High-voltage-resistant and decomposition-resistant electrolyte for thermal battery and preparation method thereof

An electrolyte and thermal battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as restricting development, and achieve the effects of promoting development, improving electrical conductivity, and improving high-power output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

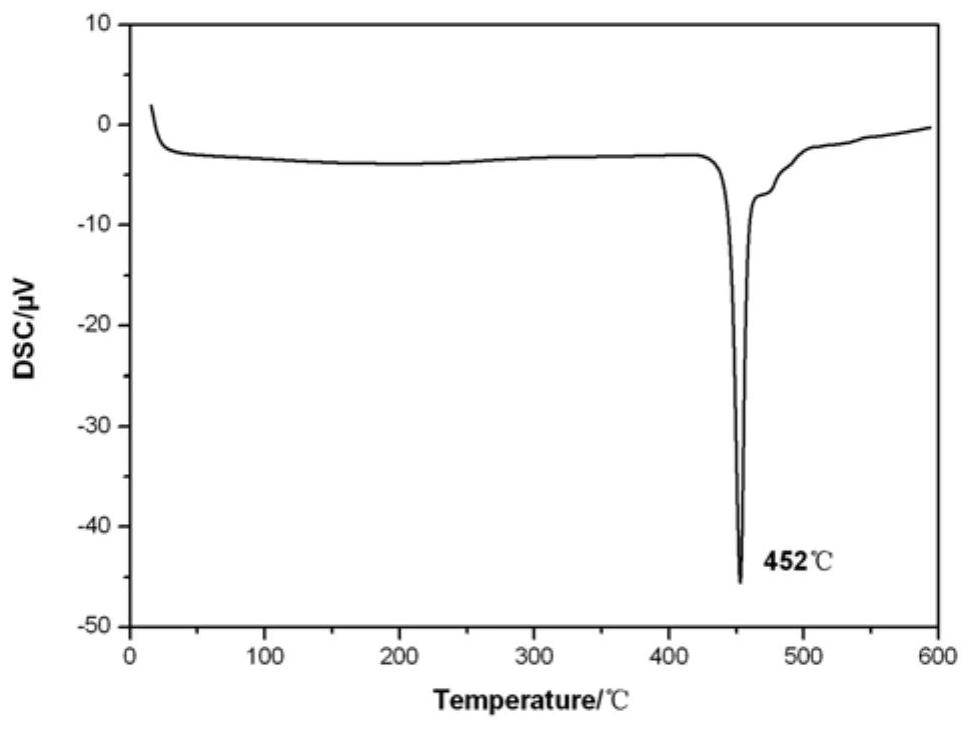

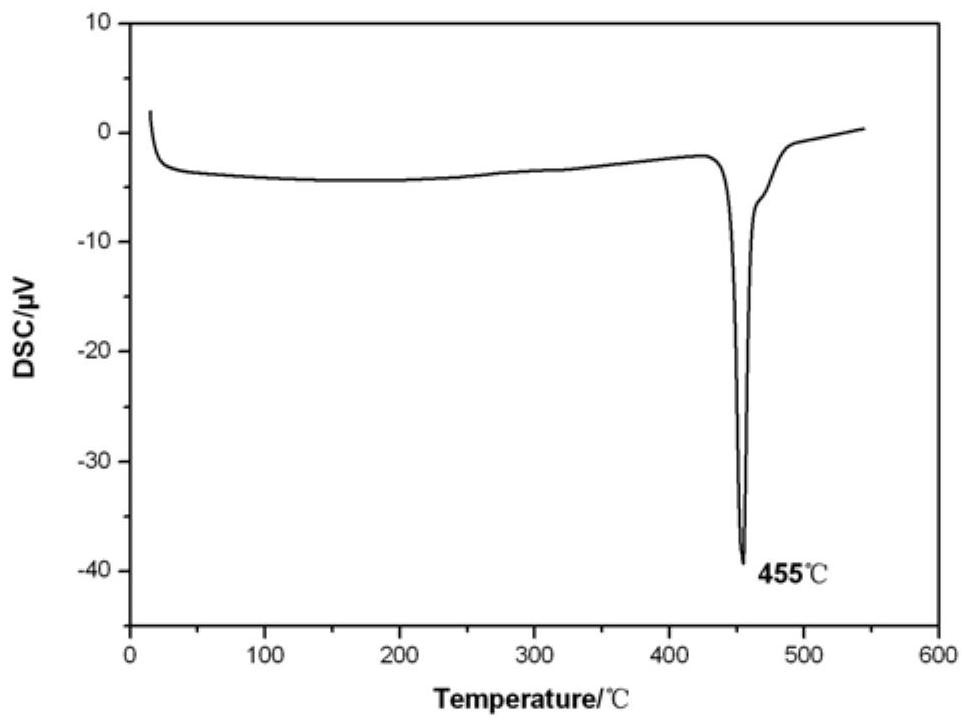

Image

Examples

Embodiment 1

[0025] S1: Ingredients:

[0026] Binary eutectic salt Li 2 CO 3 -Li 2 SO 4 , LiCl-Li 2 SO 4 and LiCl-Li 2 CO 3 The reaction raw materials are configured in a molar ratio of 1:1:1.

[0027] S2: Raw material mixing:

[0028] The reaction raw materials were placed in a graphite crucible with a volume of 300 mL, and mixed evenly.

[0029] S3: constant temperature reaction:

[0030] The homogeneously mixed reaction raw materials were placed in a constant temperature device, and the constant temperature reaction was carried out at 540° C. for 2 hours, and the heating environment was a nitrogen atmosphere.

[0031] S4: Cooling:

[0032] After the constant temperature reaction is completed, the reaction raw materials are quickly taken out from the constant temperature device until the reaction product drops to 15°C.

[0033] S5: Broken:

[0034] The reaction product was crushed with an agate mortar and sieved, and the size of the sieve was 50 mesh to obtain a white powder...

Embodiment 2

[0037] S1: Ingredients:

[0038] Binary eutectic salt Li 2 CO 3 -Li 2 SO 4 , LiCl-Li 2 SO 4 and LiCl-Li 2 CO 3 The reaction raw materials are configured in a molar ratio of 1:1.5:0.5.

[0039] S2: Raw material mixing:

