Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159results about How to "Reduce refining time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

Glass compositions

Improved glass fibers compositions, typically useful for fire resistant blankets or containers to provide high burn-through resistance at high temperatures of 2,400° F. and higher, and typically comprising silica, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, ferrous+ferric oxide, and titanium oxide; the improved glass compositions may further include alumina, lithium oxide, and boron oxide.

Owner:GLASS

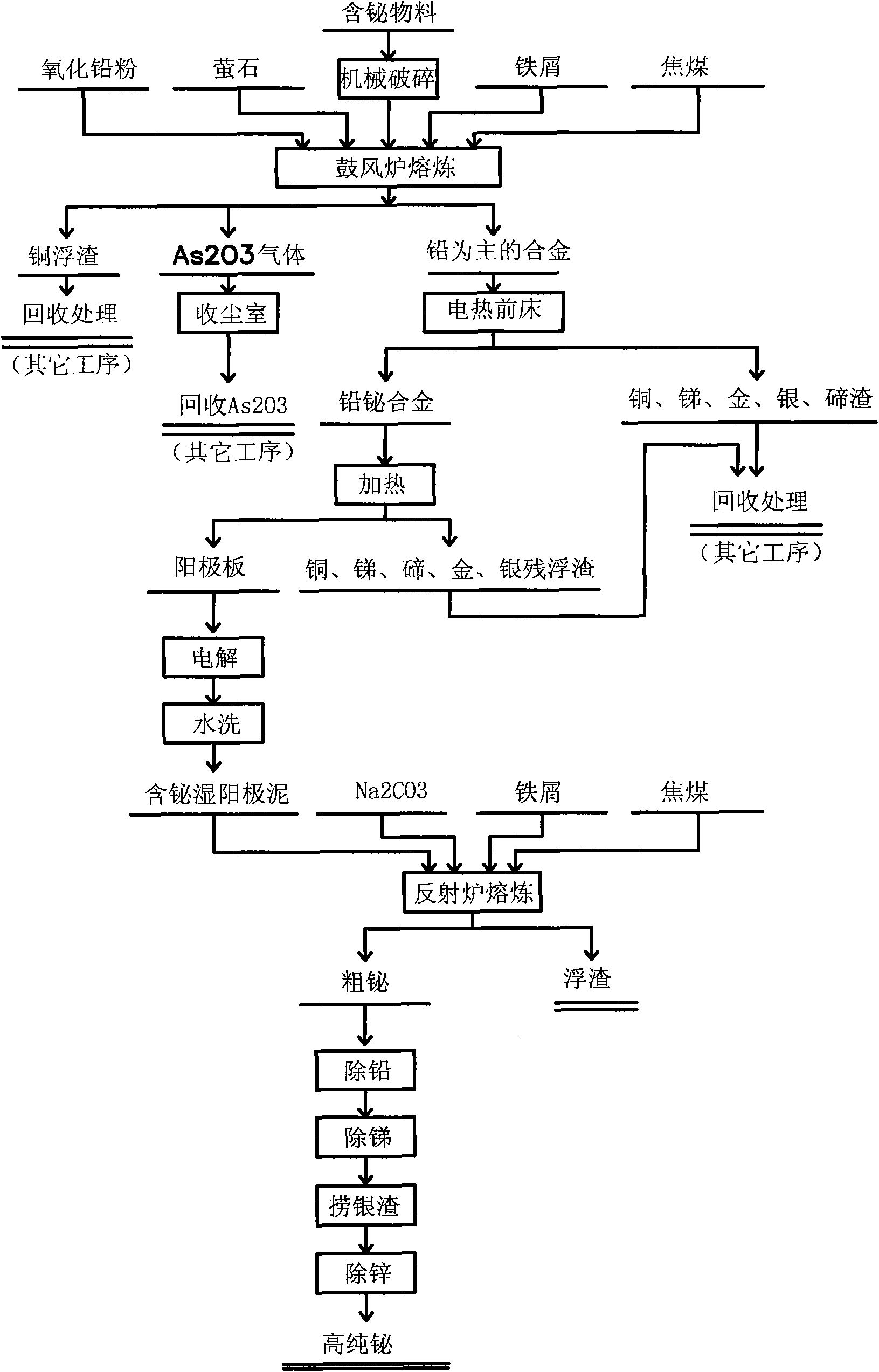

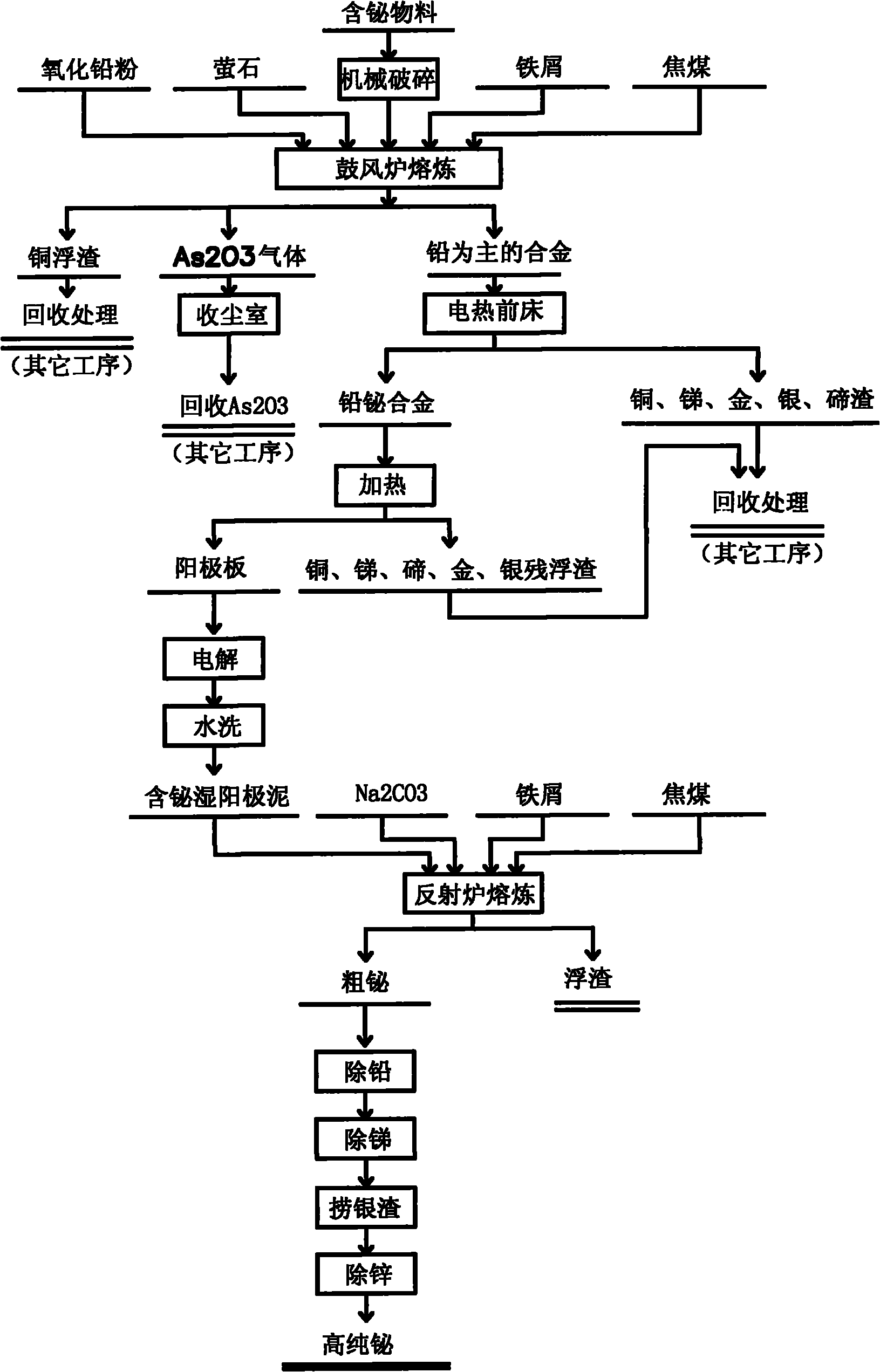

Process for refining high-purity bismuth from bismuth-containing material generated from anode mud recovery

ActiveCN101886174AReduction of Bismuth Content RequirementsExpand sourcePhotography auxillary processesProcess efficiency improvementTemperature controlBismuth

The invention relates to a process for refining high-purity bismuth from bismuth-containing materials generated from anode mud recovery, belonging to the technical field of processes of recovering smelting bismuth by combining a wet process and a pyrogenic process of non-ferrous metal. The process comprises the following steps of: firstly increasing the content of bismuth contained in the bismuth-containing materials to obtain crude bismuth by adopting an enrichment process; and then further refining and purifying the crude bismuth into the high-purity bismuth by adopting a selective accurate temperature-control smelting method according to different melting points of compounds between bismuth metal and impurity-containing metal. Compared with the prior art, the invention reduces the requirements for the content of the bismuth contained in raw materials and can realize the economic and high-efficiency recovery of the bismuth metal, refine the high-purity bismuth and reduce the environmental pollution.

Owner:郴州雄风环保科技有限公司

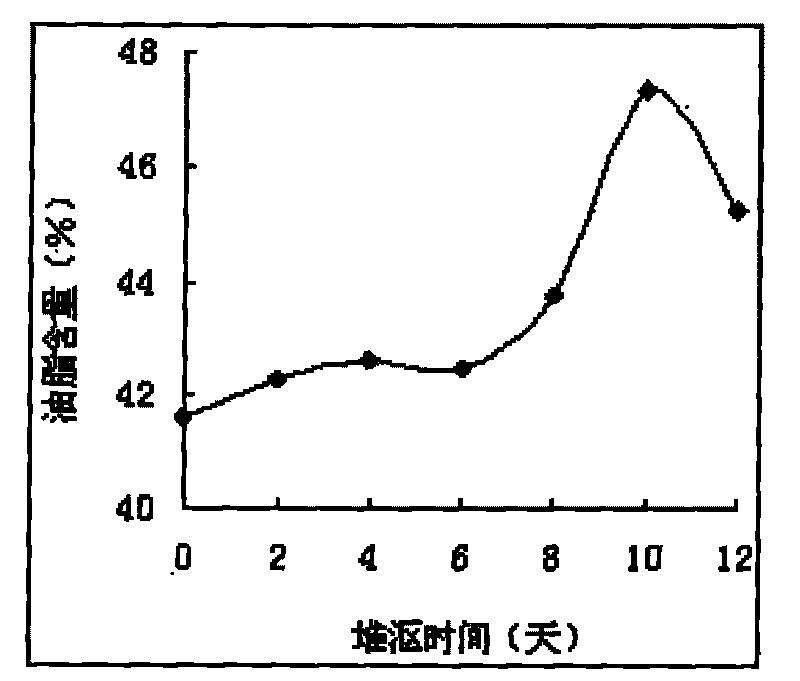

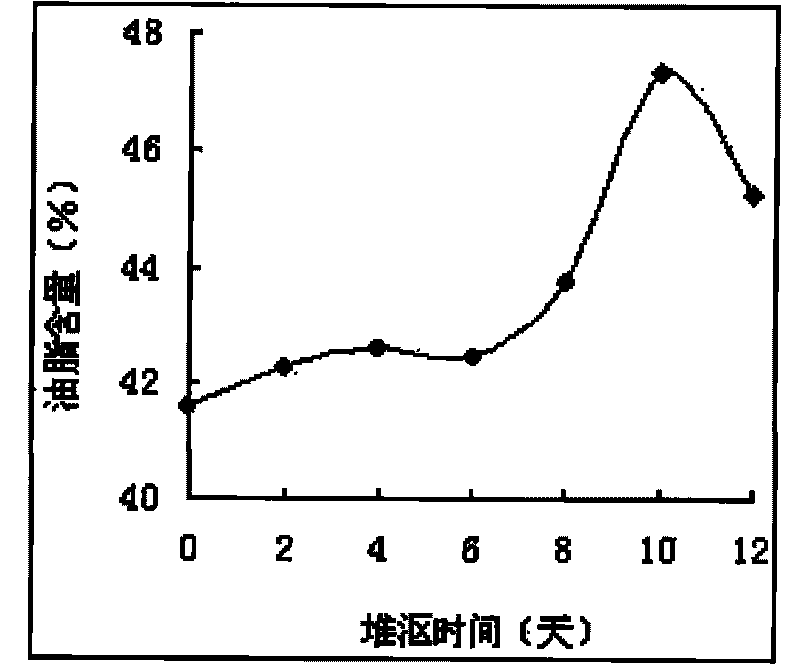

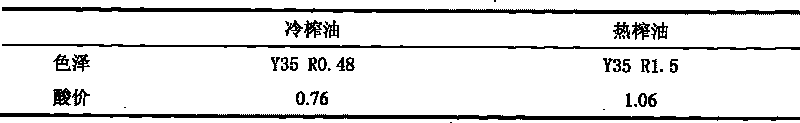

Method for preparing edible safflower tea oil

InactiveCN101692854AHigh oil contentQuality improvementEdible oils/fats production/working-upFlavorLoss rate

The invention discloses a method for preparing edible safflower tea oil, comprising the following steps: taking safflower tea seeds as raw materials; conducting stackretting, removal of the oil tea fruit shells, and taking-off of the tea seeds for low-temperature drying below safe moisture content on the harvested mature safflower oil tea fruits, and then cleaning stone, removing shells, separating kernels and shells, and crushing till the particle size is 20 to 60 meshes and adding water for tempering; adopting a cold pressing method for extracting the tea oil; and finally conducting simple refining processes such as filtration, wintering and the like so that the quality index can achieve national first-class edible tea oil standards. The method for preparing edible safflower tea oil hassimple and feasible process, easily-controlled production conditions, less refining processes, low refining loss rate, can keep various nutritional components in the safflower tea seeds from being destroyed, leads the finished tea oil to have light, clear and transparent color, aromatic natural flavor of the tea seeds, and is a nutritional and healthy tea oil.

