Damage control method for blasting excavation of offshore rock-socketed pile foundation

A control method and technology for rock-socketed piles, which are used in excavation, blasting, infrastructure engineering, etc., and can solve problems such as inconvenience in site construction, single structure, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

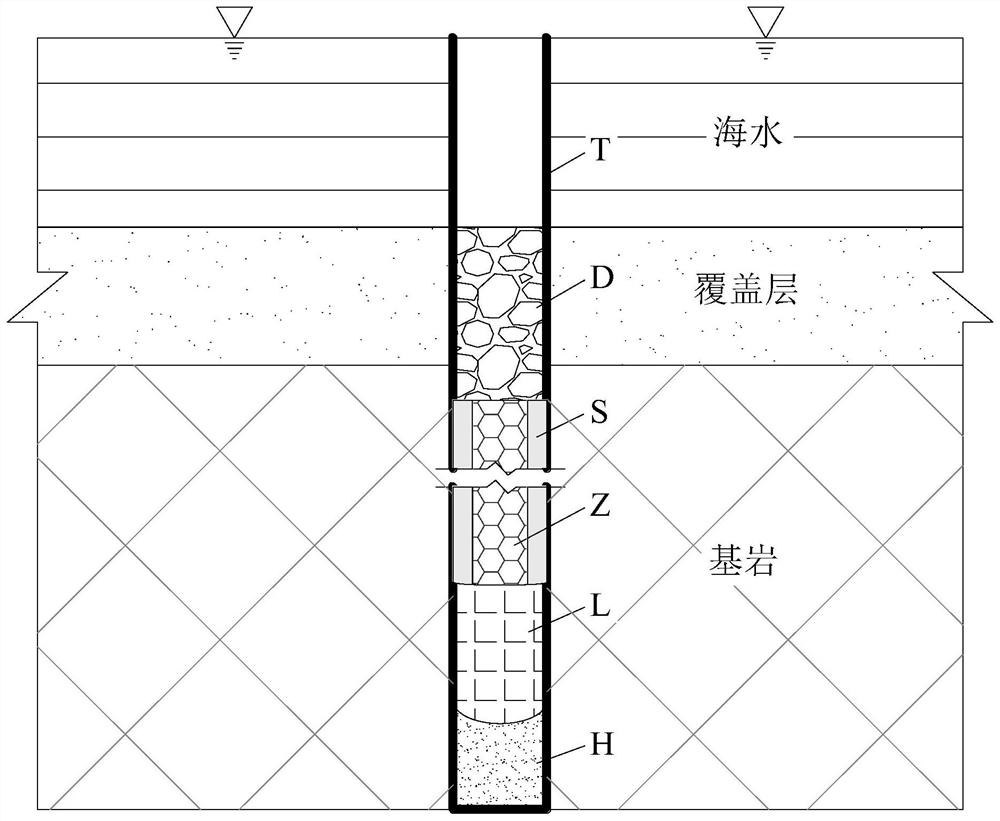

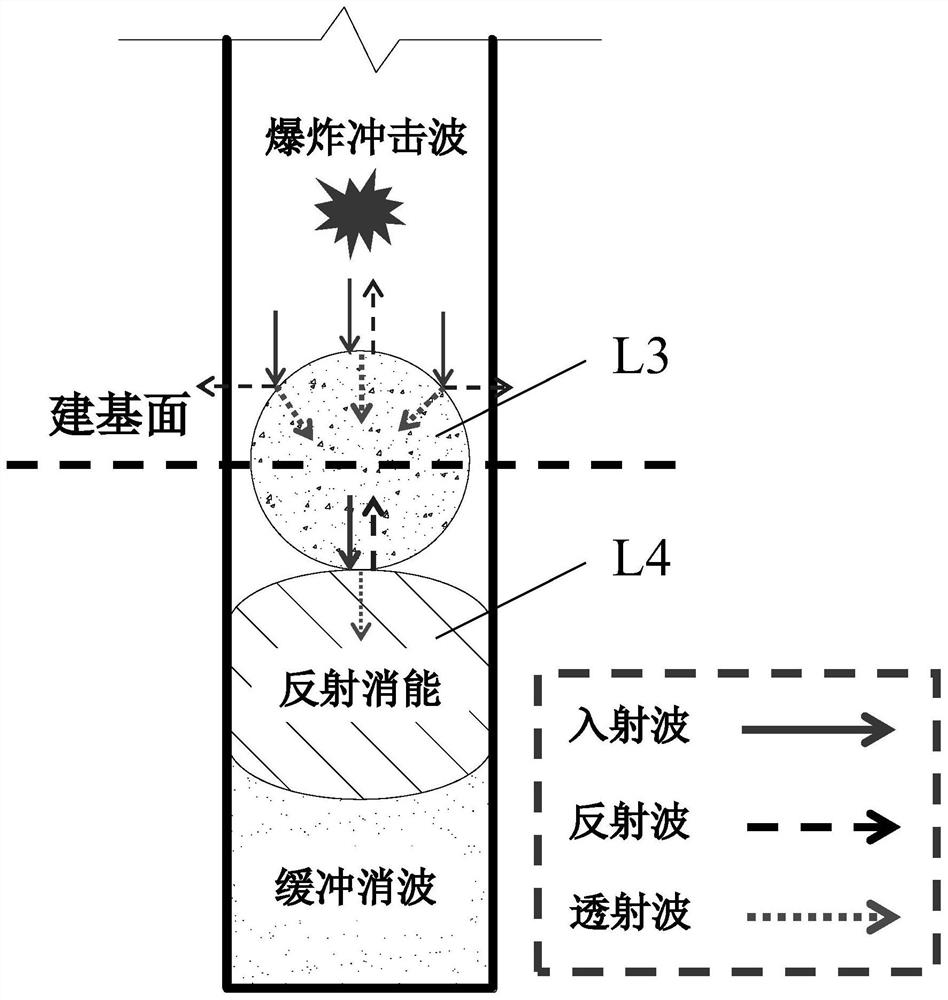

[0023]A specific embodiment of the marine rock base burst breaking excavation control method according to the present invention will be described in detail below with reference to the accompanying drawings.

[0024]

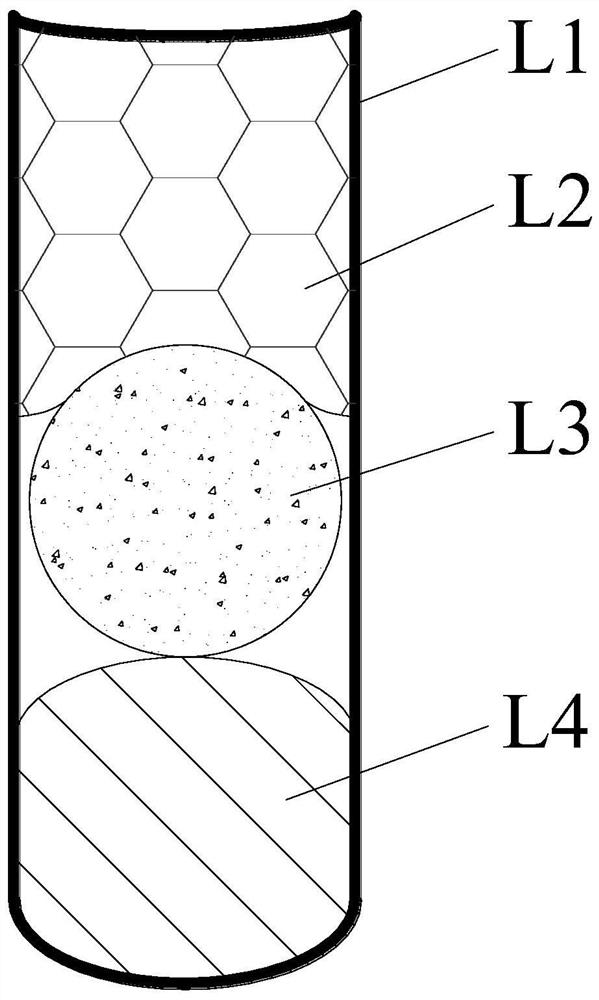

[0025]A sea wind power structure, the foundation excavation project, foundation pit diameter 8m, foundation water depth 50m, covered layer is 3 ~ 5m thin, the base rock is mainly medium, strong rock, the drilling diameter of 160mm, the on-site borehole is 160mm, The diameter of the pharmaceutical column is 120mm; the wind waves around the engineering area need to achieve rapid excavation construction and strictly control the blasting damage of the pile foundation rock mass, bringing a large problem to the site construction, and it is difficult to use traditional underwater blasting construction technology. Controlling blasting damage to the base rock body, for this purpose, the embodiment is constructed for construction.

[0026]In this embodiment, the sea-staple rock base burs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap