Method for preparing aluminum alloy anodic oxide film sealant

An anodic oxide film and sealing agent technology, which is applied in the field of preparation of aluminum alloy anodic oxide film sealing agent, can solve the problems of low qualified product rate, large consumption of medicines, many control factors, etc., so as to be beneficial to environmental protection and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

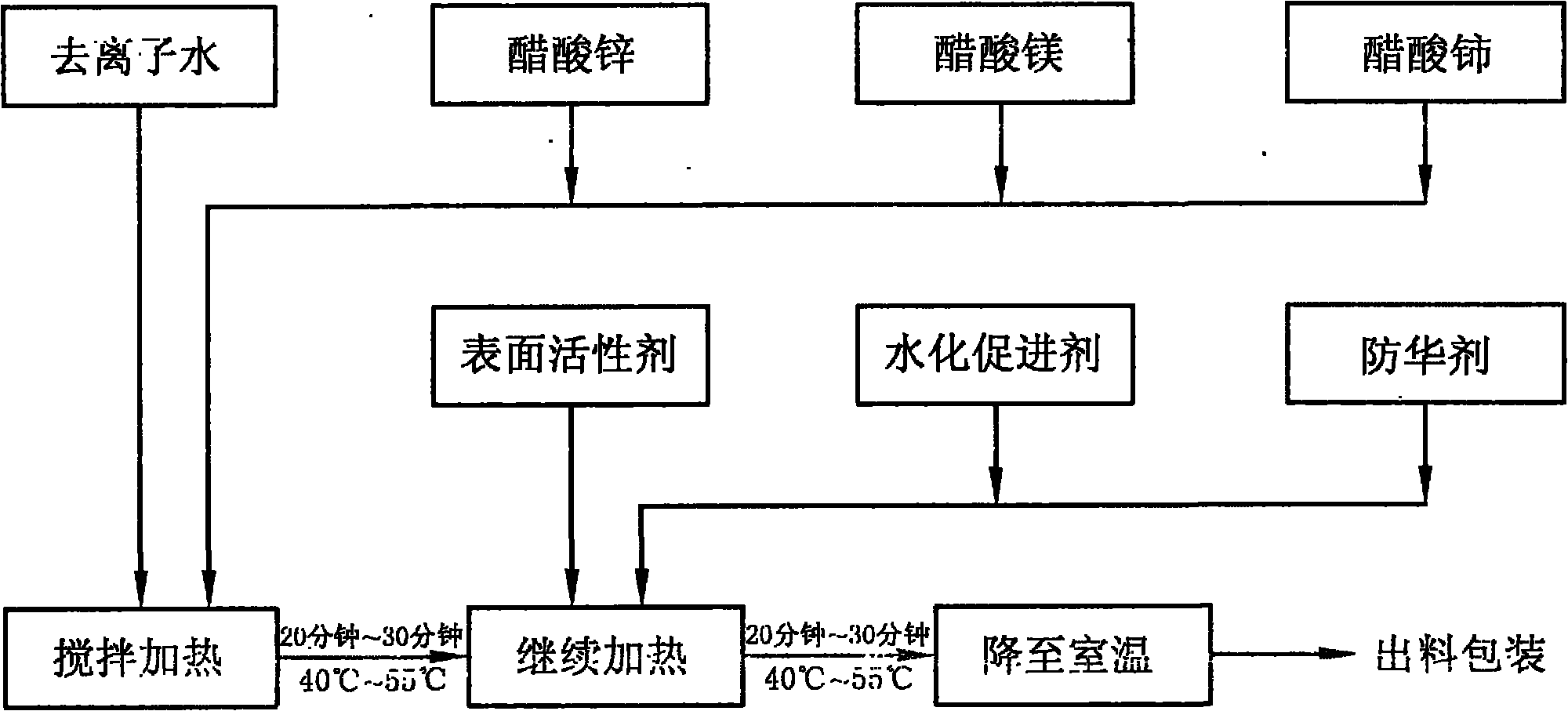

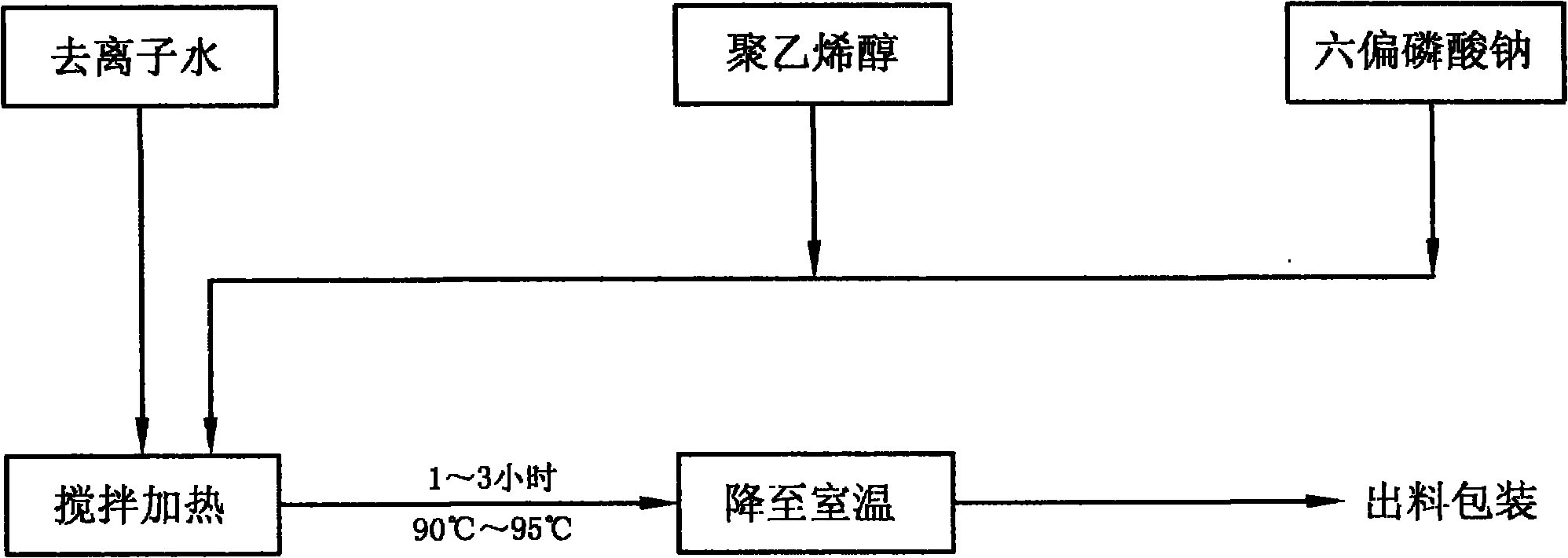

[0008] Embodiment 1: Take the preparation of 100 kg aluminum alloy anodized film sealant as an example. Weigh 99.28kg of deionized water, put it into the reaction kettle, start stirring and electric heating to 42°C±2°C, then put 0.3kg of zinc acetate, 0.1kg of magnesium acetate, and 0.01kg of cerium acetate into the reaction kettle in turn, and stir for 20 Minutes, then put into the reaction kettle successively 0.05kg of polyoxyethylene alkylphenol ether, 0.01kg of polyoxyethylene polyol ester, 0.1kg of triethanolamine, 0.05kg of hexamethylenetetramine, and a concentration of 5% anti-flowering agent 0.1kg, continue to control the temperature at 42°C±2°C, stir for 20 minutes, cool down to room temperature, and pack it as a sealing agent. The preparation process of the anti-China agent with a concentration of 5% is as follows: Take the preparation of 100kg anti-China agent as an example, weigh 95kg of deionized water, 4.8kg of polyvinyl alcohol, and 0.2kg of sodium hexametaphosp...

Embodiment 2

