Multifunctional drag reduction water system for continental shale gas fracturing and preparation method thereof

A multi-functional, drag-reducing water technology, applied in the field of oil and gas field exploration and development, can solve the problem that the inhibition effect cannot meet the requirements of continental shale rock stability, and cannot achieve long-term and efficient inhibition of clay minerals, and is sensitive to the strength of continental shale. It can reduce problems such as reducing clay particle migration, meet the requirements of large-displacement construction, and inhibit clay mineral expansion and clay particle migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A multifunctional drag-reducing water system suitable for continental shale gas fracturing, the preparation method of which comprises the following steps:

[0039] 1) Weighing and measuring of raw materials, each raw material and its mass percentage include:

[0040] Drag-reducing agent (supramolecular polymer APCF-1 40%, polyvinylpyrrolidone 20%, polyvinyl alcohol 40%) 0.02%, inhibitor 0.5%, anti-scaling agent 0.1%, synergist 0.001%, regulator 0.2% , and the rest is water;

[0041]2) Add 500ml of water into the mixer, adjust the rotation speed of the mixer to 450r / min, add the drag reducing agent and stir to dissolve for 1min, then add the measured inhibitor, anti-scaling agent, synergist and regulator in sequence, and stir evenly , to prepare the multifunctional drag-reducing water system.

[0042] According to the standard of "NB / T 14003.3-2017 Shale Gas Fracturing Fluid Part 3: Performance Index and Evaluation Method of Continuously Mixed Fracturing Fluid", some p...

Embodiment 2

[0046] A multifunctional drag-reducing water system suitable for continental shale gas fracturing, the preparation method of which comprises the following steps:

[0047] 1) Weighing and measuring of raw materials, each raw material and its mass percentage include:

[0048] Drag-reducing agent (supramolecular polymer APCF-1 60%, polyvinylpyrrolidone 25%, polyvinyl alcohol 15%) 0.05%, inhibitor 1%, anti-scaling agent 0.3%, synergist 0.003%, regulator 0.5% , and the rest is water;

[0049] 2) Add 500ml of water into the mixer, adjust the rotation speed of the mixer to 500r / min, add the drag reducing agent and stir to dissolve for 1min, then add the measured inhibitor, anti-scaling agent, synergist and regulator in sequence, and stir evenly , to prepare the multifunctional drag-reducing water system.

[0050] According to the standard of "NB / T 14003.3-2017 Shale Gas Fracturing Fluid Part 3: Performance Index and Evaluation Method of Continuous Mixed Fracturing Fluid", some perf...

Embodiment 3

[0054] A multifunctional drag-reducing water system suitable for continental shale gas fracturing, the preparation method of which comprises the following steps:

[0055] 1) Weighing and measuring of raw materials, each raw material and its mass percentage include:

[0056] Drag-reducing agent (supramolecular polymer APCF-1 50%, polyvinylpyrrolidone 15%, polyvinyl alcohol 35%) 0.03%, inhibitor 0.8%, anti-scaling agent 0.2%, synergist 0.002%, regulator 0.4% , and the rest is water;

[0057] 2) Add 500ml of water into the mixer, adjust the rotation speed of the mixer to 500r / min, add the drag reducing agent and stir to dissolve for 1min, then add the measured inhibitor, anti-scaling agent, synergist and regulator in sequence, and stir evenly , to prepare the multifunctional drag-reducing water system.

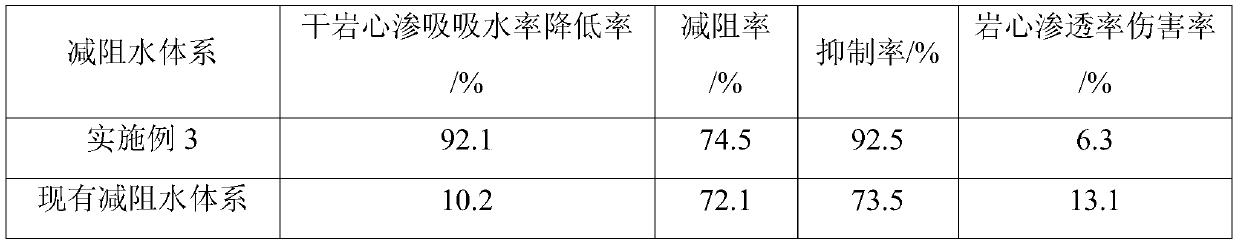

[0058] According to the standard of "NB / T 14003.3-2017 Shale Gas Fracturing Fluid Part 3: Performance Index and Evaluation Method of Continuously Mixed Fracturing Fluid", some ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com