Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Nickel fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

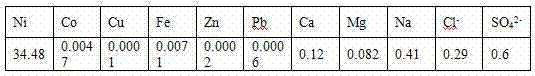

Method for preparing battery-grade nickel sulfate and cobalt sulfate from mixed nickel cobalt hydroxide

The invention discloses a method for preparing battery-grade nickel sulfate and cobalt sulfate from mixed nickel cobalt hydroxide, and belongs to the technical field of nickel cobalt hydrometallurgy.The method comprises the following steps that the mixed nickel cobalt hydroxide is leached by using sulfuric acid, iron and aluminum in the solution are removed by using a nickel / cobalt / manganese-based neutralizer, liquid-solid separation is carried out to obtain iron-removed slag, nickel and cobalt are recycled through acid dissolution, a precipitator (one or more of nickel fluoride, and cobalt fluoride and manganese fluoride) is added into iron-removed liquid to remove calcium and magnesium ions in the system. Impurities such as Mn, Cu and Zn are removed from the calcium and magnesium removed liquid by using a saponified P204 extractant, nickel and cobalt are separated from the P204 raffinate by using a saponified P507 extractant to obtain battery-grade nickel sulfate and a cobalt sulfate solution, and evaporative crystallization is carried out to obtain a product. According to the method, the use amount of calcium oxide is greatly reduced, the amount of calcium ions introduced intothe system and the corresponding nickel-cobalt loss are greatly reduced, the influence of calcium sulfate crystallization on extraction is avoided, the P507 extraction operation amount is reduced, andthe purification cost is reduced.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

High electric insulation sealing method for anodized aluminum film

InactiveCN101275266AQuality improvementGood sealingSurface reaction electrolytic coatingRoom temperatureToughness

The invention relates to a a high electric insulation sealing method for anode oxide aluminum film, which includes [the] steps: the preparation of a sealing liquid, which includes the preparations of a normal-temperature nickel fluoride system sealing liquid and a high-temperature sealing liquid; normal-temperature sealing process, which is to put[puts] an anodized aluminum material into the normal-temperature sealing liquid for 10-15 minutes; a high-temperature process, which puts the aluminum material processed by the normal-temperature sealing liquid into the high-temperature sealing liquid for 3-5 minutes; and drying process, which gets the aluminum material out from the sealing liquid for natural drying. The invention has the advantages that compounds produced by the normal-temperature sealing and high-temperature sealing seal the micro-porous of the oxide film, especially the volume of the Al2O3.3H2O produced by the high temperature sealing increases enormously, the situation that the Ni(OH)2 becomes more and more porous with the increase of in the amount of sediment at room temperature is eliminated, and the invention has excellent sealing effect, stable film quality, good toughness, smooth surface of the film after sealed, high breakdown voltage, and good insulation. The total sealing time is short, the method not only improves productivity, but also saves energy and reduces cost.

Owner:JIANGSU UNIV

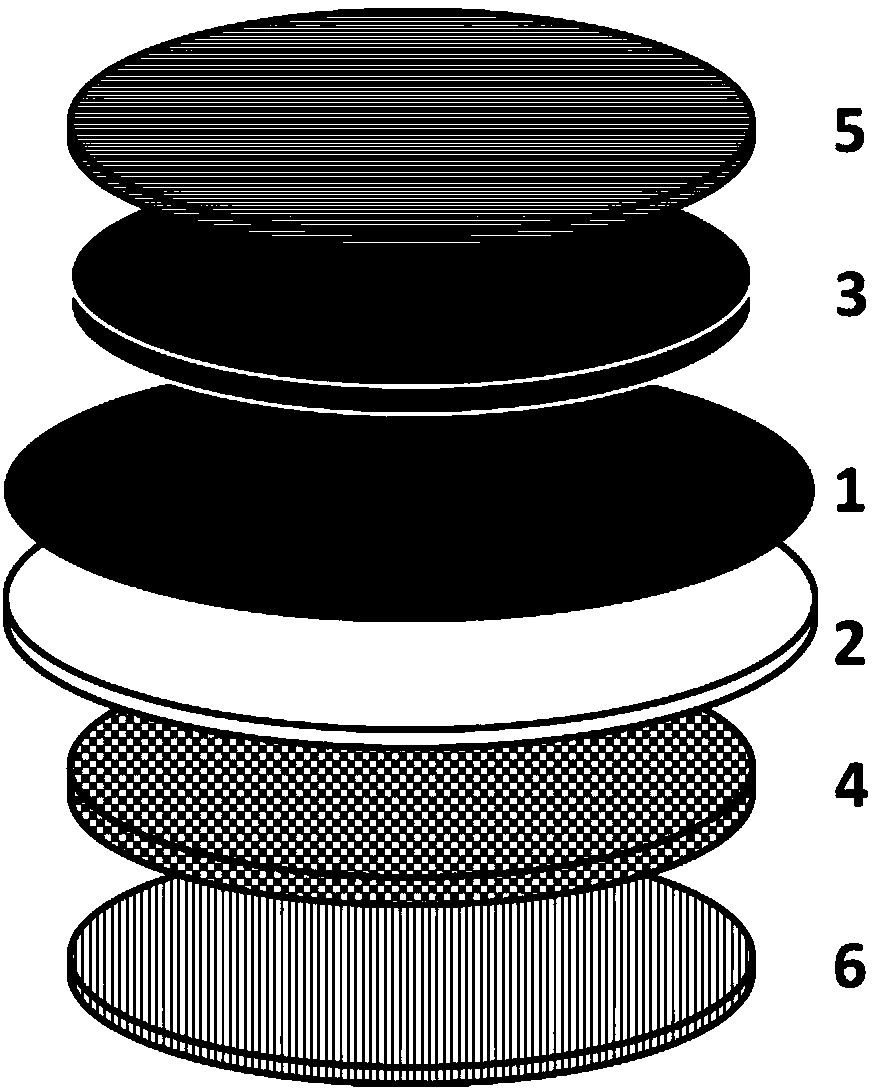

Interface protection structure, preparation method and battery comprising structure

InactiveCN109728249AEffective protectionNo side effectsCell electrodesLi-accumulatorsCyclic processTitanium fluoride

The invention provides an interface protection structure and a preparation method thereof and a battery comprising the interface protection structure. The interface protection structure comprises a metal fluoride and a binder. The metal fluoride is one or more of nickel fluoride, manganese fluoride, iron fluoride, titanium fluoride, copper fluoride, tin fluoride, and the like. The structure can form a protective layer containing lithium fluoride during the cycle process of lithium metal batteries to protect lithium metal electrodes. The interface protection structure is prepared by the following method: (1) providing a mixed slurry comprising a metal fluoride, a binder, a solvent and / or a carbon material; (2) coating one side of a diaphragm with the mixed slurry to obtain a diaphragm containing a first coating; and (3) baking the diaphragm containing the first coating to obtain the interface protection structure.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Not corrosive soldering flux in use for high frequency induced pressure braze welding

InactiveCN101003110AImprove pass rateImprove liquidityWelding/cutting media/materialsSoldering mediaTin FluoridesPotassium

A non-corrosion solder for the HF induced pressure soldering between stainless steel and aluminum contains the eutecticevaporate of potassium tetrafluoroaluminate and potassium hexafluoroaluminate (42-97 Wt%), lithium fluoride (0.5-8.5), Zinc fluoride (0.5-4.5), silicon powder and / or potassium pluorosilicate (2-4.5), nickel fluoride (0-3), cesium fluoride or cesium fluoroaluminate (0-3), copper fluoride (0-0.3), tin fluoride (0-0.5) and cadmium fluoride (0-3.5).

