Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Reduce FeO content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of high magnetic induction oriented silicon steel

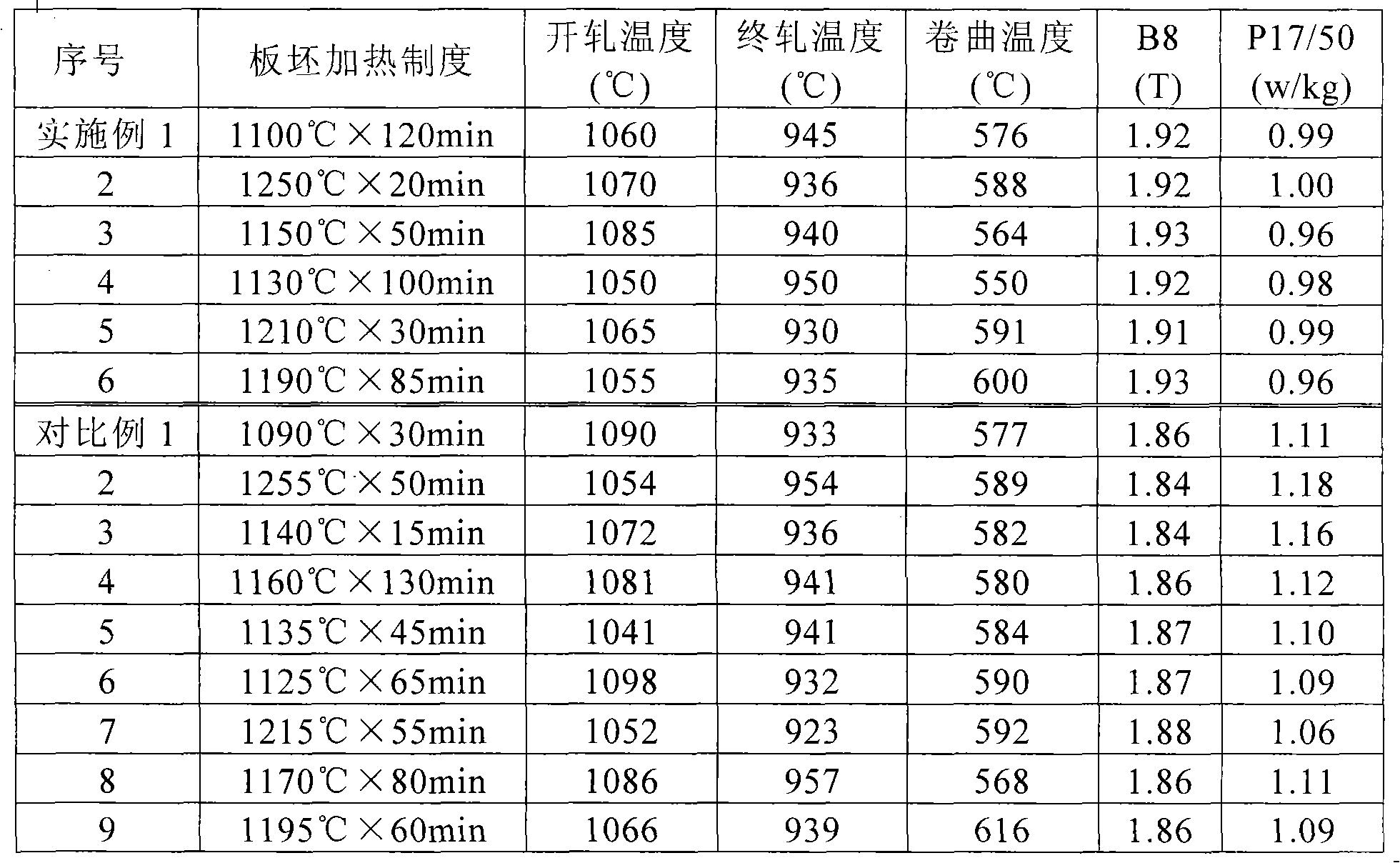

ActiveCN101845582AIncrease contentPrevent transverse crackingSolid state diffusion coatingSiliconAtmosphere

The invention relates to a production method of high magnetic induction oriented silicon steel, comprising the steps of smelting, continuous casting, hot rolling, normalization, decarbonization and annealing, MgO coating, high-temperature annealing and insulation coating, wherein the normalization comprises the steps that: normalization is carried out on a hot rolling plate, nitridation is finished synchronously, the temperature of normalization and nitridation is 1050-1150 DEG C, the atmosphere is 5-35% NH3 (volume percentage), and the balance of gas is N2; after the normalization and nitridation, the N content nitrided into the hot rolling plate is 60-250ppm; and normalization cooling is carried out, the initial temperature of fast cooling is 700-950 DEG C, and the fast cooling speed with the temperature of being reduced to 550 DEG C is 15-40 DEG C / sec. The production method solves the problem of difficult nitridation in the decarbonization procedure when a low-temperature plate blank heating technology is used for producing the high magnetic induction oriented silicon steel, carries out synchronous nitridation on the hot rolling plate in the normalization procedure, and leads the following procedure of decarbonization and annealing techniques to be simplified and easily controlled, thus not only being capable of obtaining a high magnetic induction oriented silicon steel product with excellent performance and simultaneously leading the production cost to be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

