Polymer perforating fluid and preparation method thereof

A technology of polymer and perforating fluid, applied in the field of perforating fluid, to achieve the effect of reducing alkali sensitivity, reducing cost and low core damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

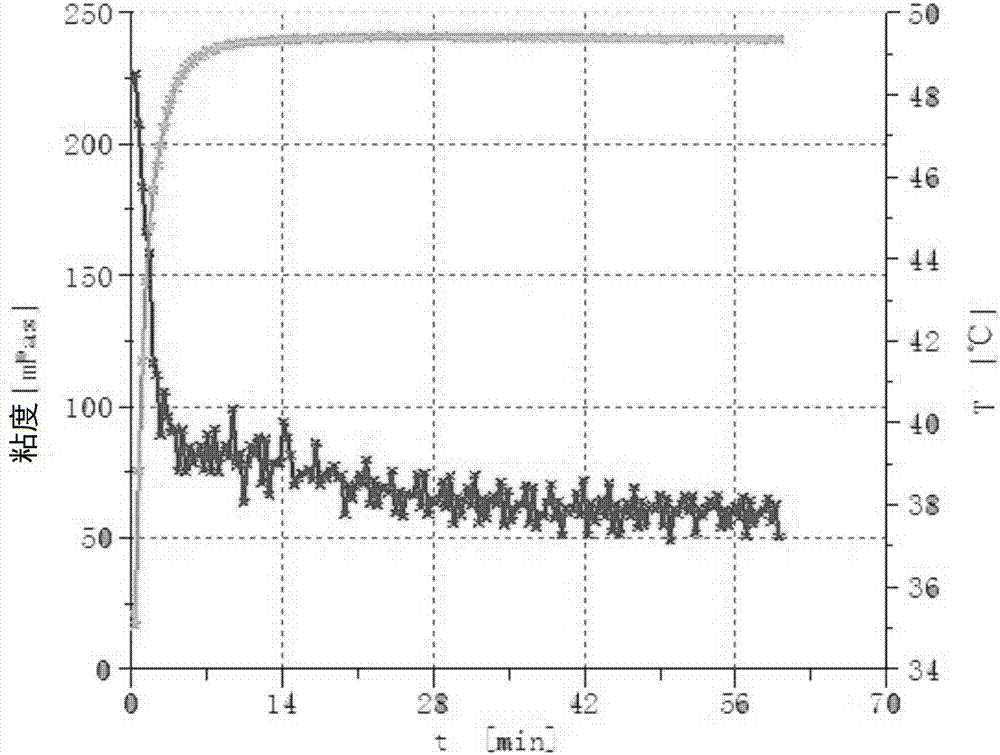

Embodiment 1

[0046] The polymer perforating fluid of this embodiment is composed of the following components in mass percentage: 0.25% polymer thickener, 12% weighting agent, 0.02% drainage aid, 0.015% gel breaker, 0.55% temporary plugging agent, The balance is the flowback treatment water; the weighting agent is a mixture of potassium bromide and sodium chloride in a weight ratio of 1:4, and the gel breaker is sodium persulfate.

[0047] The preparation method of the polymer perforating fluid of the present embodiment comprises the following steps:

[0048] 1) Add 871.65g of flowback treatment water to a 1000mL Wuyin mixer, add 120g of weighting agent at a stirring speed of 200r / min, after the weighting agent is dissolved, add 2.5g of polymer thickener, After stirring at a speed of 20 min, add 0.2 mL of drainage aid and continue stirring for 5 min to obtain a polymer perforating fluid base fluid with a density of 1.11 g / cm 3 ;

[0049] 2) Add 5.5g of temporary plugging agent and 0.15g o...

