Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Rapid flowback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

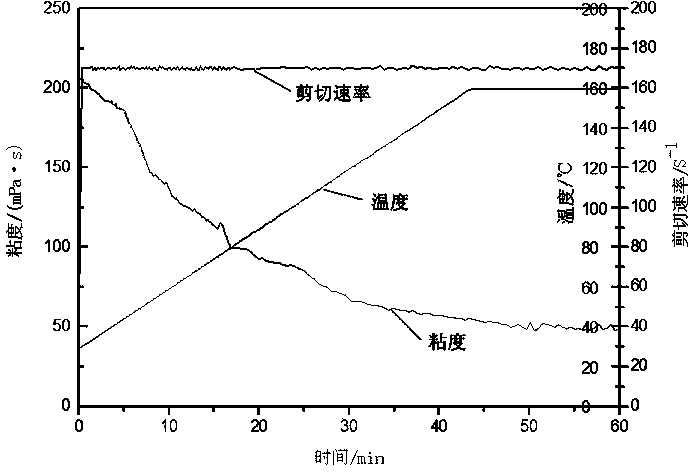

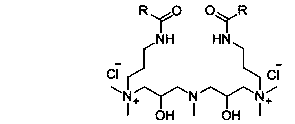

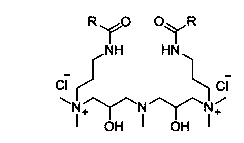

High temperature resistant Gemini cationic viscoelastic surfactant (VES) and synthetic method thereof

ActiveCN103965861ARapid flowbackGood temperature resistanceOrganic compound preparationCarboxylic acid amides preparationDiamineLong chain fatty acid

The invention provides a high temperature resistant Gemini cationic viscoelastic surfactant (VES) and a synthetic method thereof, relating to the field of oil recovery technology and engineering in the petroleum industry. The synthetic method is characterized by reacting unsaturated long-chain fatty acid with N,N-dimethyl propanediamine to synthesize a fatty acid amide intermediate; reacting methylamine with epichlorohydrin to synthesize a chloramine intermediate; reacting the intermediates synthesized in the two above steps respectively to synthesize the high temperature resistant Gemini cationic VES. The VES and the synthetic method have the beneficial effects that a high temperature surface active diverting acid system reacts with rocks at 160 DEG C, so that the liquid obviously diverts to become viscous and is subjected to automatic gel breaking under the condition that the hydrochloric acid concentration is below 5%, thus achieving rapid flowback; the VES has good temperature resistance, is relatively low in price and is beneficial for popularization and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for solving water lock effect

ActiveCN103450867AThe technical method is simpleEasy to operateDrilling compositionMetallurgySmall hole

The invention discloses a method for solving a water lock effect. By adopting the method, functional powder is added to a duct for producing a water lock, so as to remove the water lock. The functional powder is mixed powder formed by amphiphilic powder or super-hydrophilic powder and hydrophobic powder; the grain density of the functional powder is greater than 1 g / cm<3>; the mean grain size of the functional powder is smaller than 100 microns. The method disclosed by the invention is simple and feasible, convenient to operate, wide in material source, and low in cost. Meanwhile, the liquid-phase interfacial tension can be reduced by the functional powder in the using process of the method disclosed by the invention; the functional powder is in a small-granule solid state, so that the functional powder is easily left in a small hole or a gap in the rock surface, and has strong durability on inhibition of a damage of the water lock. In addition, compared with an acidification method, the flow-back effect of the method is greatly improved, so that the water lock effect can be better solved; the productivity of an oil well is greatly also improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Polyacrylamide polymer viscosity reducer

ActiveCN105419772AFast viscosity reductionEasy to flow backFluid removalDrilling compositionPolymer scienceFracturing fluid

The invention relates to a polyacrylamide polymer viscosity reducer. The polyacrylamide polymer viscosity reducer comprises the following components by mass part: 2.2-30% of a mineralization degree conditioning agent, 0.1-0.5% of a viscosity conditioning agent, 0.1-0.5% of a surfactant, 0.5-2% of a corrosion inhibitor, 0.1-1% of a cleaning compound and the balance of water; wherein a sum of the mass percentages of the components is 100%. The provided viscosity reducer can rapidly reduce viscosity of the polyacrylamide polymer and reduces the viscosity of polyacrylamide polymer fracturing fluid, the viscosity of the liquid after viscosity reduction tends to the viscosity of water, and flowback of the liquid is easily carried out.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of fracturing coal-bed gas reservoir

ActiveCN106337676AWon't clogReduce harmFluid removalDrilling compositionSoil scienceFracturing fluid

The invention discloses a method of fracturing a coal-bed gas reservoir and belongs to the field of coal-bed gas exploitation. The method comprises following steps: after perforation in a middle-upper part of the coal bed and a coal bed top board above the coal bed, active water fracturing fluid is pumped and injected in the coal bed top board to form a first crack; low sand ratio sand-carrying fluid and high sand ratio sand-carrying fluid are successively pumped and injected into the first crack, and a second crack communicated with the first crack is formed in the coal bed, and the extension of the second crack is promoted to form multiple branchlike cracks containing sand support agent. The low sand ratio sand-carrying fluid comprises following components by percentage of mass: 0.1-0.3% carboxymethyl hydroxypropyl guanidine gum, 1-2% KCl, 0.5-1% discharge aiding agent, 8-12% sand support agent, and water as balance; the high sand ratio sand-carrying fluid comprises following components by percentage of mass: 0.1-0.3% carboxymethyl hydroxypropyl guanidine gum, 1-2% KCl, 0.5-1% discharge aiding agent, 12-48% sand support agent, and water as balance. The method provided by the invention can form a long distance supporting seam network in the coal-bed gas reservoir, and effectively improve the yield of the coal-bed gas reservoir.

Owner:PETROCHINA CO LTD

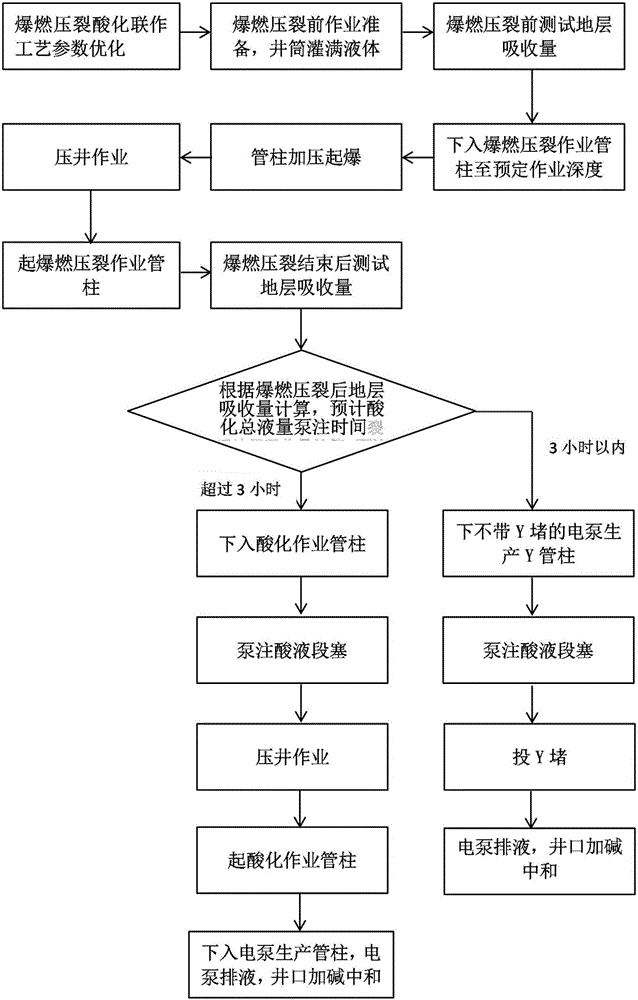

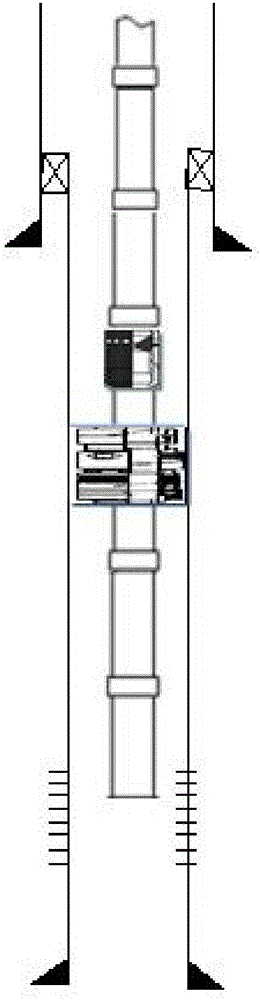

Method for detonation fracture acidizing combined operation

ActiveCN106246156AEnhancing the effectiveness of deflagration fracturingGuaranteed work effectFluid removalDrilling compositionWell killDetonation

The invention discloses a method for detonation fracture acidizing combined operation. The method comprises the steps of optimizing detonation fracture acidizing combined operation process parameters, performing operation preparation before detonation fracture and filling a pitshaft with liquid, testing stratum absorption amount before the detonation fracture, placing a detonation fracture operation tubular column to a predetermined operation depth, performing pressurization detonation of the tubular column, performing well killing operation, detonating the fracture operation tubular column, testing the stratum absorption amount after the detonation fracture, placing an acidizing operation tubular column, performing pumping injection acid liquid slug, lifting the acidizing operation tubular column, placing an electric pump production tubular column and performing electric pump liquid drainage and well opening alkalifying neutralization, placing an electric pump production Y tubular column without a Y tubular column, performing pumping injection of acid liquid slug, placing the Y tubular column, performing electric pump liquid drainage and well opening alkalifying neutralization and the like. The method has the advantages that detonation fracture and acidizing effects can be further enhanced, the acid liquid injection capability is enhanced, the acidizing radius is expanded, crack closure is further avoided, and a physical effect is enhanced; a detonation fracture effect can be enhanced, a follow-up acidizing step is selected flexibly, and the operation step is omitted while an operation effect can be guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Composite inhibitor of natural gas hydrate and application of composite inhibitor

InactiveCN106281280AEnhanced inhibitory effectInhibitivePipeline systemsDrilling compositionKinetic InhibitorDual effect

The invention relates to a composite inhibitor of natural gas hydrate. The composite inhibitor is prepared from 0.5 to 2 parts of a kinetic inhibitor, 0 to 15 parts of a thermodynamic inhibitor, 0.5 to 1.5 parts of an anti-agglomeration agent and 81.5 to 99 parts of a matrix. The inhibitor provided by the invention is used in a compounding manner, small in adding amount and good in economical efficiency; temperature and pressure of generating the hydrate can be effectively reduced; in a utilization process, the composite inhibitor is convenient to prepare on site, a pumping speed is repid and precious working time is saved; the inhibitor has relatively low surface tension and rapid backflow of residual liquid after working is finished is convenient to realize; the inhibitor can be matched with an anti-swelling agent and the aim of stabilizing a stratum is realized; the inhibitor can also be matched with quick water, so that the inhibitor has dual effect and does not need to work independently, and a lot of human and material resources can be saved.