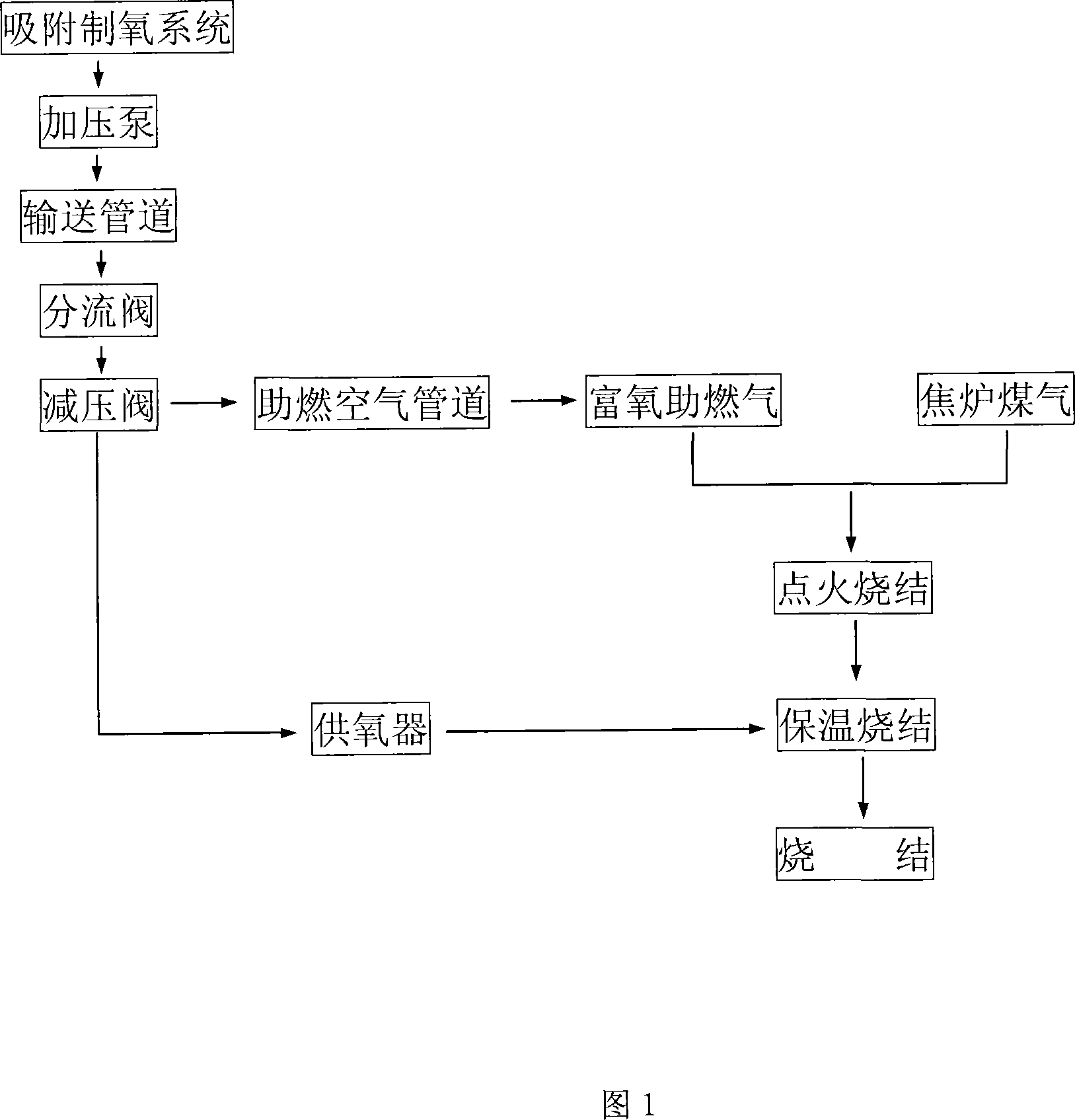

Oxygen-enriched sintering technique

The present invention relates to a rich oxygen sintering technology, which comprises ignition rich oxygen and heat preservation rich oxygen, namely, the rich oxygen sintering is used in both the ignition section and the heat preservation section of a continuous strand sinter machine. The rich oxygen sintering technology has the technical proposal that: first, ignition rich oxygen: oxygen with 93 percent purity produced with an adsorption oxygen producing system is delivered to a combustion-supporting pipeline after passing through a pressurization pump, a transfer pipeline, a flow dividing valve, and a pressure reduction valve, the oxygen and the combustion-supporting air in the combustion-supporting pipeline are mixed, to form the required combustion-supporting air with rich oxygen, and the oxygen content in the combustion-supporting air with rich oxygen is 22 to 25 percent; then ignition is performed after the combustion-supporting air with rich oxygen and coke oven gas is mixed with 2.7: 1 to 4.2:1 proportion of the combustion-supporting air with rich oxygen and the coke oven gas; second, heat preservation rich oxygen: oxygen with 93 percent purity produced with an adsorption oxygen producing system is delivered to an oxygen supply apparatus after passing through a pressurization pump, a transfer pipeline, a flow dividing valve, and a pressure reduction valve, the oxygen supply apparatus adds oxygen to the sintering heat preservation section through the periphery of a heat preservation cover, to lead the oxygen content in the heat preservation atmosphere after being filled with oxygen to achieve 22 to 30 percent, and the rich oxygen is supplied to the sintering material layer through forceful air draught.