Owner:李昕

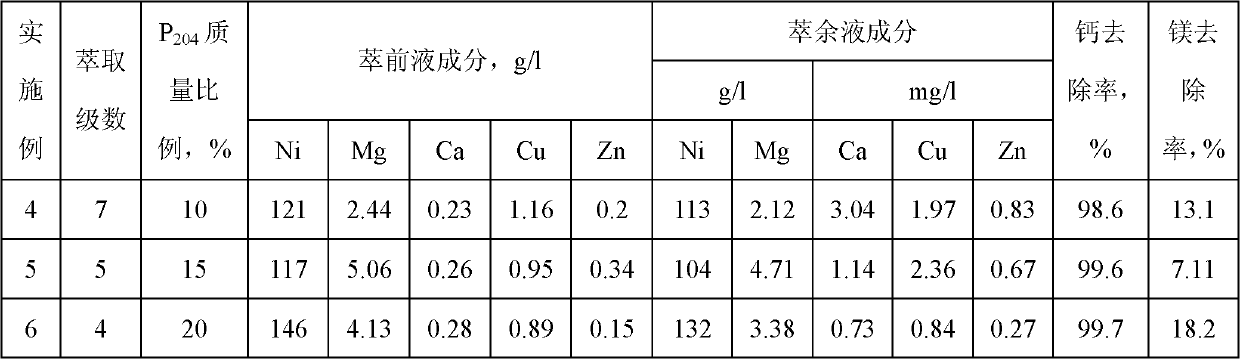

Method for removing calcium-magnesium impurities from nickel sulfate solution

The invention discloses a method for removing calcium-magnesium impurities from a nickel sulfate solution. The method comprises the following steps of: (1) heating a nickel sulfate raw material solution, concentrating, cooling and removing a precipitated solid; (2) extracting a filtrate obtained in the step (1) with a phosphorus-containing extracting agent; and adding nickel fluoride into a raffinate obtained in the step (2), heating to 60-90 DEG C for reacting, cooling and filtering to obtain a needed nickel sulfate solution. Due to the adoption of the method, the using amount of a fluorine salt and the discharge of fluorine-containing waste water are greatly reduced, and new impurity irons are not introduced, the nickel yield is high; and the method is particularly suitable for sulfate systems with high calcium content and low magnesium content.

Owner:SHANGHAI LIGHT IND RES INST

Environmental protection type thread steel surface antirust treatment agent

ActiveCN103276383AGuaranteed performanceQuality assuranceMetallic material coating processesWater basedMaterials science

The present invention discloses an environmental protection type thread steel surface antirust treatment agent, which comprises, by weight, 5-15% of a zirconium salt, 2-8% of sodium hypophosphite, 0.5-5% of an alkali, 0.1-0.5% of a corrosion inhibitor, 0.1-0.5% of a stabilizer, 0.05-0.08% of nickel fluoride, 0.5-0.8% of phenyl ethylene glycol ether, 0.05-0.1% of tert-butylhydroquinone, 0.05-0.08% of glycerol monostearate, 0.05-0.08% of 4-sulfo phthalic acid, 0.02-0.05% of 2-sulfo phenylpropionic acid, and the balance of water. With the present invention, the commonly existing problem of easy rust during a storage and transportation process of the thread steel is solved, wherein a common water base antirust agent can heavily pollute an environment, and antirust oil can affect bounding stress between the thread steel and concrete. Compared with the antirust treatment agent in the prior art, the antirust treatment agent of the present invention has characteristics of significant antirust effect, long antirust time, low cost, no pollution and high safety.

Owner:合肥华清高科表面技术股份有限公司

Coating precursor materials, turbomachinery components, and methods of forming the turbomachinery components

Coating precursor materials, turbomachinery components, and methods of manufacturing the components are provided. In an embodiment, by way of example only, a coating precursor material includes a solid film lubricant component and a bonding component comprising at least one eutectic mixture, said at least one eutectic mixture selected from a group consisting of barium fluoride / nickel fluoride, barium fluoride / cobalt fluoride, and barium fluoride / barium fluoride-boron oxide.

Owner:GARRETT TRANSPORATION I INC

Method for removing calcium and magnesium from nickel, cobalt and manganese solution

InactiveCN111455175AReduce the amount of operationEfficient method for calcium and magnesium removalSulfateManganese

The invention discloses a method for removing calcium and magnesium from a nickel, cobalt and manganese solution, and belongs to the field of nickel and cobalt hydrometallurgy. The method includes thefollowing operation steps of firstly, heating a nickel, cobalt and manganese solution to a certain temperature, adding a certain amount of precipitant, and keeping for a certain period of time, wherein the precipitant is one of or a mixture of multiple of nickel fluoride, cobaltous fluoride and manganese fluoride; secondly, performing liquid-solid separating on ore pulp to obtain a solution and calcium and magnesium removal residues; and thirdly, performing a subsequent process on the solution to obtain a nickel product and a cobalt product. The problems that calcium sulfate crystallization occurs by means of a traditional method of calcium removal through P204 extraction and separation difficulty is high by means of a traditional method of magnesium removal through P507 extraction are solved, and the method is an efficient and green method for removing calcium and magnesium from the nickel and cobalt solution.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Aluminum alloy treating agent before application

ActiveCN103088329AImprove performanceSimple to useMetallic material coating processesEthylic acidBinding force

The invention discloses an aluminum alloy treating agent before application, which is prepared from the following raw materials in mass concentration: 8-10 g / L nickelous fluoride, 6-8 g / L cobalt acetate, 3-5 g / L ferric ammonium oxalate, 1-3 g / L 2-sulfophenylpropionic acid, 1-3 g / L 4-sulfo-o-phthalic acid, 0.2-0.5 g / L crude anthracene and the balance of water. The aluminum alloy treating agent before application is non-toxic and environment-friendly, is free of hexavalent chrome heavy metal ions, has excellent properties, and can greatly enhance the binding force of the aluminum alloy with the coating and the corrosion resistance of the aluminum alloy. The treating agent disclosed by the invention has the advantages of simple use technique and short treatment time, and is convenient for large-scale practical production.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

Blocking method for improving alkali resistance of hard anodic oxidation film

ActiveCN105063716AImprove corrosion resistanceReduce corrosionSurface reaction electrolytic coatingMetallurgyBlock method

The invention relates to a blocking method for improving the alkali resistance of a hard anodic oxidation film, belongs to the technical field of cooker materials and aims to solve the problem that a conventional hard anodic oxidation film is poor in alkali resistance. The blocking method comprises the following steps: A, placing an aluminium alloy workpiece subjected to hard anodic oxidation treatment in a nickel fluoride blocking solution for first-time blocking treatment; and B, placing the aluminium alloy workpiece subjected to first-time blocking treatment in a stearate blocking solution and controlling the temperature to be 75-110 DEG C for second-time blocking treatment to obtain the blocked aluminium alloy workpiece. The blocking method can better block micropores in the hard anodic oxidation film to improve the decay resistance of the aluminium alloy workpiece, so that the alkali resistance is improved, accordingly, the cycle index of cleaning by a dish washing machine is increased and the service life is prolonged.