Owner:北京千永科技股份有限公司

Resistance reduction agent for oil well fracturing and preparation method of resistance reduction agent

InactiveCN105238383ARaw materials are easy to getSimple processDrilling compositionSolubilityHydrophilic monomer

The invention provides a resistance reduction agent for oil well fracturing. The resistance reduction agent for oil well fracturing comprises components A and components B., and the ratio of the components A to the components B is 20:80. The components A comprise 25-37.5 parts of acrylamide, 5-50 parts of hydrophilic monomers, 2.5-10 parts of sodium hydroxide, 1.25 parts of persulfate and 150.25-215.25 parts of water. The components B comprise 450-880 parts of hydrophobic monomers, 100-400 parts of spans, 10-100 parts of alkylphenol ethoxylates and 10-50 parts of alcohol amine salt type anionic fluorocarbon surfactants. Raw materials of the resistance reduction agent are easy to obtain, the preparation technology is simple, water solubility is good, friction resistance is reduced by more than 60%, the interface tension is below 10-2 mN / m after gel breaking, when the resistance reduction agent is used, fast flowback can be achieved while no discharge adding agent needs to be added, and wide application prospects are achieved.

Owner:西安长庆化工集团有限公司

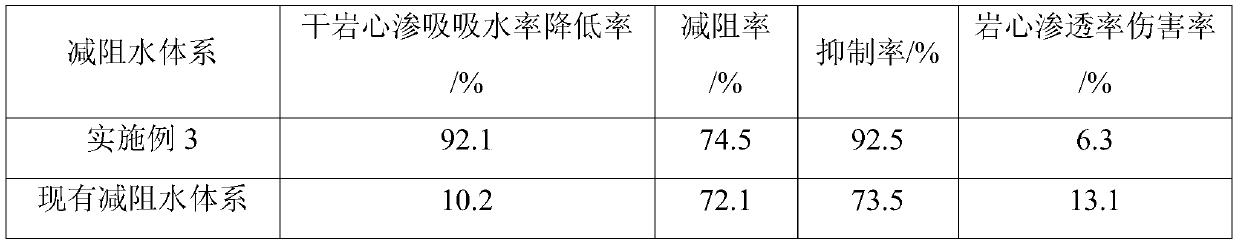

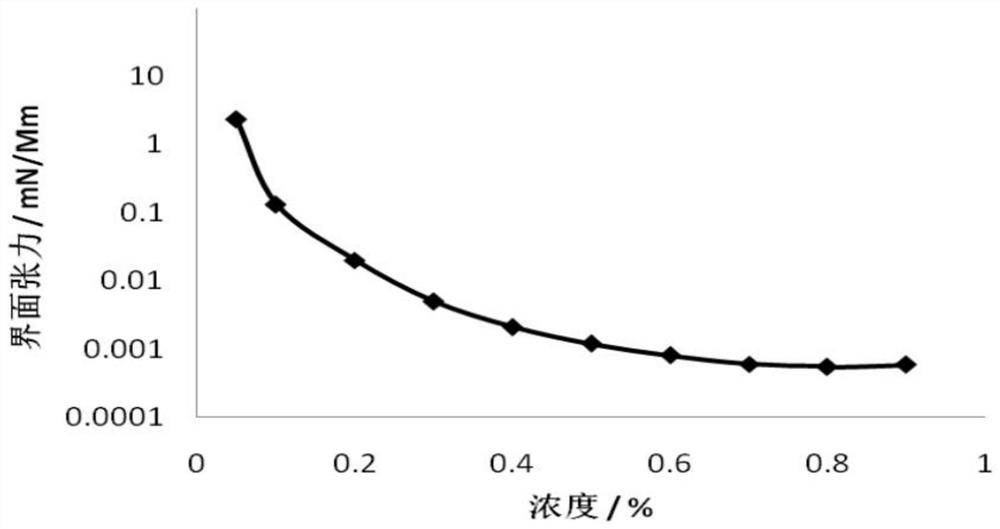

Multifunctional drag reduction water system for continental shale gas fracturing and preparation method thereof

ActiveCN110760299AReduce harmConducive to promoting green developmentDrilling compositionClay mineralsChemical reaction

The invention relates to a multifunctional drag reduction water system for continental shale gas fracturing and a preparation method thereof. The multifunctional drag reduction water system for continental shale gas fracturing comprises the following components in percentages by mass: 0.02% to 0.05% of a resistance reducing agent, 0.5% to 1% of an inhibitor, 0.1% to 0.3% of an antiscaling agent, 0.001% to 0.003% of a synergist, 0.2% to 0.5% of a regulator and the balance of water. The multifunctional drag reduction water system provided by the invention has the characteristics of high drag reduction rate, high inhibition, permeability reduction, adsorption reduction and the like, clay mineral expansion and clay particle migration can be inhibited, a seepage channel is kept smooth, water-rock physical and chemical reactions are effectively inhibited, a fracturing fluid is promoted to flow back quickly, the adsorption damage of the fracturing fluid is reduced, the requirement of continental shale gas fracturing construction is met, the damage of the drag reduction water fracturing fluid to a reservoir is reduced, and efficient development of terrestrial shale gas is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

High efficiency fracturing method using coiled tubing water-jet and soluble rubber plugs

InactiveCN106321050ARelieve pressureSolve the real problemFluid removalDrilling compositionTubing hangerCoiled tubing

The invention provides a high efficiency fracturing method using coiled tubing water-jet and soluble rubber plugs. The high efficiency fracturing method includes a sandblast and perforation stage, an annulus sand fracturing stage, a soluble rubber plug injection stage, a replacement stage, a curing and pressure test stage, and a blowout stage. The soluble rubber plugs are used as sealing members, the number of fracturing segments is not limited, the situation that sand blocks pipes can be avoided, gel-breaking of the rubber plugs can be controlled during construction, gel-breaking and rapid flow-back can be achieved at the same, and the construction efficiency and the successful rate can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microfoam acid liquid and preparation method thereof

The invention belongs to the technical field of foam acid and discloses microfoam acid liquid, constitution of a compound foaming agent of the microfoam acid liquid and a preparation method of the microfoam acid liquid. The microfoam acid liquid contains the following components in percentage by mass (100% in total): 10%-25% of HCl (hydrochloric acid), 0.36% of SDJR-2 (compound foaming agent), 0.24% of SBW-101 (foam stabilizer), 0.2% of FS3802 (thickening agent) and the balance of water, wherein the compound foaming agent SDJR-2 contains 55.56% of an FBM-5-2 foaming agent and 44.44% of an AK-304 foaming agent. The microfoam acid liquid has good properties of foaming, foam stabilization, viscosity maintenance, acid rock reaction retardance, temperature resistance, salt resistance, oil resistance, sand carrying and the like; by observing through an optical microscope, the microstructure and size of the microfoam acid liquid meet the dimensional requirement of microfoams; experimental evaluation shows that the microfoam acid liquid is a novel acid liquid system with excellent performance and has wide application prospects.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