Owner:LAIWU IRON & STEEL GRP

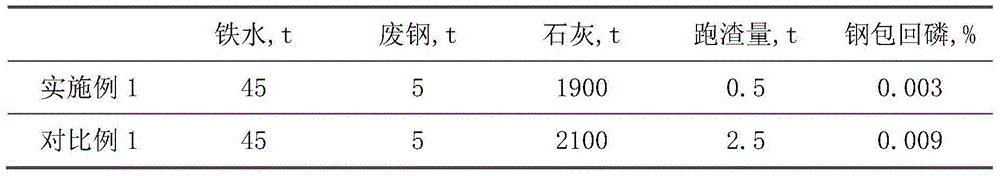

Efficient dephosphorization process for converter

ActiveCN102965463AMeet the phosphorus content control requirementsGood dephosphorization effectManufacturing convertersProcess efficiency improvementSteelmakingMolten steel

The invention relates to an efficient dephosphorization process for a converter, and belongs to the technical field of converter steelmaking. In the process, end slag of the converter is not poured out and is used for the next dephosphorization in the converter; in order to improve the smelting effect in the stage of dephosphorization in circulation of the converter, the lance position and the oxygen supply in the stage of dephosphorization and a slagging technological means are controlled to realize the efficient dephosphorization by using the end slag of the converter, so that the lime consumption can be reduced, the dephosphorization effect of the converter is improved, and compared with those of the conventional process, the lime consumption can be saved by 40 to 60 percent, the consumption of caustic calcined dolomite is saved by 40 to 46 percent, and the mass fraction of phosphorous in terminal molten steel of the converter is less than 0.006 percent.