[0040] The reaction raw materials were placed in a 300mL alumina crucible and mixed evenly.

[0041] S3: constant temperature reaction:

[0042] The homogeneously mixed reaction raw materials were placed in a horizontal splitting device, and a constant temperature reaction was carried out at 540° C. for 4 hours, wherein the heating environment was a nitrogen atmosphere.

[0043] S4: Cooling:

[0044] After the constant temperature reaction is completed, the reaction raw materials are quickly taken out from the constant temperature device until the reaction product drops to 10°C.

[0045] S5: Broken:

[0046] The reaction product was crushed and sieved by a ball mill, the size of the sieve was 300 mesh, and a white powder sample was obtained, which wa...

Embodiment 3

[0049] S1: Ingredients:

[0050] Binary eutectic salt Li 2 CO 3 -Li 2 SO 4 , LiCl-Li 2 SO 4 and LiCl-Li 2 CO 3 The reaction raw materials are configured in a molar ratio of 1:1.7:0.7.

[0051] S2: Raw material mixing:

[0052] The reaction raw materials were placed in a graphite crucible with a volume of 400 mL, and mixed evenly.

[0053] S3: constant temperature reaction:

[0054] The homogeneously mixed reaction raw materials were subjected to a constant temperature reaction at 540° C., wherein the heating environment was an air atmosphere.

[0055] S4: Cooling:

[0056] After the constant temperature reaction is completed, the reaction raw materials are quickly taken out from the constant temperature device until the reaction product drops to 20°C.

[0057] S5: Broken:

[0058] The reaction product was crushed with an agate mortar and sieved, the size of the sieve was 150 mesh, and a white powder sample was obtained, which was LiCl-Li 2 CO 3 -Li 2 SO 4 eute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com