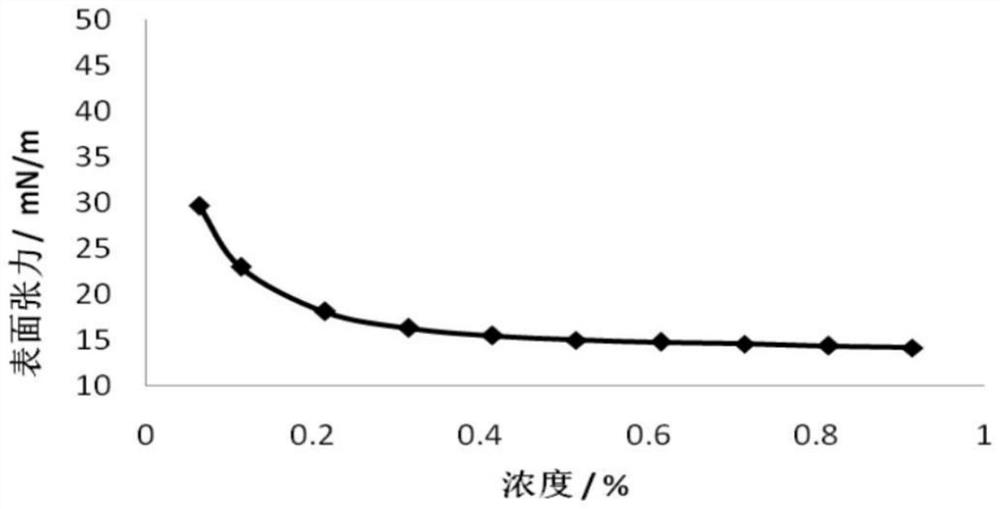

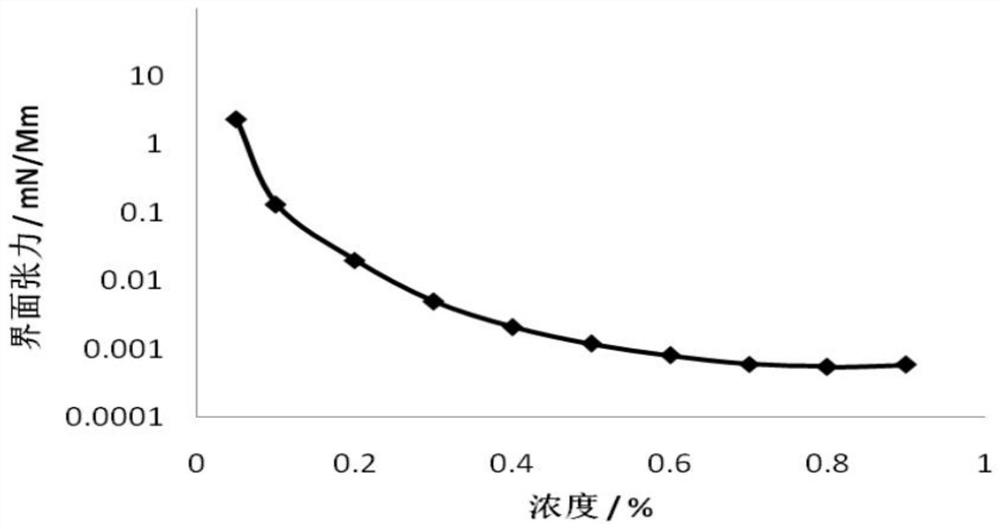

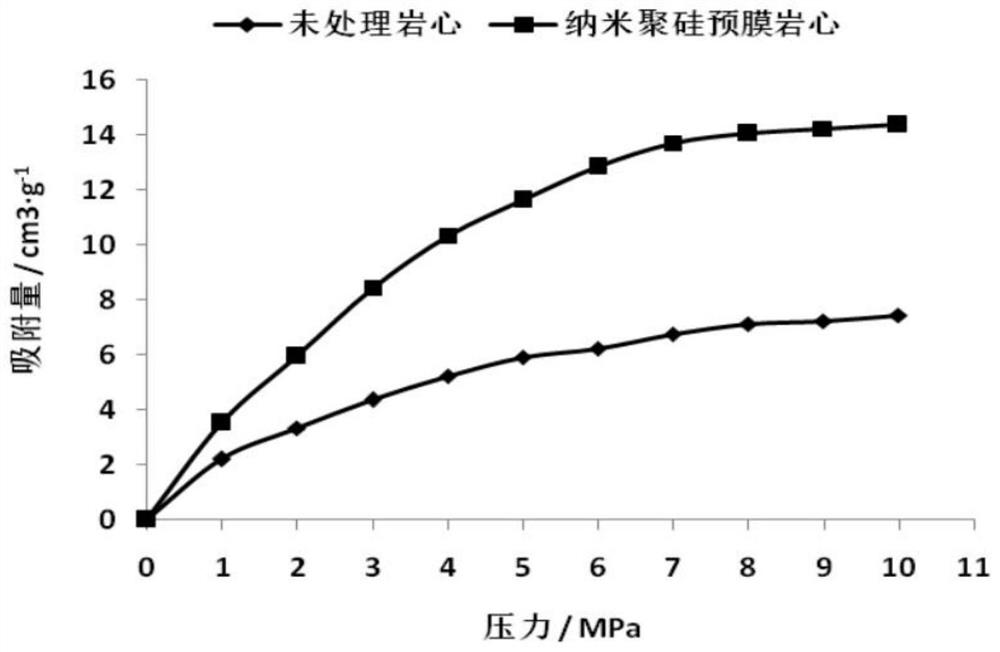

Formula and preparation method of low-pressure gas field old well re-production liquid locking removal treatment agent

ActiveCN112029490ARealize the goal of resuming production and increasing productionReduce surface tensionDrilling compositionActive agentSurface-active agents

The invention discloses a formula and a preparation method of a low-pressure gas field old well re-production liquid locking removal treatment agent. The low-pressure gas field old well re-productionliquid locking removal treatment agent comprises the following components by weight: 0.1-0.4% of a surface treatment agent, 0.05-0.3% of a nanometer material, 3-8% of a dispersant, 10-18% of a cleaning agent, 18-32% of a mutual solvent, 2-12% of a wetting reversal agent, and the balance industrial tap water. The treating agent can reduce liquid surface tension and oil-water interfacial tension ofa near wellbore area, reduce capillary resistance of a liquid, improve the contact angle of the liquid and rock and change rock surface wettability, and the effective period of the treated rock surface is prolonged through the dual adsorption effect of a nano material and a surfactant.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

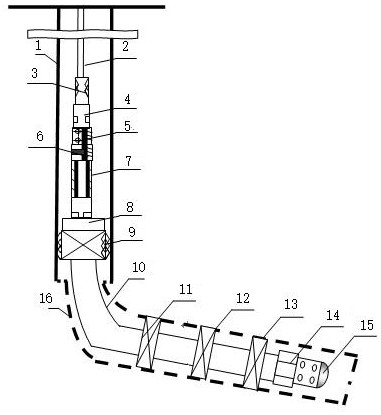

Coiled tubing and packer combined staged fracturing string and method for slim hole well

ActiveCN112211601AAvoid the risk of inaccurate pre-perforated sectionsLong extension distanceFluid removalSealing/packingSand blastingCoiled tubing

The invention provides a coiled tubing and packer combined staged fracturing string and method for a slim hole well. The string comprises a casing pipe, a coiled tubing, a connector, a hydraulic safety release, a hydraulic sandblaster, an upper packer, a sliding sleeve base, a reducing release tie-back barrel, a lower packer, an oil pipe, a plurality of bottom packers, a float collar, a guide screen pipe and an open hole section, the coiled tubing is located in the casing pipe, and the lower end of the coiled tubing is connected with the hydraulic safety release through the connector. The string is lowered to a preset position of a target reservoir, steel balls of the specified specification are pumped to set the packer, the fracturing string is released, packing of an original reservoir and a new reservoir transformation section is achieved, then segment-by-segment transformation is conducted through the fracturing string, after transformation is completed, the fracturing string is pulled out, and a production string is lowered; and after the reservoir is transformed, a wellbore has a full bore, the later wellbore maintenance and treatment difficulty and operation risk are reduced, and later secondary transformation is facilitated.