Owner:SHOUGANG CORPORATION

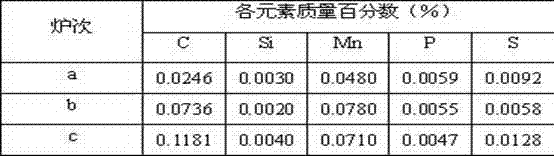

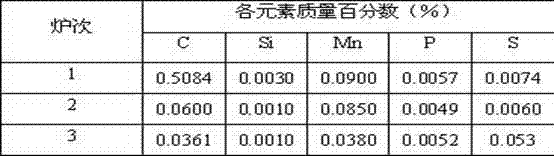

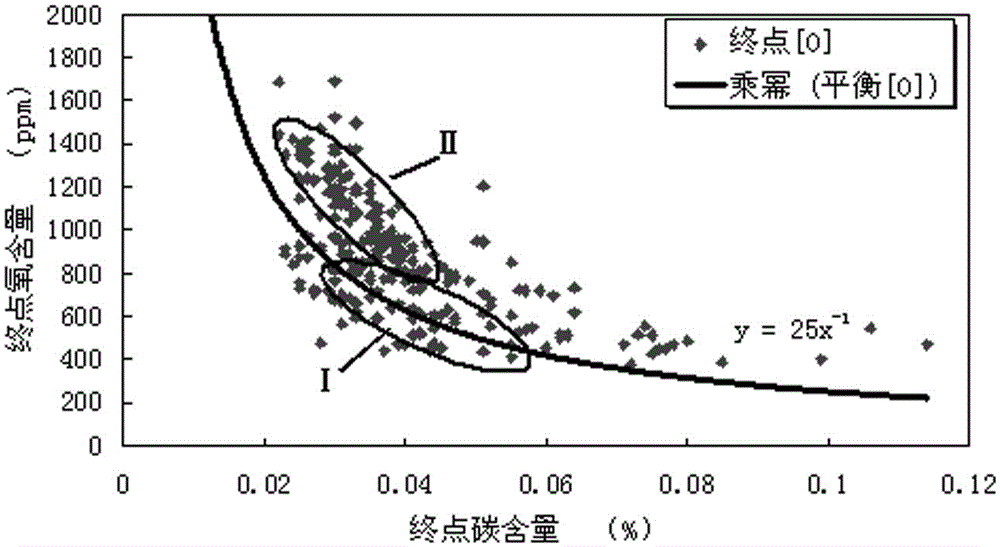

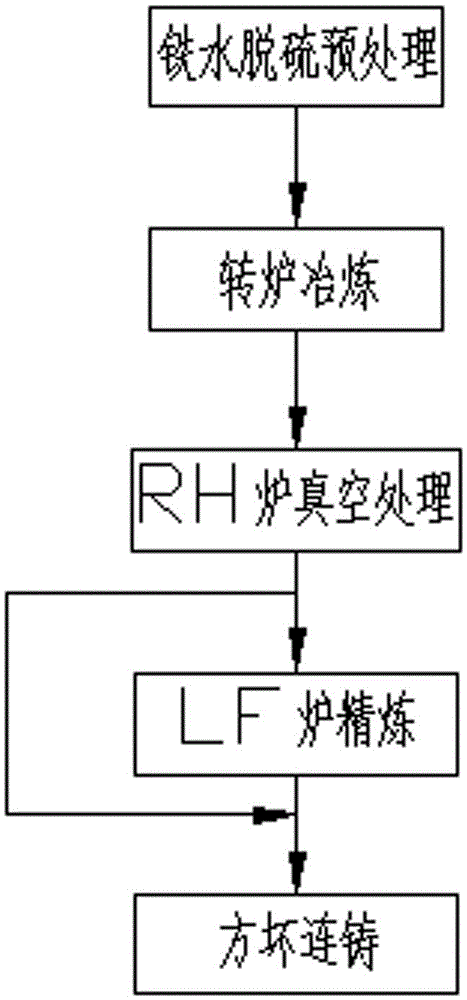

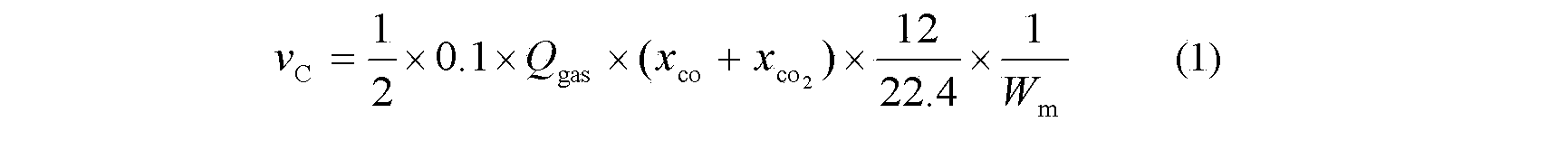

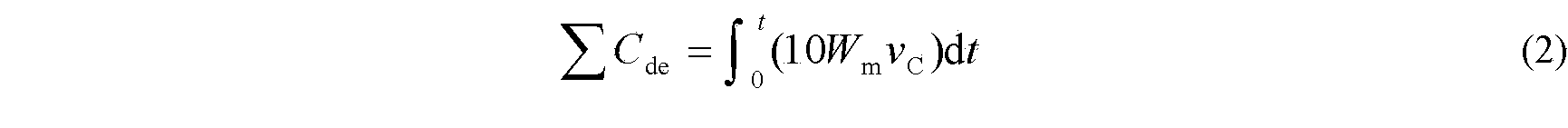

Production method of ultra-low-carbon, low-silicon, low-manganese and low-aluminum steel continuous casting blank

ActiveCN109943680AGuarantee the stability of deoxidation effectGuaranteed liquidityManufacturing convertersProcess efficiency improvementChemical compositionManganese

The invention relates to a production method of ultra-low-carbon, low-silicon, low-manganese and low-aluminum steel continuous casting blank. The continuous casting blank is composed of the followingchemical components of, in percentage by mass, less than or equal to 0.004% of C, less than or equal to 0.006% of Si, less than or equal to 0.06% of Mn, less than or equal to 0.010% of P, less than orequal to 0.010% of S, less than or equal to 0.004% of Alt, less than or equal to 0.02% of Cu, less than or equal to 0.02% of Cr and less than or equal to 0.02% of Ni, and the balance Fe and inevitable impurities; and the production process route of the continuous casting blank comprises the following steps of molten iron pretreatment, desulfurization, converter smelting, LF refining, RH vacuum treatment and continuous casting. Through the converter smelting, the LF refining, the RH vacuum treatment and the continuous casting technology, so that the chemical components are obtained to meet therequirement of the molten steel, the deoxidization effect and the liquidity of the molten steel are ensured, and casting by a small square billet continuous casting machine to obtain a steel billet with good surface and internal quality.

Owner:SGIS SONGSHAN CO LTD

Method for increasing residual manganese content in molten steel at end point of converter

InactiveCN108396093AIncrease the residual manganese contentReduce the amount addedManufacturing convertersProcess efficiency improvementSteelmakingManganese

