Coiled tubing and packer combined staged fracturing string and method for slim hole well

A staged fracturing and packer technology, applied in wellbore/well components, sealing/isolation, earthwork drilling and production, etc., can solve problems affecting wellbore maintenance and repeated reconstruction, and high construction risk, so as to benefit the later stage The effect of repeated transformation, expansion of transformation scale, reduction of maintenance and processing difficulty and operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

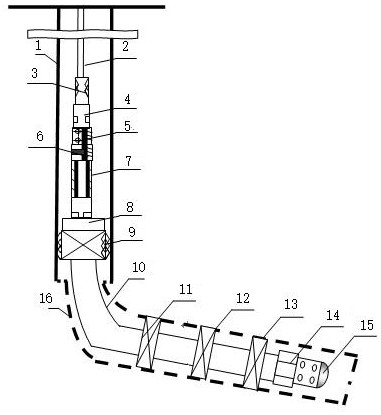

[0029] In order to overcome the existing problems of large construction risks and the influence of later wellbore maintenance and repeated transformation due to the diameter change in the pipe, the present invention provides such figure 1 In the shown slim-bore well, coiled tubing and packer are used as staged fracturing strings and methods. After reservoir reconstruction in the present invention, the wellbore has a full diameter, which reduces the difficulty of wellbore maintenance and operation risks in the later stage, and is conducive to later repetition. remodel.

[0030] Coiled tubing and packer are used as a staged fracturing string for slimhole wells, including casing 1, coiled tubing 2, connector 3, hydraulic safety handle 4, hydraulic sand blaster 5, upper packer 6, Sliding sleeve seat 7, variable diameter drop-back barrel 8, lower packer 9, tubing 10, multiple bottom packers, floating hoop 14, guide screen 15 and open hole section 16, the coiled tubing 2 is located ...

Embodiment 2

[0040] Based on Embodiment 1, in this embodiment, preferably, the variable-diameter throw-back sleeve 8 is a cylindrical structure with a small upper end and a larger lower end.

[0041] Preferably, the plurality of bottom packers are connected through short joints of tubing.

[0042] Preferably, the coiled tubing 2 has a pipe diameter of 1"~1½", and the casing 1 is a 5½" casing.

[0043] Preferably, the naked eye section 16 is a 4" naked eye section.

[0044] Preferably, the lower packer 9 is a Y441 packer, and the bottom packer is a Y341 packer.

[0045] The middle and upper packer of the present invention adopts a controllable packer, and the large-diameter part of the variable-diameter drop-back barrel 8, Y441 packer, tubing 10, multiple Y341 packers, floating hoop 14, and guide screen in the present invention Pipe 15 constitutes the isolated string.

[0046] Coiled tubing 2, connector 3, hydraulic safety handle 4, hydraulic sandblasting device 5, controllable packer 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com