Owner:PETROCHINA CO LTD

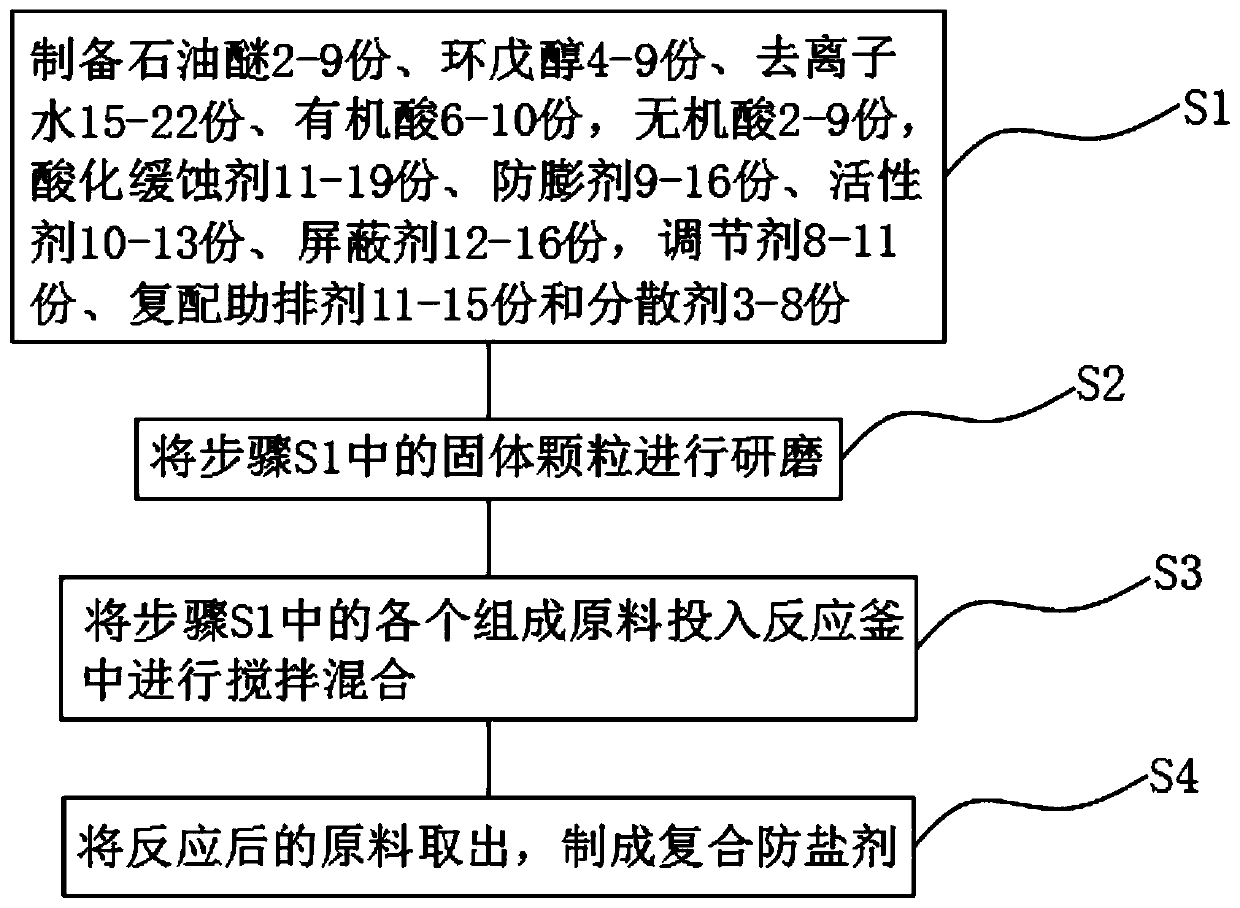

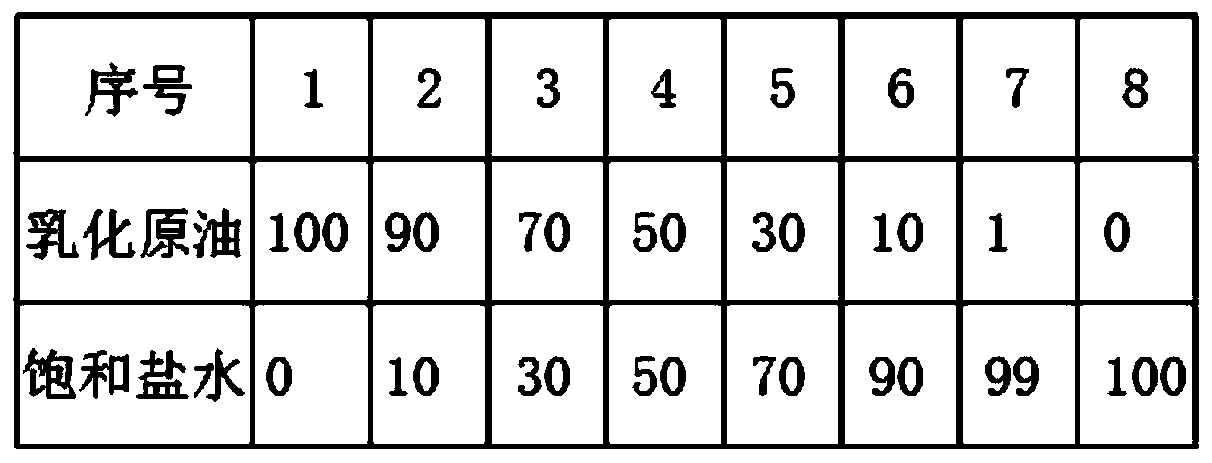

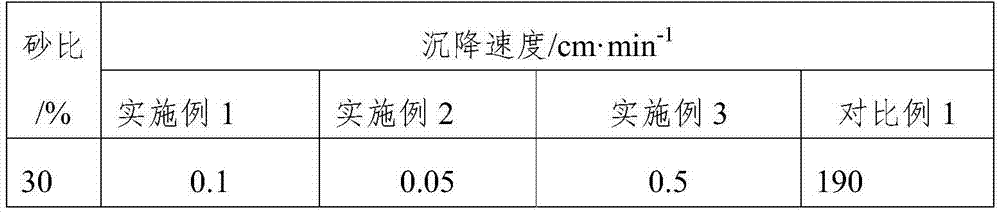

Production method of composite preventive salt for salt prevention and blocking removal in shaft

InactiveCN109796952AImprove solubilityInhibition of salt precipitationDrilling compositionOrganic acidCyclopentanol

The invention discloses a production method of a composite preventive salt for salt prevention and blocking removal in a shaft. The composite anti-salt production method comprises the steps of S1, preparing, 2-9 parts of petroleum ether, 4-9 parts of cyclopentanol, 15-22 parts of deionized water, 6-10 parts of an organic acid, 2-9 parts of an inorganic acid, 11-19 parts of an acidizing corrosion inhibitor, 9-16 parts of an anti-swelling agent, 10-13 parts of an activator, 12-16 parts of a shielding agent, 8-11 parts of a regulating agent, 11-15 parts of a complex cleanup additive, and 3-8 parts of a dispersant; S2, grinding the solid particles of the step S1; S3, adding the components of the step S1 into a reactor, and mixing; S4, extracting the reacted material to obtain a composite preventive salt. The composite preventive salt agent helps improve NaCl solubility, the NaCl with improved solubility exists in ion form, and massive salt deposition from a formation is inhibited.

Owner:曹高维

Acid solution system capable of relieving damage of mud to low-permeability reservoir

InactiveCN104059624ASlow reaction speedSlow responseDrilling compositionEthylmethane SulfonateClay minerals

The invention discloses an acid solution system capable of relieving damage of mud to a low-permeability reservoir, which is composed of the following components in percentage by weight: 5-10% of methyl sulfonic acid derivative, 2-5% of isoascorbic acid, 0.5-1% of nonionic surfactant, 0.1-0.5% of corrosion inhibitor, 3-5% of hydrofluoric acid, 3-10% of low-polymer alcohol and the balance of water. The methyl sulfonic acid derivative is aminomethane sulfonate, ethyl methanesulfonate, methyl methanesulfonate, methanesulfonic acid or mixture thereof; the nonionic surfactant is fatty alcohol polyethenoxy ether; the corrosion inhibitor is imidazoline quaternary ammonium salt; and the low-polymer alcohol is methanol, ethanol, isopropanol or mixture thereof. The system can effectively relieve damage of clay minerals in drilling mud to the reservoir, and can restore the permeability of the reservoir, so that oil gas can flow into the shaft from the stratum; and thus, the system has important practical meanings.

Owner:SOUTHWEST PETROLEUM UNIV

Filtrate loss reducer and application thereof to non-tackifying pure liquid-state CO2 sand fracturing

ActiveCN106833594AReduce fluid lossHigh viscosityFluid removalDrilling compositionWater basedEcological environment

The invention discloses a filtrate loss reducer. The filtrate loss reducer is prepared from the following raw materials in parts by weight: 10-25 parts of 5# white oil, 0.5-2 parts of NP-1, 0.1-1 part of TX-4, 1-10 parts of n-caprylic acid, 1-10 parts of KCl, 4-15 parts of a carboxymethyl guanidine gum solution with the concentration of 1%. According to the filtrate loss reducer, the sand carrying capability of pure liquid-state CO2 fracturing liquid can be improved and the loss of the fracturing liquid is effectively reduced. Meanwhile, the invention further provides application of the filtrate loss reducer to a pure liquid-state CO2 sand fracturing process; the filtrate loss reducer is pumped into a stratum before pure liquid-state CO2 fracturing is constructed, and the sand fracturing is carried out; the filtrate loss reducer has the advantages of rapid backflow, increased backflow rate, shortened period of putting into production and the like; and water-based fracturing liquid does not need to be prepared in the process and backflow liquid does not need to be treated, so that the environment pollution degree is reduced, and the filtrate loss reducer has relatively good practical significance on regions with lacked water resources and regions with fragile ecological environments.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

A kind of multifunctional drag reducing water system and preparation method for continental shale gas fracturing

ActiveCN110760299BReduce harmConducive to promoting green developmentDrilling compositionClay mineralsChemical reaction

The present invention relates to a multifunctional drag-reducing water system for continental shale gas fracturing and a preparation method thereof. The components and mass percentages of the multifunctional drag-reducing water system for continental shale gas fracturing are as follows: Drag reducer 0.02-0.05%, inhibitor 0.5-1%, anti-scaling agent 0.1-0.3%, synergist 0.001-0.003%, regulator 0.2-0.5%, and the balance is water. The multi-functional drag-reducing water system provided by the present invention has the characteristics of high drag-reducing rate, strong suppression, reduced imbibition, and reduced adsorption. , chemical reaction, promote the rapid flowback of fracturing fluid, reduce the adsorption damage of fracturing fluid, meet the requirements of continental shale gas fracturing construction, reduce the damage of drag-reducing water fracturing fluid to reservoirs, and realize continental shale Efficient development of gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil and gas field exploitation method

InactiveCN106930745ALow costReduce labor intensityFluid removalUltimate tensile strengthNatural water

The invention provides an oil and gas field exploitation method. The oil and gas field exploitation method comprises the steps that 5-60 parts of self-suspension proppants are added into 100 parts of natural water by volume to form proppant suspension liquid; and then the proppant suspension liquid is conveyed into an underground rock stratum. According to the oil and gas field exploitation method, the natural water is directly used as sand carrying liquid, no thickener is needed, and cost of construction liquid is remarkably reduced. No fracturing liquid needs to be prepared, the number of construction equipment is decreased, the construction process is simplified, the construction time is shortened, and the labor intensity of workers is relieved. The natural water contains no thickener, has little damage to a reservoir and is good in yield increasing effect. Stratum water is not polluted, and the environment is protected.

Owner:BEIJING RECHSAND SCI & TECH GRP

Guar gum fracturing fluid for ultrahigh-temperature reservoirs and method for preparing guar gum fracturing fluid

InactiveCN108795402AReduce harmGuarantee the sand-carrying performance of fracture makingDrilling compositionPolymer scienceFracturing fluid

The invention relates to guar gum fracturing fluid for ultrahigh-temperature reservoirs and a method for preparing the guar gum fracturing fluid. The guar gum fracturing fluid and the method have theadvantages that the seam generating and sand carrying performance of the guar gum fracturing fluid can be guaranteed under the condition that the temperatures of the reservoirs are higher than 140 DEGC, the guar gum fracturing fluid is particularly suitable for fracturing and production increase of high-temperature and ultrahigh-temperature sandstone and carbonate reservoirs and is low in surfaceinterfacial tension, residue content and friction drag, good in stratum viscose mineral stability and high in flow back speed, damage on the reservoirs due to fluid can be effectively reduced, fracturing transformation effects for the high-temperature and ultrahigh-temperature reservoirs and effects of production increase transformation measures can be improved, and the oil and gas recovery ratios of the high-temperature reservoirs can be increased.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

Multi-hydrogen acid system suitable for reservoir plugging-removing acidification and preparing method thereof

InactiveCN109777389AHigh activityStrong smooth performanceDrilling compositionPhosphoric acidPotassium

The invention belongs to a multi-hydrogen acid system suitable for reservoir plugging-removing acidification and a preparing method thereof. The multi-hydrogen acid system is prepared from, by weight,30-60 parts of hydrochloric acid, 7-12 parts of multi-hydrogen acid, 3-6 parts of a multipurpose additive, 2-4 parts of a shrinking agent, 1-3 parts of an activating agent, 3-8 parts of an initiatingagent, 2-4 parts of a corrosion inhibitor and 3-52 parts of water; the hydrochloric acid is selected from industrial hydrochloric acid with the HCL content of 28% to 31%; the multi-hydrogen acid is selected from one of citric acid, phosphoric acid, oxalic acid and sulfuric acid or a mixture of citric acid, phosphoric acid, oxalic acid and sulfuric acid; the multipurpose additive is a mixture of afluorocarbon surfactant, potassium amine triacetate, potassium chloride and water; the activating agent is selected from one of a demulsifying agent AE1910, a demulsifying agent 1031 and polyethenoxyether or a mixture of a demulsifying agent AE1910, a demulsifying agent 1031 and polyethenoxy ether; the initiating agent is peracetic acid. The multi-hydrogen acid system has the advantages that theacid liquor activity, H+ mild releasing and the buffering effect are achieved, and the multi-hydrogen acid system is suitable for reservoir plugging-removing acidification.