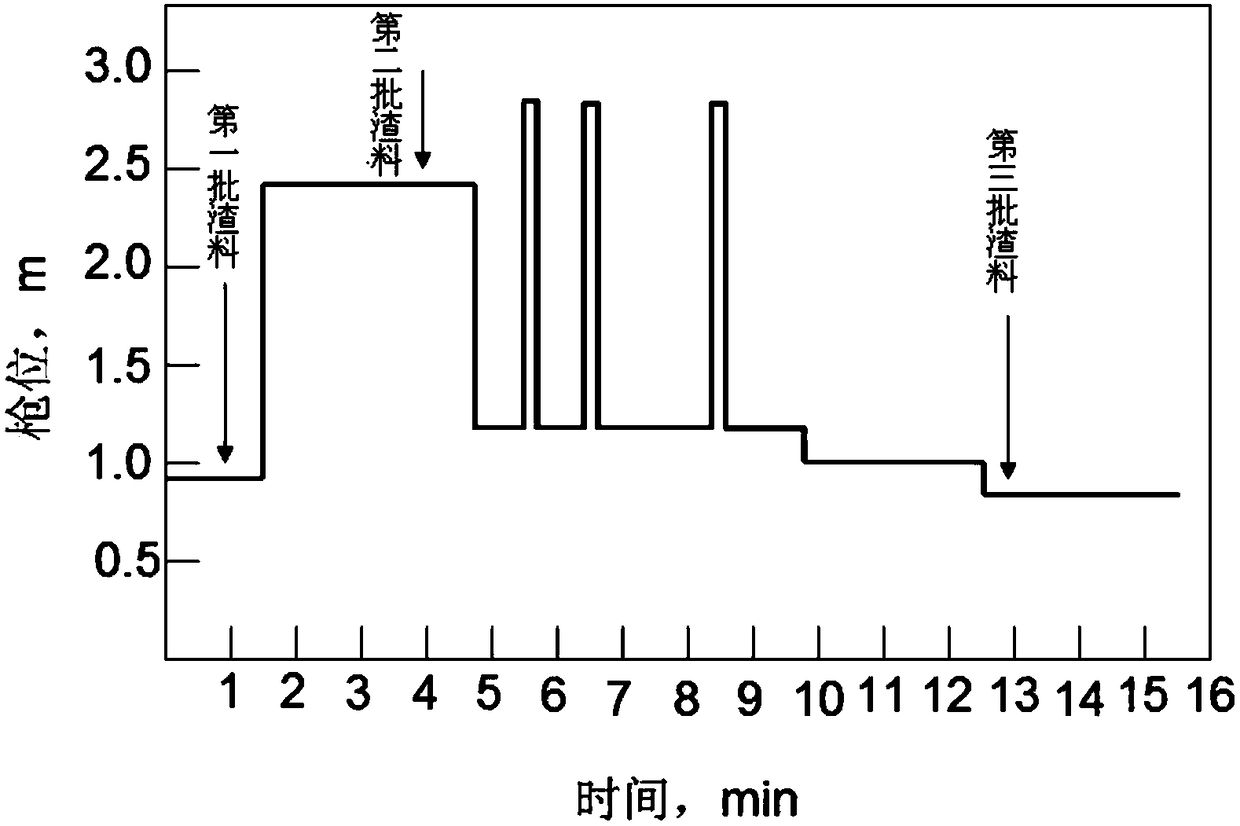

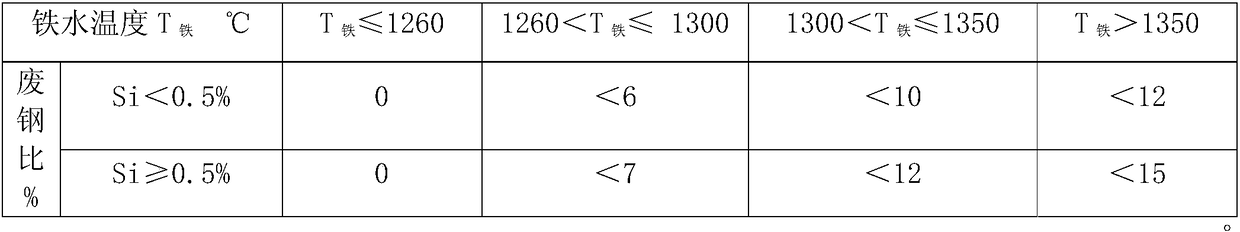

The invention provides a method for increasing the residual manganese content in molten steel at the end point of a converter. According to the method, the waste steel loading amount of the converteris controlled according to the waste steel ratio of not more than 15%; at the early stage of the smelting, the iron-carbon ball slag is added while the white ash slag is added into the converter, theadding amount of the first batch of the slagging material is 50-70% of the total adding amount, the blowing starting position of the oxygen gun is 0.8-1.2 m, and the gun position is increased to 2.2-2.6 m after blowing is performed for 1-2 min; 25-40% of the remaining slag is added after blowing is performed for 3-6 min; at the middle stage of the smelting, the oxygen gun is lifted to 2.5-3.0 m, blowing is performed for 10-30 s, and then the oxygen gun is lowered to the basic gun position; and at the late stage of the smelting, the gun position is controlled at 1.0-1.2 m, and the remaining slag is added to the converter at 2-5 min before the tapping. According to the present invention, with the method, the residual manganese content in the end point molten steel can be increased, the alloyaddition amount during alloying can be reduced, the steelmaking cost can be reduced, the FeO content in the final slag can be reduced, the converter blow loss can be reduced, and the rephosphorization and the tapping slag discharge can be effectively prevented.

Owner:ANGANG STEEL CO LTD

Bottom dusting electrical furnace steelmaking process

InactiveCN101787412ASmall particle sizeQuick responseProcess efficiency improvementElectric furnaceMelting tankSteelmaking