Owner:ZHEJIANG SUPOR CO LTD

Method of directly electrodepositing zinc-nickel alloy on magnesium alloy surface

InactiveCN101054700ALow costEase of industrial productionHexamethylenetetramineVolumetric Mass Density

The present invention relates to a process for direct electrodeposition of zincium nickel alloy at electron alloys surfaces. According to the process, an electroplating method is adopted, electron alloys is selected as cathode, zincium nickel alloy containing nickel of 8-12% therein is selected as anode, the electric current density during electric plating is controlled at 1-2 A / dm2, and the electric plating time is 1 hour; finally, the electron alloys suffering an electrodeposition of zincium nickel alloy is put to a heat treatment furnace for a heat treating at the temperature of 150-200 DEG C and for 1 hours; the electrolysing solution adopted uses deionized water as solvent, wherein the components and their concentrations are as follows: ZnF2 8-12 g / L, NiF2, 15-25 g / L, ammonium citrate 80-120 g / L, potassium sodium 50-70 g / L, EDTA 8-12 g / L, hexamethylenetetramine 1-2 g / L, all the solutes are stirred to being entirety dissolved and into clear solution , in which the mole ratio of zincium ion to ion is controlled within 1:2-3. Said process for electrodeposition of zincium nickel alloy at electron alloys surfaces by adopting electric plating method is not dependant on the grade of electron alloys, in other words, surfaces of electron alloys of any grades can be electrodeposited with zincium. On one hand, the cost for electron alloys mat-forming treatment is reduced; on the other hand, the electroplating method is easy to realize industrialisation production. The fluorinion in zinc fluoride (nickel fluoride) plating solution exhibits an inactivating sheltering effect of the electron alloys, preventing the electron alloys being eroded in the solution. And the zinc fluoride (nickel fluoride) plating solution is of periodic duty and will not pollute the environment.