Owner:北京国海能源技术研究院

A high-efficiency self-produced gas foam fracturing fluid and its construction method

ActiveCN109762549BImprove liquiditySimplify field processesFluid removalDrilling compositionToxic gasThermodynamics

The present invention provides a high-efficiency self-generated gas foam fracturing fluid and a construction method. The foam fracturing fluid is composed of a base fluid, a gas-generating fluid and a heat-generating agent, wherein the mass ratio of the base fluid, gas-generating fluid, and heat-generating agent is 100: (30‑42): (5‑9). During construction, the base fluid and the gas-producing fluid are pumped downhole together through the suction of the sand mixing truck according to the mass ratio, and the heat generating agent is pumped into the downhole along with the proppant. The invention does not need liquid nitrogen accompanying injection, simplifies the on-site process and reduces the construction cost, and a large amount of gas generated through the chemical reaction achieves the purpose of increasing the energy of the formation, improving the flow capacity of the reservoir liquid, and increasing the output. It can quickly generate a large amount of inert and safe gas, and will not produce toxic gas of nitrogen oxides, reducing construction risks. At the same time, the alkaline environment generated by the reaction product is conducive to the formation of fracturing fluid gel and the corrosion protection of downhole pipe strings. By generating foam, the Jiamin effect is used to increase the net pressure of the formation, which can quickly flow back, generate heat in the deep formation to promote gel breaking, and reduce the damage of fracturing fluid to the reservoir.

Owner:PETROCHINA CO LTD

A formula of a low-pressure gas field old well recovery liquid lock treatment agent and its preparation method

ActiveCN112029490BRealize the goal of resuming production and increasing productionReduce surface tensionDrilling compositionActive agentTap water

The invention discloses a formula of a low-pressure gas field old well re-production unlocking treatment agent and a preparation method thereof, which, in terms of weight percentage, are composed of the following components: 0.1-0.4% of a surface treatment agent, 0.05-0.3% of a nanomaterial %, dispersant 3-8%, cleaning agent 10-18%, mutual solvent 18-32%, wetting reversal agent 2-12%, industrial tap water to make up the balance. The liquid unlocking treatment agent of the invention can reduce the liquid surface tension and the oil-water interfacial tension in the near-wellbore zone, reduce the capillary resistance of the liquid, increase the contact angle between the liquid and the rock, and change the wettability of the rock surface. , prolong the effective period of rock surface treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of fluid loss reducer and its non-viscosifying pure liquid co 2 Application in sand fracturing

ActiveCN106833594BReduce fluid lossHigh viscosityFluid removalDrilling compositionEcological environmentLiquid state

The invention discloses a filtrate loss reducer. The filtrate loss reducer is prepared from the following raw materials in parts by weight: 10-25 parts of 5# white oil, 0.5-2 parts of NP-1, 0.1-1 part of TX-4, 1-10 parts of n-caprylic acid, 1-10 parts of KCl, 4-15 parts of a carboxymethyl guanidine gum solution with the concentration of 1%. According to the filtrate loss reducer, the sand carrying capability of pure liquid-state CO2 fracturing liquid can be improved and the loss of the fracturing liquid is effectively reduced. Meanwhile, the invention further provides application of the filtrate loss reducer to a pure liquid-state CO2 sand fracturing process; the filtrate loss reducer is pumped into a stratum before pure liquid-state CO2 fracturing is constructed, and the sand fracturing is carried out; the filtrate loss reducer has the advantages of rapid backflow, increased backflow rate, shortened period of putting into production and the like; and water-based fracturing liquid does not need to be prepared in the process and backflow liquid does not need to be treated, so that the environment pollution degree is reduced, and the filtrate loss reducer has relatively good practical significance on regions with lacked water resources and regions with fragile ecological environments.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Strong bunching inhibition environment-friendly drilling completion fluid

The invention discloses a strong bunching inhibition environment-friendly drilling completion fluid which comprises 80-90 parts of a base liquid and 10-20 parts of a micro emulsion nano preparation, wherein the micro emulsion nano preparation consists of an oxidation gel breaker, a bio-enzyme gel breaker, an acidic gel breaker and a capsule shell; and the oxidation gel breaker and the bio-enzyme gel breaker and the bio-enzyme gel breaker and the acidic gel breaker are isolated by using wrapping membranes. By adopting the drilling completion fluid, a filtering shell can be thoroughly eliminated, the biodegradation flowback effect is good, a hydrocarbon reservoir can be prevented from damage since the fluid is nontoxic, the capacity of an oil and gas well can be increased to the maximum extent, and reservoir stratums can be sufficiently protected.

Owner:新疆大德广源石油技术服务有限公司

A kind of fracturing method of coalbed methane reservoir

ActiveCN106337676BWon't clogReduce harmFluid removalDrilling compositionSoil scienceFracturing fluid

The invention discloses a method of fracturing a coal-bed gas reservoir and belongs to the field of coal-bed gas exploitation. The method comprises following steps: after perforation in a middle-upper part of the coal bed and a coal bed top board above the coal bed, active water fracturing fluid is pumped and injected in the coal bed top board to form a first crack; low sand ratio sand-carrying fluid and high sand ratio sand-carrying fluid are successively pumped and injected into the first crack, and a second crack communicated with the first crack is formed in the coal bed, and the extension of the second crack is promoted to form multiple branchlike cracks containing sand support agent. The low sand ratio sand-carrying fluid comprises following components by percentage of mass: 0.1-0.3% carboxymethyl hydroxypropyl guanidine gum, 1-2% KCl, 0.5-1% discharge aiding agent, 8-12% sand support agent, and water as balance; the high sand ratio sand-carrying fluid comprises following components by percentage of mass: 0.1-0.3% carboxymethyl hydroxypropyl guanidine gum, 1-2% KCl, 0.5-1% discharge aiding agent, 12-48% sand support agent, and water as balance. The method provided by the invention can form a long distance supporting seam network in the coal-bed gas reservoir, and effectively improve the yield of the coal-bed gas reservoir.

