Gel polymer lithium ion battery electrolyte, preparation method and application thereof

A technology of lithium-ion batteries and gel polymers, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of difficult industrial production of lithium ions, improvement of electrochemical performance, low ion conductivity, etc., and achieve optimal liquid absorption The effects of improved performance and liquid retention, improved electrochemical performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

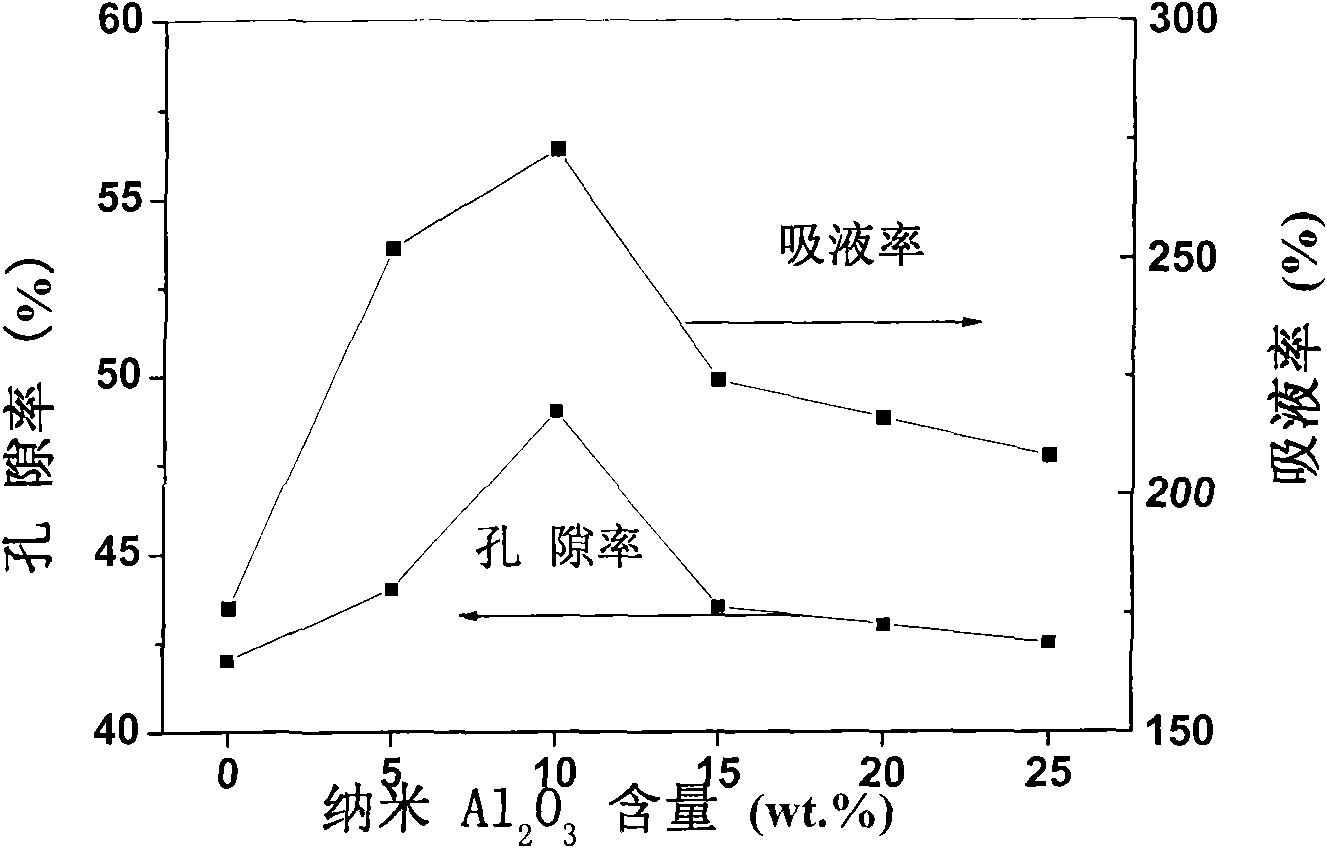

[0035] (1) Under an inert gas atmosphere, the PEO and PVDF-HFP blends with a mass ratio of 1:1 were dissolved in acetone at a ratio of 2% by mass, and 20% of the blend mass of nanoparticles was added Al 2 o 3 , heated and stirred at a temperature of 45°C for 4 hours in a flask with a reflux tube.

[0036] (2) After completely dissolving, soak the non-activated support polypropylene (PP) with higher mechanical strength in the gel liquid obtained in step (1), take it out after 15 minutes, and dry it naturally to obtain a certain Thickness of Supported Nanoparticle-Doped Gel-Polymer Membranes for Li-ion Batteries.

