Construction method for dam body seepage preventing curtain grouting

An anti-seepage curtain and construction method technology, applied in water conservancy engineering, marine engineering, construction and other directions, can solve the problem of impermeability, poor corrosion resistance and durability, neglect of anti-corrosion measures of the curtain body, and difficulty in forming an effective curtain body, etc. problems, to achieve the effect of improving the strength of the stone, improving the anti-seepage ability of the curtain, and increasing the thickness of the curtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

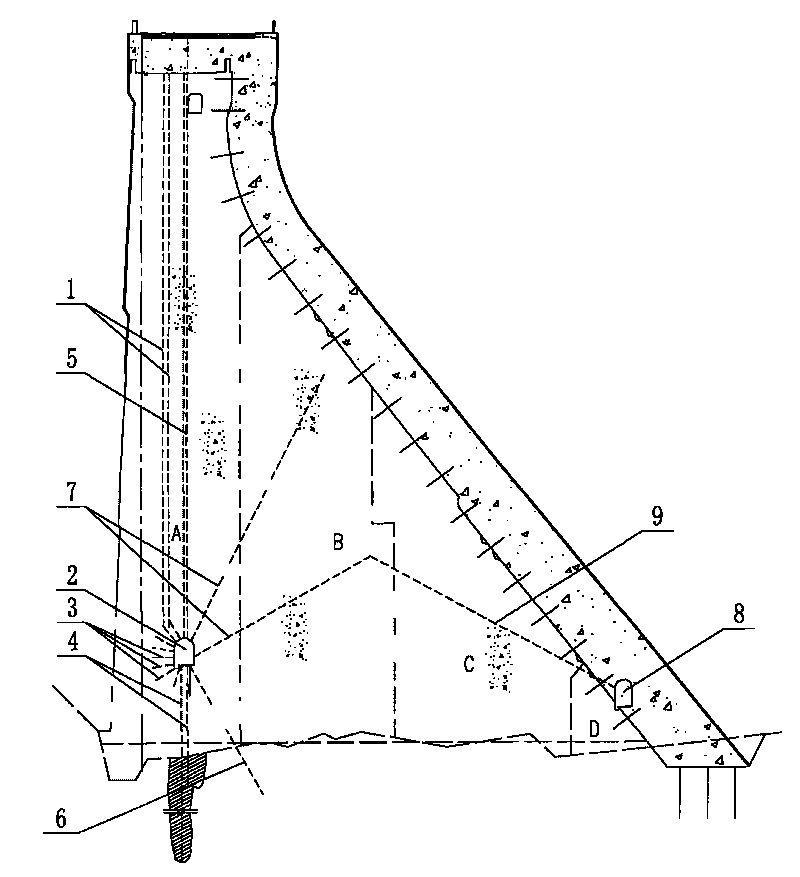

[0020] Such as figure 1 Shown, the specific construction method of this embodiment is as follows:

[0021] a. Drill a group of curtain grouting holes 1 vertically downward on the dam crest, the bottom of the holes is 4m away from the top of the foundation corridor 2, the hole diameter is 56mm, the hole spacing is 1m, the row spacing is 0.5m, and it is arranged in a plum blossom shape;

[0022] b. In the foundation corridor 2, fan-shaped radial grouting holes 3 are drilled on the upstream surface, and intersect and connect with the vertical curtain grouting holes 1;

[0023] c. In the foundation corridor 2, the curtain connection grouting hole 4 is drilled vertically down to the dam foundation 5m (the depth is the depth of the dam anti-seepage curtain, which must be connected with the dam foundation anti-seepage curtain), and its aperture is 56mm. The distance is 1m, so that the dam body and the dam foundation anti-seepage curtain are connected to form a complete anti-seepage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com