Owner:PETROCHINA CO LTD

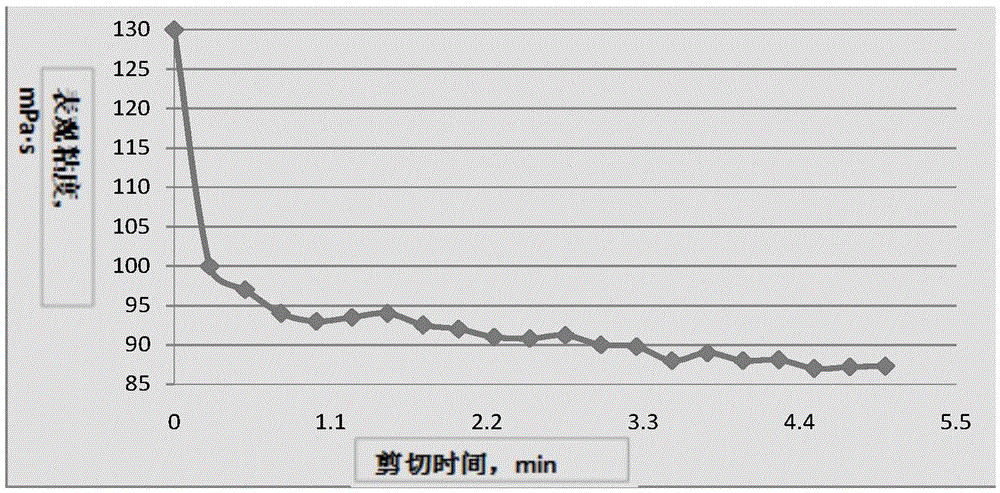

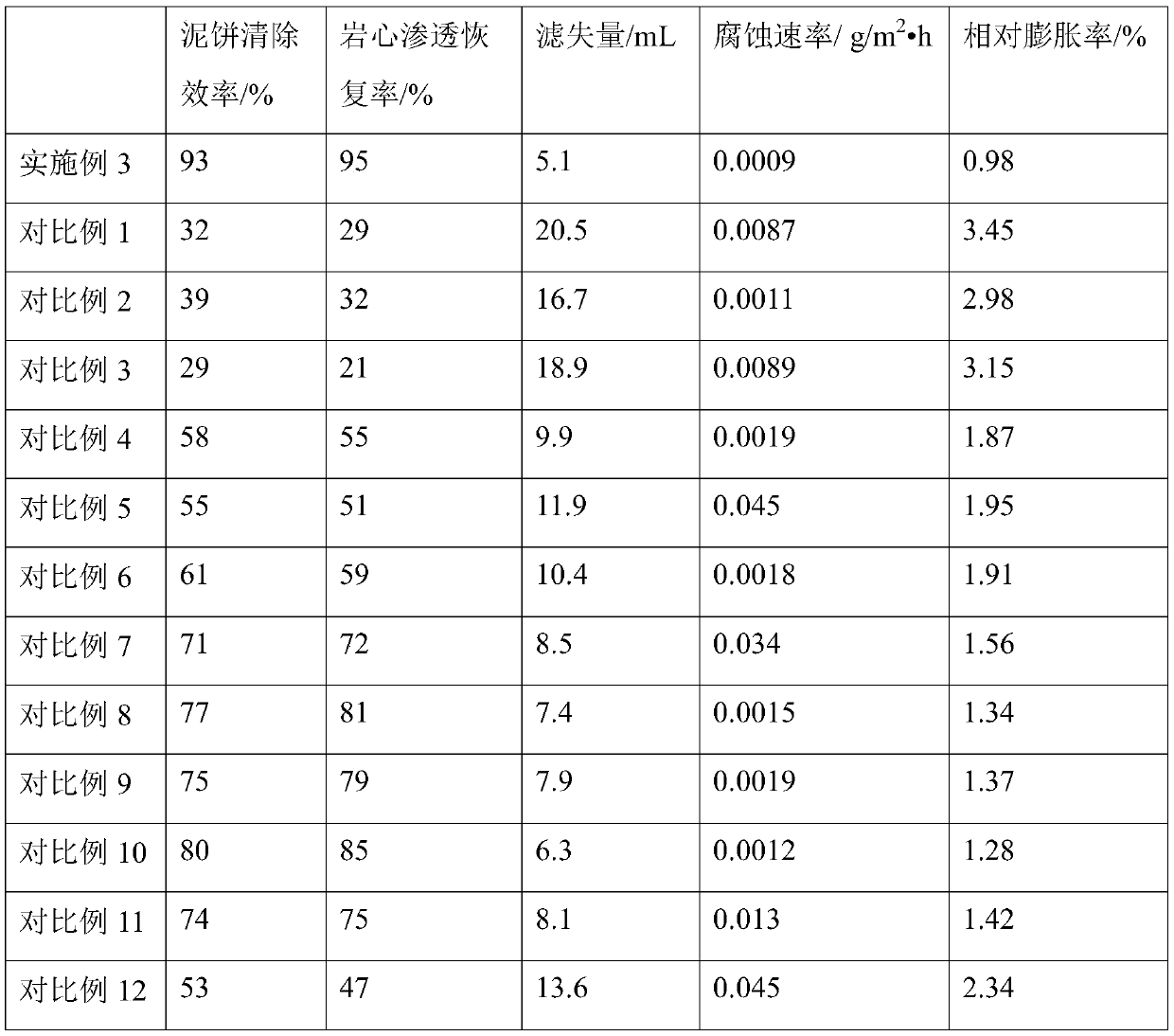

Polymer perforating fluid and preparation method thereof

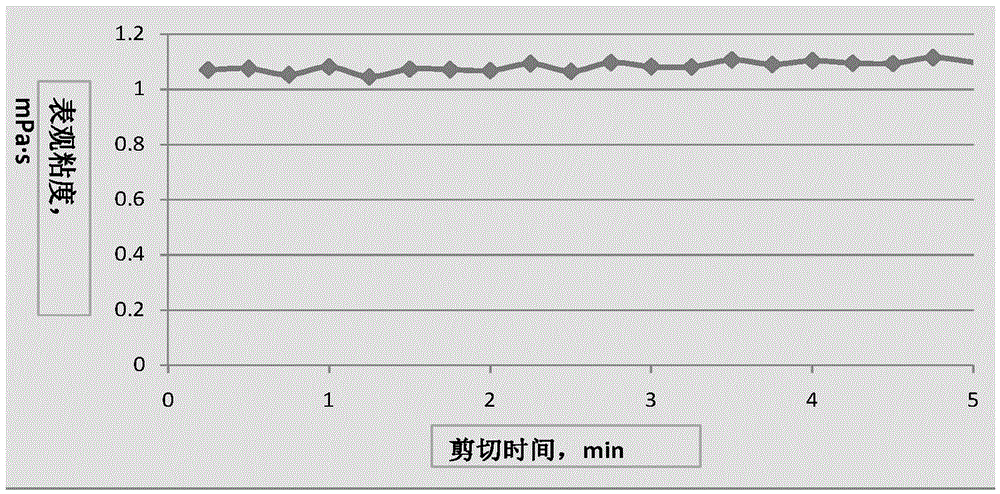

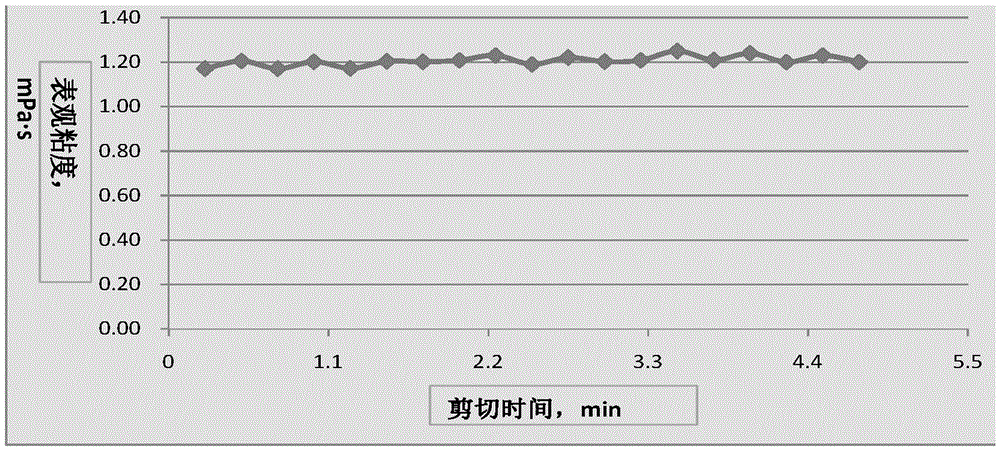

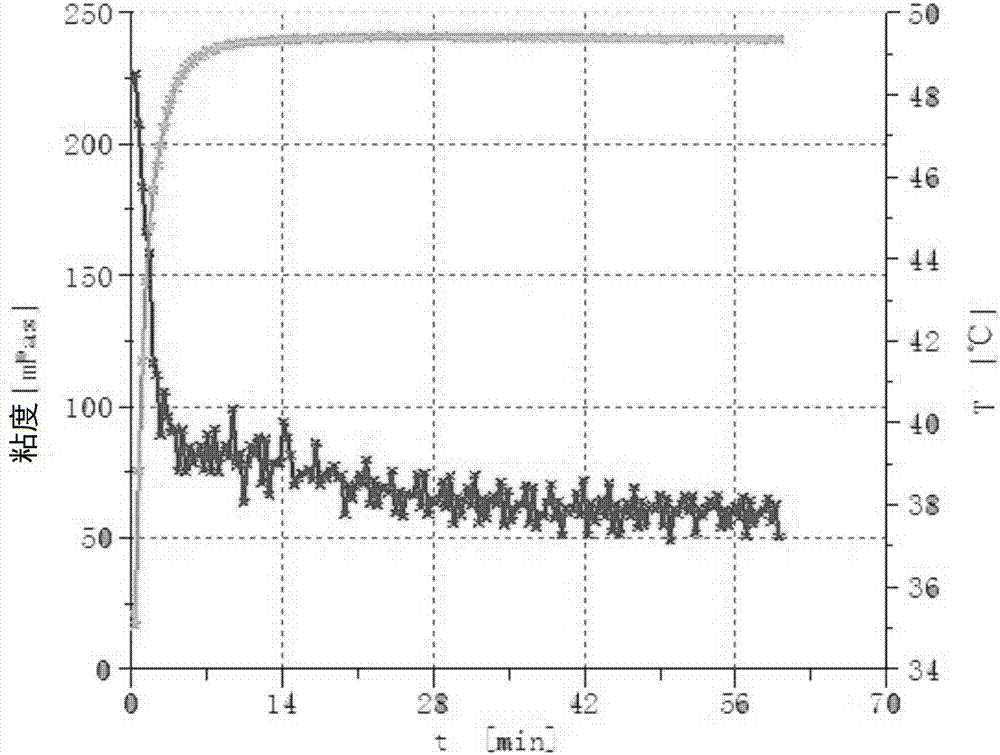

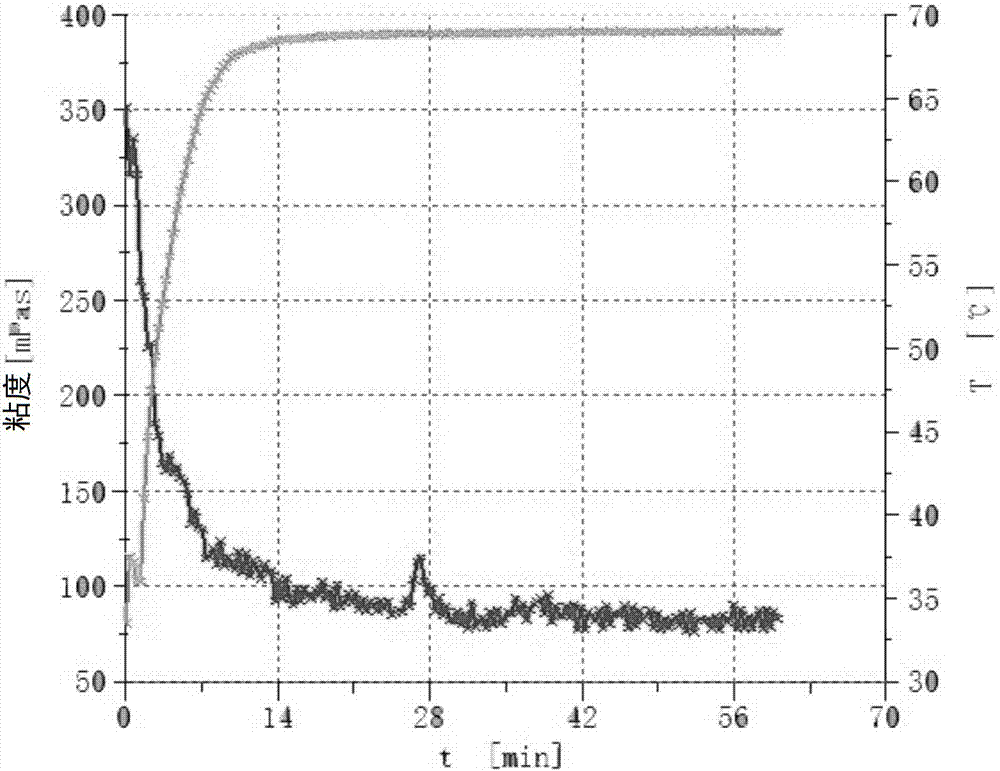

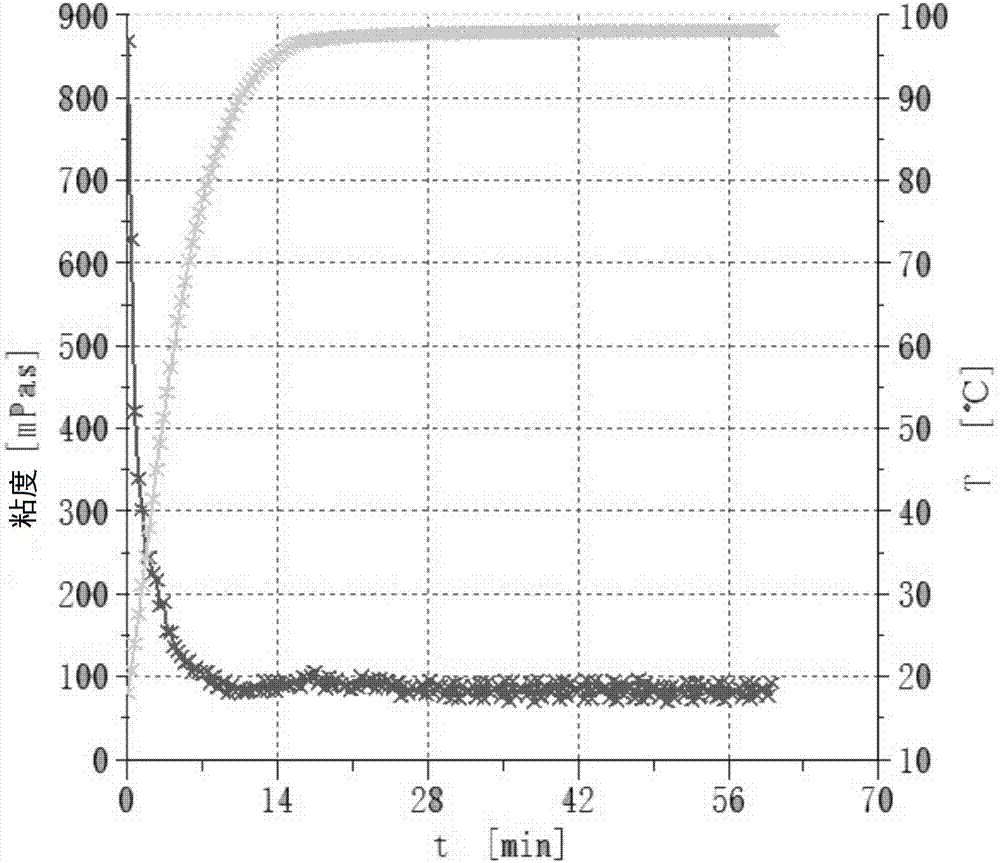

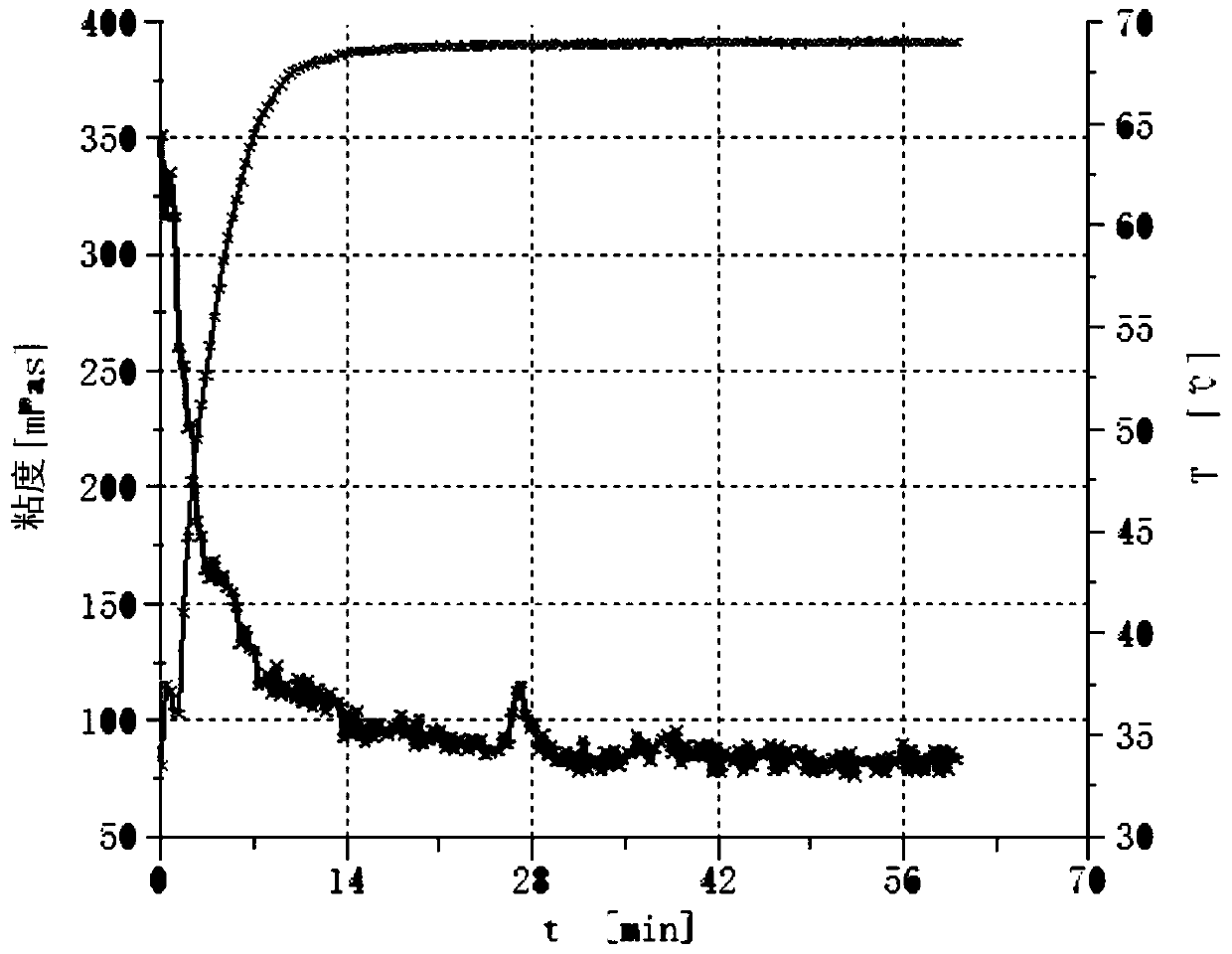

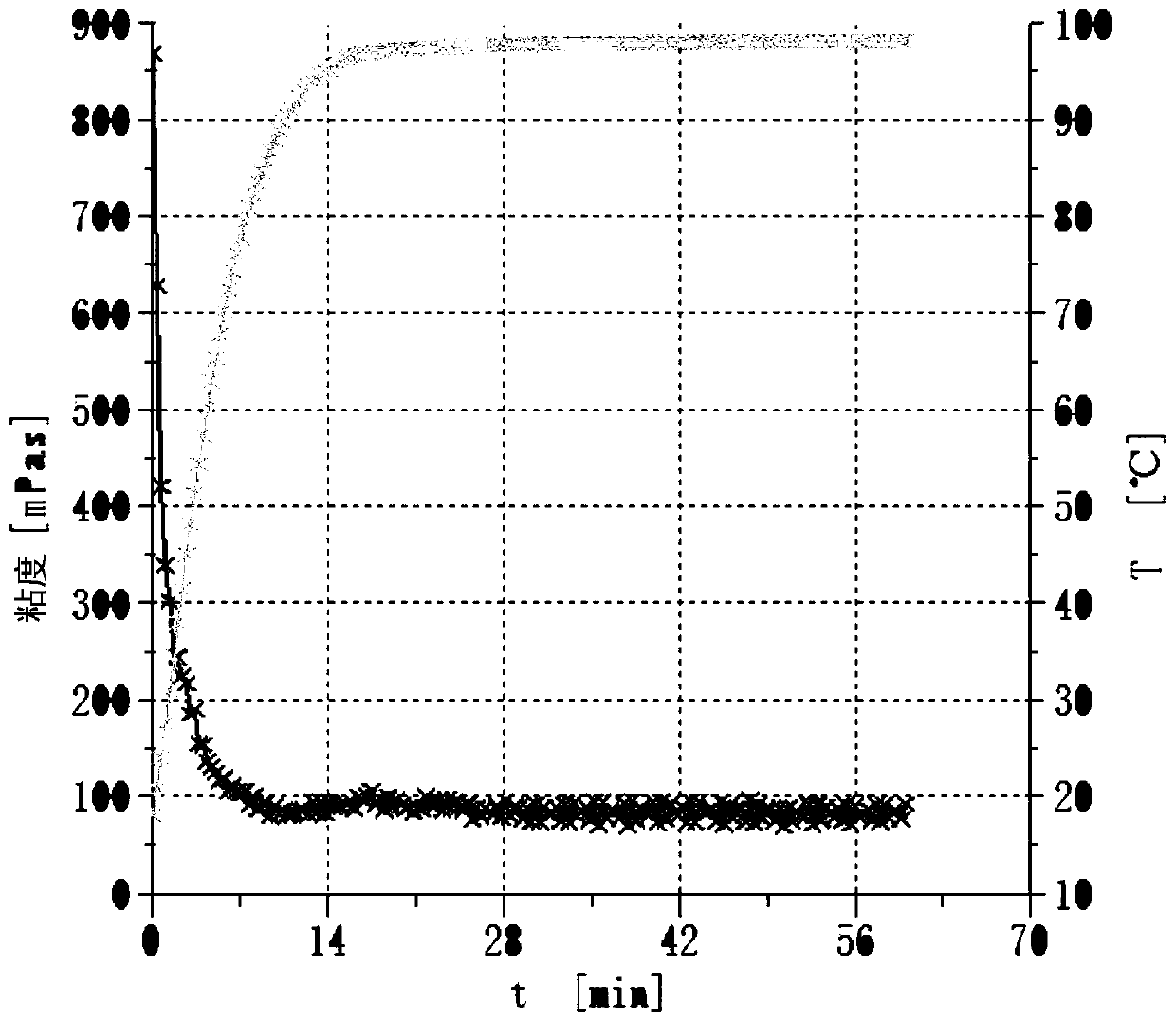

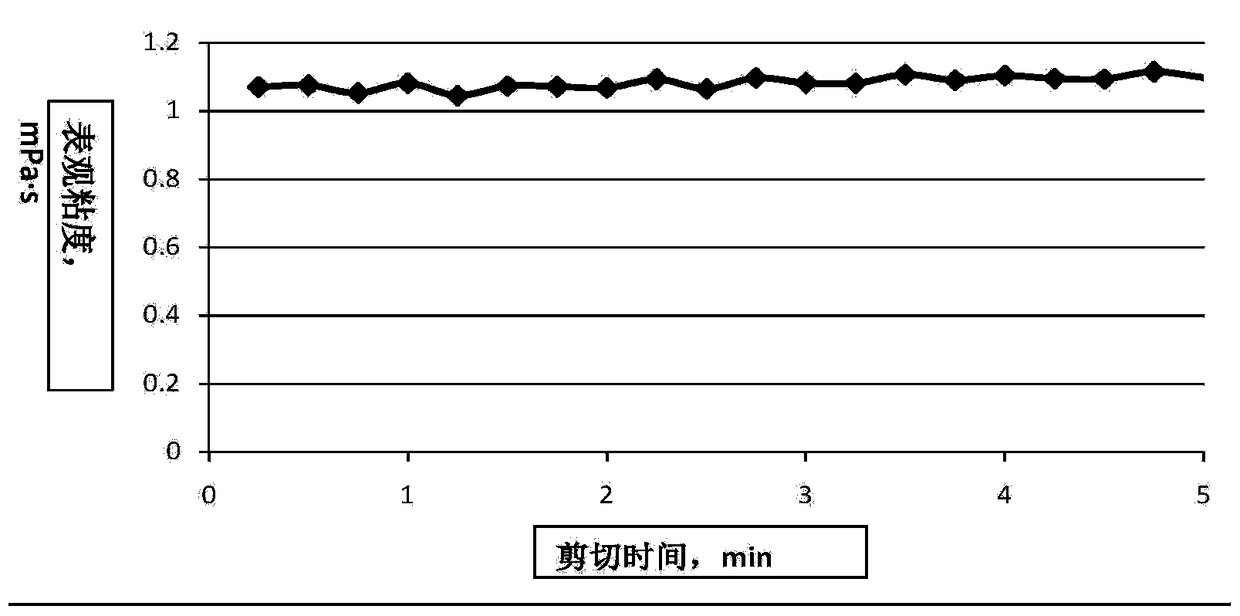

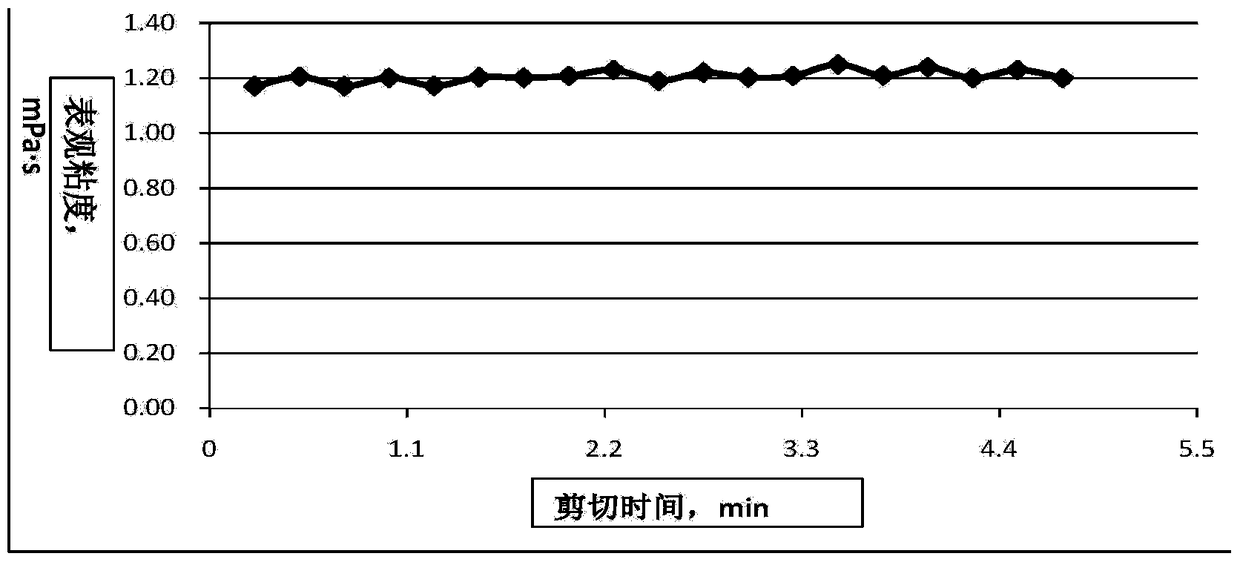

ActiveCN106967394AGood temperature and shear resistanceReduce interfacial tensionDrilling compositionA-weightingCorrosion

The invention discloses a polymer perforating fluid and a preparation method thereof. The polymer perforating fluid comprises, by mass, 0.25 to 0.45% of a polymer densifier, 12 to 26% of a weighting agent, 0.02 to 0.08% of a cleanup additive, 0.015 to 0.03% of a gel breaker and 0.55 to 2.5% of a temporary plugging agent, with the balance being water. The polymer perforating fluid provided by the invention has a density adjustable in a range of 1.10 to 1.25 g / cm<3> and has a viscosity of 50 mPa.s or above after shearing for 60 min under the conditions of a temperature of 50 to 100 DEG C and a rotating speed of 1000 / s; a gel-broken fluid has a viscosity of no more than 2 mPa.s and low interfacial tension and can rapidly flow back after construction; and the polymer perforating fluid is especially applicable to high-porosity high-permeability alkali-sensitive strata with abnormally high pressure and has the characteristics of adjustable density, leak-proof and leak-stopping performance, resistance to temperature and shearing, low fluid loss, low corrosion rate, low damage to rock cores, thorough gel breaking and easiness in flowback.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of polymer perforating fluid and preparation method thereof

ActiveCN106967394BGood temperature and shear resistanceImprove breaking performanceDrilling compositionPolymer scienceRock core

Owner:CHINA PETROLEUM & CHEM CORP +1

A method to solve the water lock effect

ActiveCN103450867BThe technical method is simpleEasy to operateDrilling compositionMetallurgyParticle density