Owner:JIANGSU XINYE HEAVY IND

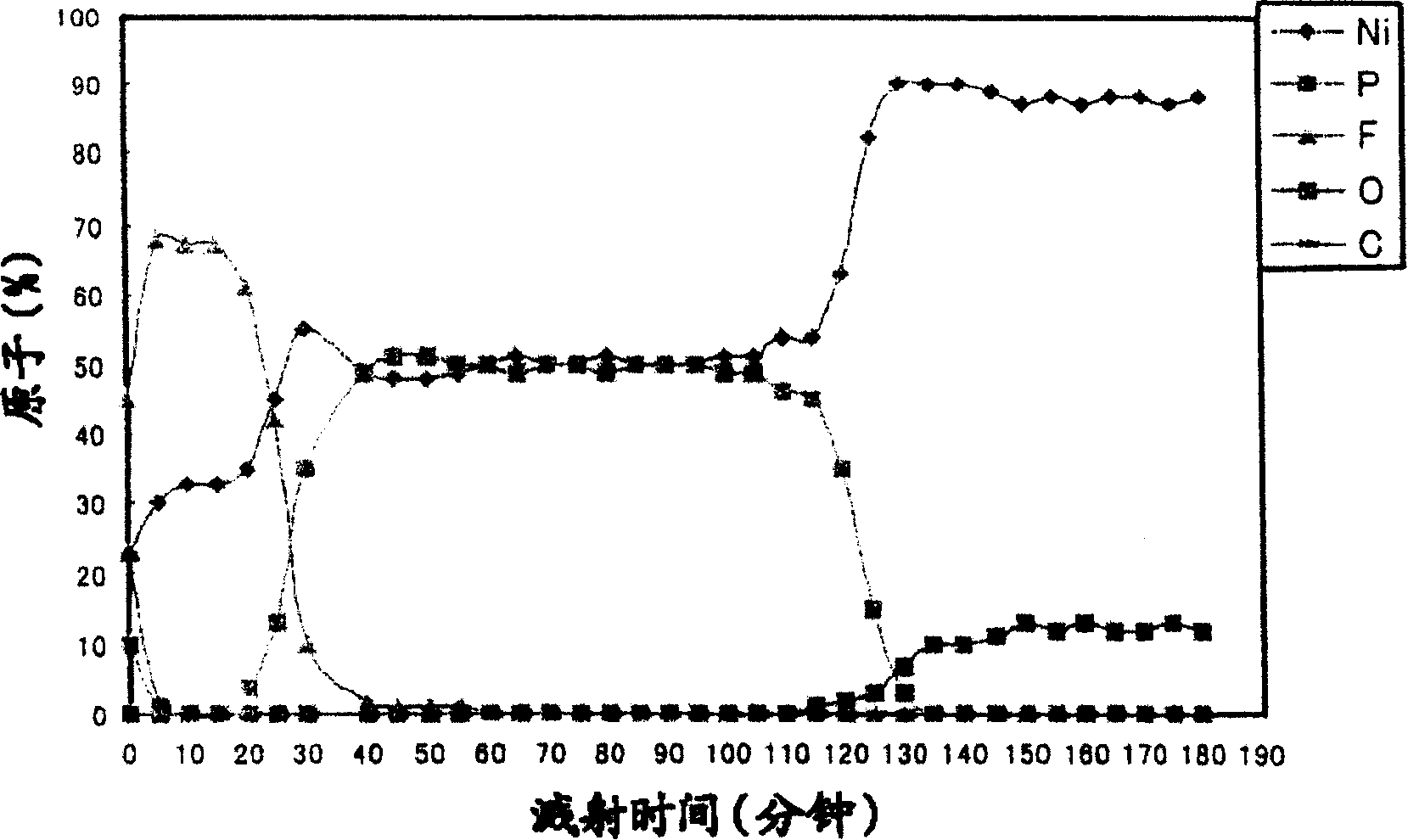

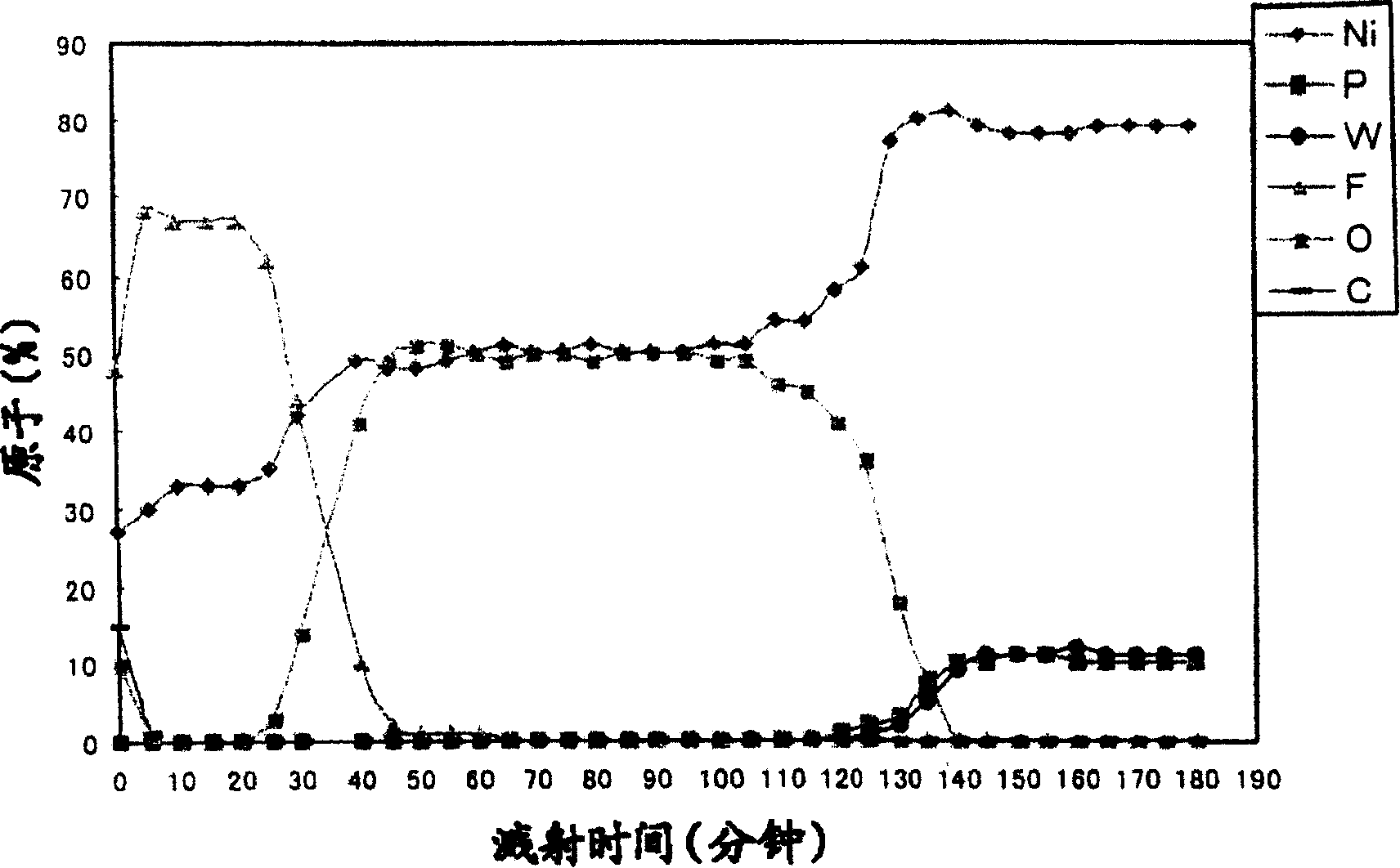

Catalyst for synthesizing trifluoroethylene and preparation method thereof

ActiveCN107243352AShort lifeExtend your lifePreparation by hydrogen halide split-offPhysical/chemical process catalystsNickel compoundsCerium

The invention provides a catalyst for synthesizing trifluoroethylene and a preparation method thereof. The main active component of the catalyst is a mixture of single element Ni (nickel), NiF2 (nickel fluoride), AlF3 (aluminum fluoride), C (carbon) and additives M (Ce (cerium) and Pd (palladium)). The preparation method of the catalyst comprises the following steps of mixing an aluminum-containing compound, a nickel-containing compound and an M-containing compound, dissolving into water, and adding ammonia water until completely precipitating, so as to obtain a mixture of Al(OH)3 (aluminum hydroxide), Ni(OH)2 (nickel hydroxide) and M(OH)n; adding polyols into the mixture of Al(OH)3, Ni(OH)2 and M(OH)n, mixing, drying, and roasting under the inert atmosphere, so as to obtain a carbon-containing composite oxide; reducing the carbon-containing composite oxide by hydrogen-containing mixed gas, and treating by hydrogen fluoride-containing mixed gas, so as to obtain the catalyst. The prepared catalyst has the advantages that the activity is high, the service life is long, the anti-coking ability is strong, and the like; the catalyst is especially suitable for 1,1,1,2-tetrafluoroethane to remove hydrogen fluoride to synthesize the trifluoroethylene.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD +1

Corrosion resistant material, and its production method

InactiveCN1609273AImprove corrosion resistanceImprove wear resistanceSuperimposed coating processNickel alloySemiconductor