Owner:SOUTH CHINA AGRI UNIV

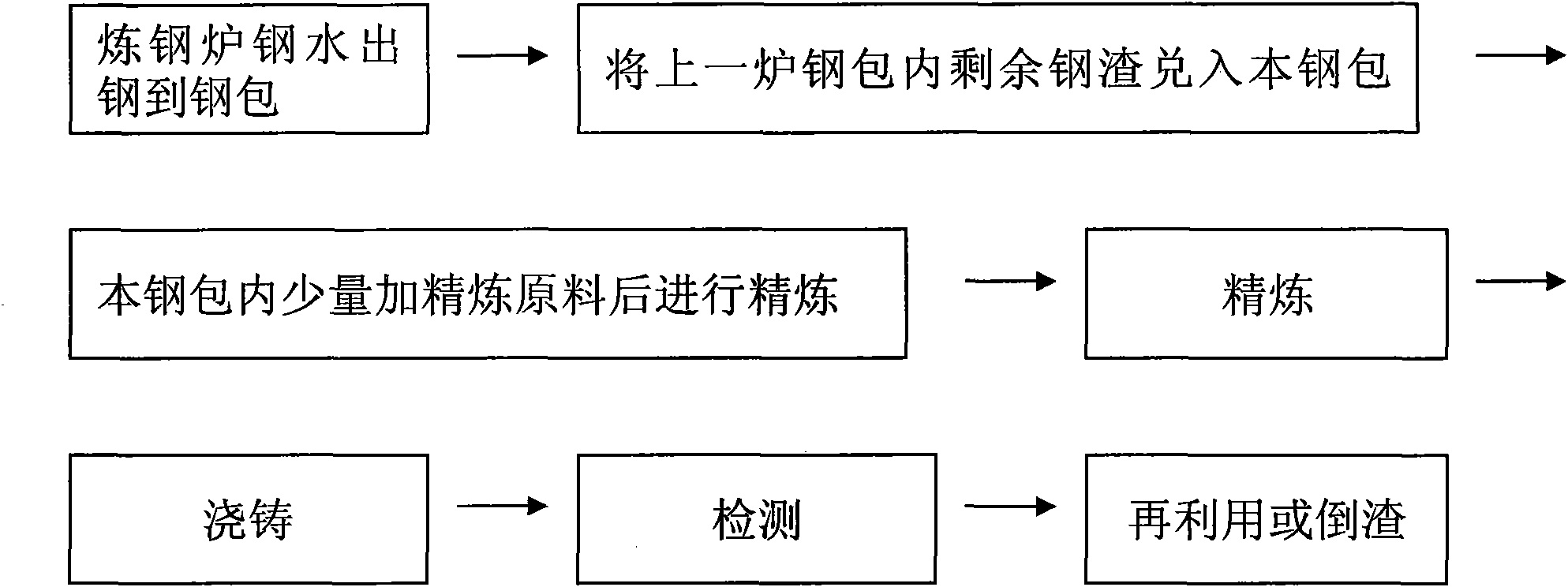

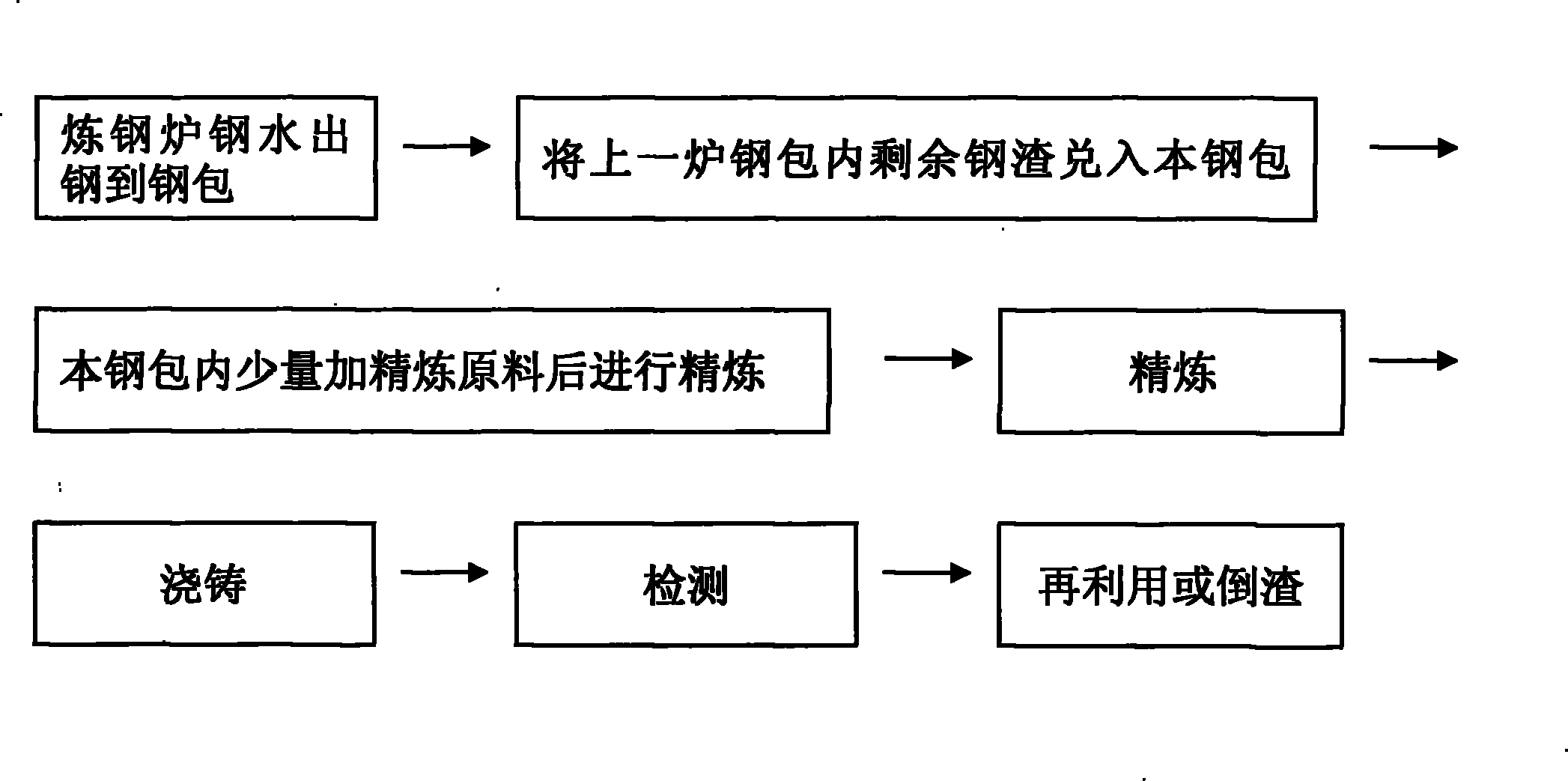

LF (Ladle Furnace) hot steel slag recycling process

ActiveCN102041329AThe method is simpleReduce refining timeRecycling and recovery technologiesProcess efficiency improvementEcological environmentSlag

The invention provides an LF (Ladle Furnace) hot steel slag recycling process. The process is characterized in that deslagging indicates that residual hot steel slag in a steel ladle is poured into molten steel of a steel ladle of a next ladle, and then refining raw materials are added, wherein the sulfur capacity of the residual hot steel slag is larger than 0.020. The steel slag poured in the past after refining is renewedly returned to the steel ladle for recycling, thus the physical heat of steel ladle poured allowance and the steel slag can be recovered, and the consumption of various raw materials of the LF is also saved, so that the process creates considerable economic benefits for steel enterprises, reduces the pollution of the hot steel slag to the environment, protects the ecological environment and realizes circular economic benefit.

Owner:HENAN FENGBAO SPECIAL STEEL CO LTD ANYANG IRON & STEEL GRP

Permeable fireproof materials for aluminium refining and process for preparing same

The invention discloses a poromeric fire-proof material and preparing method of refined aluminum, which comprises the following parts: 60-92 percent sintered compact calcium hexaluminate, 8-30 percent auxiliary material and 2.5-5.5 percent binder, wherein the auxiliary material is some or all of board-shaped corundum, electric melting white corundum, mild-clay, quartz, kyanite, chromium hemitrioxide green and zircon. The preparing method comprises the following steps: blending poromeric fire-proof material and binder completely; loading the material in the mould; placing the mould on the vibrating platform; pressurizing on the material at 10-20 ton; vibrating at 3-5 mm amplitude at 5-15 s; sintering at 1400-1700 deg.c.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for purifying silicon through removing boron

The invention which belongs to the technical field of silicon purification concretely discloses a method for purifying silicon through removing boron. The method comprises the following steps: 1, heating and melting silicon to form a silicon liquid, keeping the temperature of the silicon liquid at 1600-1800DEG C, accessing a mixed gas to the silicon liquid and simultaneously adding a slag former sodium metasilicate, and smelting the silicon liquid, wherein the mixed gas comprises a carrier gas, oxygen and water vapor; and 2, cooling and ingoting the smelted silicon liquid, and cutting off an impurity enrichment part. According to the method of the invention, the smelting time is substantially shortened, the loss of a silicon raw material is substantially reduced, and the yield of silicon purification is improved; the content of boron in purified silicon is low, and the boron removal efficiency is high; and no new impurities are introduced, and there is a certain removal effect on metal impurities, so the purity of silicon can be further improved. The method of the present invention has the advantages of simple required equipment, no need of high energy equipment of plasma equipment and the like, and low energy consumption.

Owner:BYD CO LTD

Preliminary melting type calcium aluminate for ultra-clean steel and method of manufacturing the same

ActiveCN101244835AImprove deoxygenatioImprove purification effectProcess efficiency improvementAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagCalcium aluminates

The invention relates to a premelt calcium aluminate for super clean steels and the preparation method, the weight percentages of the chemical components in the calcium aluminate are as follows: CaO is 48 to 56%, Al2O3 is 40 to 50%, SiO2 is 0.5 to 3%, MgO is 0.5 to 1.5%, Fe2O3 is no more than 0.5%, TiO2 is no more than 0.02%, C is no more than 0.02%, S is no more than 0.02% and P is no more than 0.02%. The preparation method comprises the following steps: pressing calcium carbonate and alumina of certain amount into block, the weight percentage of the components: calcium carbonate 47 to 55.5% and alumina 36 to 50%; adding the calcium carbonate and the alumina in a melting furnace in batches for melting; obtaining the premelt calcium aluminate for super clean steels with the composition. The preparation method has the advantages of continuous feeding and slag tapping, simple process, stable components and low cost of products.

Owner:上海彭浦冶金辅料有限公司

Method of removing arsenic and selenium for antimony smelting by pyrometallurgy

The antimony-pyrosmelting refining method for removing arsenic and removing selenium includes the following steps: placing crude antimony containing arsenic and selenium into refining furnace, heating and melting them, and heating to 650-1000 deg.C, and once adding alkaline metal hydroxide required for removing arsenic and selenium, then introducing compressed air and stirring for 15-150 min. to implement slagging, arsenic-removing and selenium-removing reaction to produce arseniate and selenite float slag, separating slag and antimony.

Owner:锡矿山闪星锑业有限责任公司

Purifying method for casting-smelting mag nesium alloy and air blowing apparatus thereof

The present invention relates to a method for cleaning impurity in the course of casting and smelting magnesium alloy and its air-blowing equipment. It is characterized by that the impurity-removing solvent using pressure inert gas as carrier is blown into the molten alloy, its gas pressure is 0.05MPa-0.5 MPa, flow rate is 5Lmin-100 L / min, and the flow rate of solvent carrier by gas is 100g / min-500g / min. Said invention also provides its cleaning operation steps, it not only raises alloy purity and property, but also raises its production efficiency.