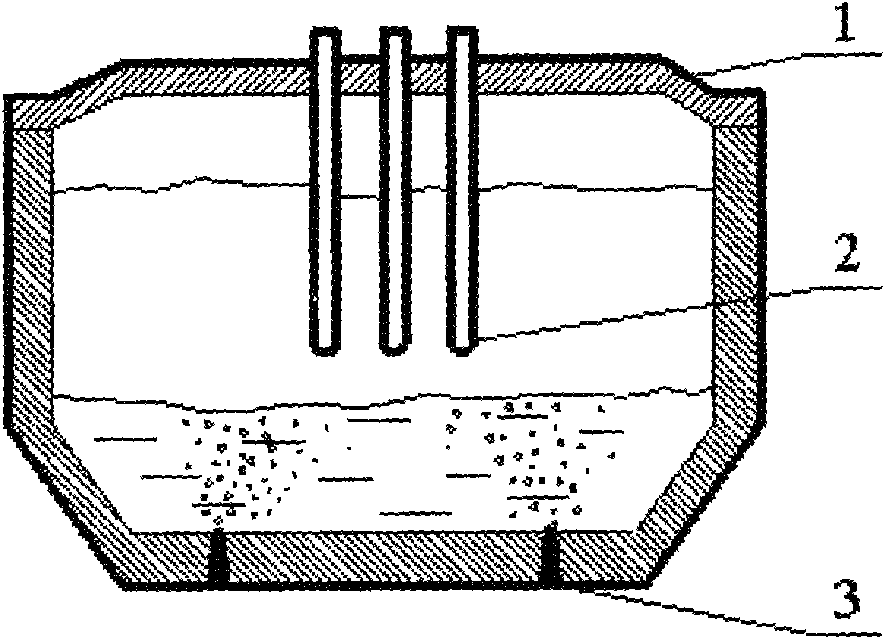

The invention relates to a bottom dusting electrical furnace steelmaking process. The technical scheme includes that the bottom of an electrical furnace 1 is provided with 1-6 bottom guns 3 based on electrical furnace steelmaking method with precharing system, current-carrying gas is adopted to blow powder into a metal pool by 1-6 bottom guns 3, and blowing amount of powder is 20-100wt% of addition when the powder is added into the furnace; wherein, the bottom guns 3 are arranged symmetrically or asymmetrically 0-0.7 time of furnace bottom radius away from the furnace bottom center; the bottom gun 3 is in contact or non-contact structure; the current-carrying gas is one of Ar, N2, natural gas, O2 and CO2; the powder is one or more than one of ground quick lime, limestone powder, ferric oxide powder, concentrate fines, carbon dust, dolomite powder, flousper powder, calcium carbide powder and alloy powder; powder granularity is 0.01-0.10mm; blowing technological parameters include that pressure is 0.3-1.2MPa, gas supply flow is 0.1-1.0Nm3 / t steel and powder gas ratio is 4-10. The invention has the characteristics that stirring effect is enhanced, metal material yield is improved and residue material utilization ratio is improved, duration of heating is shortened and steel quality is improved.

Owner:WUHAN UNIV OF SCI & TECH

Liquid steel pre-deoxidizing technology in steelmaking revolving furnace

The invention provides a liquid steel pre-deoxidizing technology in a steelmaking revolving furnace, belonging to the technical field of metallurgical steel making for solving the problem that the common deoxidizing technology of the revolving furnace can not reduce FeO content in the final steel slag of the revolving furnace. The technical scheme is as follows: the technology is carried out on the final liquid steel when revolving furnace semi-steel steel making or revolving furnace liquid-steel steel making. The technology comprises the following steps of: a. at the final smelting of the steel making revolving furnace, adding with carbon-containing deoxidizing materials or silicon-containing deoxidizing materials into slag liquid surface of the revolving furnace; b. after adding the deoxidizing materials into the revolving furnace, injecting nitrogen into the revolving furnace to be taken as power source to carry out pre-deoxidization; and c. after injecting the nitrogen, tapping steel after reaction in the revolving furnace is steady. The technology essentially has the following characteristics of: 1. reducing the corroding of the liquid steel and the steel slag to the furnace lining, the steel tapping hole and the steel ladle of the revolving furnace, and improving service life thereof; 2. reducing alloy materials added in the process of the oxidizing and the steel tappingof the liquid steel with high oxygen content, and improving the absorption of the alloy; and 3. reducing rolling slag or final slag tapping quantity in the process of steel tapping in the revolving furnace; and 4. reducing the yield of oxidation products with high melting point.