Disclosed is a method for solving water block effect, the method comprising: adding functional powder to pores producing water block to eliminate the water block, the functional powder being amphiphilic powder, or mixed powder consisting of ultra-hydrophilic powder and hydrophobic powder, the particle density of the functional powder being greater than 1 g / cm3, and the average particle diameter of the functional powder being less than 100 microns. The method of the present invention is simple, easy, of low cost, and has wide sources of raw material. During the use of the method, the functional powder reduces liquid-phase interfacial tension, and has good durability for inhibiting water block damage because the functional powder is small solid particles easily held in tiny holes or cracks on rock surfaces. In addition, compared with an acidifying method, the present invention greatly improves the inverted discharge effect, better solving the water block effect, thus greatly improving the productivity of an oil well.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

A kind of viscosity reducer of polyacrylamide polymer

ActiveCN105419772BFast viscosity reductionEasy to flow backFluid removalDrilling compositionPolymer scienceFracturing fluid

The invention relates to a polyacrylamide polymer viscosity reducer. The polyacrylamide polymer viscosity reducer comprises the following components by mass part: 2.2-30% of a mineralization degree conditioning agent, 0.1-0.5% of a viscosity conditioning agent, 0.1-0.5% of a surfactant, 0.5-2% of a corrosion inhibitor, 0.1-1% of a cleaning compound and the balance of water; wherein a sum of the mass percentages of the components is 100%. The provided viscosity reducer can rapidly reduce viscosity of the polyacrylamide polymer and reduces the viscosity of polyacrylamide polymer fracturing fluid, the viscosity of the liquid after viscosity reduction tends to the viscosity of water, and flowback of the liquid is easily carried out.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid CO2 fracturing technology for shale gas well

ActiveCN102852508BMaximum fracturing effectMaximize the effect of fracturing stimulationFluid removalCo2 storageTruck