Owner:JILIN UNIV

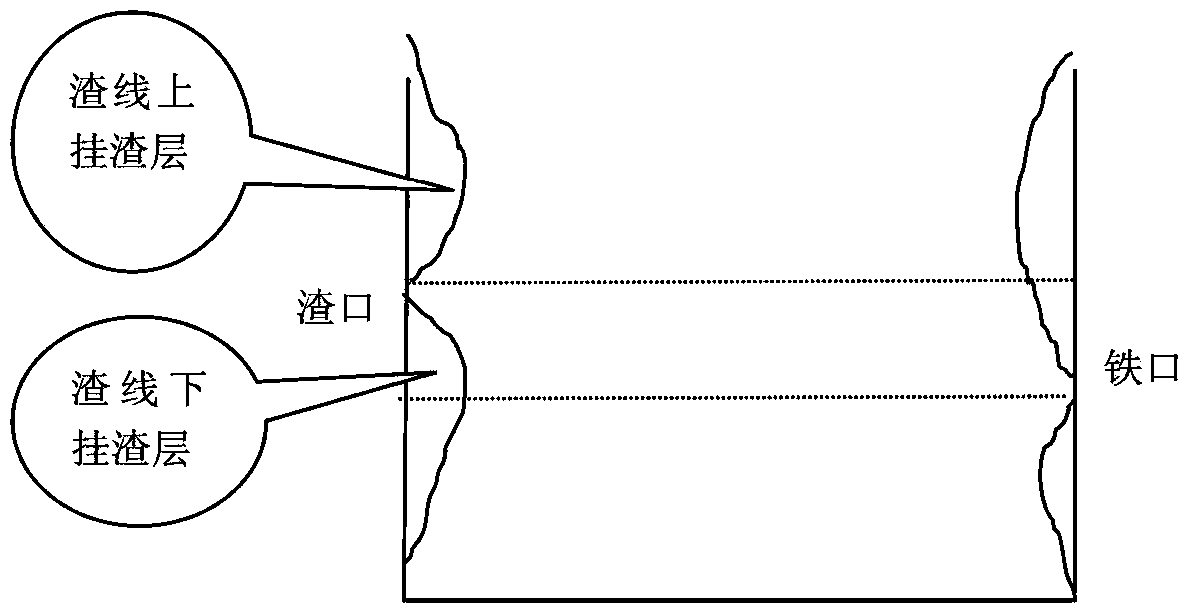

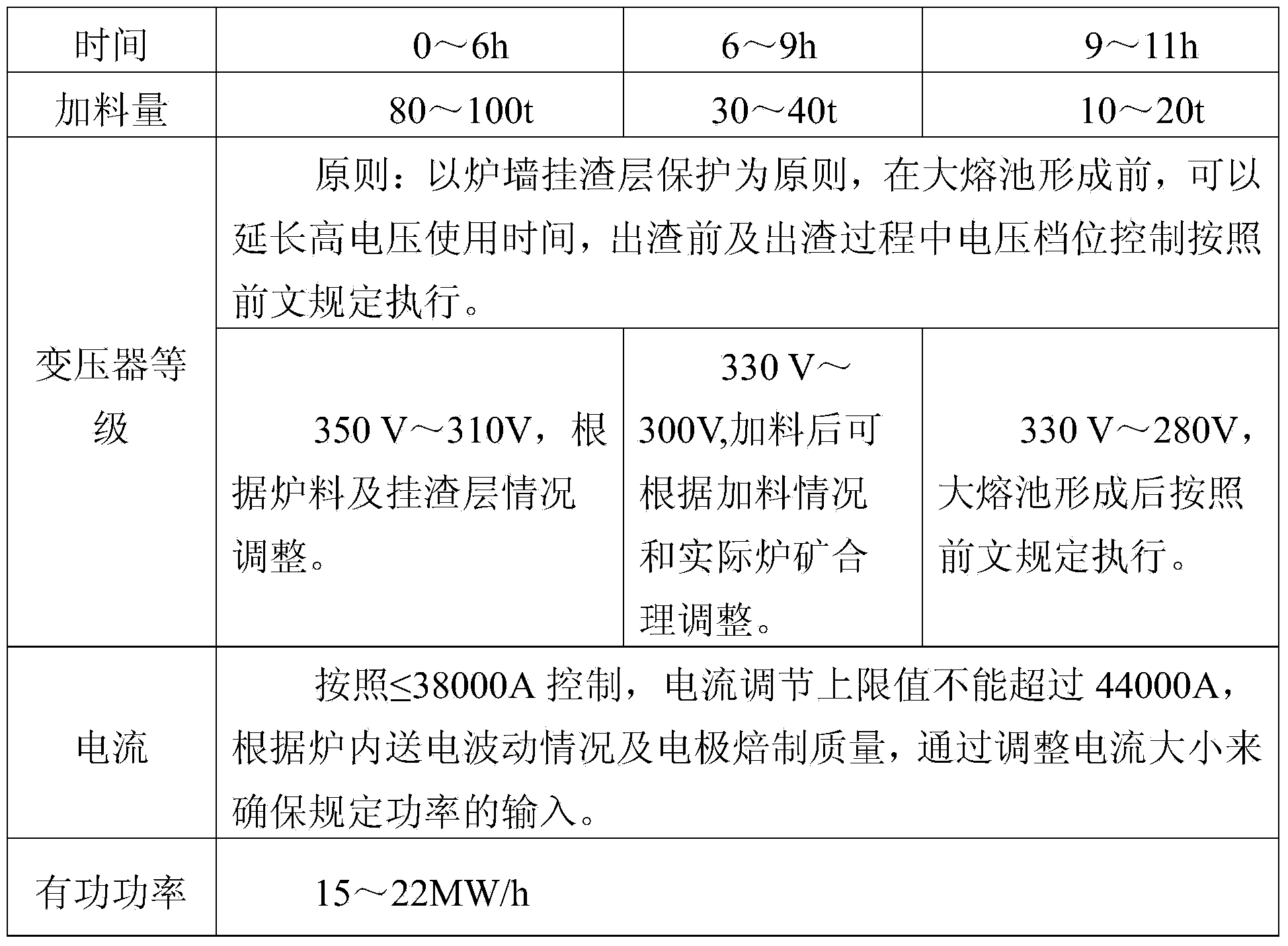

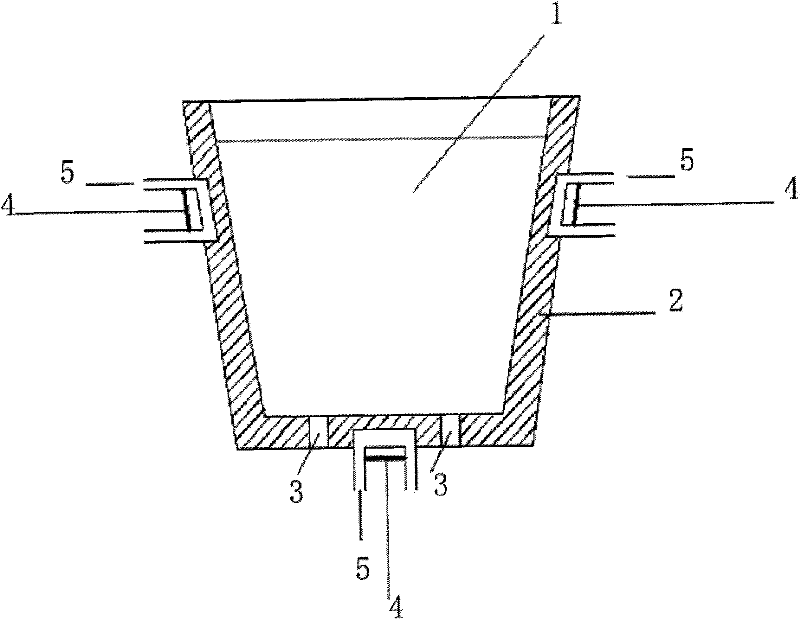

Method for adhering slag onto electric furnace for smelting titanium slag

ActiveCN103820600APrevent scrubbingReduce refining timeElectric furnaceMelting tankElectric arc furnace

The invention provides a method for adhering slag onto an electric furnace for smelting titanium slag. The method comprises the following steps: with a low carbon ratio, adopting furnace burden and coke according to the ratio of 100:10 to form a molten pool quickly, controlling FeO to be more than or equal to 15% in slag, and controlling liquid-level temperature of titanium slag to be more than or equal to 1,720 DEG C; adding coke at the upper part of the molten pool according to 100-200 Kg / batch to enable the electrode to rise for 300-1,000 mm in position, after the electrode drops to the position before the coke is added, adding the coke again, and repeating the operation for 2-3 times; using multipoint charging at the edge of the molten pool in the molten pool section; adding the coke to the position, directly facing to the slag hole and iron notch of the molten pool, according to the ratio, in which, the coke is increased by 3-4% compared with that in the normal ratio, of the furnace burden to coke; adding the coke to other edge adding positions according to the ratio, in which, the coke is increased by 2-3% compared with that in the normal ratio, of the furnace burden to coke, wherein the normal ratio of the furnace burden to coke is 100:12, and the power transmission voltage is less than or equal to 320 V; controlling tapping temperature strictly; shortening refining time of grade adjustment at later stage at a high temperature.

Owner:PANGANG GROUP TITANIUM INDAL

Method for recycling ladle slag

InactiveCN102337379AAvoid cloggingArgon blowing obstacleRecycling and recovery technologiesProcess efficiency improvementSlagAlloy

The invention provides a method for recycling ladle slag, comprising the following steps: carrying out solidification and fragmentation on the ladle slag, and then carrying out iron election, allowing residues after iron election as refining slag to contact with molten steel containing added alloy for LF refining. According to the invention, the recycle of the ladle slag is realized, and slag component in the recycle process can be accurately controlled, so that effect of refining of the molten steel is further improved; by adding the refining slag in the alloyed molten steel, the problem of argon blowing fault generated in tapping after adding the ladle slag in the empty ladle, and the time of refining of the molten steel is greatly reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Novel direct slag-feeding washing mixed material application method in converter tapping process

InactiveCN103233098ALighten the refining burdenReduce dosageProcess efficiency improvementSlagAluminium powder

The invention relates to a novel direct slag-feeding washing mixed material application method in a converter tapping process. A mixed material comprises the following components in parts by weight: 5-40 parts of aluminium powder, 35-60 parts of alumina, 30-50 parts of calcined lime, 1-6 parts of magnesium oxide, 0-6 parts of fluorite and 5-6 parts of silicon dioxide powder. The application method is used in a tapping process according to the following steps: firstly, adding 30% of the novel direct slag-feeding washing mixed material into the bottom of a steel ladle; adding the rest 70% of the material and the calcined lime along with molten steel flow when 1 / 4 tapping is completed; and moreover, feeding the mixed material into an argon blowing station, blowing argon to stir for 10-15 minutes, and then directly and continuously casting blanks so as to form finished products. The slag washing mixed material has high desulfurization degree in the converter tapping process, the refining time can be effectively shortened, and the cost of each ton of steel can be greatly lowered.

Owner:涟源市飞达冶金炉料厂

Ladle Refining Method Using Ultrasonic to Improve Kinetic Conditions

The invention discloses a ladle refining method which uses ultrasonic wave to improve dynamic conditions, and ultrasonic wave is input into molten steel to solve the problem of stirring dead zone in bottom blowing gas stirring. The invention includes the following contents: after the converter or electric furnace taps steel, pour the molten steel into the ladle, place the ladle in the refining station, start blowing argon gas at the bottom of the ladle to stir, add slagging and deoxidizing materials, and turn on the ultrasonic generator at the same time , input ultrasonic waves at the bottom and side walls of the ladle to stir the molten steel. The power of the ultrasonic is determined by the weight of the molten steel in the ladle. The ultrasonic power range is 5-500kW / ton of molten steel. The input time of the ultrasonic is the time taken for the ladle to finish refining. The invention can reduce the inclusion and gas content of molten steel, and significantly improve the ladle refining effect.

Owner:UNIV OF SCI & TECH LIAONING

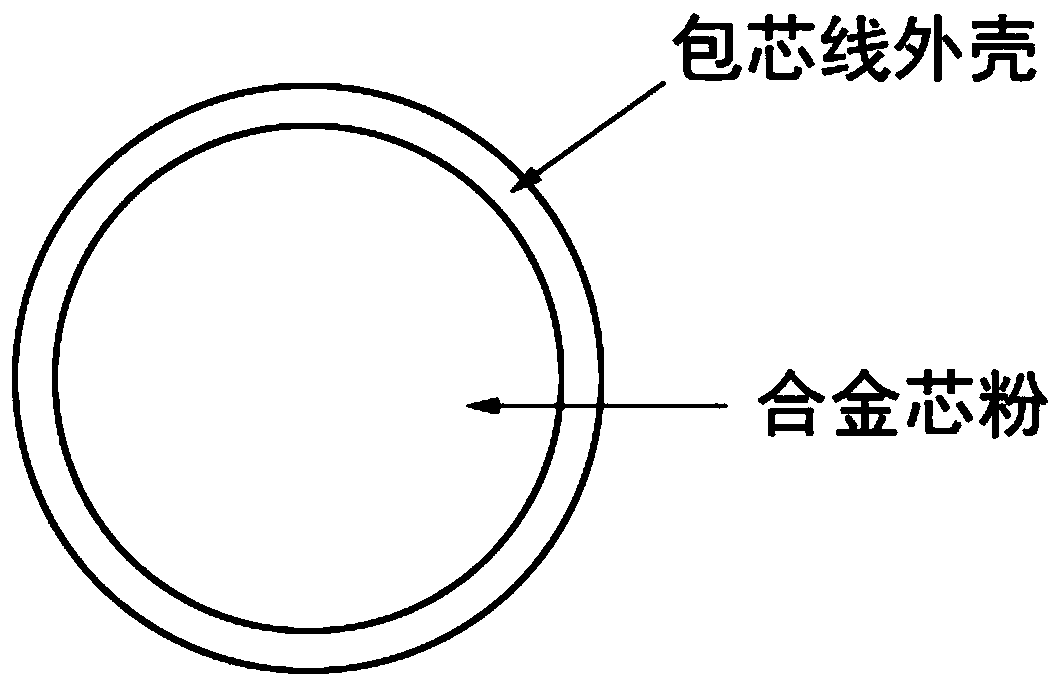

Composite core-spun yarn and large-line-energy welding steel preparing method

The invention discloses a composite core-spun yarn and a large-line-energy welding steel preparing method, and belongs to the technical field of steel metallurgy. Based on the oxide metallurgy basic principle, multiple alloy composite adding modes are selected in the core-spun yarn, and through reasonable core powder chemical component design, the functions of deep deoxygenation, deep desulfuration and inclusion harmless control in the steel smelting process are fused, the metallurgy process chemical reaction is sufficiently utilized, and fine, spheroidization, dispersion and composite controlof inclusions in the steel is achieved. According to a 60 mm EH36 ship making steel plate manufactured through the core-spun yarn, after EGW is conducted when the line energy is 460 kJ / cm, the -40 DEG C ballistic work value of the welding heat affected zone is larger than or equal to 170 J. After the core-spun yarn is used for replacing a Ni-Mg alloy commonly used during current large-line-energywelding steel production, the ton-steel alloy cost can be reduced to be smaller than or equal to 100 yuan from the cost higher than 300 yuan in the original technology, economic and social benefits are obvious, and very good popularization and application prospects are achieved.