This invention provides a corrosion resistant material which is excellent in corrosion resistance to halogen based corrosive gas, e.g., used for a semiconductor production process, has satisfactory durability in a fluoride passive layer, and has reduced generation in contaminated gas on use, and to provide its production method. The corrosion resistant material consists of a nickel layer or a nickel alloy layer formed on the surface of a base material consisting of metal or the like, a nickel oxide layer formed on the surface thereof and a nickel fluoride layer formed on the surface of the nickel oxide layer.

Owner:SHOWA DENKO KK

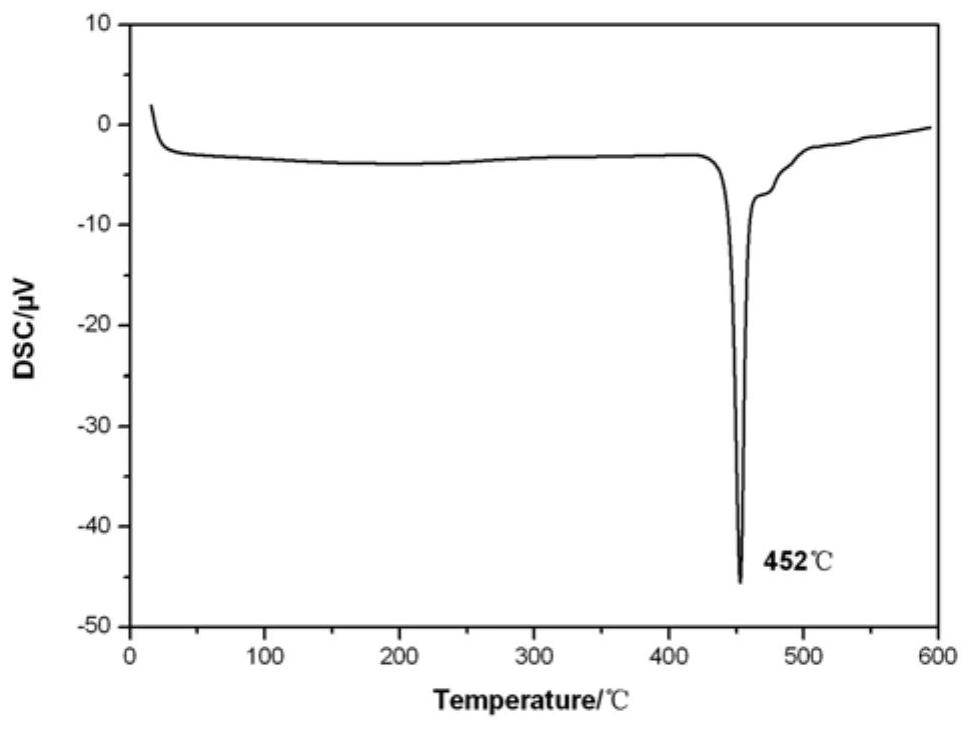

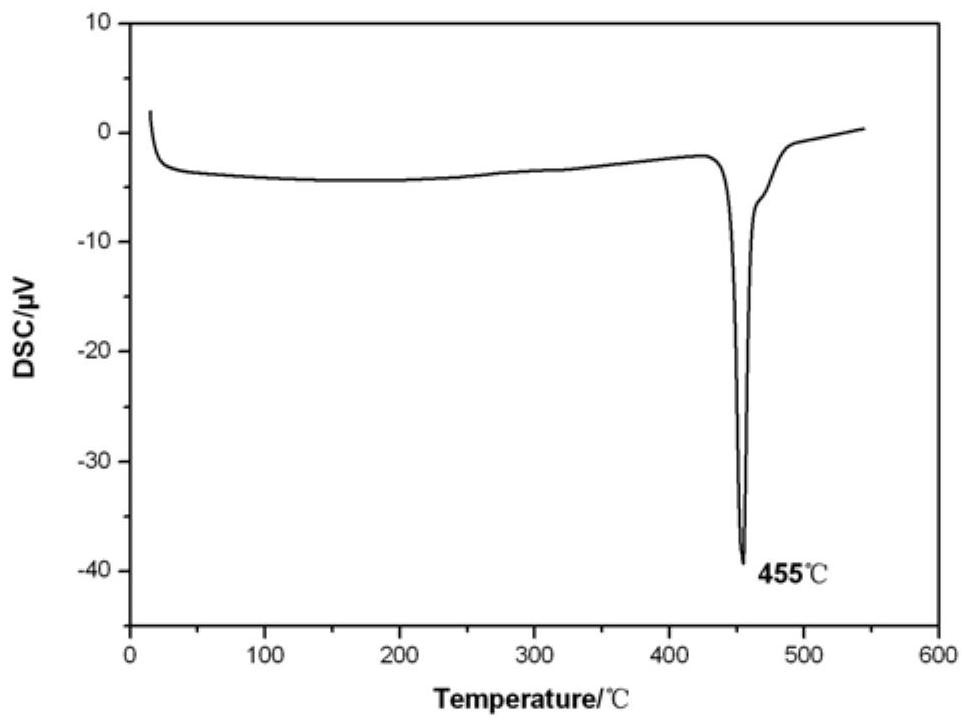

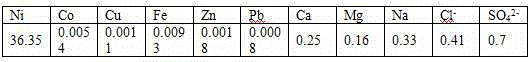

Nickel fluoride preparation method

The invention relates to a nickel fluoride preparation method, and relates to a hydrometallurgy nickel fluoride preparation method, and the method is characterized in that: in the preparation process, nickel fluoride is prepared from nickel carbonate and ammonium fluoride as raw materials by four steps of nickel carbonate slurrying, synthesis preparation, purification and impurity removal, and filtering and washing and drying. The specific method is as follows: the nickel fluoride is prepared from the nickel carbonate and the ammonium fluoride as the raw materials by four steps of nickel carbonate slurrying, synthesis preparation, purification and impurity removal, and filtering and washing and drying, in the preparation process, an auxiliary material is a soluble carbonate, no fluorine gas, hydrofluoric acid and other strong corrosive materials is used, and compared with the traditional process, the method has high safety, low equipment requirement, simple operation, high product quality and other advantages.

