Blast cap

A hood and air guide technology, which is used in vertical pipes, building components, buildings, etc., can solve the problems of poor exhaust, large exhaust air resistance, and reduced airflow speed at the exhaust port, which is conducive to productization. , save space, avoid the effect of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

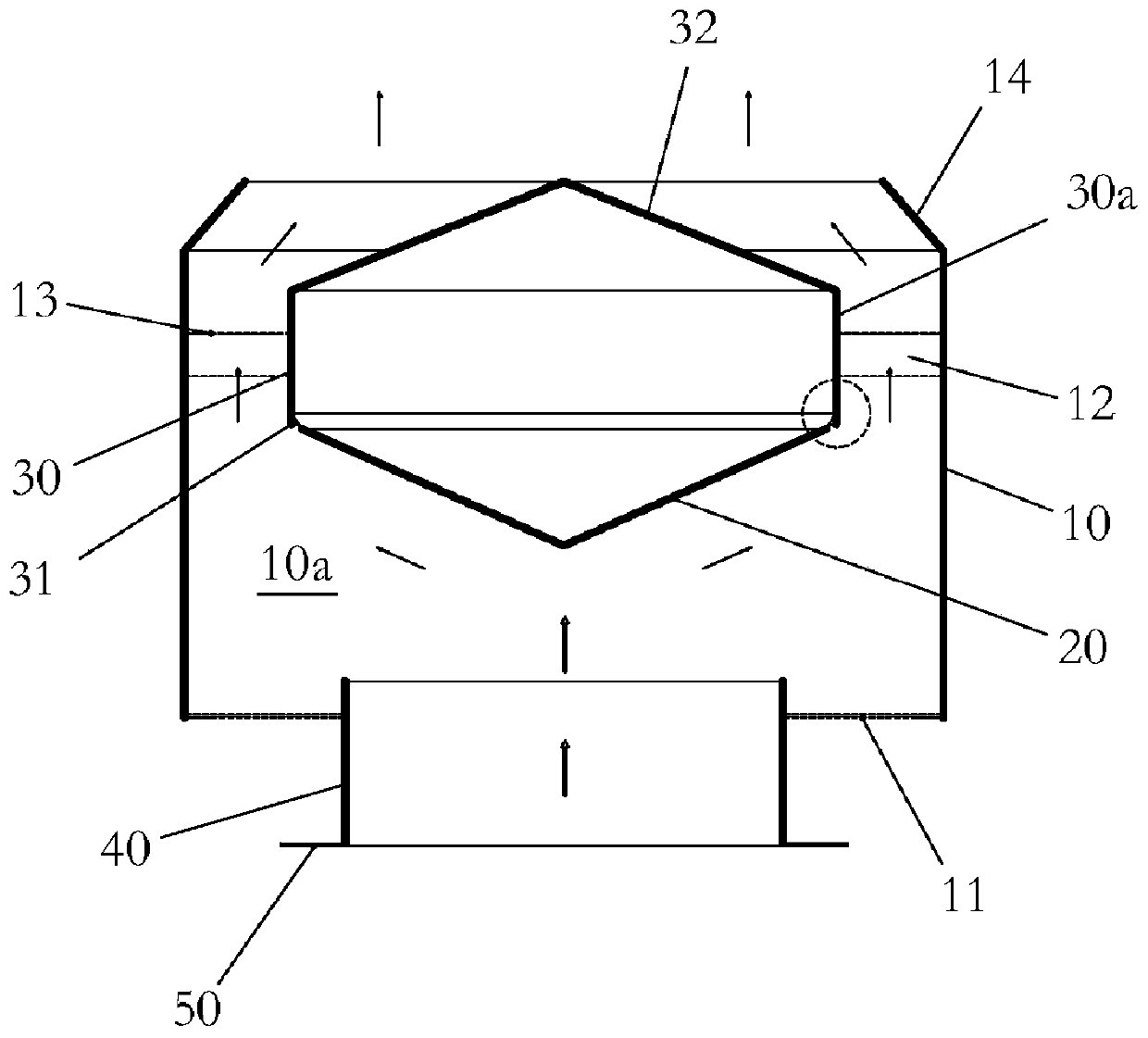

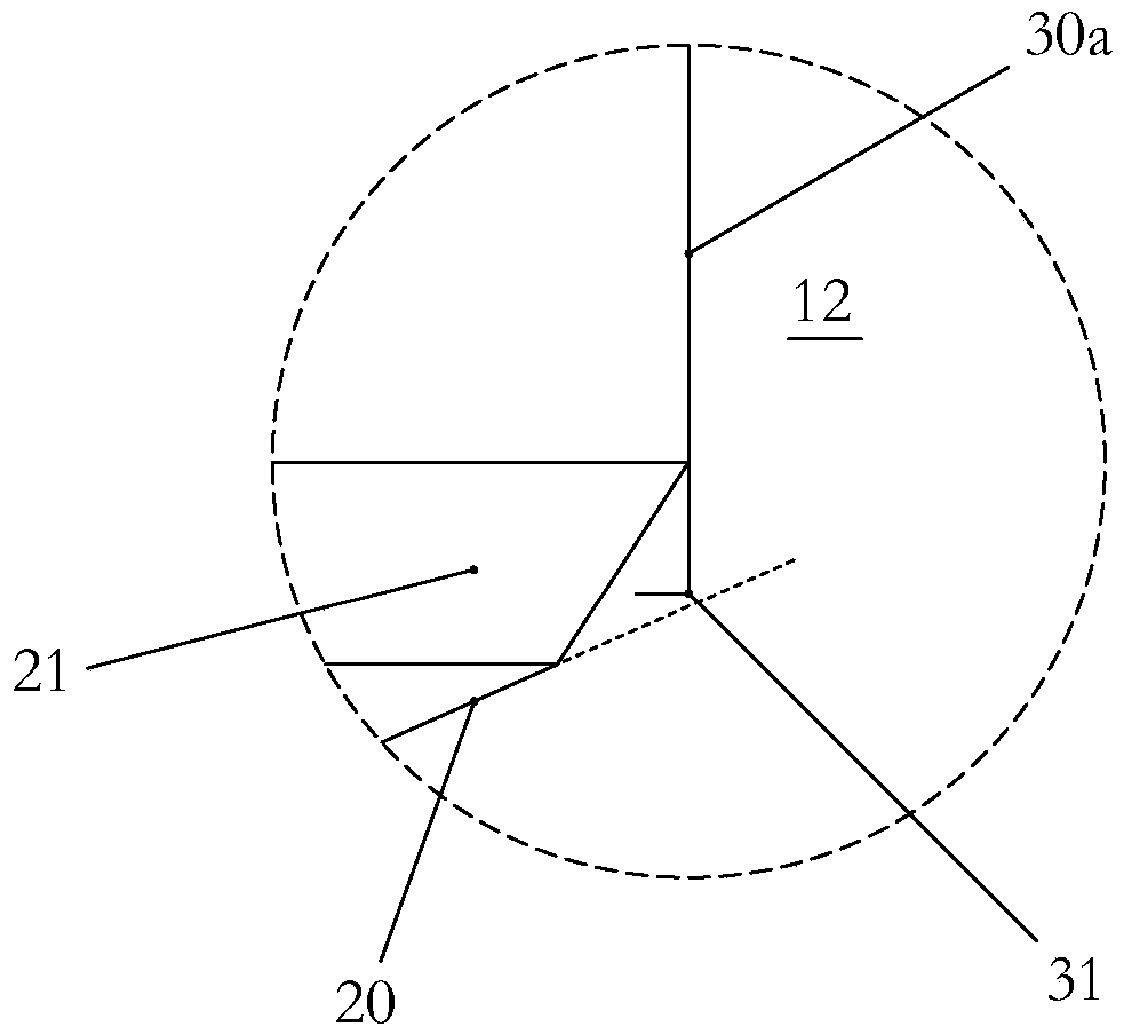

[0048] A wind cap includes an outer air guide tube 10 , a guide body 20 and an inner air guide tube 30 .

