Catalyst applied to hydrogen chloride oxidization to prepare chlorine as well as preparation method and application thereof

A catalyst, hydrogen chloride technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, preparation with chloride, physical/chemical process catalyst, etc., can solve problems such as pipeline blockage, production interruption, etc., and achieve long service life , stable activity, good fluidity and active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

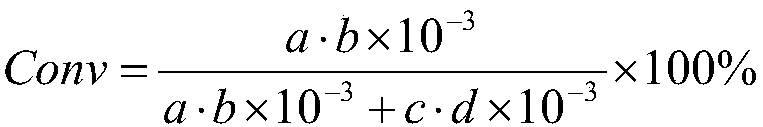

Method used

Image

Examples

Embodiment 1

[0069] (1) Catalyst preparation:

[0070] Preparation of precursor b: Weigh 240g of cerium nitrate, 240g of lanthanum nitrate, 60g of potassium chloride, and 10g of magnesium nitrate and dissolve them in 1000mL of distilled water; Dry in an oven at 90°C to obtain precursor b; divide precursor b into two equal parts.

[0071] Preparation of catalyst precursor B: Take 1 part of precursor b and roast it at 500° C. for 5 h, and then pulverize it into a powder with an average particle size of 5 μm to obtain catalyst precursor B.

[0072] Preparation of catalyst precursor A: Weigh 130g of copper nitrate, 50g of neodymium nitrate, and dissolve 10g of 50wt% manganese nitrate aqueous solution in 500mL of distilled water, add another part of the above-prepared precursor b, soak for 12h and place at 90°C Dry it in an oven to obtain precursor a, then bake it at 500° C. for 5 hours, and pulverize it into a powder with an average particle size of 5 μm to obtain catalyst precursor A.

[00...

Embodiment 2

[0078] (1) Catalyst preparation:

[0079] Preparation of precursor b: Weigh 240g of cerium nitrate, 240g of lanthanum nitrate, 60g of potassium chloride, and 10g of magnesium nitrate and dissolve them in 600mL of distilled water; impregnate 1200g of activated alumina balls with an average diameter of 4.5mm (Zibo Chaoke Aluminum Oxide Materials Co., Ltd.); and then dried by drum vacuum drying to obtain the precursor b; the precursor b was divided into two equal parts.

[0080] Preparation of catalyst precursor B: Take 1 part of precursor b and roast it at 500° C. for 5 h, and then pulverize it into a powder with an average particle size of 5 μm to obtain catalyst precursor B.

[0081] Preparation of catalyst precursor A: Weigh 130g of copper nitrate, 50g of neodymium nitrate, and dissolve 10g of a 50wt% manganese nitrate aqueous solution in 300mL of distilled water, and impregnate the other part of the precursor b prepared above by spraying, and then transfer Drum vacuum dryin...

Embodiment 3

[0087] (1) Catalyst preparation:

[0088] Preparation of precursor b: Weigh 180g praseodymium nitrate, 160g lanthanum nitrate, 50g potassium chloride, 60g cobalt nitrate and dissolve in 550mL distilled water; add 1100g HY molecular sieve (Qilu Huaxin Hi-Tech Co., Ltd.), soak for 12h and place at 90°C drying in an oven to obtain the precursor b; divide the precursor b into 3 equal parts.

[0089] Preparation of catalyst precursor B: Take a part of precursor b and roast it at 450° C. for 3 h, and then pulverize it into a powder with an average particle size of 7 μm to obtain catalyst precursor B.

[0090] Preparation of catalyst precursor A: Weigh 155g of copper nitrate and dissolve it in 600mL of distilled water, add it to the two parts of the above-prepared precursor b, soak it for 12 hours and place it in an oven at 90°C to dry to obtain the precursor a, then in Calcined at 400° C. for 6 h, pulverized into a powder with an average particle size of 4 μm, and obtained catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com