Owner:JINCHUAN GROUP LIMITED

Treatment method of fluorine-containing nickel slag generated in nitrogen trifluoride preparation process

ActiveCN112645396AImprove solubilityEasy to operateIron oxides/hydroxidesNickel halidesFerric hydroxideSlag

The invention relates to a treatment method of fluorine-containing nickel slag generated in a nitrogen trifluoride preparation process, and belongs to the technical field of harmless treatment of nickel-containing hazardous wastes. The method comprises the following steps: (1) crushing the fluorine-containing nickel slag into solid powder; (2) dissolving the fluorine-containing nickel slag solid powder by using a hydrofluoric acid solution, performing stirring at 30-60 DEG C, and adding an oxidizing substance in the stirring dissolution process until the fluorine-containing nickel slag is completely dissolved to obtain a mixed solution a; (3) adjusting the pH value of the mixed solution a to 3.5-4.5 by using ammonia water, and performing filtering to obtain ferric hydroxide precipitate and a mixed solution b; and (4) continuing to adjust the pH value of the mixed solution b to 6.5-7.5 with the ammonia water, performing filtering to obtain nickel fluoride and a mixed solution c, heating and concentrating the mixed solution c, and performing cooling crystallizing to obtain ammonium fluoride and a mixed solution d. The method realizes recovery and cyclic utilization of nickel metal resources and ammonium fluoride, and can significantly reduce the production cost of nitrogen trifluoride.

Owner:PERIC SPECIAL GASES CO LTD

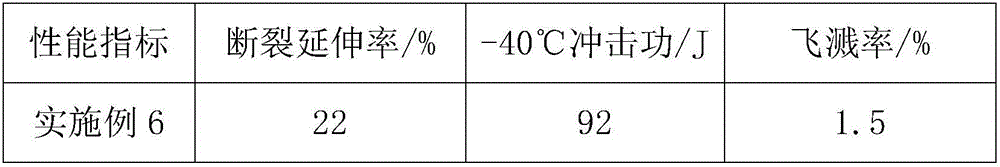

Flux-cored wire with excellent low-temperature impact toughness

InactiveCN106624424AImprove low temperature impact toughnessGood welding performanceWelding/cutting media/materialsSoldering mediaRutileBarium carbonate

The invention discloses a flux-cored wire with excellent low-temperature impact toughness. The flux-cored wire comprises a low-carbon steel sheath and a flux core with which the low-carbon steel sheath is filled, wherein the flux core comprises the following components by weight percent: 10-20% of calcined bauxite, 3-8% of calcium ferrite, 0-5% of rutile, 5-6% of feldspar, 5-7% of aluminum fluoride, 3-4% of nickel fluoride, 1-3% of magnalium powder, 1-2% of ferromanganese powder, 2-3% of marble, 0.5-1% of barium carbonate and the balance of iron powder. As calcined bauxite replaces part of rutile, the low-temperature impact toughness of a weld joint is effectively improved, and meanwhile, the flux-cored wire has the advantages of easy deslagging and small splashing.

Owner:天长市通联焊业有限公司

High-voltage-resistant and decomposition-resistant electrolyte for thermal battery and preparation method thereof

ActiveCN112687947AImproved high power output characteristicsElectrolyte boostDeferred-action cellsSecondary cellsElectrical batteryTitanium nitride

The invention provides a high-voltage-resistant and decomposition-resistant electrolyte for a thermal battery and a preparation method of the electrolyte, the electrolyte comprises LiCl-Li2CO3-Li2SO4 eutectic salt and a binder, and the binder is one of magnesium oxide, aluminum oxide, titanium nitride or TiN ceramic materials. The electrolyte has the beneficial effects that the decomposition voltage of the prepared ternary eutectic salt remarkably exceeds that of a traditional thermal battery electrolyte system, and the development of thermal battery systems such as high-voltage chlorine / nickel fluoride and oxide is effectively promoted; the TiN ceramic material with ionic conductivity is used as an electrolyte binder, and especially in a high-temperature working state of the thermal battery, the conductivity of the electrolyte is effectively improved, so that the high-power output characteristic of the thermal battery is improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

