proportion quantitatively for mixing and crushing. When the process is initially started, additional auxiliary materials such as wood chips are added to The water content of the sludge is adjusted, and after the process runs normally, the process of the present invention uses fermented products as auxiliary materials. After the mixture is mixed and crushed into pile particles smaller than 20mm, the pile particles are evenly distributed into the primary fermentation bin by the distributor. odor. Through the detachable, easy-to-clean, and anti-clogging ventilation and oxygen supply system in the warehouse, the ventilation and oxygen supply are provided, and the wind pressure is 0.5kPa, so that the stack can be fully supplied with oxygen and keep the whole warehouse in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com