Owner:李素坤

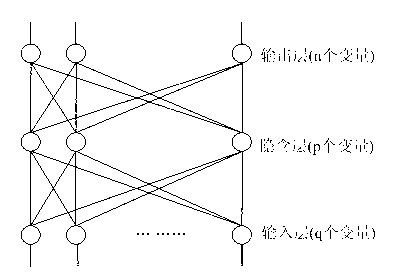

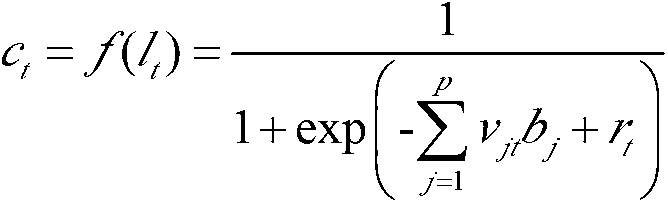

Method for forecasting alloy composition of molten steel during LF refining process

The invention discloses a method for forecasting alloy composition of molten steel during the LF refining process, which belongs to the technical of metallurgy. The method comprises the following steps: (1) collecting the composition testing data of molten steel and the quality data of pre-melting matters when the former step before refining is ended; (2) establishing an artificial neural network model during the refining process; and (3) carrying out the mode training. The method disclosed by the invention adopts the alloy composition data obtained in the former LF step as the initial value, adopts the molten steel testing value during the refining process as the standard value at sampling time, considers the influence on molten steel composition after adding the related pre-melting matters, slagging material, silk threads, desoxidant and desulphurizer, and adopts the BP neural network to forecast the alloy composition of molten steel at the non-sampling time. The method disclosed by the invention can forecast the alloy composition of molten steel in real time during the LF refining process, can effectively reduce the LF refining time and can reduce the refining cost, so that the LF refining process can be quickly finished.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

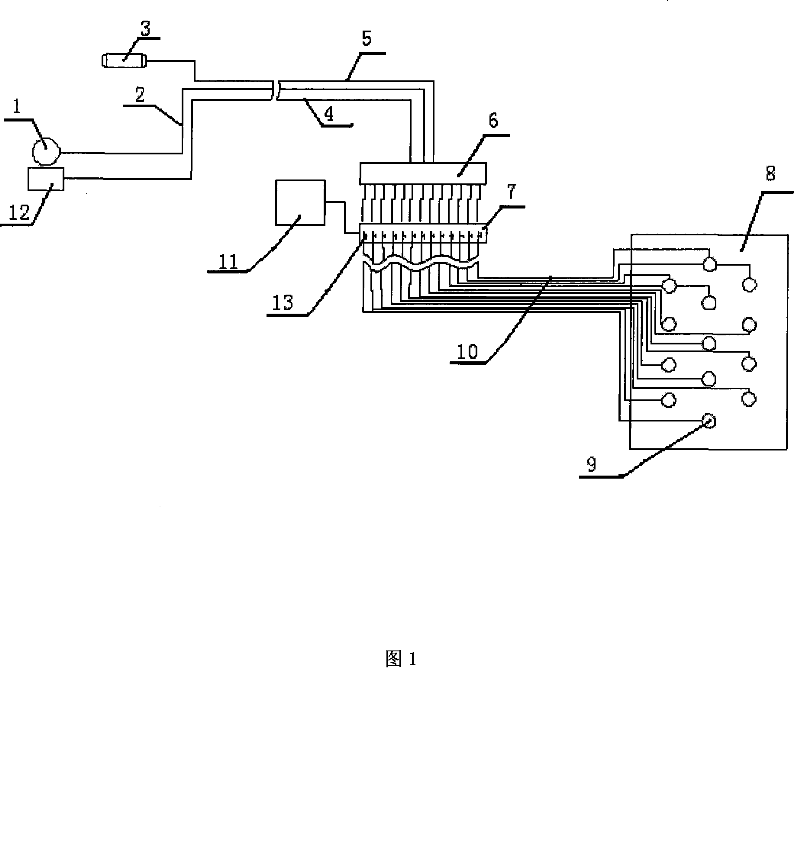

Ventilating air-eliminating refining method of 3104 aluminum alloy flat ingot in casting furnace

The invention relates to a method for degassing and deslag in smelting, more specially, to to a refining method of venting, degassing and deslag in 3104 aluminium alloy flat section ingot casting furnace. The refining method of venting, degassing and deslag in 3104 aluminium alloy flat section ingot casting furnace includes kettle furnace, thirteen air bricks built on the fireproofing structure of the furnace bottom, 13 venting pipelines mounted on the furnace bottom, the said refining method for venting, degassing and deslag is that inert gas or inert mixing gas enters into maintaining furnace through the venting pipelines mounted on the bottom of thirteen air bricks, the inert gas adsorbs the impurity in aluminium liquid and then floats with air bubble up to the surface of aluminium liquid and exhausts to obtain the product. The advantage of the invention is: improving the degassing and deslag efficiency; improving the product quality of aluminium alloy flat section ingot; reducing the defect for casting flat section ingot; shortening the cost for producing flat section ingot, improving the productivity and reducing the flow of gas. The invention is usable for aluminium and aluminium alloy casting industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

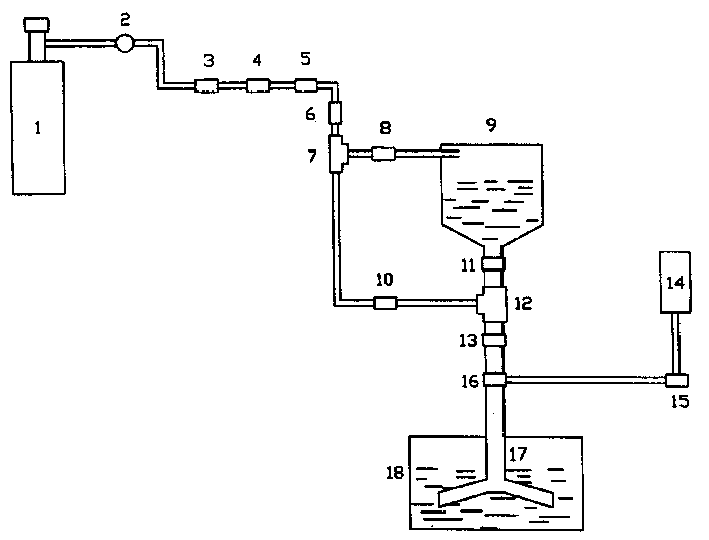

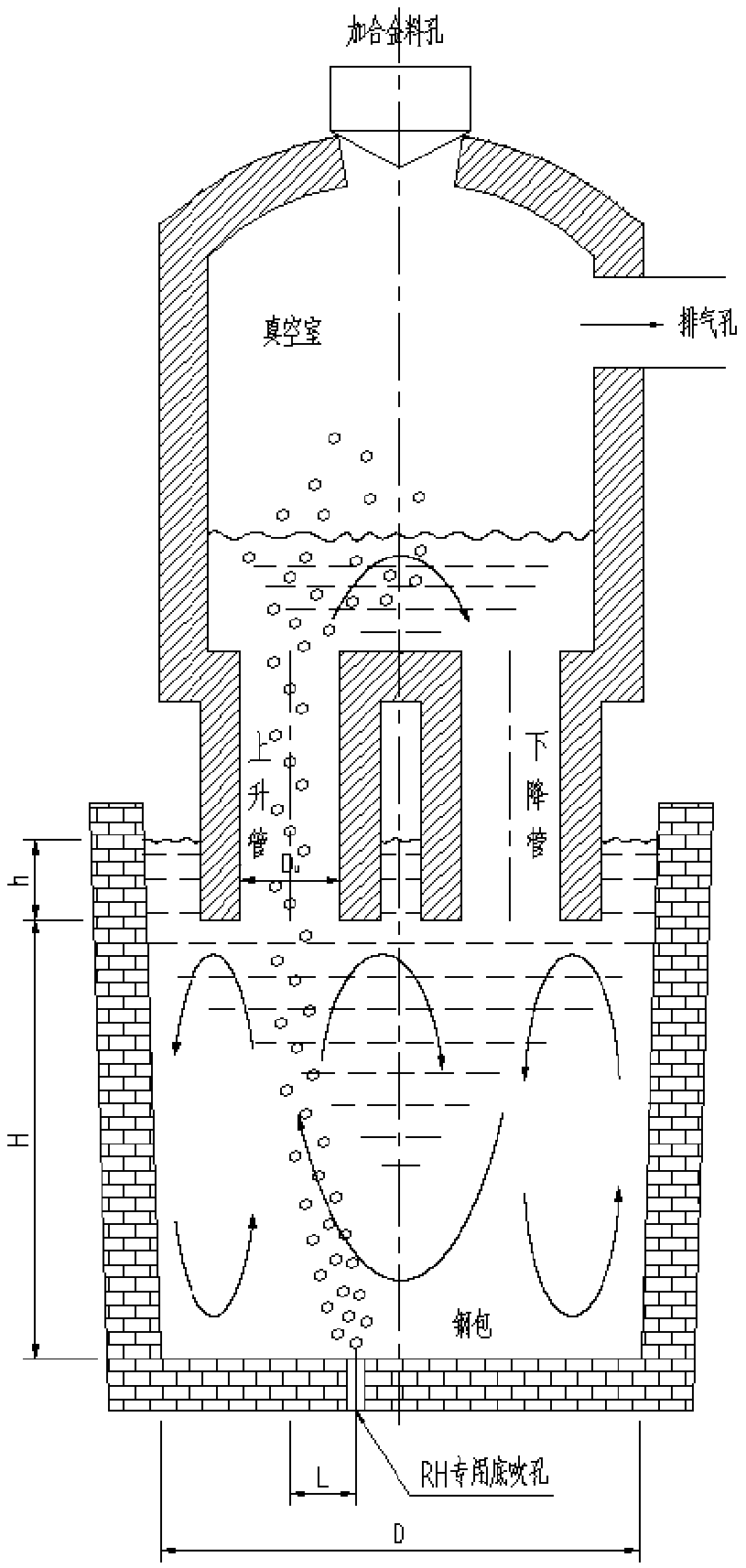

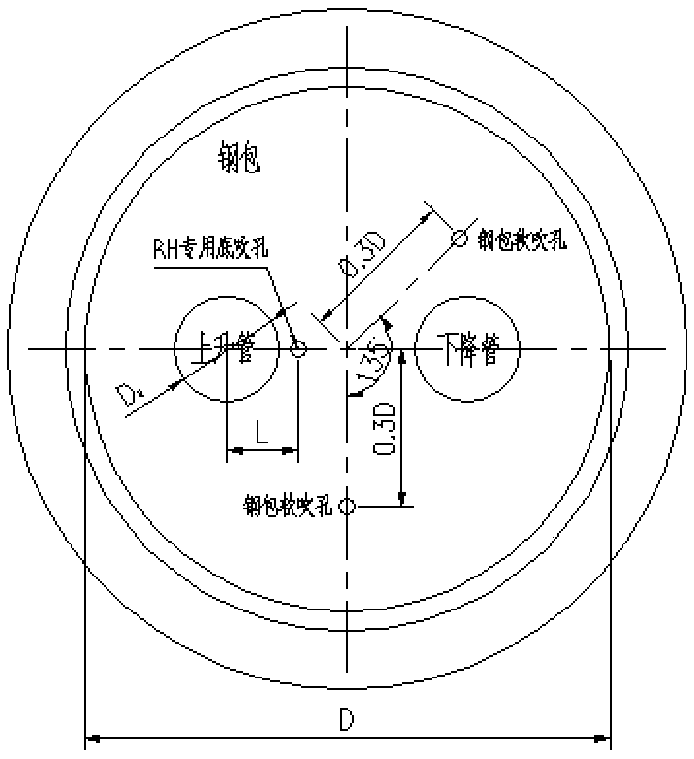

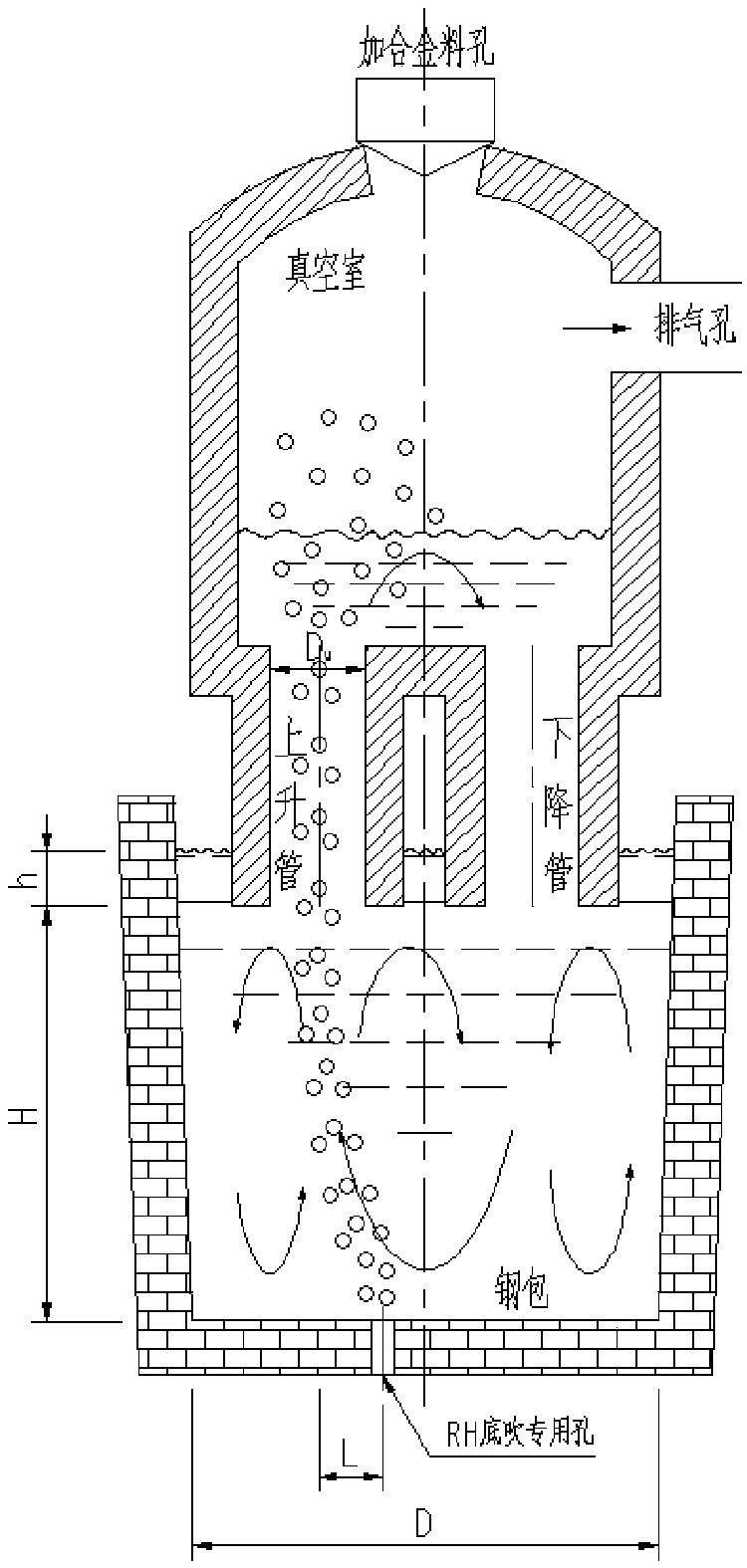

Method for increasing molten steel circulating flow quantity in RH refining process

The invention provides a method for increasing the molten steel circulating flow quantity in the RH refining process and belongs to the technical field of molten steel refining. According to the method for increasing the molten steel circulating flow quantity in the RH refining process, a process procedure of converter / electric furnace-refining RH-continuous casting is adopted to produce high-quality pure steel, in the RH refining process, by means of utilization of an existing steel ladle argon bottom blowing system, argon is blown into the bottom of a steel ladle, argon bubbles blown in thebottom move along with a molten steel flow field, molten steel is lifted to enter an RH dipping pipe ascending pipe, coordinated control between steel ladle argon bottom blowing and dipping pipe inside gas lifting is realized, so that adverse effects in actual production that the air blowing hole position of an RH dipping pipe cannot be remolded and the lifting gas flow quantity is too large to blow through the molten steel inside the dipping pipe to reduce the lifting driving force instead are overcome, and the purpose of increasing the steel circulating flow quantity in the RH refining process is finally achieved. The method for increasing the molten steel circulating flow quantity in the RH refining process has the advantages of being simple and reliable, high in operability and convenient to realize, the RH circulating flow quantity is increased, the decarbonization efficiency is high, the refining time is obviously shortened, and the molten steel purity is improved.

