Flux-cored wire with excellent low-temperature impact toughness

A technology of low-temperature impact toughness and flux-cored wire, which is applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of reducing the low-temperature impact toughness of welded joints, and achieve the effects of desulfurization, diffusion suppression, and cold crack suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

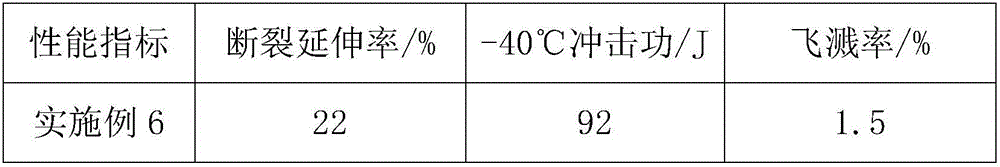

Examples

Embodiment 1

[0032] A flux-cored welding wire with excellent low-temperature impact toughness, which is characterized in that it includes a low-carbon steel sheath and a flux core filled in the low-carbon steel sheath, and the raw materials of the flux core include: 20% of roasted bauxite, calcium ferrite 6%, 1% rutile, 5% feldspar, 5% aluminum fluoride, 3% nickel fluoride, 3% magnesium alloy powder, 2% ferromanganese powder, 2% marble, 1% barium carbonate, and the balance is iron pink.

Embodiment 2

[0034] A flux-cored welding wire with excellent low-temperature impact toughness, comprising a low-carbon steel sheath and a flux core filled in the low-carbon steel sheath, the raw materials of the flux-core include: 10% roasted bauxite, 8% calcium ferrite, long 5.5% of stone, 6% of aluminum fluoride, 3.5% of nickel fluoride, 1.5% of magnesium alloy powder, 1% of ferromanganese powder, 2.5% of marble, 0.5% of barium carbonate, and the balance is iron powder; in roasted bauxite , Al 2 o 3 , SiO 2 and Fe 2 o 3 The weight percentage is 85%, Fe 2 o 3 The percentage by weight is 10%.

Embodiment 3

[0036] A flux-cored welding wire with excellent low-temperature impact toughness, including a low-carbon steel sheath and a flux core filled in the low-carbon steel sheath. The raw materials of the flux core include: 15% roasted bauxite, 6% calcium ferrite, rutile 3%, feldspar 6%, aluminum fluoride 7%, nickel fluoride 4%, magnesium alloy powder 1%, manganese iron powder 1.3%, marble 3%, barium carbonate 0.65%, the balance is iron powder; In bauxite, Al 2 o 3 , SiO 2 and Fe 2 o 3 The weight percentage is 80%, Fe 2 o 3 The weight percentage is 12%, and the roasted bauxite is roasted at 900° C. for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| -40°c impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com