A temperature and liquid level joint adjustment device and magnesium electrolyzer using the device

A technology of liquid level adjustment and combined adjustment, which is applied in the field of magnesium electrolytic cells, can solve the problems of inability to adjust the liquid level of the electrolytic cell and the device cannot maintain pressure, and achieve the effects of saving manufacturing costs, saving manufacturing costs, and reasonable technical conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the technical means, creative features and goals achieved by the present invention, the present invention will be further elaborated below in conjunction with specific schematic diagrams, but the scope of protection claimed by the present invention is not limited to the scope described in the specific embodiments.

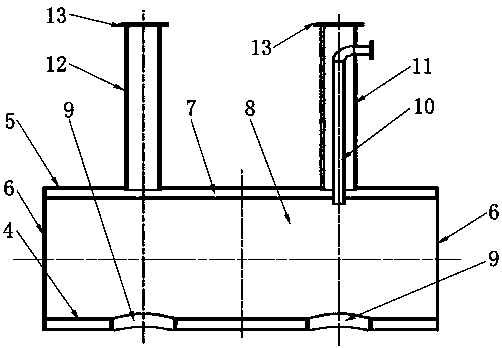

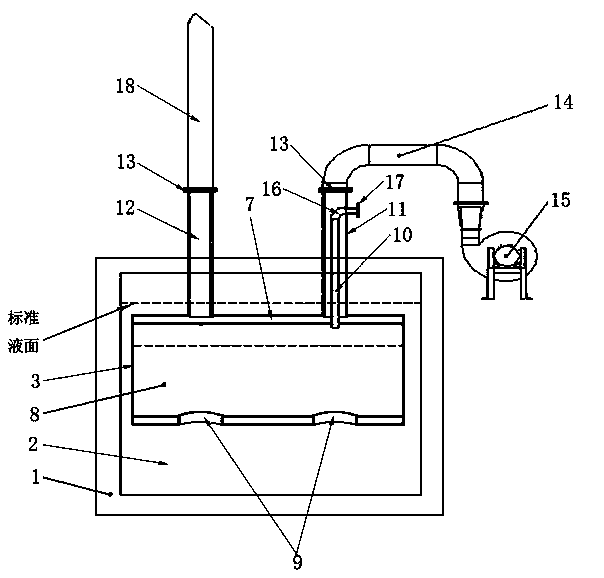

[0025] A combined adjustment device for temperature and liquid level, including a sealed cylinder, such as figure 1 As shown, the cylinder body is provided with a temperature regulation chamber 7 and a liquid level regulation chamber 8 which are independent of each other. Pipe 9, the upper part of the cylinder is provided with a connecting pipe 10 connected with the liquid level regulating chamber 8, through which the gas is filled into the liquid level regulating chamber 8, and the liquid contained in the liquid level regulating chamber 8 is discharged from the discharge pipe 9 flows out; the two ends of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com