A kind of trivalent chromium multicolored passivator

A technology of passivating agent and trivalent chromium, which is applied in the coating process of metal materials, etc., can solve the problems that the trivalent chromium passivation film does not have self-healing property and the stability of the passivation film is poor, and achieves low operating temperature and high operating efficiency. The effect of simplicity and wide process range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

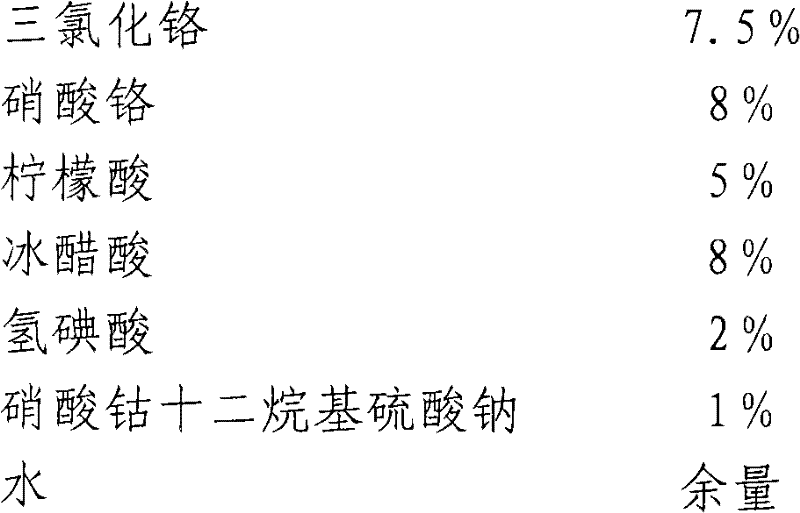

[0021] Raw material selection: select the raw materials according to the weight ratio as follows:

[0022]

[0023] Preparation:

[0024] 1. After adding an appropriate amount of water to the reaction kettle, add trivalent chromium main salt, chelating agent, reducing agent, and salt spray additive, and then stir at 80°C for 2 hours;

[0025] 2. After cooling the solution to room temperature, add surfactant, and stir for 30 minutes to complete the preparation.

Embodiment 2

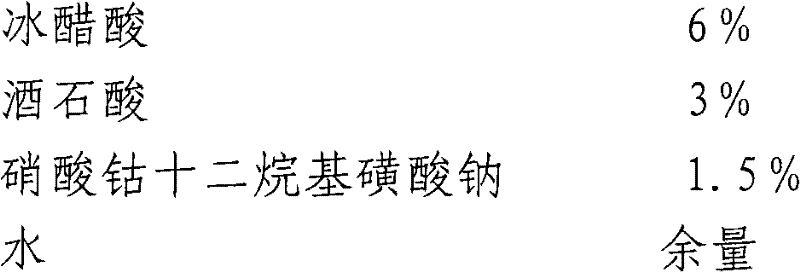

[0027] Raw material selection: select the raw materials according to the weight ratio as follows:

[0028]

[0029]

[0030] Preparation method: with embodiment one

[0031] In addition, the present invention has a variety of combinations in the selection of raw materials, and is not limited to the specific scheme selected in the specific examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com