Integrated plate type heave-current control cabinet

A technology of strong current control cabinet and integrated board, which is applied in substation/power distribution device shell, cooling/ventilation of substation/switchgear, board/panel/desk of substation/switchgear, etc., and can solve wire short circuit and short circuit accidents , Troubleshooting inconvenience and other problems, to achieve the effect of increasing the effective space, reducing the workload, eliminating the processing of thread ends and line lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

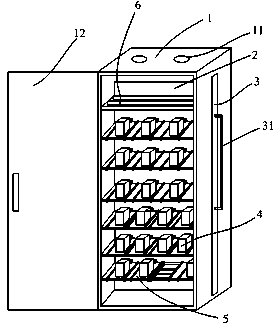

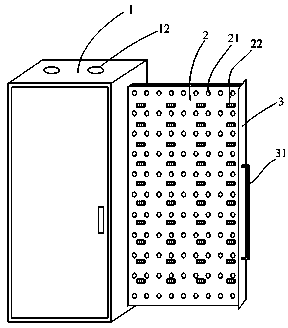

[0030] Such as figure 1 and figure 2 As shown, the integrated strong current control cabinet includes a cabinet body 1 and a cabinet door 12 for closing the cabinet body 1, and an exhaust fan 11 is arranged above the cabinet body to conduct heat out of the cabinet body. The side of the cabinet body 1 is provided with a strip groove to facilitate the removal of the integrated board 2. A slide rail frame is installed in the cabinet body 1. The slide rail frame includes a slide rail fixed on the upper and lower sides of the inner wall of the cabinet body 1 and a slide bar 7 matched with the slide rail. , the integrated board 2 is fixedly connected with the slide bar 7, and its purpose is to block the baffle plate 3 of the strip groove, and the baffle plate 3 is provided with a handle 31 which is convenient for pushing and pulling. During installation, the integrated board 2 and the slide bar 7 are fixed, and then the baffle plate 3 with the handle 31 is fixed; the entire integr...

Embodiment 2

[0039] Such as Figure 7 As shown, the other structures of the integrated strong current control cabinet are the same as in Embodiment 1, the only difference is that the bottom plate 24 in the integrated board 2 is composed of a plurality of monomers 201, and at least one wire 241 is embedded in the monomer 201, and each unit The body 201 is provided with card ribs 203 or / and card slots 202 for clamping between the monomers. When the monomer 201 is manufactured, a wire 241 is reserved inside to be embedded in the groove. When the design of the wire part of the equipment circuit diagram is to be realized, the The assembly of the entire bottom plate 24 is realized through the cooperation of the card ribs 203 and the card slots 202 between the monomers 201 .

Embodiment 3

[0041] The other structures of the integrated strong current control cabinet are the same as in Embodiment 1, the only difference is that there are two circuit layers in the integrated board, and the ventilation layer 25 is arranged between the two circuit layers. The circuit layer is laid out. At this time, both sides need to dissipate heat, and the cooling air of the ventilation layer is directly poured into both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com