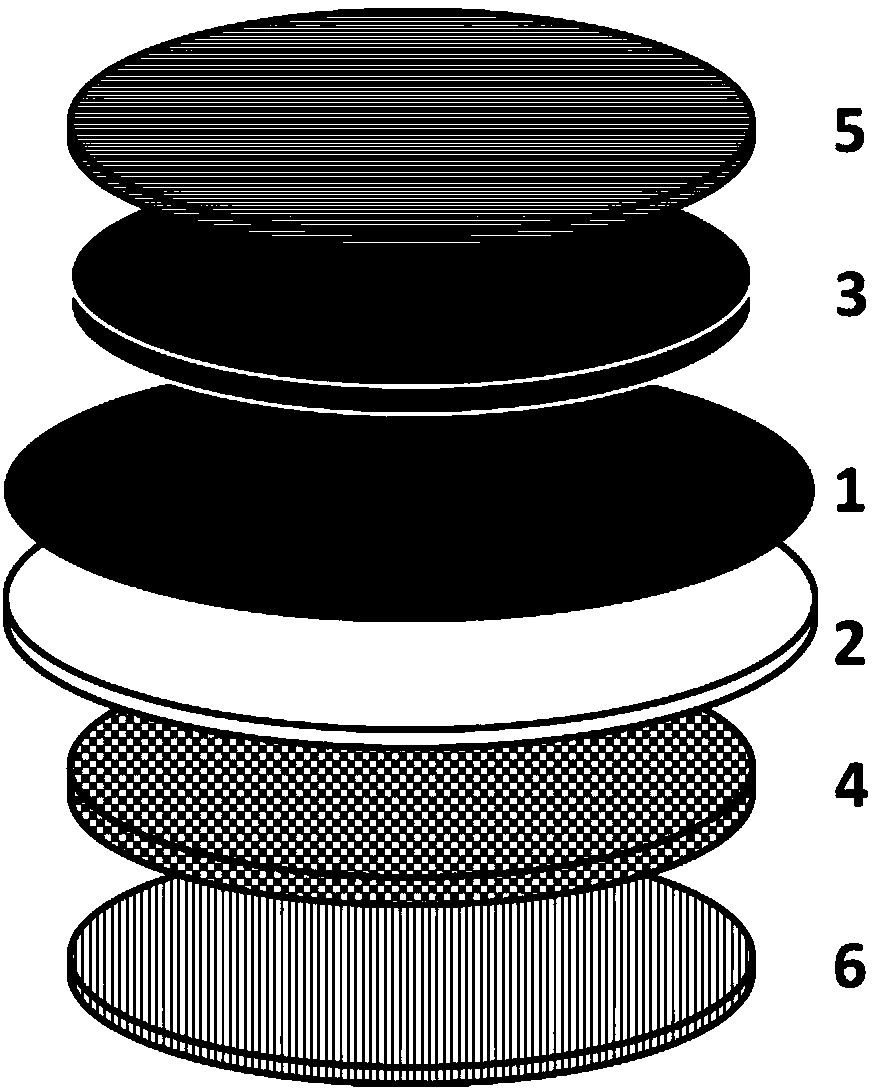

Interface protection structure, preparation method and battery comprising structure

A technology for interface protection and batteries, applied in the field of electrochemistry, can solve problems such as uneven dendrite growth, increased electrode interface impedance, and low cycle efficiency, and achieve excellent cycle performance, huge application potential, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An interface protection structure, in parts by weight, comprising 70 parts of nickel fluoride, 20 parts of polyvinylidene fluoride, 10 parts of special high-conductivity carbon black (Super-P), and the load of fluoride is 1 to 5 mg / square centimeter. Preferably, the particle size of the nickel fluoride particles is 10-100 nanometers.

[0051] A kind of lithium-iron phosphate lithium battery with above-mentioned interface protection structure, its preparation process is as follows:

[0052] a. Pre-dissolve polyvinylidene fluoride (PVdF) with a mass ratio of 10% in N-methylpyrrolidone (NMP) solvent, and mix and stir in a magnetic stirrer for 3 hours to obtain a uniform solution;

[0053] b. Stir nickel fluoride, polyvinylidene fluoride, and special high-conductivity carbon black (Super-P) according to the mass ratio of 7:2:1, add solvent N-methylpyrrolidone (NMP) into the mixture and place it under magnetic stirring Mix and stir in the container for 3 hours to obtain a...

Embodiment 2

[0061] Compared with Example 1, the only difference is: in step b, the metal fluoride is manganese fluoride.

Embodiment 3

[0063] Compared with Example 1, the only difference is that in step b, the ratio of nickel fluoride: polyvinylidene fluoride is 8:2, and there is no carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com