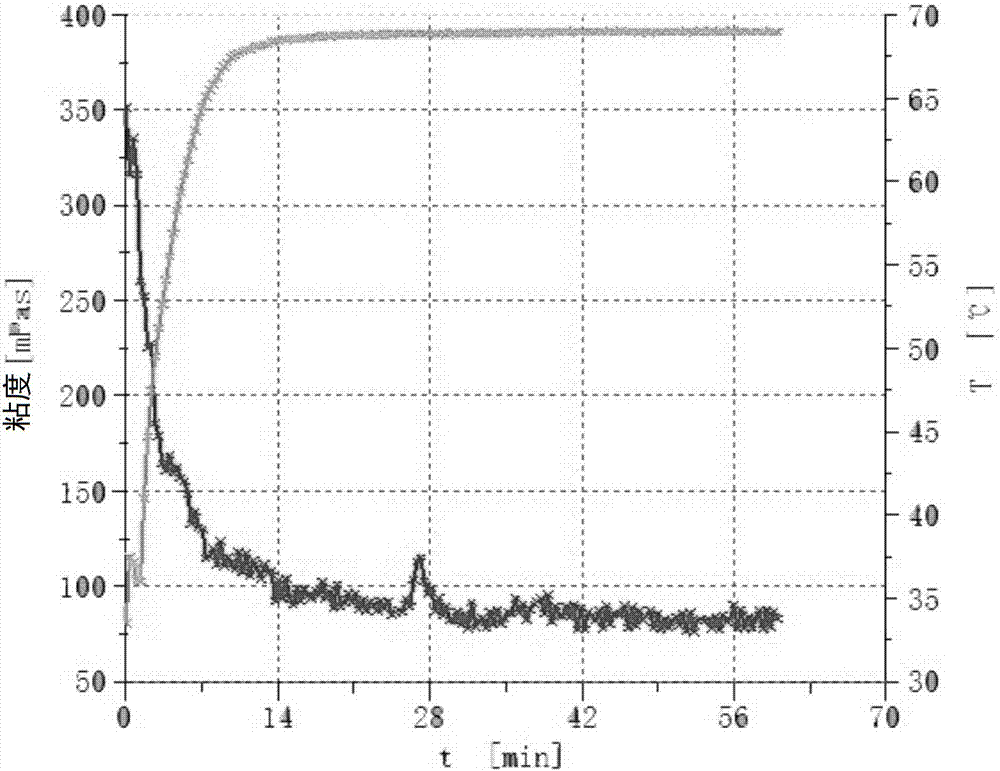

Embodiment 2

[0051] The polymer perforating fluid of this embodiment is composed of the following components in mass percentage: 0.3% polymer thickener, 16% weighting agent, 0.03% drainage aid, 0.018% gel breaker, 1% temporary plugging agent, The balance is reinjection water; the weighting agent is a mixture of potassium bromide and sodium chloride in a weight ratio of 1.2:3.5, and the breaker is ammonium persulfate.

[0052] The preparation method of the polymer perforating fluid of the present embodiment comprises the following steps:

[0053] 1) Add 826.52g of reinjection water to a 1000mL Wuyin mixer, add 160g of weighting agent at a stirring speed of 400r / min, after the weighting agent is dissolved, then add 3g of polymer thickener, at a speed of 500r / min After stirring for 20 minutes, add 0.3 mL of drainage aid and continue stirring for 5 minutes to obtain polymer perforating fluid base fluid with a density of 1.15 g / cm 3 ;

[0054] 2) Add 10g of temporary plugging agent and 0.18g ...

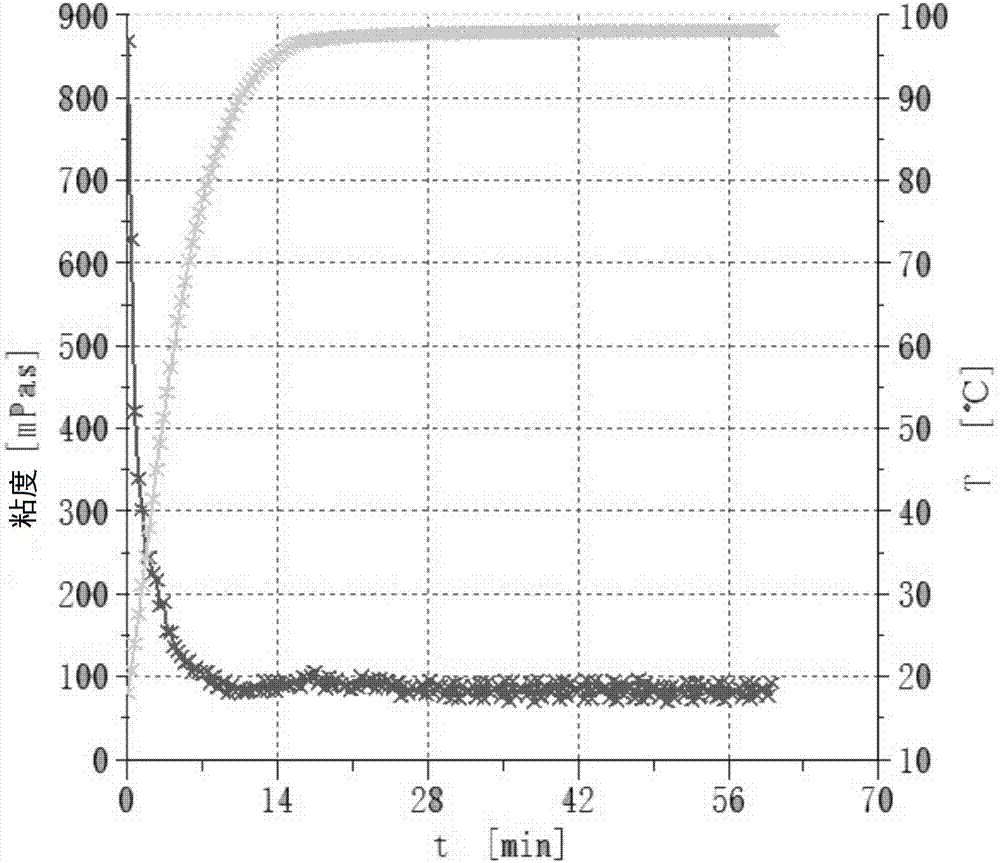

Embodiment 3

[0056] The polymer perforating fluid of this embodiment is composed of the following components in mass percentage: 0.35% polymer thickener, 22% weighting agent, 0.04% drainage aid, 0.02% gel breaker, 1.5% temporary plugging agent, The balance is reinjection water; the weighting agent is a mixture of potassium chloride and sodium chloride in a weight ratio of 6.4:1.3, and the breaker is ammonium persulfate.

[0057] The preparation method of the polymer perforating fluid of the present embodiment comprises the following steps:

[0058] 1) Add 780.9g of reinjection water to a 1000mL Wuyin mixer, add 200g of weighting agent at a stirring speed of 300r / min, after the weighting agent is dissolved, then add 3.5g of polymer thickener, After stirring at high speed for 30 minutes, add 0.4 mL of drainage aid and continue stirring for 5 minutes to obtain polymer perforating fluid base fluid with a density of 1.19 g / cm 3 ;

[0059] 2) Add 15g of temporary plugging agent and 0.2g of gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com