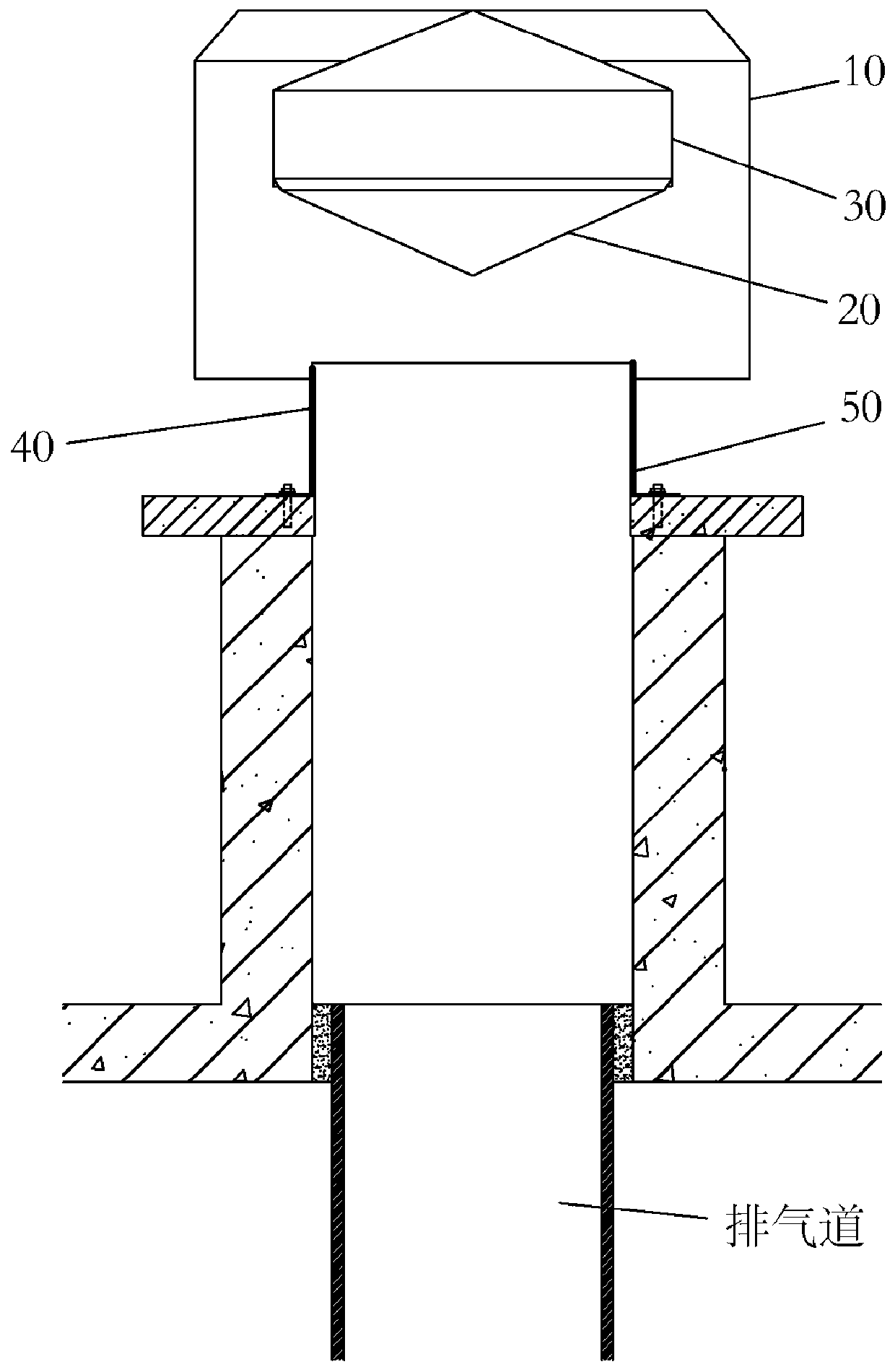

[0049] see figure 1 , the outer air guide tube 10 is covered on the upper outer side of the wind cap connecting pipe 40, and an upward exhaust passage 10a is formed inside it, and the guide body 20 is supported on the outer air guide tube 10 and is located in the exhaust passage 10a, wherein the outer guide air The barrel 10 is supported on the hood connecting pipe 40 through the bracket 11 or on the hood base of the roof slab, such as image 3 As shown, the outer guide tube 10 is supported on the hood connecting pipe 40 through the bracket 11;

[0050] Among them, see again figure 1 , the bracket 11 has a certain distance from the top smoke outlet of the wind cap connecting pipe 40, and when the dripping rainwater drops on the bracket 11, it will not splash into the wind cap connecting pipe 40. Preferably, the bracket 11 can also be Cylindrical struts, while stably su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com