Owner:HEBEI IRON AND STEEL

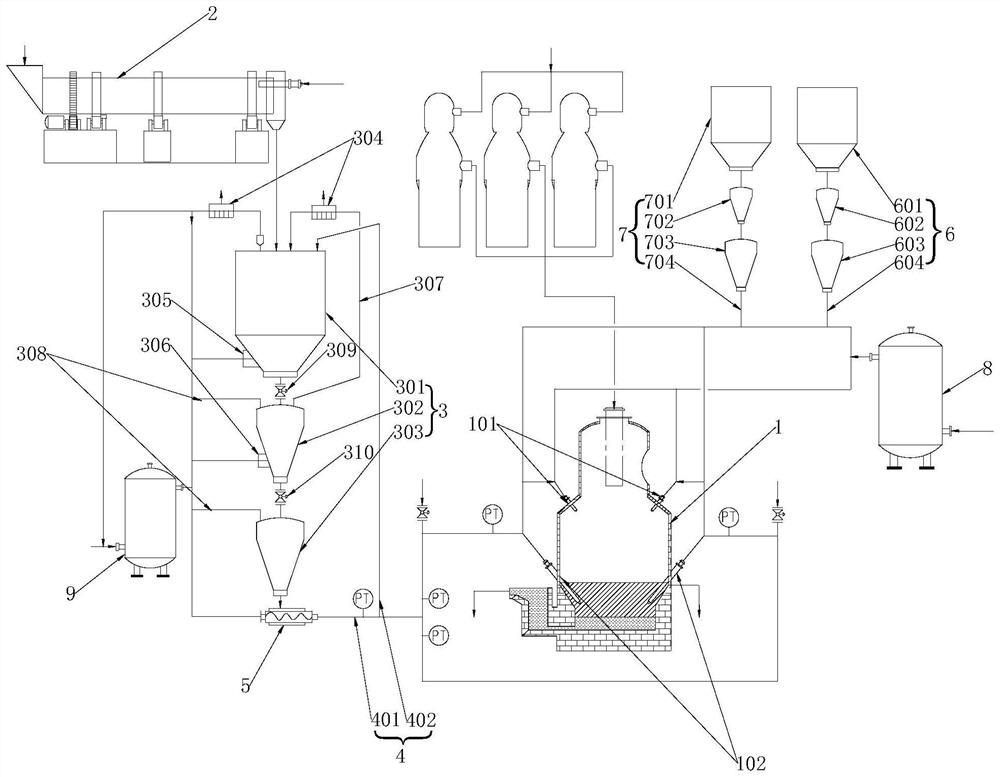

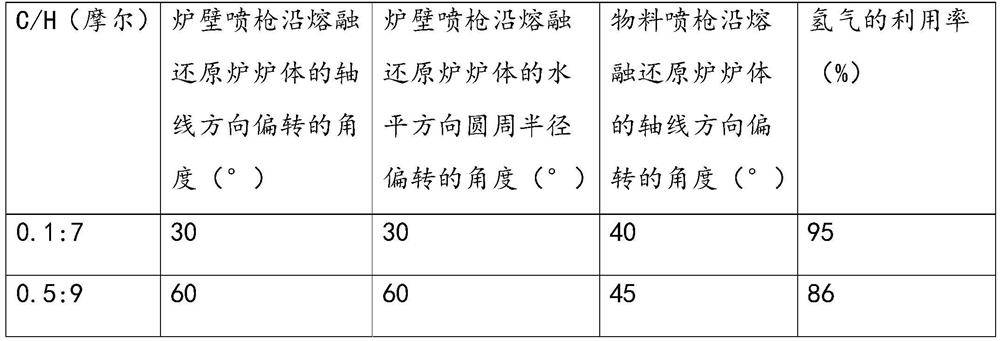

Smelting reduction hydrogen metallurgy process and device

The invention discloses a smelting reduction hydrogen metallurgy process and device. The smelting reduction hydrogen metallurgy process includes the steps that hydrogen is injected into a combustion area of a smelting reduction furnace to form high-pressure rotational flow in the combustion area; and a mixture of an iron-containing material and a magnesium-containing flux, a first carburant and first lime are blown into an iron bath area of the smelting reduction furnace by taking the hydrogen as a carrier gas. According to the smelting reduction hydrogen metallurgy process, the high-pressurerotational flow is formed in the combustion area, so that the retention time of the hydrogen in the smelting reduction furnace and the contact time of the hydrogen and iron-containing materials are prolonged, the amount of the hydrogen entering the combustion area discharged out of the smelting reduction furnace along with flue gas is reduced, the reduction reaction of the iron bath area is enhanced, the content of FeO in slag is reduced, the refractory material erosion speed is reduced, and the hydrogen utilization rate is increased; and the hydrogen is used as the carrier gas, so that the injection depth of a reducing agent can be effectively increased, the fountain effect in the smelting reduction furnace is enhanced, the reduction efficiency in the smelting reduction furnace is improved, and carbon emission in the metallurgical process is reduced.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

Composite fluxing medium for revolving furnace

ActiveCN101671756AHigh content of FeOReduce FeO contentManufacturing convertersIron oxideManganese oxide

The invention relates to metallurgy, in particular to a composite fluxing medium for a revolving furnace. The composite fluxing medium can be used for slagging when in steel-making of the revolving furnace so as to improve the smelting efficiency of the revolving furnace, and comprises the raw materials including ferric oxide and manganese oxide, wherein the ferric oxide accounts for the weight percent of 40-60%, the manganese oxide accounts for the weight percent of not more than 20%, and the rest component is additive. The composite fluxing medium has the advantages that the content of the FeO is high and the content of the MnO is low, so that initial period slagging of the revolving furnace can be more easily carried out; the loss of molten iron can reduced; and the composite fluxing medium adopts the industrial wastes such as OG mud, dedusting powder, iron scale and the like which are low in price and hard to recover as raw materials, so that the product has the advantages of low cost and being environment-friendly and economical.

Owner:上海盛宝冶金科技有限公司

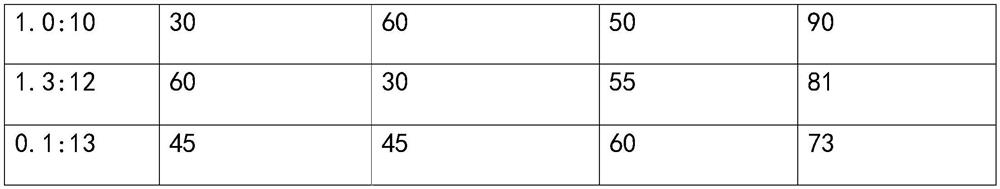

Process for mixing materials and making external-rolled coal through sintering machine

InactiveCN103498046AReduce consumptionHigh calcium oxide content on the surfaceSolid fuelEngineering

The invention relates to a process for mixing materials and making external-rolled coal through a sintering machine, wherein the process includes the steps of preparing materials, conducting mixing and making balls. The process is characterized in that a mixing and ball making technology combining internal matched solid fuel with externally-rolled fuel is adopted, the internal matched solid fuel which is 25wt% to 35wt% of the amount of the solid fuel added to the mixed raw material is added to the mixed raw material in a material preparing chamber fuel mine tank, mixing and ball making are conducted to make small balls which contain the internal matched solid fuel accounting for 50wt% to 60wt% of the total weight of balls and have the particle size ranging from 1mm to 3mm, the solid fuel which is 65wt% to 75wt% of the amount of the solid fuel added to the mixed raw material is used as externally-rolled fuel and added into the fuel material preparing tank, the mixture along with the made small balls are fed to a three-time feed belt machine through a constant weight feeder, then, the mixture and the small balls are sent to a coal rolling machine so that sinter of the externally-rolled fuel can be obtained, and the sinter is conveyed to a sintering chamber through a sealing-tape machine so that sintering can be conducted. The process for mixing the materials and making the external-rolled coal through the sintering machine has the advantages that the fuel is evenly distributed, the combustion condition of the fuel is improved, the sintering quality is improved, and meanwhile consumption of the solid fuel can be lowered.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