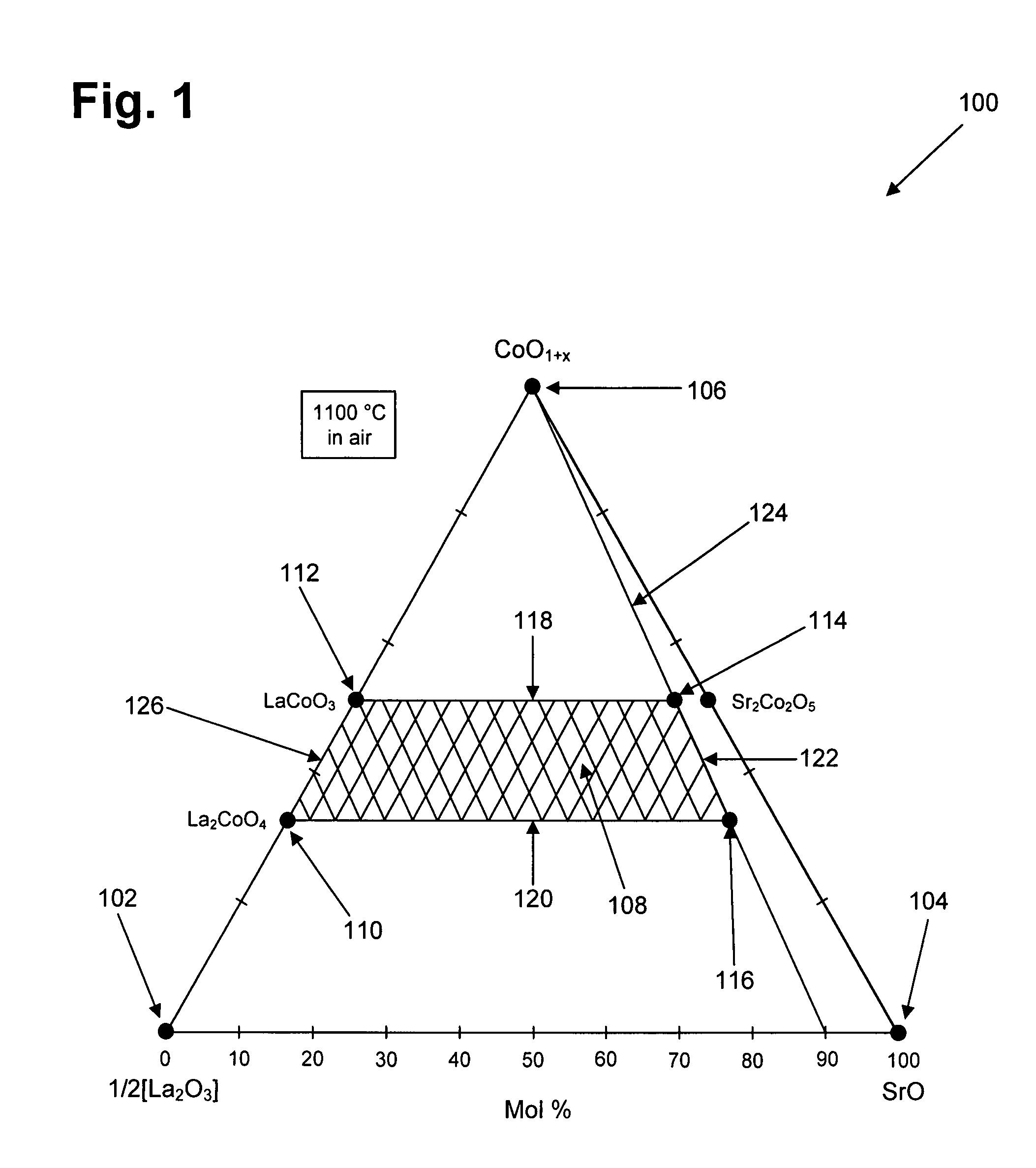

Wide temperature range dielectric absorber

According to one exemplary embodiment, a wide temperature range dielectric absorber includes a dielectric absorber comprising a blend of lanthanum oxide, strontium oxide, and cobalt oxide, and is represented by (1−z)[La1−xSrxCoO3±y]+z[La2−xSrxCoO4±y]. The dielectric absorber includes a first crystalline structure existing independently from a second crystalline structure causing the dielectric absorption composition to have a wide temperature range of electromagnetic radiation absorption. In one embodiment, the first crystalline structure is a perovskite crystalline structure and the second crystalline structure is a potassium nickel fluoride crystalline structure.

Owner:ALLUMAX TTI LLC

Novel hot galvanizing flux and using method thereof

ActiveCN111206197AReduce oxygen contentPermeation barrierHot-dipping/immersion processesChloride potassiumAmmonium chloride mixture

The invention relates to a novel hot galvanizing flux and a use method thereof. The novel hot galvanizing flux is prepared by taking zinc chloride, potassium chloride, nickel fluoride, a passivator, adeoxidant, a complexing agent, a flux film thickness control agent and water as components; every 1L (liter) of plating assistant is prepared from the following components by weight, 50 to 100g of zinc chloride, 10 to 40g of potassium chloride, 5 to 30g of nickel fluoride, 0.05 to 0.50 g of passivator, 0.5 to 2.0 g of deoxidant, 0.5 to 1.0 g of complexing agent, 0.2 to 1.0 g of plating assistantthickness control agent and the balance of water, and the components are mixed to be prepared into 1 liter of solution, and the plating assistant is formed. Through the synergistic effect of all the components and process conditions of the plating assistant agent, a good plating assistant effect is achieved; during use, heating and drying are not needed, the dosage is only less than half of that of a zinc ammonium chloride plating aid, smoke is less, the problem that a zinc coating is ultra-thick is solved, and the zinc coating is smooth in surface, free of skip plating, low in cost and good in quality.

Owner:ZHUZHOU CHUANGLIN ALLOY

High-wear resistance material for metal surface treatment

The invention discloses a high-wear resistance material which comprises 3-7 parts of zinc, 2-4 parts of manganese, 5-9 parts of niobium, 1-5 parts of nickel, 7-11 parts of carbon, 2-8 parts of copper,11-15 parts of iron, 23-25 parts of silicon, 12-16 parts of epoxy resin, 3-8 parts of tungsten metal powder, 4-6 parts of titanium carbide, 7-9 parts of copper metal powder, 2-8 parts of phenolic resin, 3-5 parts of titanium oxide, 6 to 9 parts of silicon oxide, 2-7 parts of chromium oxide, 3-8 parts of quartz sand, 7 to 9 parts of ferrotitanium, 3 to 8 parts of ferrovanadium, 3-8 parts of silicon carbide crystal grains, 7-12 parts of molybdenum disulfide, 3-7 parts of magnesium oxide, 2-4 parts of nickel fluoride, 3-6 parts of organic amine substances, 1-3 parts of fibers, 2-6 parts of ferroboron, 3-6 parts of bauxite, 2-6 parts of silicon-calcium-barium, 4-7 parts of mineral filler, 3-5 parts of tungsten slag iron alloy, 4-8 parts of corrosion-resistant resin, 3-9 parts of alumina tabular and 5-11 parts of flake corundum. According to the present invention, the high-wear resistance material has the good wear resistance and corrosion resistance, the very strong adhesion and the higher mechanical strength and physical performance after surface treatment, is simple in formule, effectively reduces the maintenance cost, and can effectively prolong the service life of the metals afterthe material is used.

Owner:马鞍山海华耐磨材料科技有限公司

Aqueous rust preventive capable of improving deformed steel bar concrete holding and wrapping performance

ActiveCN107893226AImprove grip strengthImprove the air environmentMetallic material coating processesTert-ButylhydroquinoneBalance water

The invention discloses an aqueous rust preventive capable of improving deformed steel bar concrete holding and wrapping performance. The aqueous rust preventive comprises raw materials including, byweight, 5%-15% of zircon salt, 2%-8% of sodium hypophosphite, 0.5%-5% of alkali, 0.1%-0.5% of a corrosion inhibitor, 0.1%-0.5% of a stabilizer, 0.05%-0.08% of nickel fluoride, 0.05%-0.1% of tert-butylhydroquinone, 0.02%-0.05% of potassium oxalate and the balance water. Compared with the prior art, the rust prevention effect is obvious, and the outdoor atmospheric and rain corrosion resistant performance is excellent; in addition, a high temperature deformed steel bar is free of obvious pungent smells in the rust prevention treatment process, the air environment of a steel rolling site is facilitated, and influences on the body health of operators are reduced; and meanwhile, the holding and wrapping strength of the deformed steel bar and concrete can be greatly improved after rust prevention treatment is treated.

Owner:汉高乐泰(宁夏)新材料有限公司

Normal-temperature brush-coating phosphatization technology for household appliances

InactiveCN104233246AOvercome the defect of high temperatureImprove corrosion resistanceMetallic material coating processesPhosphoric acidMonocalcium phosphate

The invention discloses a normal-temperature brush-coating phosphatization technology for household appliances. A phosphating solution used in the technology comprises 44-48 g / L of phosphoric acid, 24-28 g / L of zinc dihydrogen phosphate, 10-12 g / L of zinc oxide, 16-20 g / L of monocalcium phosphate, 6-8 g / L of calcium oxide, 6-8 g / L of tartrate, 5-7 g / L of sodium citrate, 12-14 g / L of oxalic acid, 3-6 g / L of hydroxylammonium hydrogensulphate, 7-9 g / L of nickel fluoride, 6-8 g / L of nickel sulfate, 3-5 g / L of OP-10, 2-4 g / L of sodium dodecanesulphonate and the balance water. The phosphatization technology comprises the following steps: 1) oil removing by the use of an organic solvent; 2) oil removing by the use of alkali lye; and 3) phosphatization: the above ingredients are used to prepare the phosphating solution; an acid-resistant brush is used to directly brush the phosphating solution uniformly on household appliance components to form a layer of phosphating solution film; and drying is carried out.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Alloy zinc strip and preparation method thereof

The invention discloses an alloy zinc strip and a preparation method thereof. The alloy zinc strip comprises, by weight, zinc, aluminum, copper, pure magnesium, low-arsenic pure antimony, elemental selenium, lithium cobalt oxide and nickel fluoride. The preparation method comprises the following steps of preparing materials; preheating a smelting furnace; and smelting, wherein the lithium cobalt oxide and the nickel fluoride are sequentially added into the smelting furnace which is preheated to the temperature of 900-1000 DEG C, after uniform stirring is carried out, the temperature of the smelting furnace is increased to 1500-1800 DEG C, the zinc, the aluminum, the copper, the pure magnesium, the low-arsenic pure antimony and the elemental selenium are sequentially added and stirred untilthe mixture is completely melted, and standing for 20-30 minutes, zinc alloy is prepared, cast, formed and stored. A certain amount of aluminum, copper, pure magnesium and low-arsenic pure antimony is added into the zinc, the elemental selenium, the lithium cobalt oxide and the nickel fluoride, so that the anti-fatigue performance of metal zinc can be effectively improved, the machining of materials is facilitated, and the convenience in use is effectively improved.