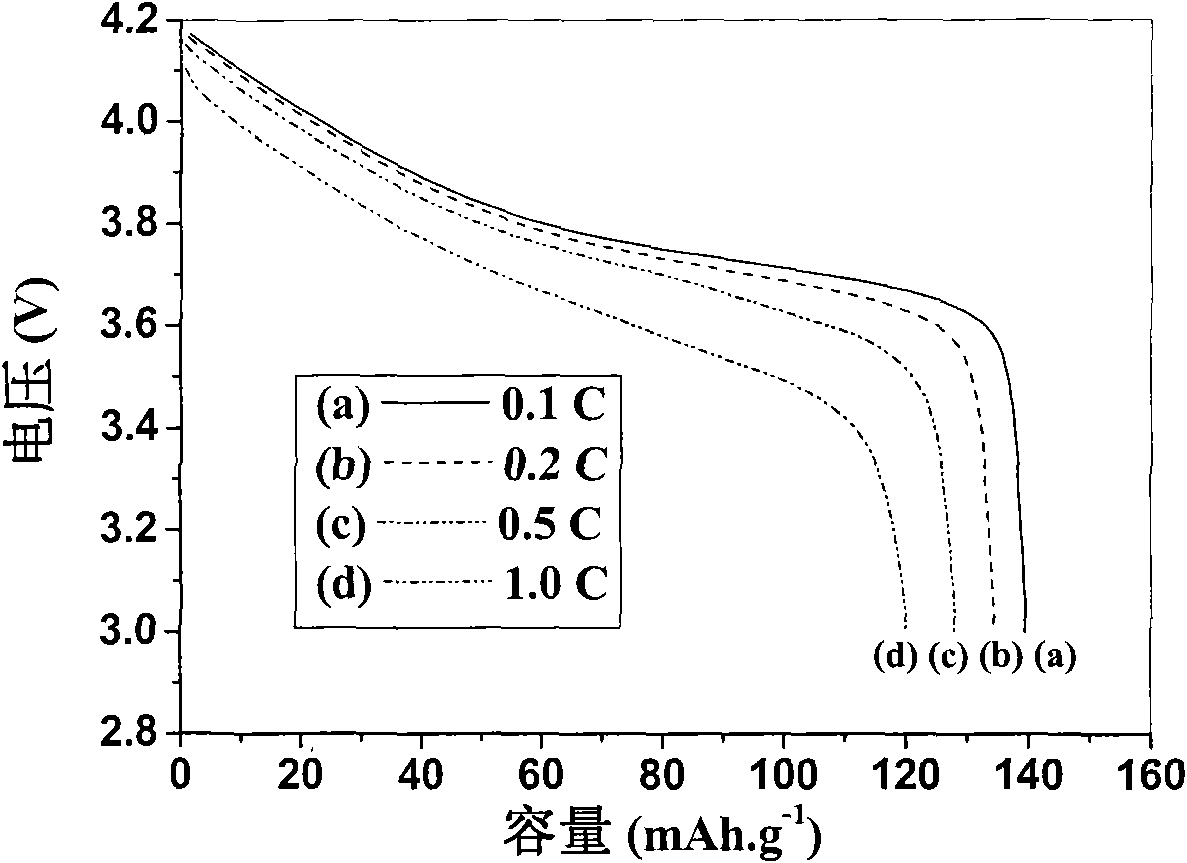

[0037] (3) After the polymer film is cut to an appropriate size, it is placed in a vacuum drying oven at 45°C for 15 hours under vacuum, and then quickly transferred to a glove box (Mikrouna Super 12201750, which is used to control the water content in the environment to less than 60ppm , the oxygen content is less than 2000ppm). The polymer membrane was soaked in...

Embodiment 2

[0039] (1) Under an inert gas atmosphere, the PEO and PVDF-HFP blends with a mass ratio of 1:2 were dissolved in acetone at a ratio of 1.5% by mass, and 5% of the blend mass of nanoparticles was added al 2 o 3 , heated and stirred at 40°C for 5 hours with a flask equipped with a reflux tube.

[0040] (2) After completely dissolving, soak the unactivated support body polyethylene (PE) with higher mechanical strength in the gel liquid obtained in step (1), take it out after 15 minutes, and dry it naturally, that is, a certain Thickness of Supported Nanoparticle-Doped Gel-Polymer Membranes for Li-ion Batteries.