[0009] Embodiment 2: Take the preparation of 100 kg aluminum alloy anodic oxidation film sealing agent as an example. Weigh 98.715 kg of deionized water, put it into the reaction kettle, start stirring and heat it up to 46°C±2°C, then put 0.5kg of zinc acetate, 0.2kg of magnesium acetate, and 0.03kg of cerium acetate into the reaction kettle in turn, and stir for 25 Minutes, then put into the reaction kettle successively 0.1kg of polyoxyethylene alkylphenol ether, 0.03kg of polyoxyethylene polyol ester, 0.125kg of triethanolamine, 0.075kg of hexamethylenetetramine, and a concentration of 10% anti-scaling agent 0.225kg, continue to control the temperature at 46°C±2°C, stir for 25 minutes, cool down to room temperature, and pack it as a sealing agent. The preparation process of the anti-China agent with a concentration of 10% is as follows: Take the preparation of 100kg anti-China agent as an example, weigh 90kg of deionized water, 9.7kg of polyvinyl alcohol, and 0.3kg of sodium...

Embodiment 3

[0010] Embodiment 3: Take the preparation of 100 kg aluminum alloy anodic oxidation film sealing agent as an example. Weigh 98.15 kg of deionized water, put it into the reaction kettle, start stirring and electric heating to 50°C±2°C, then put 0.7kg of zinc acetate, 0.3kg of magnesium acetate, and 0.05kg of cerium acetate into the reaction kettle in turn, and stir for 30 Minutes, then put into the reaction kettle successively 0.15kg of polyoxyethylene alkylphenol ether, 0.05kg of polyoxyethylene polyol ester, 0.15kg of triethanolamine, 0.10kg of hexamethylenetetramine, and a concentration of 15% anti-scaling agent 0.35kg, continue to control the temperature at 50°C±2°C, stir for 30 minutes, cool down to room temperature, and pack it as a sealing agent. The preparation process of anti-China agent with a concentration of 15% is as follows: Take the preparation of 100kg anti-China agent as an example, weigh 85kg of deionized water, 14.5kg of polyvinyl alcohol, and 0.5kg of sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com