Oil and gas field exploitation method

A mining method and oil and gas field technology, applied in gas fields, oil fields, and shale gas mining fields, can solve problems such as groundwater pollution, unfavorable flowback, and poor strength, and achieve the effects of fast flowback, full filling, and shortened construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

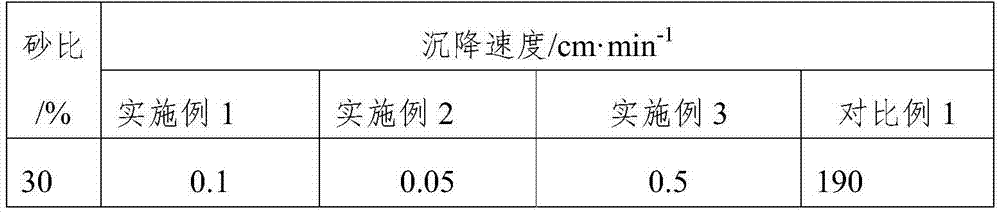

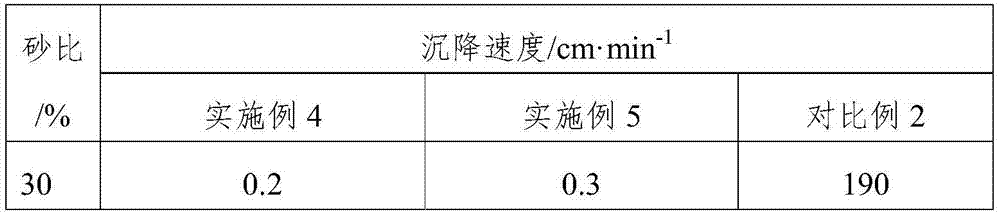

Examples

Embodiment 1

[0030] 1) Use quartz sand (river sand) 1000g as raw material, after scrubbing and drying, the sand does not contain water completely, and screens 20-40 mesh quartz sand as aggregate (the pretreatment process of quartz sand is the same in the following examples);

[0031] 2) Epoxy resin E-55, mixed with ethyl acetate at a ratio of 1:1. Stir evenly to prepare 50 mL of adhesive solution, then add aggregate and 10 g of guar gum to the adhesive solution.

[0032] 3) After the mixture obtained in step 2) is dried naturally, it is sieved.

[0033] The obtained proppant is particles with a particle size of 20-40 mesh (slightly larger than the particle size of the aggregate), and the surface of the aggregate is coated or partially coated with guar gum polymer material.

Embodiment 2

[0035] 1) Take 40-70 mesh 1kg quartz sand (eolian sand) as aggregate and set aside;

[0036] 2) Epoxy resin E-51, mixed with ethyl formate at a ratio of 1:1. Stir evenly to prepare 50 mL of adhesive solution, then add aggregate and 10 g carboxymethyl guar gum to the adhesive solution.

[0037] 3) After the mixture obtained in step 2) is dried naturally, it is sieved.

Embodiment 3

[0039] 1) Take 30-50 mesh 1kg quartz sand (sea sand) and sintered alumina as aggregates, the two materials have the same mesh, mix them in equal volumes, and set aside;

[0040] 2) Add 20 g of ethanol to 8 g of resole phenolic resin. Stir evenly, then add aggregate and 10g polyacrylamide to the adhesive solution.

[0041] 3) After the mixture obtained in step 2) is dried naturally, it is sieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com