Owner:CENT IRON & STEEL RES INST

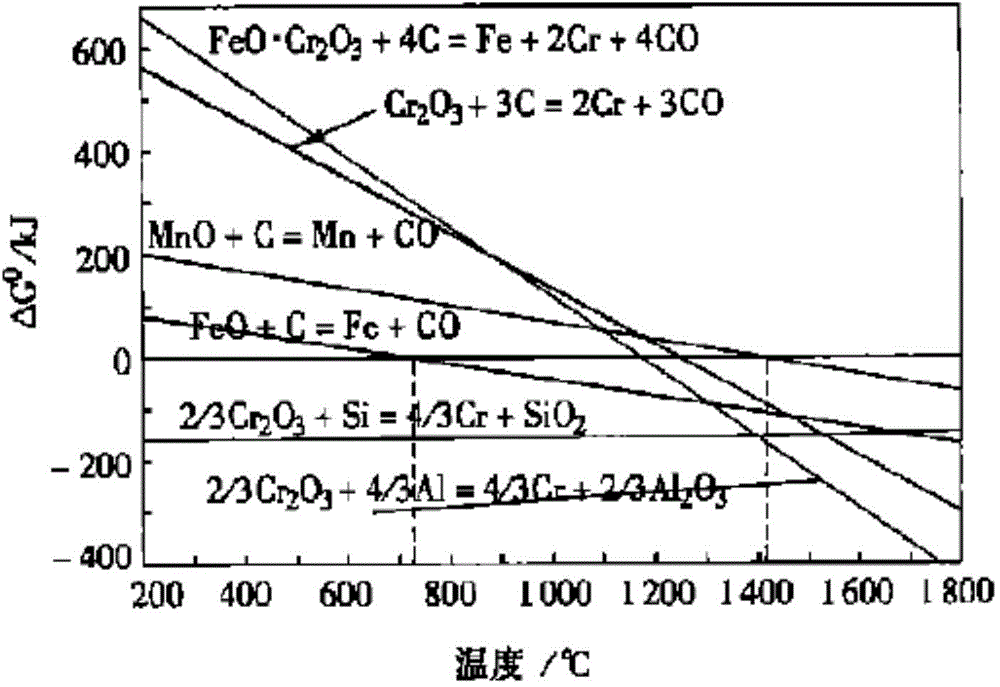

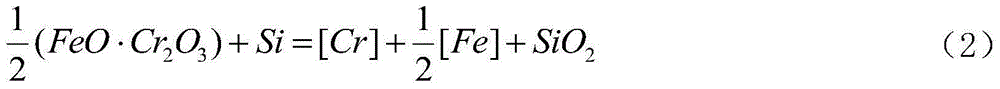

Method for increasing yield of molten steel chromium in chromium ore direct-alloying

The invention relates to a method for increasing yield of molten steel chromium in chromium ore direct-alloying and belongs to the technical field of molten steel chromium alloying in steelmaking. The method includes making chromium ore, limestone, anthracite or coke and silicon iron into powder, adding water glass to obtain mixture according to a certain proportion, making into core-spun wires, feeding the core-spun wires into molten steel in the process of refining of steelmaking and reducing to obtain chromium. The method can ensure quick reaction of the mixture in the high-temperature molten steel and promote reaction balance and contact area of powder and molten steel and is conducive to increasing recovery rate of chromium.

Owner:CENT IRON & STEEL RES INST +1

Multi-element intermediate alloy for impure copper refining, preparation thereof and application thereof

ActiveCN106399744AReduce brittlenessReduced propensity for hydrogen sicknessSmelting processBar product

The invention belongs to the technical field of non-ferrous metal material processing, and particularly relates to a multi-element intermediate alloy for impure copper refining, preparation thereof and application thereof. A Cu-P-La-B multi-element intermediate alloy is adopted, and strengthened refining is carried out on impure copper in a smelting process and a casting process, so that good deoxidation and deslagging effects are achieved; the quality of a copper bar product produced by the alloy is equivalent to that of a copper bar which is produced by taking cathode copper as a raw material; and moreover, operations are simple and convenient, and cost is relatively low. According to the multi-element intermediate alloy, the preparation thereof and the application thereof, equivalent or value-added recycling of the impure copper can be expected to be realized, and the application prospect is wide.

