Tower type biomass gasifier

A technology of biomass and gasification furnace, which is applied in the manufacture of combustible gas and petroleum industry, etc. It can solve the problems that the ash collected in the furnace body is not easy to discharge, affects normal production, and the contact area is small, so as to facilitate cracking, prevent explosion, large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described below in conjunction with the accompanying drawings.

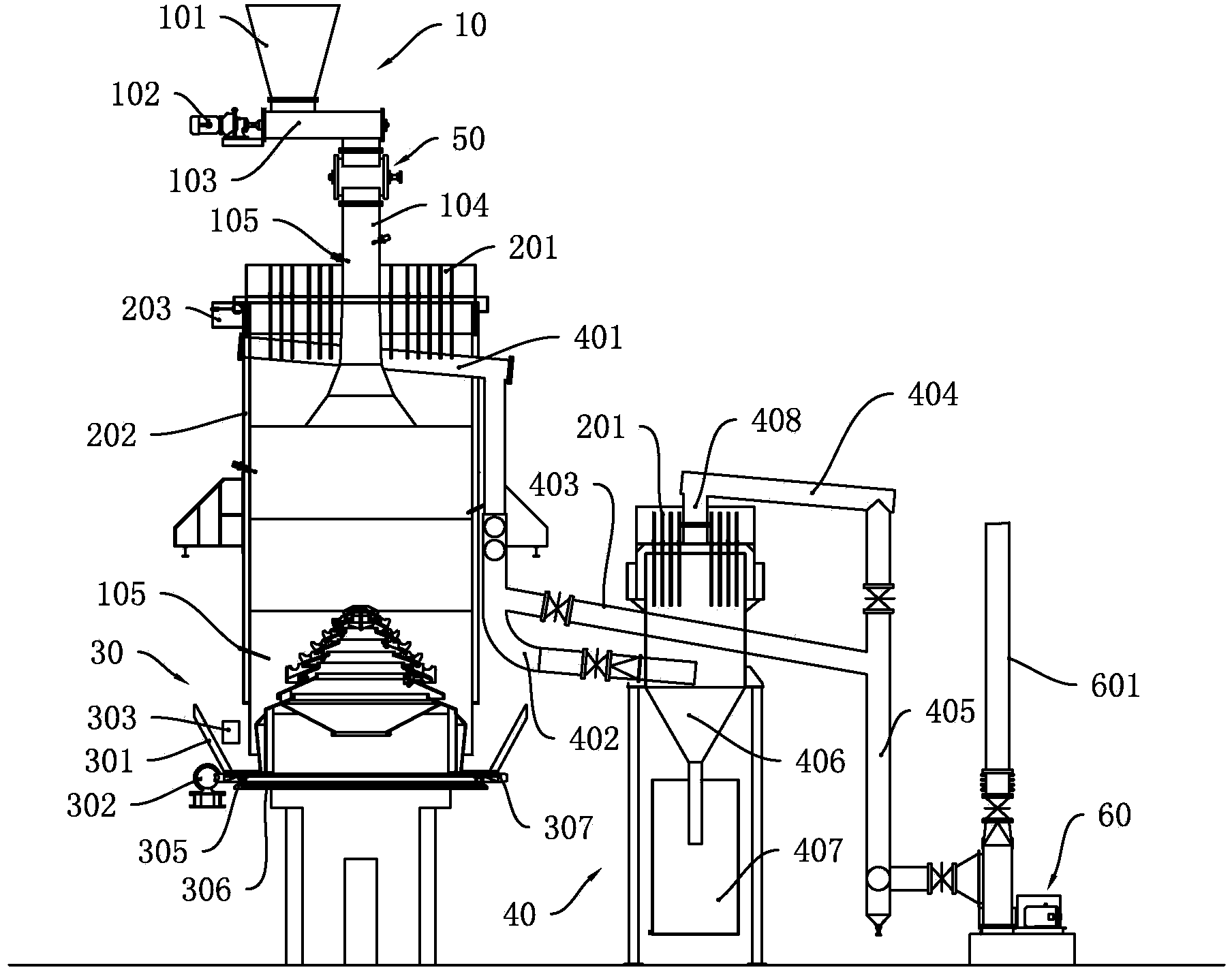

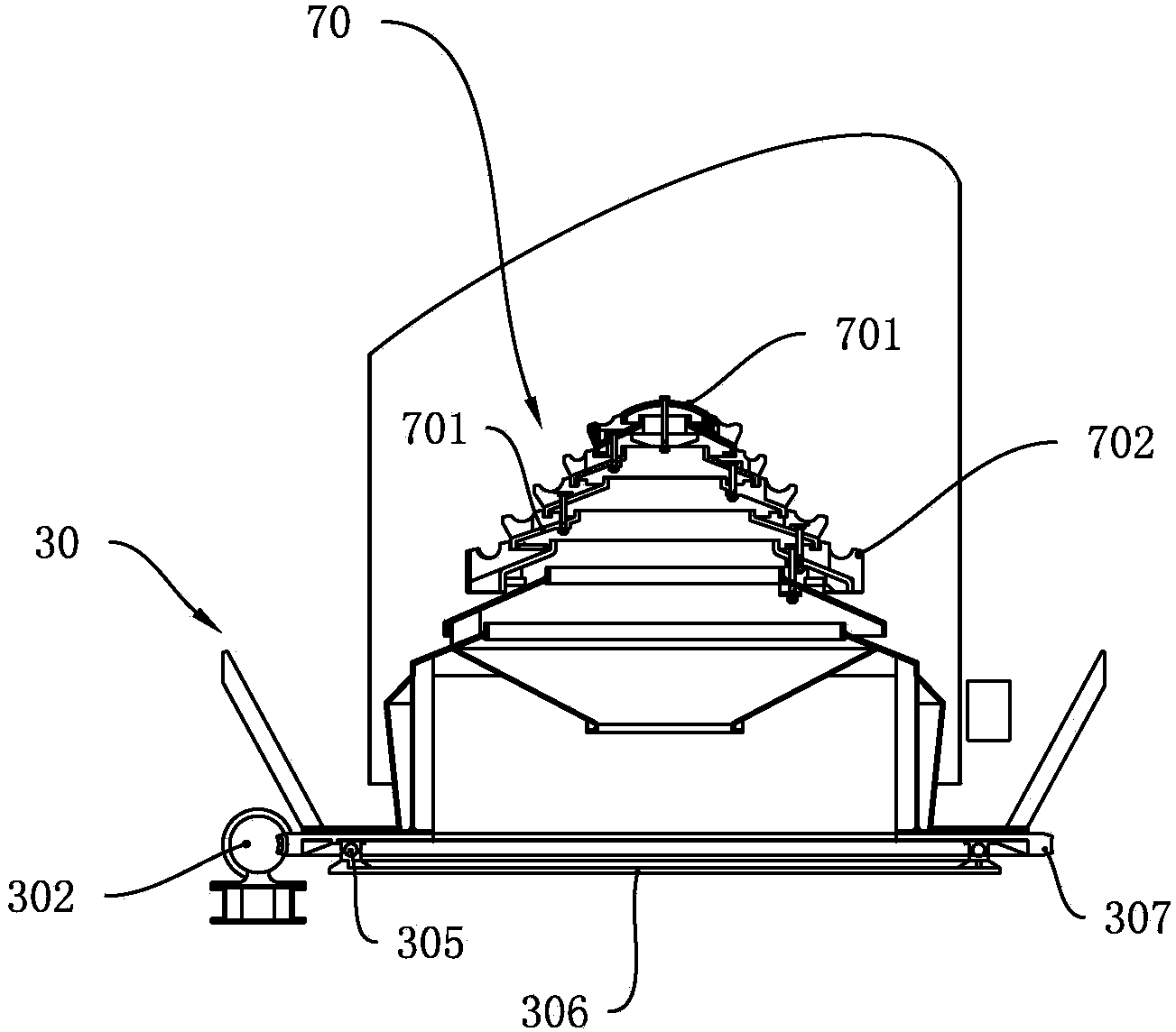

[0028] Such as figure 1 and figure 2 As shown, a tower-type biomass gasification furnace includes a furnace body 202, a feed device 10 for conveying raw materials, and an ash removal device 30 arranged at the bottom of the furnace body 202, and also includes a drive for driving the ash removal device 30 to rotate System 302, the inner side of the ash removal device 30 is supported by a tower-shaped fire grate 70, the inner top of the furnace body 202 is provided with several heat pipes 201 parallel to the axis of the furnace body 202, and there is a gap between the bottom of the furnace body 202 and the ash removal device 30, And the bottom of the furnace body 202 and the ash removal device 30 are sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com