Oil shale fluidized bed dry distillation system

A fluidized bed and oil shale technology, which is applied in special dry distillation, petroleum industry, coke oven, etc., can solve the problems of high operating cost, low shale oil yield, single product form, etc., and achieve heat exchange efficiency and High carbonization efficiency, control of NOX and SO2, control of generation and emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

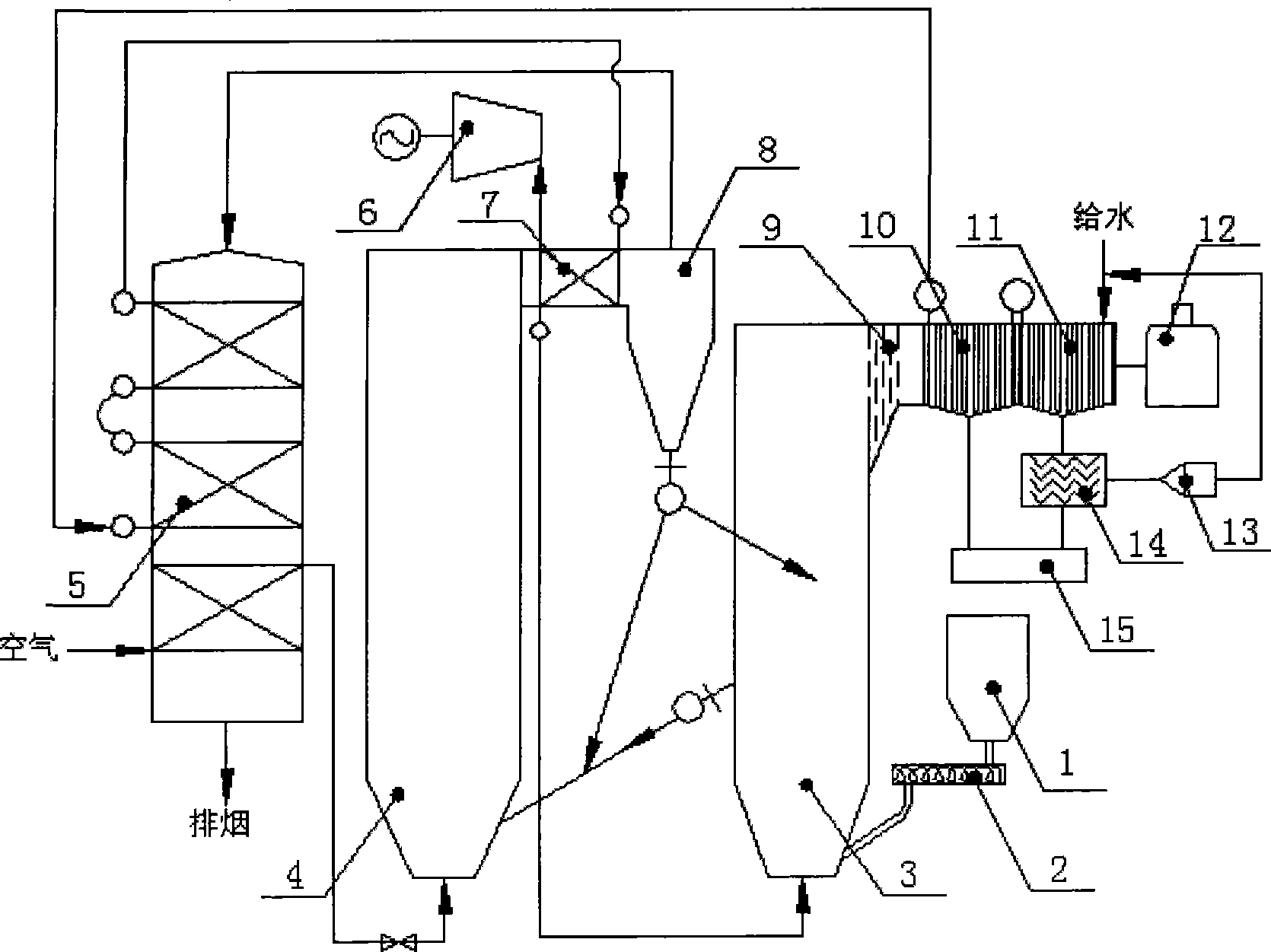

[0011] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] figure 1 It is a schematic diagram of the system structure of the present invention. like figure 1 As shown, the connection form of the system of the present invention is: the outlet of the oil shale silo 1 is connected to the inlet of the feeder 2, the outlet of the feeder 2 is connected to the inlet of the fluidized bed retort chamber 3, and the top outlet of the fluidized bed retort chamber 3 is connected to the inlet of the feeder 2. The inlet of the fly ash separator 9 is connected, the outlet of the fly ash separator 9 is connected to the gas side inlet of the second stage cooler 10, the gas side outlet of the second stage cooler 10 is connected to the gas side inlet of the first stage cooler 11, and the first stage The gas side outlet of the cooler 11 is connected to the inlet of the gas storage tank 12, the condensate outlet o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com