Blasting ignition method of fan-shaped medium-length hole

A fan-shaped medium-deep hole and detonation method technology, which is applied in blasting and other directions, can solve problems such as large differences in ore block size, unfavorable ore drawing, and large amount of explosives, so as to increase recovery, reduce secondary hazards, and optimize the action process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following specific embodiments will further clarify the present invention. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

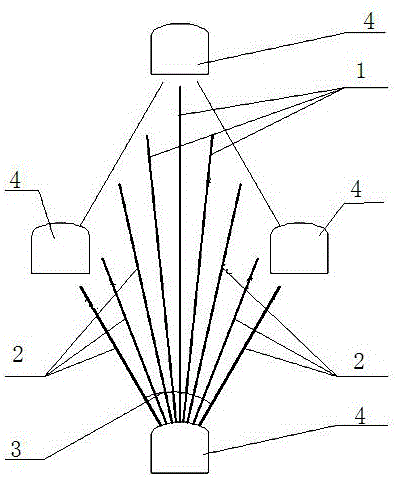

[0014] A method of blasting initiation of sector-shaped medium and deep holes. The method is to divide the blast holes in the same row into two groups, the deepest third of the blast holes in the middle are group A, and the other blast holes on both sides are group B ; In the process of blasting, let the A group blast hole detonate first, and the B group blast hole detonate later.

[0015] In the blasting method of the sector-shaped medium and deep holes described in this embodiment, each blast hole in the A group is sequentially installed with a low-segment high-precision detonator with an interval of 25 milliseconds, and each of the B group High-precision detonators are installed in the blastholes with an interval of 25 milliseco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com