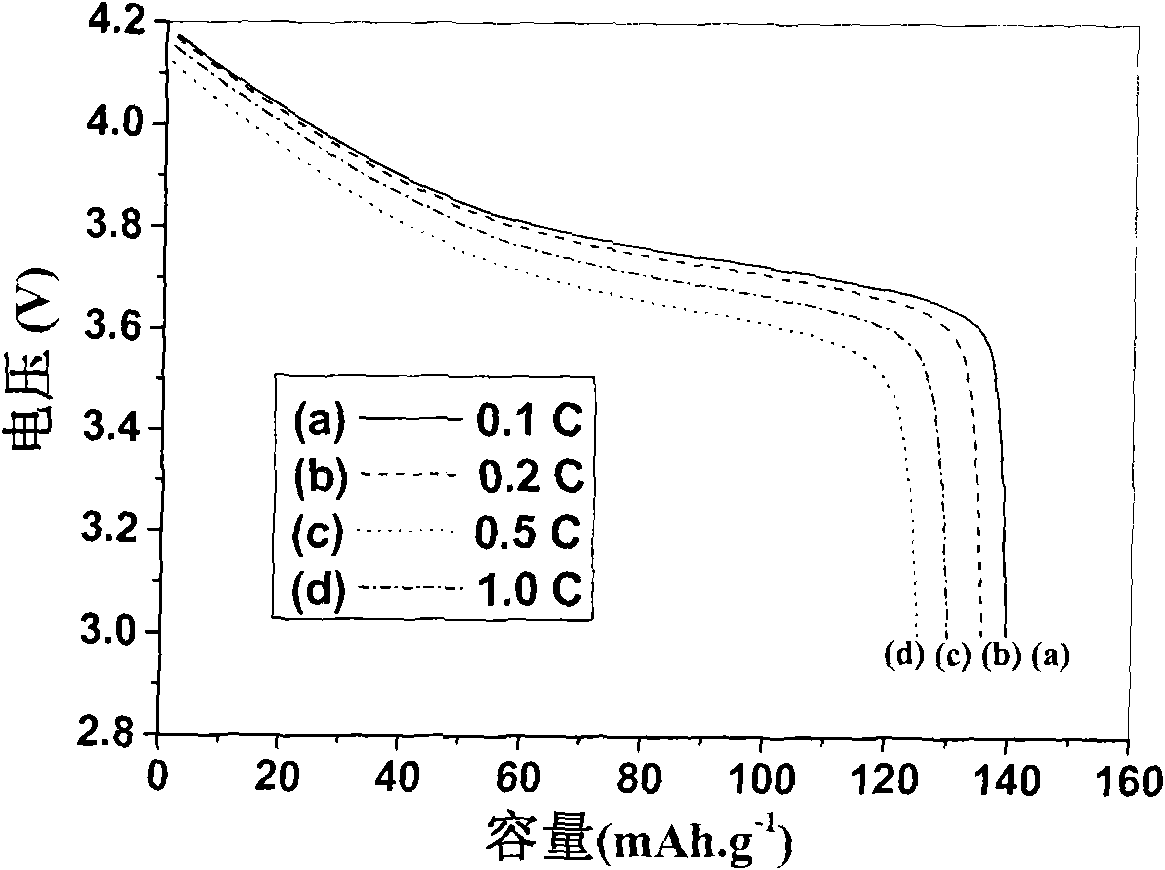

[0041] (3) After the polymer film is cut to an appropriate size, it is placed in a vacuum drying oven at 40° C. for 20 hours in vacuum and then quickly transferred to a glove box. After the polymer film was soaked in the electrolyte for 2 hours, a supported nanoparticle-doped lithium-ion battery gel polymer electrolyte was obtained.

Embodiment 3

[0043] (1) Under an inert gas atmosphere, the blend of PEO and PVDF-HFP with a mass ratio of 1:3 was dissolved in N-N-dimethylformamide (DMF) at a ratio of 2.5% by mass, and added 10% nanoparticle SiO by mass of the blend 2 , heated and stirred with a flask with a reflux tube at a temperature of 50° C. for 6 hours.

[0044] (2) After completely dissolving, soak the unactivated support non-woven fabric with high mechanical strength in the gel liquid obtained in step (1), take it out after 12 minutes, and dry it naturally, that is, a certain thickness of non-woven fabric is prepared. Supported nanoparticle-doped gel-polymer membranes for lithium-ion batteries.

[0045] (3) After the polymer film is cut into an appropriate size, it is placed in a vacuum drying oven at 50° C. for 17 hours in vacuum and then quickly transferred to a glove box. After the polymer film was soaked in the electrolyte for 1 hour, a supported nanoparticle-doped lithium-ion battery gel polymer electrolyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com