Owner:JIANGXI BAOTAI NON FERROUS METAL GRP

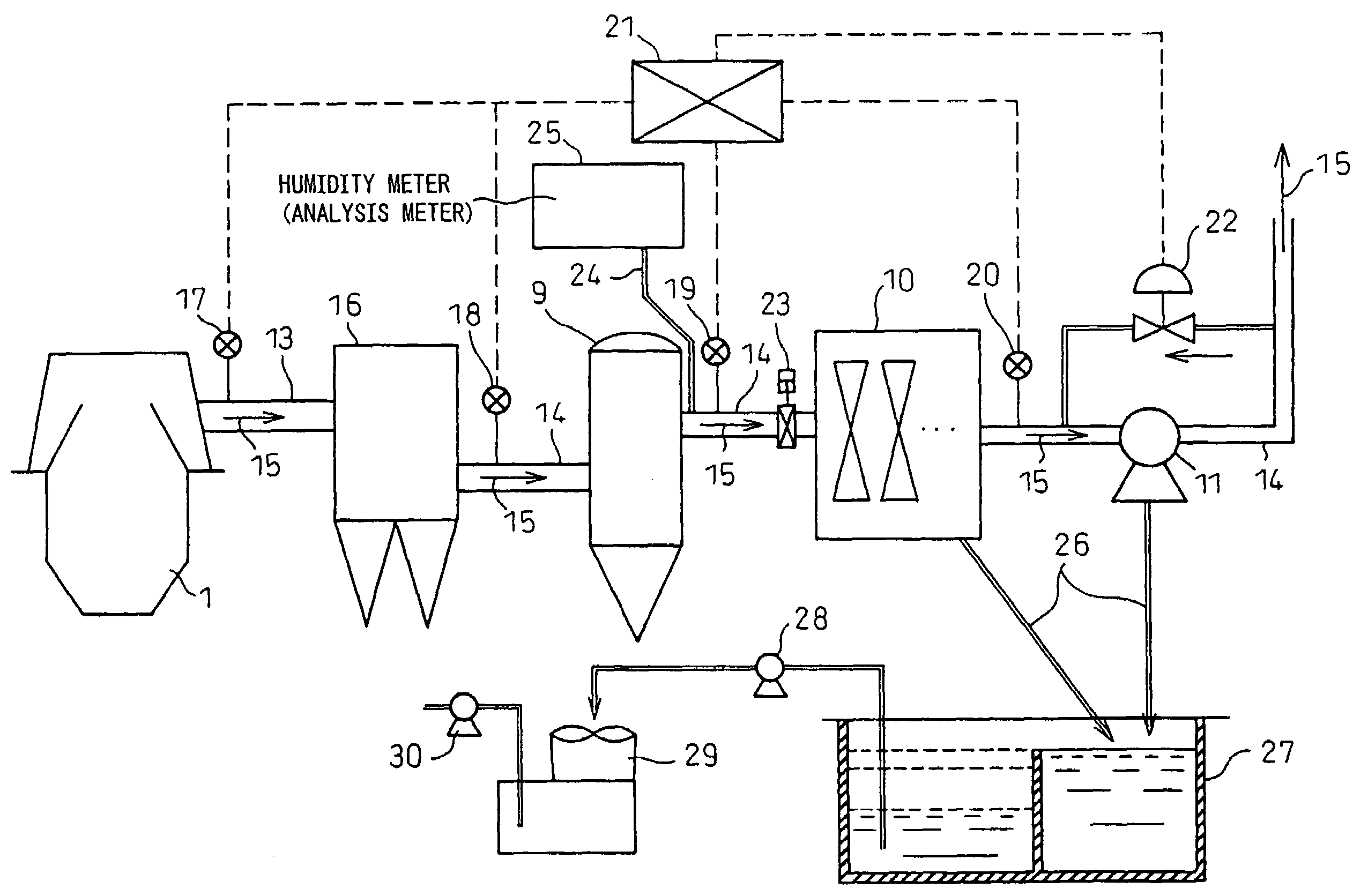

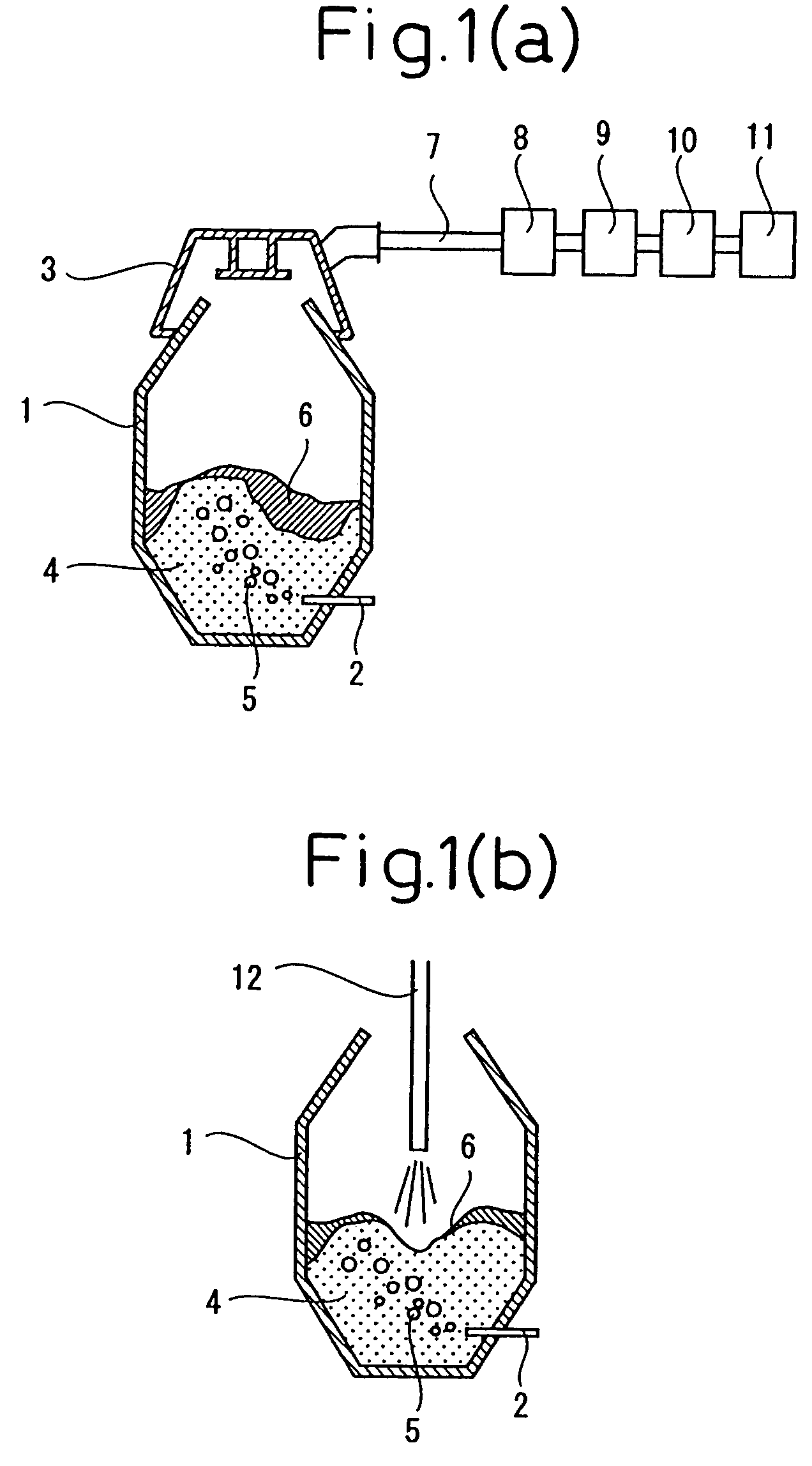

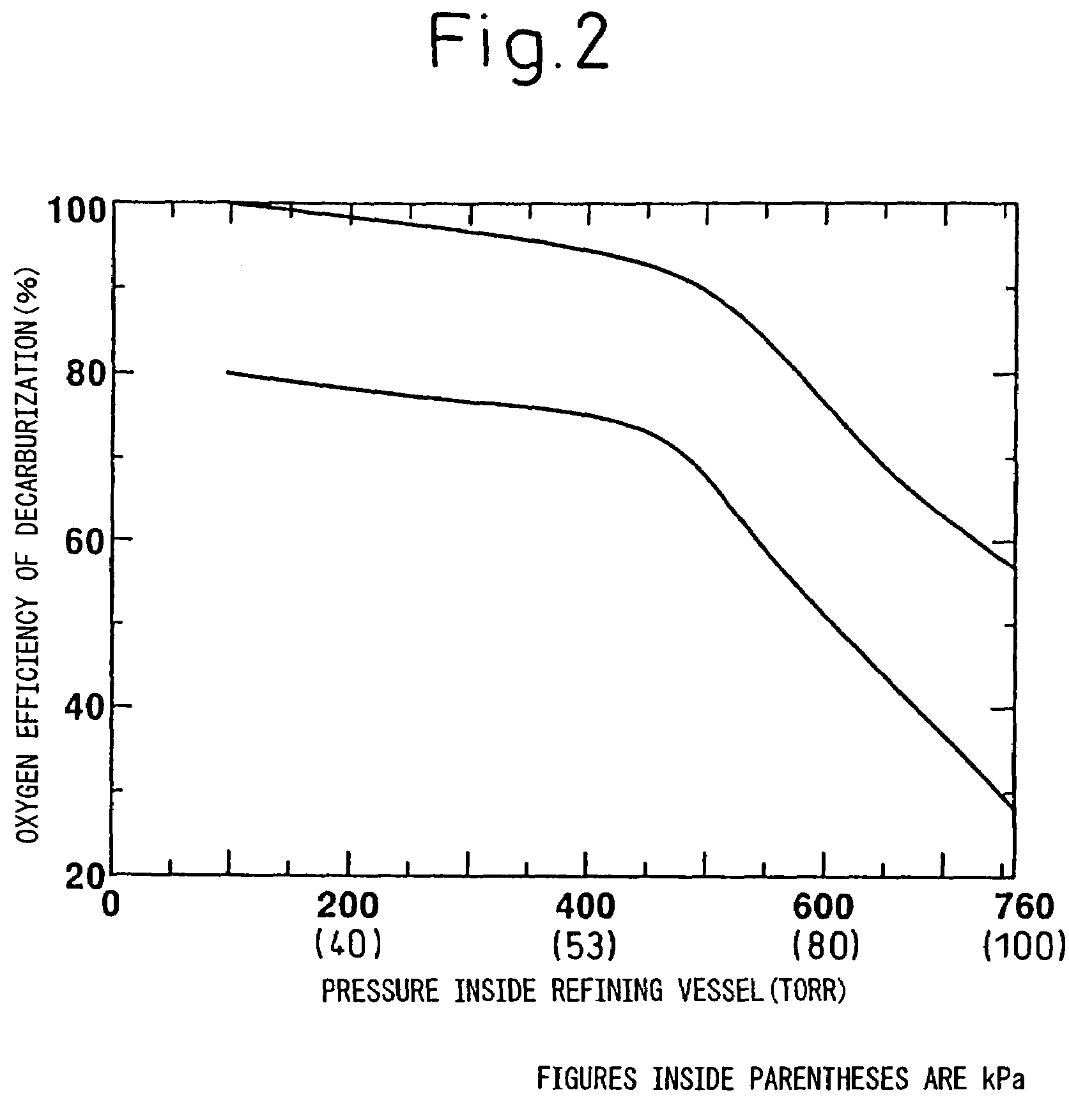

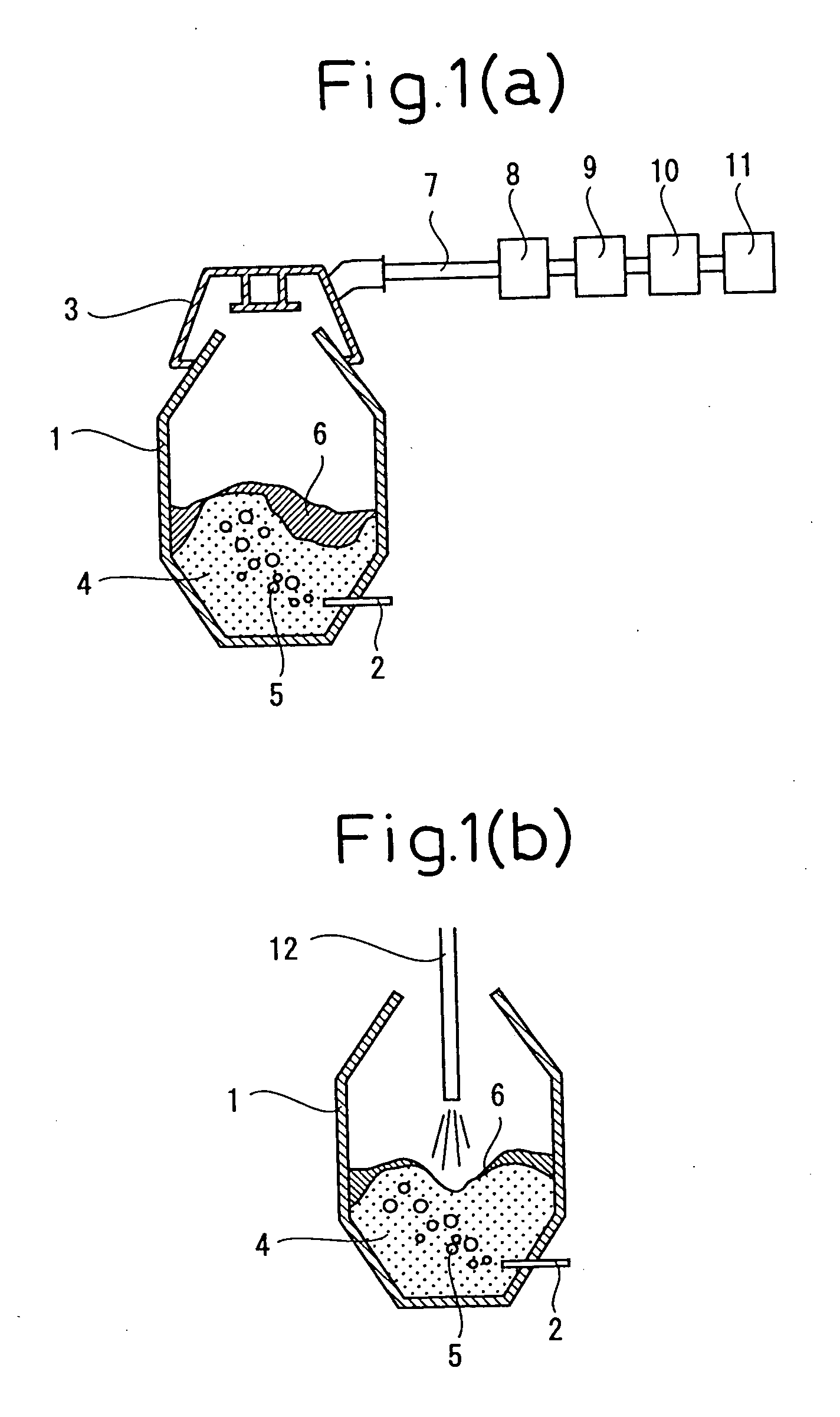

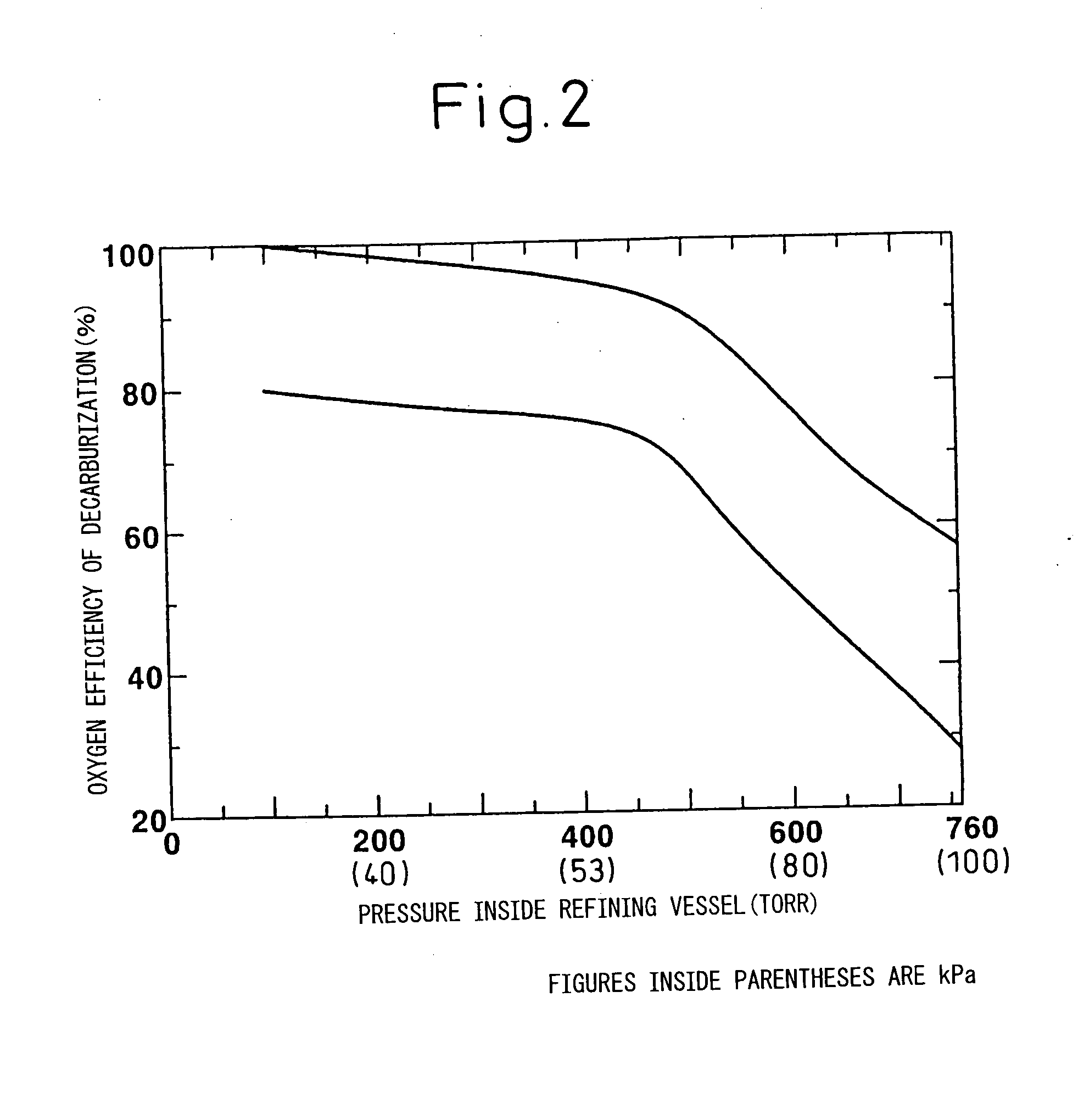

Refining method and refining apparatus for chromium-contained molten steel

InactiveUS7497987B2Reduce usageReduce refining timeCharge manipulationManufacturing convertersMolten steelIndustrial engineering

A refining method and apparatus for decarburization refining of chromium containing molten steel in a vessel having a first step of blowing oxygen while the inside of the vessel is at a pressure of between 400 Torr and atmospheric pressure, a second step of blowing oxygen while evacuation the inside of the vessel to 250 to 400 Torr and a third step of blowing gas while evacuating the vessel to not more than 250 Torr. Further, a refining method and apparatus for ultra-low carbon chrome melt by performing a first vacuum refining until the third step, then restoring the pressure in the vessel to at least 400 Torr, then performing second vacuum refining while making the bottom blowing gas blow rate at least 0.4 Nm3 per to steel.

Owner:NIPPON STEEL CORP +1

Preparation method of high-purity polished glutinous rice protein and application of high-purity polished glutinous rice protein for preparing protein beverage

The invention discloses a preparation method of high-purity polished glutinous rice protein, and belongs to the technology of refining of polished glutinous rice protein. The protein is used for preparing a protein beverage, and belongs to the technical field of beverages. The preparation method is characterized by comprising the following steps of (1) preprocessing polished glutinous rice protein residues; (2) performing fine grinding twice, and performing screening; (3) performing swelling; (4) performing enzymolysis for the first time; (5) performing micro jet; (6) performing enzymolysis for the second time, performing enzyme deactivation, and performing washing; (7) performing drying; and (8) compounding the polished glutinous rice protein and a stabilizing agent, and preparing the polished glutinous rice protein beverage. According to the preparation method disclosed by the invention, two grinding methods including a conventional grinding method and a micro jet method are utilized, so that the grain size of the protein is reduced to the greatest limit; the step of performing enzymolysis for the first time is added between the grinding steps, and the enzymolysis and the grinding are alternately performed, so that the refining time is shortened, the refining efficiency is improved, and the purity of the protein is improved; and when the high-purity polished glutinous rice protein is used for preparing the protein beverage, the polished glutinous rice protein has the notable characteristics better than other vegetable proteins that the mouth feel is soft, glutinous and smooth and during drinking, no residues exist in an oral cavity, so that the protein beverage is easy to accept by a consumer.

Owner:WUXI JINNONG BIOTECH CO LTD

Method for deflection bottom tapping of revolving furnace

InactiveCN101368223ASolve the problem of slagReduce back phosphorusManufacturing convertersSlagEngineering

The invention discloses a method used for tapping through deflecting the bottom of a convertor, which is characterized in that the tapping opening of the converter is designed at the lower part of the converter; the position at the upper end of the tapping opening is arranged below a molten liquid surface; the lower end is higher than the slag surface after tapping in the convertor only with the slag left by 10 to 20cm; the diameter of the tapping opening is between 10 and 20cm; when the smelting reaches the end point, the converter is deflected by 20 to 60 degrees; the rotated angle leads the position of the tapping opening to be arranged at the lowest side of the converter; then the tapping opening is opened, the molten steel flows into a ladle arranged below the tapping opening; after the molten steel flows out, the converter is resumed to the normal vertical position and the ladle is removed, then the liquid surface of slag is lower than the lowest position of the tapping opening of the converter; then the ladle is arranged below the converter and the converter is deflected to lead the opening of the converter to face the lower side; and then the slag is spilled out from the opening of the converter. The method used for tapping through deflecting the bottom of a convertor solves the problem of slag during the tapping of the converter, ensures the slag amount of the converter to be lower than 0.5kg / t. Not only the rephosphorization of the molten steel can be reduced and the alloy recycling rate is improved, but also the occluded foreignsubstance in the steel can be reduced and the cleanness of the molten steel can be improved. Besides, the refining time can be shortened and the desulfurization degree can be improved.

