Process for producing direct methanol fuel cell electro-catalyst

A methanol fuel cell and electrocatalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as agglomeration of metal particles, and achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 1 gram of chloroplatinic acid and 1 gram of sodium hydroxide in 50 mL of ethylene glycol solution, and then ultrasonically disperse and mix uniformly; blow nitrogen for 15 minutes to remove air, and then heat to reflux in an oil bath at 130°C for 3 hours under a nitrogen atmosphere, during which time Electromagnetic stirring was continued; after the temperature dropped to room temperature, the ventilation was stopped, and 3.76 mg / mL platinum sol was prepared.

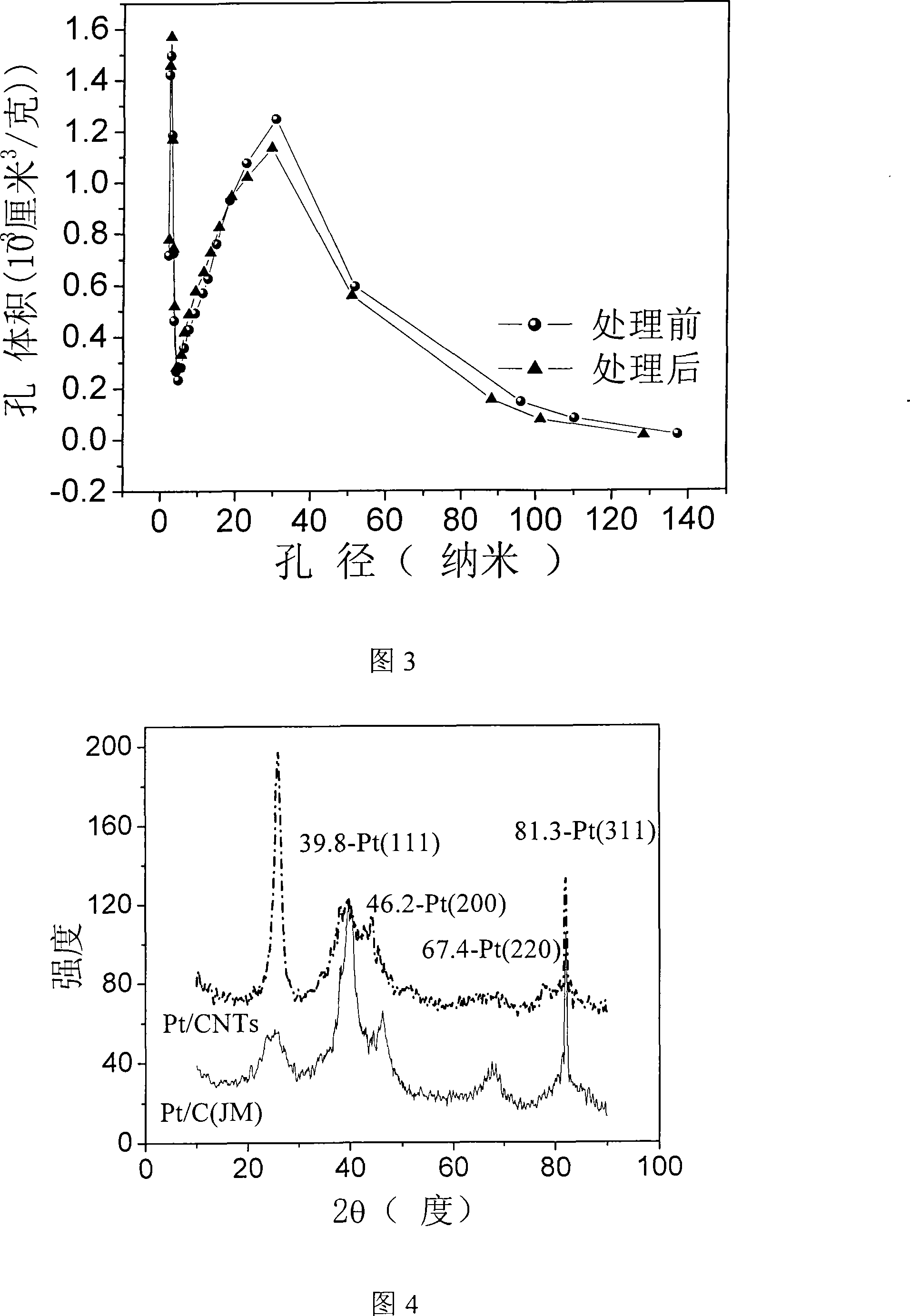

[0022] The carbon nanotubes are soaked in concentrated hydrochloric acid for 24 hours, then filtered and washed until the filtrate is neutral, and then dried at 100° C. for 2 hours to obtain a purified carbon nanotube carrier. Then put the carbon nanotubes into a round bottom flask, heat NaOH (3mmol / L) at 70°C for 1 hour, centrifuge, filter until the filtrate is neutral, and dry at 100°C for 2 hours; then place the volume ratio at 3:1 Concentrated HNO 3 Hwanon H 2 SO 4 In the mixed acid solution, heat reflux...

Embodiment 2

[0025]Dissolve 0.4 g of ruthenium trichloride and 1 g of sodium hydroxide in 50 mL of ethylene glycol solution respectively, and then disperse and mix uniformly by ultrasonic; bubbling nitrogen for 15 minutes to remove air; then heating and refluxing in an oil bath at 130°C for 3 hours under nitrogen atmosphere, during Electromagnetic stirring was continued; after the temperature dropped to room temperature, the ventilation was stopped, and 0.39 mg / mL ruthenium sol was prepared.

[0026] The carbon nanotubes are soaked in concentrated hydrochloric acid for 24 hours, then filtered and washed until the filtrate is neutral, and then dried at 100° C. for 2 hours to obtain a purified carbon nanotube carrier. Then put the carbon nanotubes into a round bottom flask, heat NaOH (3mmol / L) at 70°C for 1 hour, centrifuge, filter until the filtrate is neutral, dry at 100°C for 2 hours; then place the volume ratio at 3:1 Concentrated HNO 3 Hwanon H 2 SO 4 In the mixed acid solution, heat reflux...

Embodiment 3

[0028] This embodiment is the same as embodiment 1 except for the following features: heating and refluxing in an oil bath at 130°C under a nitrogen atmosphere for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com