The invention relates to the technical field of shale gas exploitation, in particular to a liquid CO2 fracturing technology for a shale gas well. When the liquid CO2 fracturing technology is constructed, a fracturing pump truck, a sealed fracturing blender truck, a CO2 boosting pump truck, a measuring truck, a fracturing pipeline truck, a CO2 tank vehicle and a CO2 storage tank need to be arranged; the fracturing pipeline truck is provided with a pressure manifold and a high pressure manifold; and the measuring truck is provided with a monitoring instrument. The liquid CO2 fracturing technology is characterized in that the liquid CO2 fracturing technology is executed according to six steps of placing fracturing equipment and construction vehicles, testing the pressure, processing pre-acid, constructing liquid CO2 fracturing, closing the well after carrying out fracturing and opening the well for gushing and carrying out flowback after carrying out fracturing. The liquid CO2 fracturing technology for the shale gas well implements high flowback speed and short operation period and basically has harmlessness to a shale gas reservoir stratum.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Seawater-based polyamine well completion fluid and preparation method thereof

ActiveCN102002349BStrong anti-expansion suppression functionStrong chelating abilityDrilling compositionAqueous solutionPolyamine

The invention discloses seawater-based polyamine well completion fluid, which comprises the following components in percentage by weight: 0.1 to 10 percent of polyamine, 0.1 to 10 percent of alkali chelating agent, 0.1 to 10 percent of bactericide and the balance of aqueous solution. In addition, the invention also discloses a preparation method for the seawater-based polyamine well completion fluid. The method comprises the following steps of: adding the weighed aqueous solution, polyamine, alkali chelating agent and bactericide into a circulating pool provided with a stirring device in turn, and fully stirring and circulating the mixture to obtain the polyamine well completion fluid. The polyamine well completion fluid is neutral or alkali, and the pH is 7.5 to 8.5; and the polyamine well completion fluid has strong anti-swelling inhibition function (the anti-swelling rate is over 90 percent), strong chelating capability on high valent metal cations, low interfacial tension (generally less than 1mN / m) and little damage to reservoirs, and the permeability recovery value is over 95 percent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com