Owner:UNIV OF SCI & TECH BEIJING

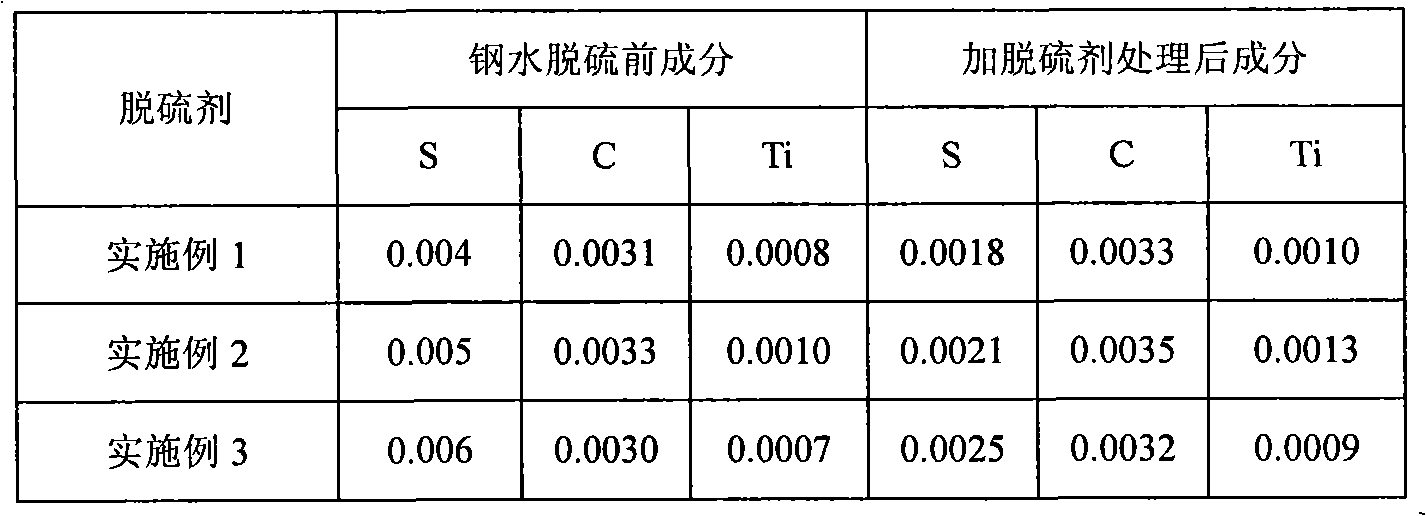

Desulfurizing agent suitable for high-aluminum silicon steel and preparation method thereof

The invention provides a desulfurizing agent suitable for high-aluminum silicon steel and a preparation method thereof. The desulfurizing agent comprises the following components: 75-80 percent of calcium oxide (CaO), 10-15 percent of aluminum oxide (Al2O3), 3-6 percent of magnesium oxide (MgO), 3-6 percent of magnesium chloride (MgCl2), not greater than 1.5 percent of silicon dioxide (SiO2), not greater than 0.02 percent of all titanium (Ti) and not greater than 0.02 percent of all carbon (C). The preparation method comprises the following steps: (1) weighing the raw materials: 72-77 percent of CaO, 8-13 percent of Al2O3 and 10-20 percent of binder; (2) respectively crushing the CaO and the Al2O3 into particles of which the particle sizes are less than 0.1mm; (3) heating the CaO to 120-150 DEG C, and carrying out spray treatment on the CaO particles by using silicone oil so as to form a protective film; (4) mixing the CaO and the Al2O3 with the binder; and (5) pressing into balls by using a ball press, and drying and packaging. The desulfurizing agent provided by the invention is easy to store, has high desulfurizing rate and low environmental pollution and has low corrosion on the refractory of a vacuum slot body; in the desulfurizing process, the molten steel carburetion and titanizing can be controlled to be under 5ppm; and the desulfurizing rate can reach at least 50 percent on the premise of not increasing the refining time.

Owner:ANGANG STEEL CO LTD

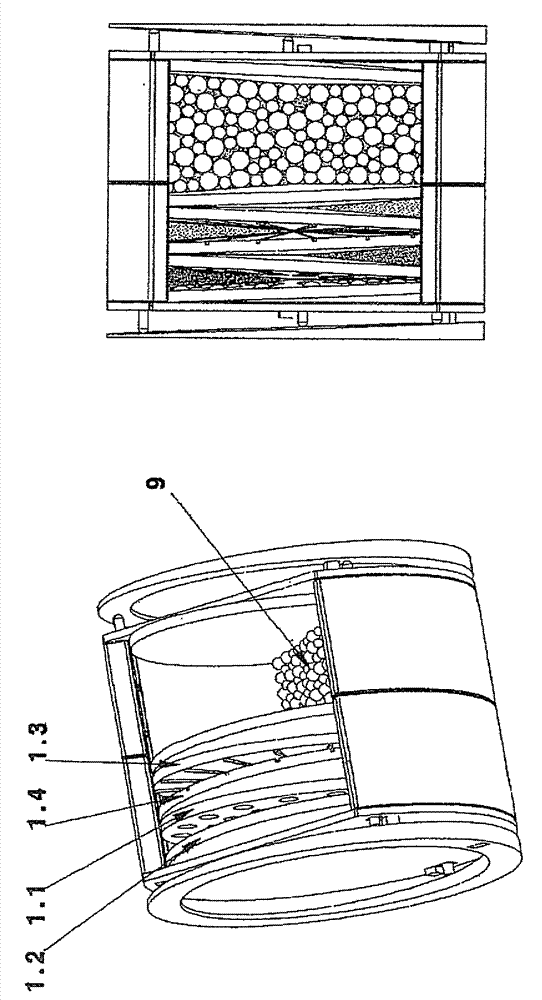

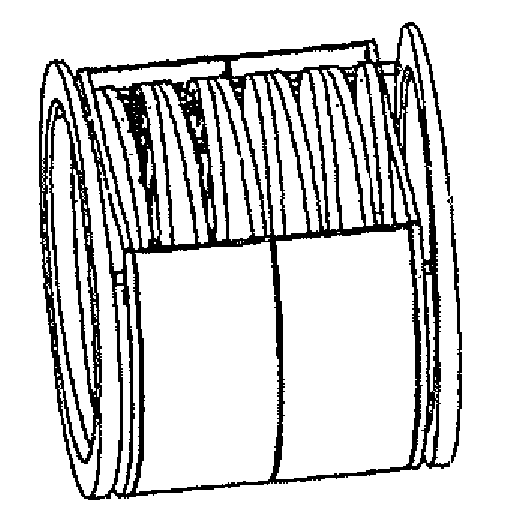

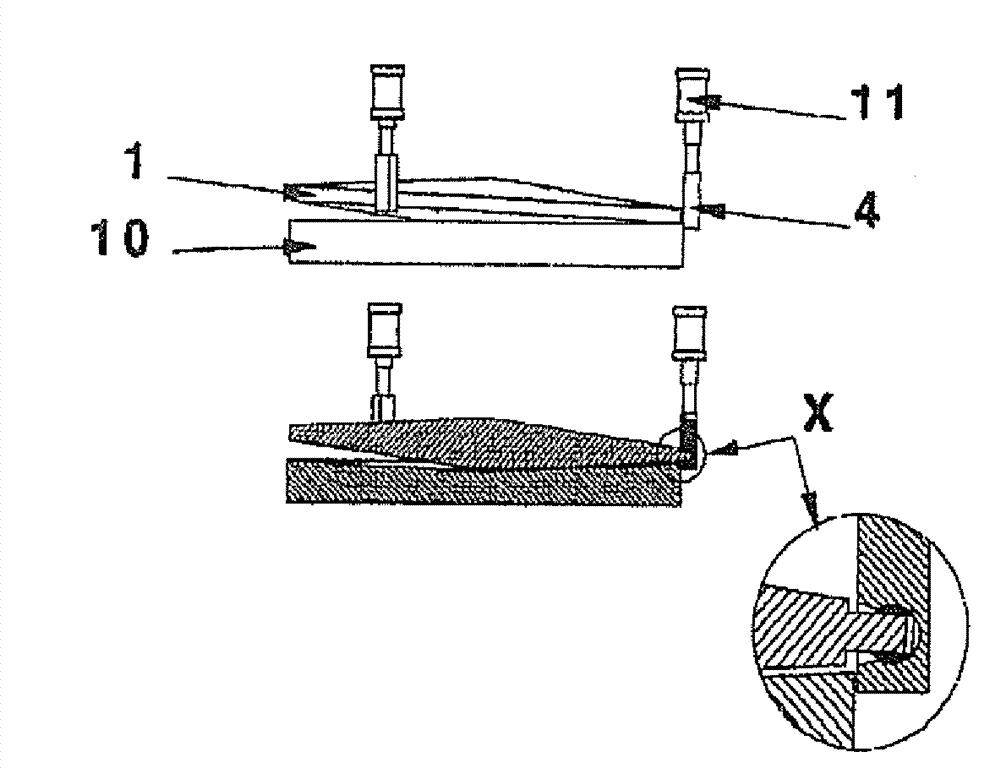

Device and method for the continuous treatment of masses and milling material

InactiveCN103097031AMultiple inputMultiple and controlled inputTransportation and packagingCocoaEngineeringSwashplate

The invention relates to a device and a method for processing milling material and masses in continuous processes, in particular the treatment of fat-containing masses. Milling with one swashplate (1) with a fixed plate or two swash plates (1), conching with swashplates (1) and also, as a final process step, tempering and crystallizing by means of swashplates (1).

Owner:亚历克斯・诺贝尔 +1

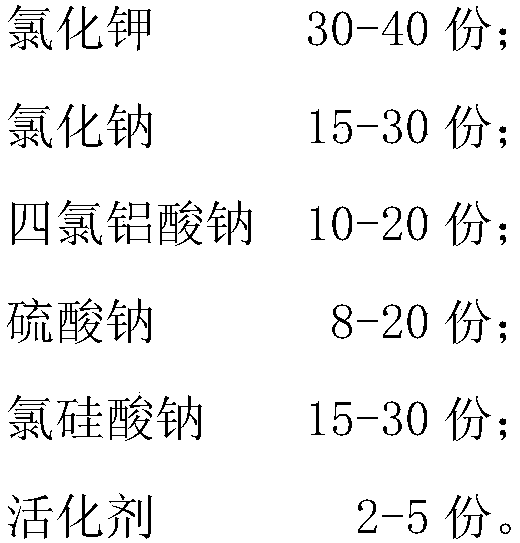

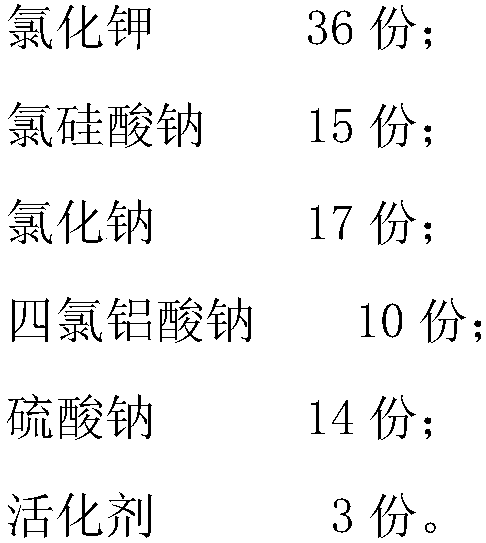

Refining agent for metal smelting, preparation method and refining technology

InactiveCN108660331APromote decompositionImprove refining efficiencyLead smeltingAtmospheric pollution

The invention relates to the technical field of aluminum and aluminum alloy purifying and refining treatment, in particular to a refining agent for metal smelting, a preparation method and a refiningtechnology. The refining agent for metal smelting aims to remove impurities of molten aluminum in the aluminum alloy refining process, so that the product quality is improved, and atmospheric pollution is avoided. The refining agent for metal smelting comprises, by weight, 30-40 parts of potassium chloride, 15-30 parts of sodium chloride, 10-20 parts of sodium tetrachloroaluminate, 8-20 parts of sodium sulfate, 15-30 parts of chloride sodium silicate and 2-5 parts of activating agent. According to the refining agent for metal smelting, the activating agent is added to the refining agent, the activating agent can promote sodium tetrachloroaluminate in the refining agent to decompose and reduce the interfacial tension between the refining agent and oxide inclusion at the same time, so that the oxide inclusion can smoothly float on the surface of the melt and then is removed, and therefore the product quality is improved.

Owner:湖北新金洋资源股份公司

Method for refining molten iron containing chromium

InactiveUS20040245682A1Reduce forceMinimal damageCharge manipulationManufacturing convertersAtmospheric pressureMolten steel

A refining method and refining apparatus, able to shorten the time required for refining and reduce the refining costs in decarburization refining of a chromium-contained molten steel, which refining method for chromium-contained molten steel etc. performing decarburization refining by blowing a gas containing oxygen gas into a chromium-contained molten steel under a vacuum or atmospheric pressure and vacuum, said refining method for a chromium-contained molten steel etc. characterized by having a first step for blowing oxygen gas while making the inside of the vessel a pressure of a range of 400 Torr (53 kPa) to atmospheric pressure, a second step for blowing oxygen gas while evacuating the inside of the vessel to 250 to 400 Torr (33 to 53 kPa), and third step for blowing gas while evacuating the inside of the vessel to not more than 250 Torr (33 kPa). Further, a refining method and refining apparatus for an ultra-low carbon chrome melt characterized by performing a first vacuum refining until the third step, then restoring the pressure in the vessel to at least 400 Torr (53 kPa), then performing second vacuum refining while making the bottom blowing gas blow rate at least 0.4 Nm<3> / min per ton steel.

