Cleaning agent for heavy oil dirt

A cleaning agent and dirt technology, applied in the direction of detergent compounding agent, detergent composition, non-ionic surface active compound, etc., can solve the problems of strong corrosion of copper metal, narrow range of applicable materials, increase of cleaning cost, etc., and achieve the goal of using The effect of low temperature, wide application range and excellent cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of heavy oil dirt cleaning agent of the present invention, this cleaning agent composition and weight are:

[0031] Sodium metasilicate 4.5g;

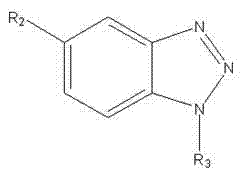

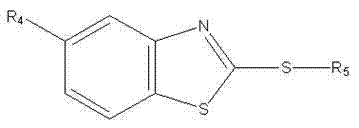

[0032] Tolylbenzothiazole thiol 1 g;

[0033] Tetrasodium EDTA 2 g;

[0034] Sodium bicarbonate 1 g;

[0036] Dipotassium salt of m-methylphenoxy polyethylene oxide phosphate 3 g;

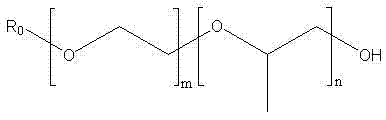

[0037] Isomerized 13-carbon alcohol polyoxyethylene ether 3 g;

[0038] Fatty acid methyl ester polyoxyethylene ether sodium sulfate 7.5 g;

[0039] Deionized water 77g.

[0040] Dissolve sodium metasilicate, methylbenzothiazole mercaptan, tetrasodium edetate, sodium bicarbonate, and sodium hydroxide in deionized water first, then add m-methylphenoxypolyepoxide Ethane phosphate dipotassium salt, isomeric 13-carbon alcohol polyoxyethylene ether, fatty acid methyl ester polyoxyethylene ether sodium sulfate, mixed in proportion and stirred evenly.

Embodiment 2

[0042] A kind of heavy oil dirt cleaning agent of the present invention, this cleaning agent composition and weight are:

[0043] Sodium silicate 5 g;

[0044] 2,2'-dithiodibenzothiazole 1.5 g;

[0045] Disodium edetate 2 g;

[0046] Potassium carbonate 2 g;

[0047] Sodium p-cumene sulfonate 5 g;

[0048] Octylphenol polyoxyethylene polyoxypropylene ether 3.5 g;

[0049] 12-carbon alcohol polyoxyethylene ether ammonium sulfate 5 g;

[0050] Deionized water 76g.

[0051] Dissolve sodium silicate, 2,2'-dithiodibenzothiazole, disodium edetate, potassium carbonate, and sodium p-cumene sulfonate in deionized water, and then add octylphenol polyoxygen Ethylene polyoxypropylene ether, 12-carbon alcohol polyoxyethylene ether ammonium sulfate, mix and stir evenly.

Embodiment 3

[0053] A kind of heavy oil dirt cleaning agent of the present invention, this cleaning agent composition and weight are:

[0054] Sodium silicate 5 g;

[0055] 2,2'-dithiodibenzothiazole 1.5 g;

[0056] Trisodium edetate 3g;

[0057] Potassium carbonate 2 g;

[0058] Sodium p-cumene sulfonate 5 g;

[0059] Octylphenol polyoxyethylene polyoxypropylene ether 3.5 g;

[0060] 12-carbon alcohol polyoxyethylene ether ammonium sulfate 5 g;

[0061] Deionized water 75g.

[0062] Dissolve sodium silicate, 2,2'-dithiodibenzothiazole, trisodium edetate, potassium carbonate, and sodium p-cumene sulfonate in deionized water, and then add octylphenol polyoxygen Ethylene polyoxypropylene ether, 12-carbon alcohol polyoxyethylene ether ammonium sulfate, mix and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com