High temperature resistant Gemini cationic viscoelastic surfactant (VES) and synthetic method thereof

A technology of surfactant and synthesis method, which is applied in chemical instruments and methods, drilling compositions, preparation of organic compounds, etc., can solve the problems of limited popularization and application, poor temperature resistance, etc., and achieve favorable promotion and application and low price Inexpensive, fast flowback effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

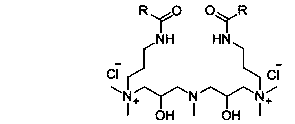

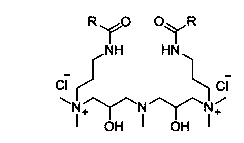

[0026] 1. Preparation of high temperature resistant Gemini cationic viscoelastic surfactant:

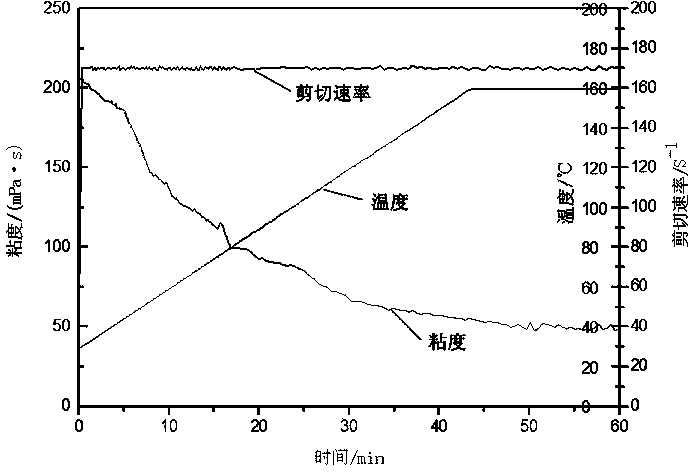

[0027] 1. Preparation of high temperature resistant erucic acid amide-based Gemini cationic viscoelastic surfactant:

[0028] Add erucic acid into the three-necked flask, heat until it completely melts, and add N,N-dimethylpropylenediamine and appropriate amount of potassium hydroxide dropwise to the flask with a constant pressure dropping funnel under argon protection and stirring Aqueous solution, the dropping time is controlled at about 15 minutes, in which the molar ratio of unsaturated fatty acid, N,N-dimethylpropylenediamine and potassium hydroxide is 1:1.12~1.15:0.003; after dropping, stir and heat to 180°C , After reacting for 12 h, cool to room temperature, and distill off unreacted amine and water under reduced pressure to obtain intermediate product A as a light brown solid.

[0029] Add methanol solution of methylamine to another flask, then add absolute ethanol, put it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com