Owner:NIPPON STEEL CORP +1

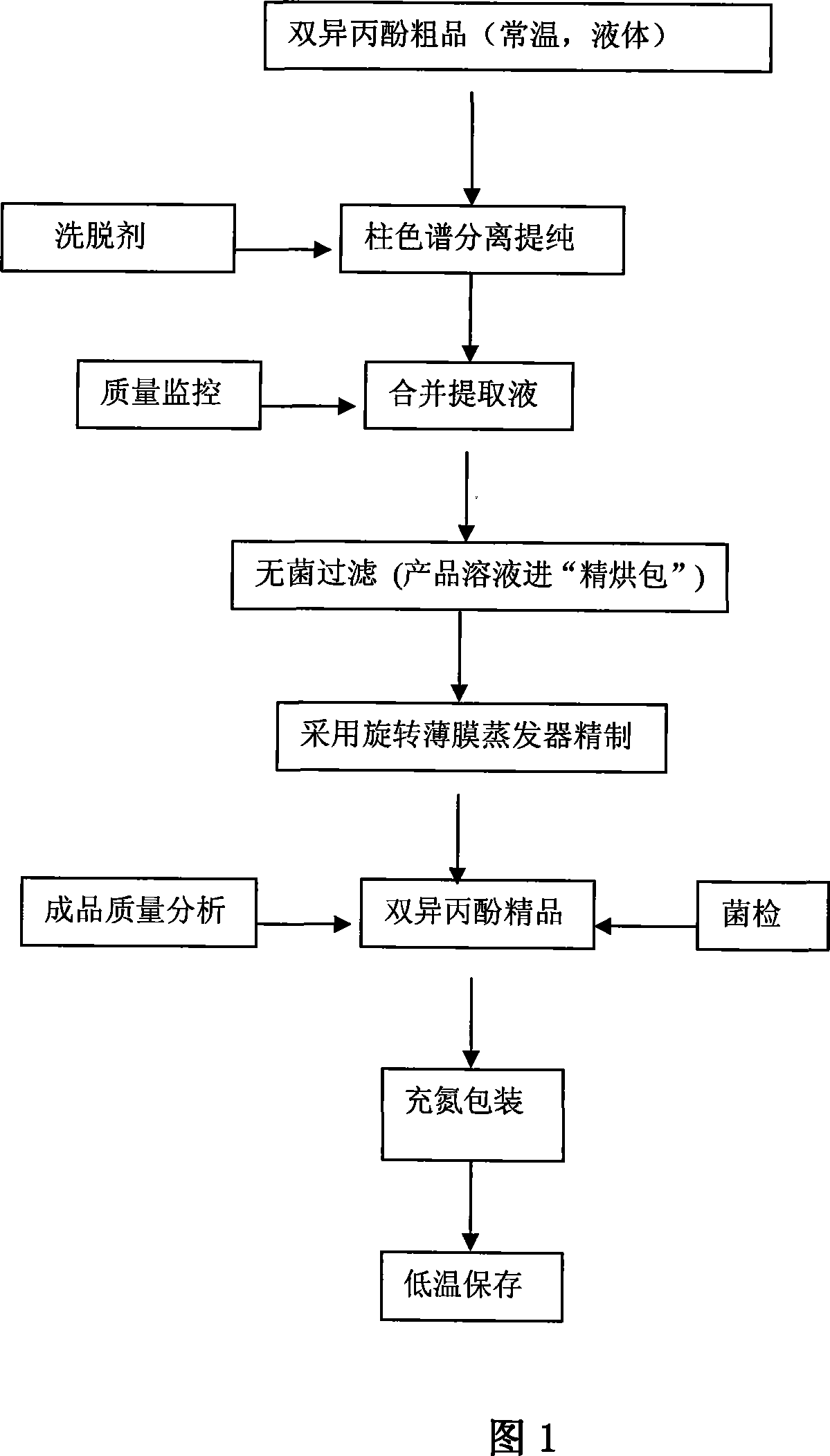

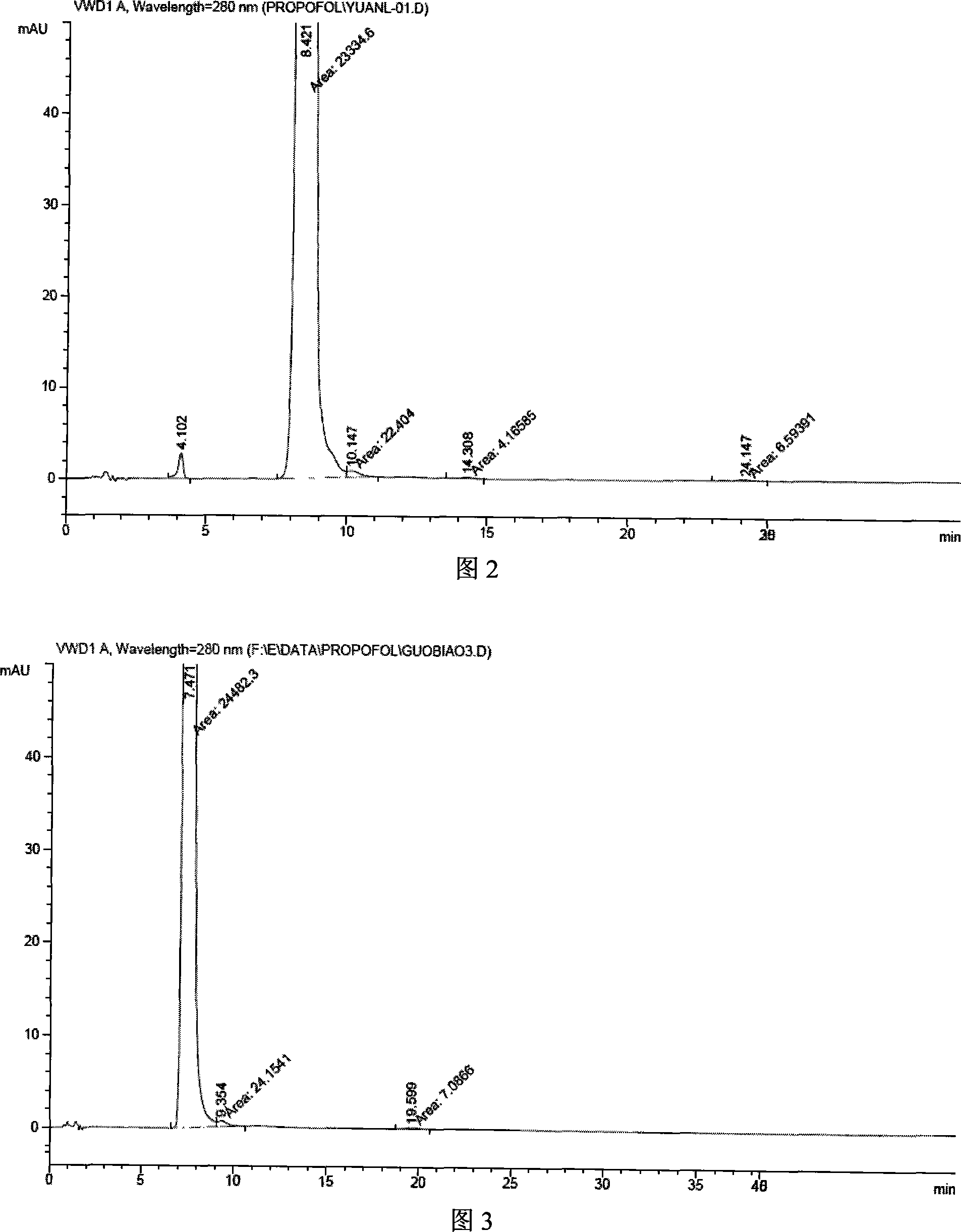

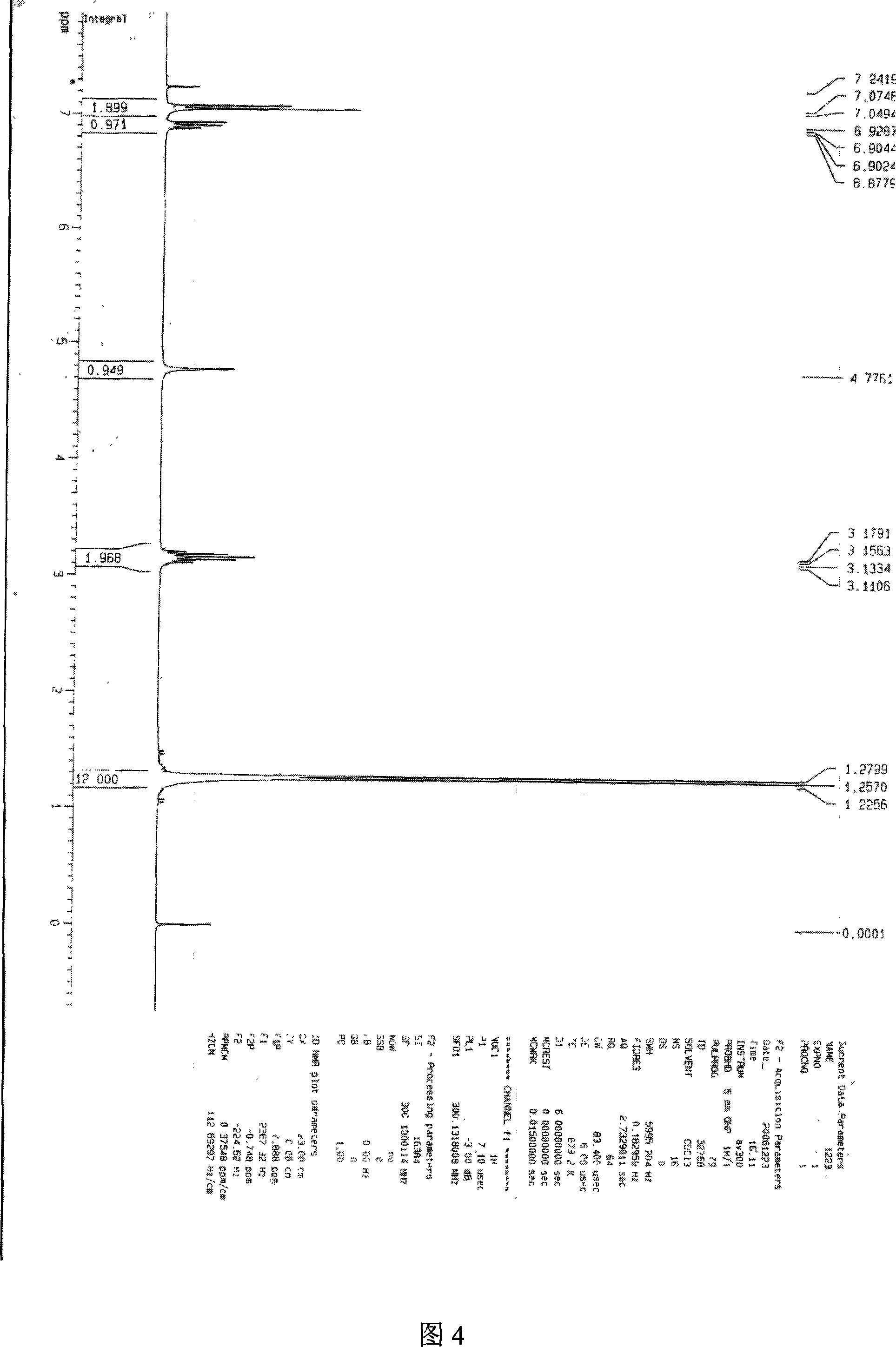

Refining method for propofol injection

ActiveCN101081804AAvoid destructionReduce refining timeOrganic chemistryOrganic compound preparationChemical structureChromatographic separation

The present invention discloses bipropofol refining process, which includes chromatographic column separation to eliminate impurities with similar chemical structures, and rectification in a rotary film evaporator with shortened detention period of the material in the heating evaporation region and reduced thermal decomposition of bipropofol. The process of the present invention is superior to available refining processes, and has short refining period, less degradation of bipropofol and high product quality controllability.

Owner:XIAN LIBANG PHARMA

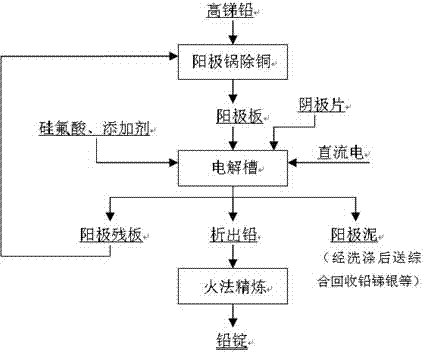

Electrolytic method of high-antimony lead

InactiveCN104120445AReduce refining timeReduce coal consumptionPhotography auxillary processesHigh current densityReverberatory furnace

The invention relates to an electrolytic method of high-antimony lead, belonging to the field of pyrogenic-process and wet-process combined metallurgical technology. The method comprises the following steps: performing dosing and copper removal on the high-antimony lead produced by blast smelting in an anode pot, casting into an anode plate, and controlling the content of Sb in the lead anode plate to be 6%-7%; feeding the anode plate into an electrolytic tank, electrolyzing at high-current density of 183-187A / m<2>, adding gelatin and beta-naphthol into electrolytic liquid to adjust the crystallization quality of a cathode, washing anode mud produced by electrolysis, and feeding to a reverberatory furnace for smelting and recovering metal such as lead, antimony, silver and bismuth; melting produced separated lead in a refining pot, adding caustic soda for refining, and performing ingot casting to obtain a national-standard lead ingot. The method has the characteristics that the yield of separated lead is high, the current efficiency is high (not less than 94%), the direct-current consumption is low (not more than 115kwh / t electrical lead), the electrolytic process is low in cost, yellow lead does not need to be added for increasing lead ions, the antimony product yield is increased, and the like.

Owner:蒙自矿冶有限责任公司

Submerged arc refining slag and preparation method thereof

InactiveCN102220456AImprove ingredient stabilityHigh yieldProcess efficiency improvementSlagHigh carbon

The invention discloses submerged arc refining slag, which is prepared from the following raw materials in part by weight: 35 to 40 parts of sintered bauxite, 1 to 2 parts of metal aluminum powder, 8 to 12 parts of silicon carbide, 2 to 4 parts of high carbon powder, 40 to 45 parts of limestone, 1 to 3 parts of blast furnace grain slag and 2 to 4 parts of lignin. In the invention, deoxygenation, submerged arc foaming and refining are integrated, production process is simplified, working environment is improved, the stability of ingredients of molten steel is improved, smelting cost is lowered, refining time is reduced, yield of expensive metal is increased, secondary oxidization of molten steel is relieved, the recovery rate of molten steel is increased, arc and noise pollution are reduced and the service life of refractory materials is prolonged.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com