Liquid CO2 fracturing technology for shale gas well

A technology for shale gas wells and CO2, which is applied in wellbore/well components, production fluids, and earth-moving drilling, etc., can solve the problems of large water resource consumption, clay mineral expansion, dispersion and migration, environmental hazards, etc., and reduce environmental pollution. Pollution degree, good practical significance, and the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

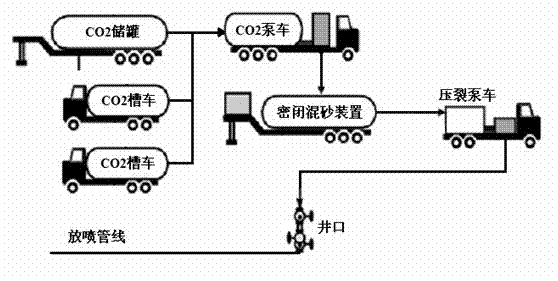

[0034] Shale gas well liquid CO 2 Fracturing process, it needs to be equipped with fracturing pump truck, closed sand mixing truck, CO 2 Booster pump truck, instrument truck, fracturing manifold truck, CO 2 Tanker and CO 2 For storage tanks, the fracturing manifold truck is equipped with low-pressure manifolds and high-pressure manifolds, and the instrument truck is equipped with monitoring instruments, which is characterized in that: the method is carried out according to the following steps:

[0035] Step 1, put some CO 2 Tanker and CO 2 Storage tanks are connected in parallel, and then sequentially connected with CO 2 The booster pump truck, the closed sand mixer truck, and the fracturing pump truck are connected, the fracturing pump truck is connected to the discharge pipeline at the wellhead, and the instrument truck is connected to the above-mentioned vehicles to monitor the working status; all vehicles pass through the fracturing manifold The low-pressure manifold ...

Embodiment 2

[0044] Taking Well X of Yanye as an example, the target interval is 1136 to 1201 meters deep, and the interval is the black shale of the Chang 7 member. The mud logging gas logging shows obvious, and there is no productivity after perforation.

[0045] The well uses liquid CO 2 No sand is used for fracturing, and the fracturing string is a 5.5-inch casing of J55 steel grade.

[0046]Before fracturing, mix 3.0 to 10.0% of HCl, 0.5% of drainage aid, 0.3% of corrosion inhibitor, 0.2% of iron ion stabilizer, and mix the balance with water to prepare a pre-acid treatment solution of 10.0m 3 , the above ratio units are by weight. (The above raw materials are sold in the market)

[0047] Here, signal EL-11 is used as the drainage aid, N-553 as the corrosion inhibitor, and IRON-2066A as the iron ion stabilizer.

[0048] The fracturing construction is carried out according to the following steps:

[0049] Step 1, such as figure 1 As shown, prepare 4 SS2000 fracturing pump trucks, ...

Embodiment 3

[0058] Taking Well Yanye Y as an example, the target interval is 1,370 to 1,420 meters, and the interval is black shale in the Chang 7 Member. The mud logging gas logging shows obvious, and there is no productivity after perforation.

[0059] The well was completed with J55 steel grade 5.5-inch casing and liquid CO 2 Sand fracturing.

[0060] Preparation of pre-acid treatment fluid before fracturing 10.0m 3 , the formula is 6.0% HCl, 0.5% drainage aid, 0.3% corrosion inhibitor and 0.2% iron ion stabilizer, the balance is water, and the units of the above ratios are by weight. (The above raw materials are sold in the market)

[0061] The fracturing construction is carried out according to the following steps:

[0062] Step 1, prepare 6 SS2000 fracturing pump trucks, 1 closed sand mixing pump truck, 1 closed sand mixing truck (volume 5m 3 ), 2 CO 2 Booster pump truck (single maximum displacement 4m 3 / min), 1 instrument car, 1 pressure manifold car, 10 CO 2 Tank car (sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com