Owner:NANTONG XINXIANG ZINC IND

A kind of preparation method of nickel fluoride

The invention relates to a nickel fluoride preparation method, and relates to a hydrometallurgy nickel fluoride preparation method, and the method is characterized in that: in the preparation process, nickel fluoride is prepared from nickel carbonate and ammonium fluoride as raw materials by four steps of nickel carbonate slurrying, synthesis preparation, purification and impurity removal, and filtering and washing and drying. The specific method is as follows: the nickel fluoride is prepared from the nickel carbonate and the ammonium fluoride as the raw materials by four steps of nickel carbonate slurrying, synthesis preparation, purification and impurity removal, and filtering and washing and drying, in the preparation process, an auxiliary material is a soluble carbonate, no fluorine gas, hydrofluoric acid and other strong corrosive materials is used, and compared with the traditional process, the method has high safety, low equipment requirement, simple operation, high product quality and other advantages.

Owner:JINCHUAN GROUP LIMITED

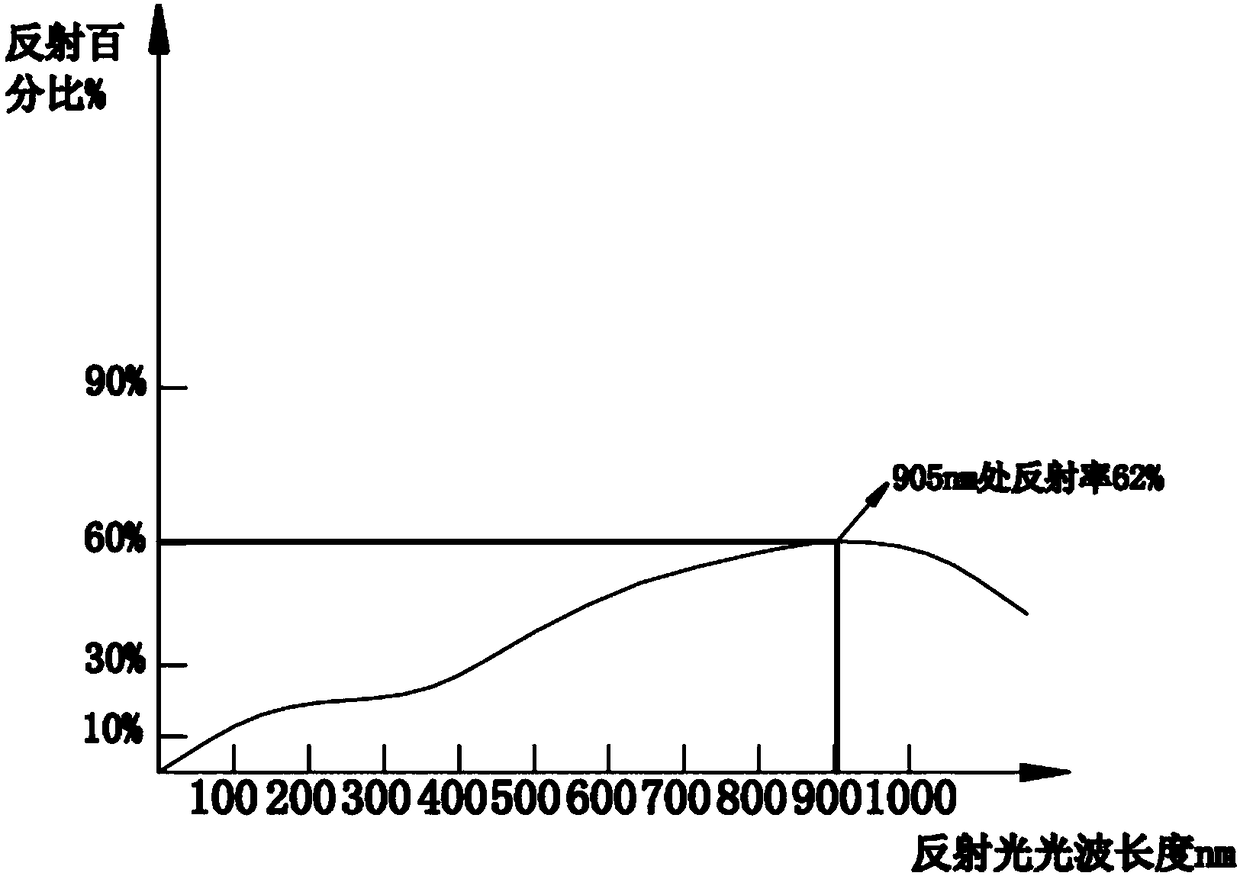

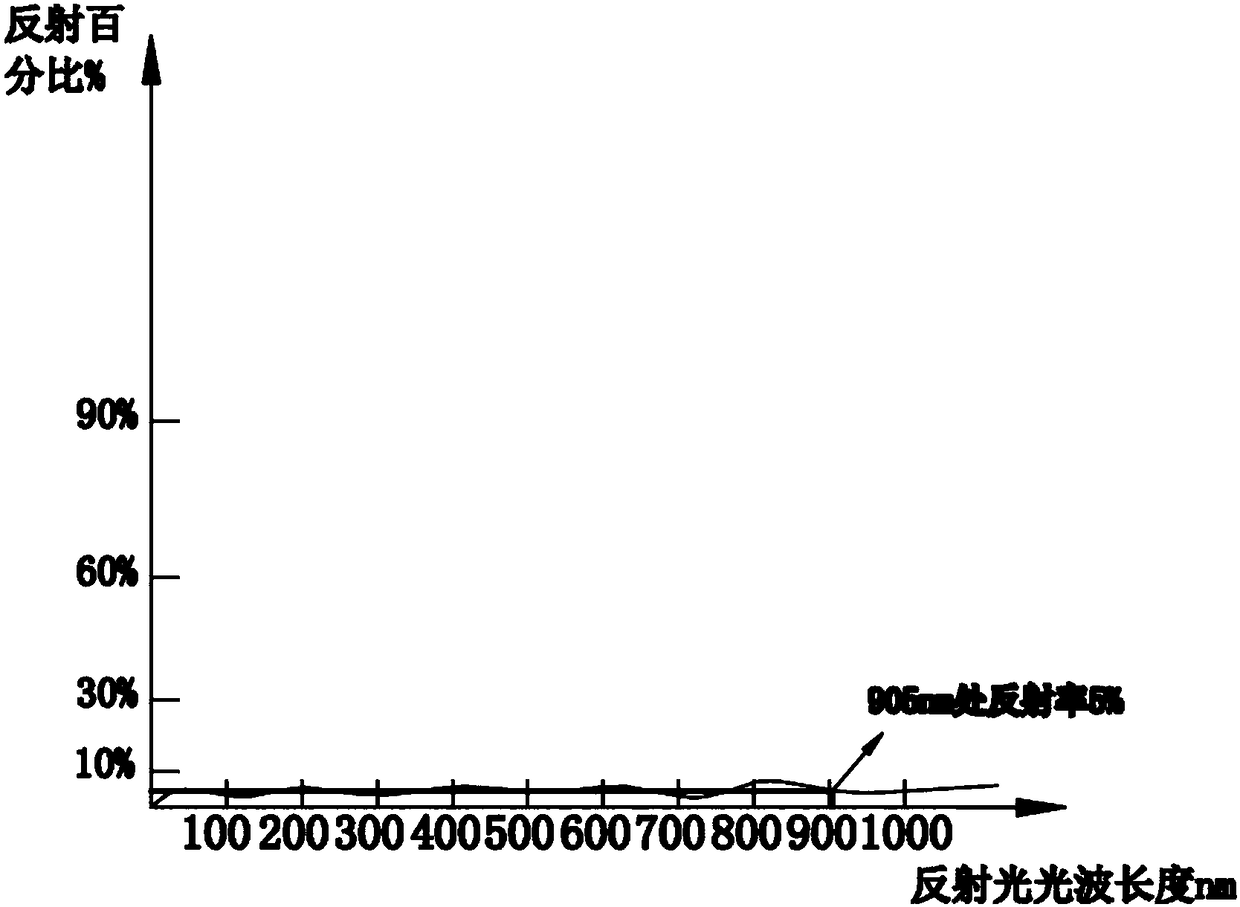

Optical reflectivity surface treatment method

ActiveCN108441914AImprove wear resistanceImprove corrosion resistanceAnodisationEnvironmental engineeringPre treatment

The invention discloses an optical reflectivity surface treatment method. The optical reflectivity surface treatment method comprises the following steps that a product is placed on a product fixing frame, product surface oil contamination is removed through degreasing an water washing working procedures, and the product is cleaned; primary anodic oxidation treatment is carried out, and a sulfuricacid solution is adopted for carrying out primary anodic oxidation on the product; water washing is carried out after primary anodic oxidation, an alkaline solution is used for neutralization, and cleaning is carried out through water washing; sealed pretreatment is carried out, an activating agent is adopted for carrying out sealed pretreatment on the product; neutralization and water washing treatment is carried out after sealed pretreatment; secondary anodic oxidation treatment is carried out, and a sulfuric acid solution is adopted for carrying out secondary anodic oxidation on the product; water washing and neutralization are carried out after secondary anodic oxidation treatment, and water washing treatment is carried out; sealing treatment is carried out, and nickel fluoride and activating agent are adopted for carrying out sealing treatment on the product; and after sealing treatment, cleaning, drying and appearance detection are carried out, and the product is packaged. The product surface optical reflectivity is effectively reduced.

Owner:国泰达鸣精密科技集团有限公司

Method for preparing two-dimensional locally-oxidized transition metal fluoride catalyst through rapid heating

The invention relates to a method for preparing a two-dimensional locally-oxidized transition metal fluoride catalyst through rapid heating, belonging to the fields of material science and engineeringtechnology and chemistry. The oxidized transition metal fluoride catalyst prepared by using the method disclosed by the invention is formed by local oxidation of nanometer materials such as cobalt fluoride (CoF2), nickel fluoride (NiF2), iron fluoride (FeF3) and the like. The preparation method comprises the following steps: weighing a certain mass of hydrated fluoride as a raw material A, and rapidly changing the temperature environment of the raw material A to prepare the two-dimensional locally-oxidized transition metal fluoride catalyst. The method has the advantages of easiness, feasibility, high yield, high efficiency, good applicability and the like, and has remarkable advantages compared with traditional methods for preparing ultrathin two-dimensional nanomaterials.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Treatment method for surface of heat-insulation corrosion-resistant aluminum alloy door and window

InactiveCN112138962ANot easy to fall offImprove continuityPretreated surfacesAnti-corrosive paintsThermal breakThermal insulation

The invention discloses a treatment method for the surface of a heat-insulating corrosion-resistant aluminum alloy door and window. The treatment method comprises the following steps that the surfaceof a window frame is subjected to cleaning, oil removal, polishing, soaking, air drying, sand blasting treatment, passivation treatment, and is sprayed with a thermal insulation layer formed by a thermal insulation composition, and is sprayed with a corrosion-resistant layer formed by a corrosion-resistant composition, and layer sealing treatment and aging treatment are conducted on the corrosion-resistant layer through a nickel fluoride cold hole sealing agent. According to the method, before the thermal insulation composition and the corrosion-resistant composition are sprayed to form the thermal insulation layer and the corrosion-resistant layer, and the window frame of an aluminum alloy door and window is subjected to a series of treatment, so that the binding force of the thermal insulation layer and the corrosion-resistant layer on the surface of the window frame of the aluminum alloy door and window can be improved, and the thermal insulation layer and the corrosion-resistant layer are not prone to falling off; and the continuity and integrity of a film layer of the corrosion-resistant layer can be improved by carrying out layer sealing and aging treatment after the corrosion-resistant layer forms a film, and the surface quality of the aluminum alloy door and window can be effectively improved.

Owner:ANHUI PROVINCE JINPENG ENERGY SAVING TECH CO LTD

Wear-resistant material

The invention discloses a wear-resistant material. The wear-resistant material is characterized by comprising the following raw materials of, by weight, 15-30 parts of tungsten metal powder, 30-50 parts of titanium carbide, 15-25 parts of copper metal powder, 40-50 parts of silicon carbide grains, 20-25 parts of flaky corundum, 15-20 parts of molybdenum disulfide, 5-8 parts of magnesium oxide, 2-5parts of nickel fluoride, 3-5 parts of niobium and 0.5-5 parts of a flexibilizer. The wear-resistant material has excellent high temperature resistance and wear resistance.

Owner:HUZHOU WUSHI TECH CO LTD

Spraying treatment method of aluminum alloy door and window profiles

InactiveCN110449331AImprove stabilityHigh strengthPretreated surfacesMetallic material coating processesHydrogenNitrogen atmosphere

The invention discloses a spraying treatment method of aluminum alloy door and window profiles. The spraying treatment method comprises the steps of degreasing; detecting the levelness, and finely polishing; passivating in a passivation solution to form a passivation film; performing hole sealing treatment by using a nickel fluoride hole sealing agent; aging to modify the surface quality; standingin a sealed environment of 150-180 DEG C; chromizing to form a compact chromized film; and spraying a protective coating to form a coating, and then thermally curing the coating in a nitrogen atmosphere. According to the spraying treatment method of the aluminum alloy door and window profiles, the surfaces of the aluminum alloy door and window profiles are subjected to a series of treatments before spraying treatment, so that the stability and the strength of the surface state of the aluminum alloy door and window profiles are effectively improved; by standing the aluminum alloy door and window profiles in a sealed environment of 150-180 DEG C, hydrogen atoms in the aluminum alloy door and window profiles are effectively removed, stress of the aluminum alloy door and window profiles is reduced, and product quality of the aluminum alloy door and window profiles after spraying treatment is effectively improved.

Owner:ANHUI PROVINCE JINPENG ENERGY SAVING TECH CO LTD

Corrosion resistant material, and its production method

InactiveCN100392151CImprove corrosion resistanceImprove wear resistanceSuperimposed coating processNickel alloySemiconductor

This invention provides a corrosion resistant material which is excellent in corrosion resistance to halogen based corrosive gas, e.g., used for a semiconductor production process, has satisfactory durability in a fluoride passive layer, and has reduced generation in contaminated gas on use, and to provide its production method. The corrosion resistant material consists of a nickel layer or a nickel alloy layer formed on the surface of a base material consisting of metal or the like, a nickel oxide layer formed on the surface thereof and a nickel fluoride layer formed on the surface of the nickel oxide layer.

Owner:RESONAC HOLDINGS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com