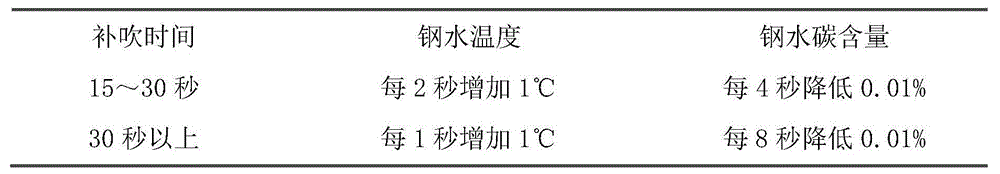

Converter final slag thickening method

InactiveCN104531940AReduce FeO contentHigh yieldManufacturing convertersLime productionSlagLaboratory test

The invention discloses a converter final slag thickening method. The converter final slag thickening method includes the steps that firstly, after oxygen is blown for 10 minutes, gun pressing operation is conducted, in other words, the position of the gun is reduced by 200 mm, the oxygen pressure is kept between 0.75 MPa and 0.80 MPa, and duration is larger than 40 seconds; secondly, through a sampling laboratory test, and when the carbon content of molten steel is higher than the requirement of a smelting steel grade or the temperature of the molten steel is lower than the requirement of the smelting steel grade, reblowing treatment is conducted; thirdly, raw dolomite or lime is added so as to serve as a thickening material before steel is placed, and the addition amount of steel ranges from 2 kg / t to 5 kg / t. Through the optimization of converter end point gun pressing and reblowing, the FeO content of furnace slag is reduced, the metal yield is increased, the slag blocking success rate can be increased, the steel ladle slag amount is reduced, rephosphorization is reduced, the splashed slag furnace protecting effect can be improved, the furnace age can be prolonged, the slag amount requirement for slag residual operation is guaranteed, and lime consumption can be reduced.

Owner:SHANDONG IRON & STEEL CO LTD

Application of coal serving as steelmaking slag pressing agent and method for inhibiting steel slag bubbles

The invention discloses application of coal serving as a steelmaking slag pressing agent. Steel can be directly tapped without forward deslagging in dephosphorization smelting, smelting period is shortened, average production period is shortened from the original 35 minutes to 25 minutes, steel consumption is effectively reduced, the service life of a converter lining is prolonged, a semi-steel smelting dephosphorization furnace achieves the production target of low cost, high efficiency, energy conservation and environmental protection, environments are affected, and the requirements of semi-steel on chemical components and temperatures are met.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Smelting method for melting steel slag into mineral wool material in converter steelmaking process

InactiveCN108264224ASolve heat utilizationSolve the problem of utilizing converter steel slagGlass making apparatusManufacturing convertersSteelmakingThermal energy

The invention discloses a smelting method for melting steel slag into a mineral wool material in a converter steelmaking process. The smelting method can process steel slag in the initial stage of steelmaking into a mineral wool material with acidity and temperature satisfying the requirements through a conditioner or a reducing agent. The smelting method fully utilizes the existing converter equipment of the steel factory, fully utilizes steel slag and the thermal energy of the steel slag to produce a high value-added mineral wool material, solves the problems of steel slag thermal energy useand converter steel slag use and provides an efficient path for high value-added use of steel slag. Through use of the conditioner, the steel slag fluidity is greatly improved. After the initial stage of steelmaking, the poured phosphorus-containing steel slag is greatly increased and the burden of subsequent dephosphorization is reduced. In the later stage of tempering blowing, a gun caulking process is carried out so that the FeO content and metal iron content of the slag are greatly reduced, the steel consumption is reduced and the mineral wool quality is improved. The conditioner comprises a variety of waste slag so that waste slag use is realized and a use value of the waste slag is improved. The smelting method greatly reduces the yield of the mineral wool, reduces the coal consumption and waste gas pollution caused by the coal consumption and has enormous economic and social benefits.

Owner:王虎

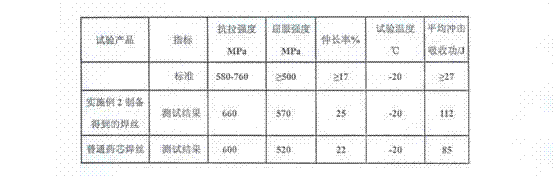

Great line energy gas-electric vertical welding flux core wire and production method thereof

ActiveCN104259688AIncreased crunchGood deoxidation effectWelding/cutting media/materialsSoldering mediaSlagSilicon alloy

The invention provides a great line energy gas-electric vertical welding flux core wire and a production method thereof. The great line energy gas-electric vertical welding flux core wire is mainly formed by reduced iron powder, manganese silicon alloy, rare earth silicon, nickel powder, fluoride, magnesia, 45 silicon iron, aluminum and magnesium powder, molybdenum iron, boron iron, titanium iron through production. The metal slag series formula is adopted, the aluminum and magnesium content is appropriately added into a flux core formula, and accordingly the deoxidization capability of the flux core is improved, the content of the iron oxide on the weld surface is reduced, the slag crunchy is increased, the weld deslagging effect is improved. A small amount of elements such as nickel, molybdenum, titanium and boron are added to the flux core and reasonable matching is performed, the proeutectoid ferrite is inhibited through the boron, and accordingly the impact toughness of deposited metal is effectively improved, meanwhile the continuity and the stability of an electric arc are maintained, the requirements of the welding efficiency and the deposited metal performance during thick plate welding are met, the weld metal slag is uniform in coverage, and the weld forming is good.

Owner:山东聚力焊接材料有限公司

Vanadium-titanium concentrate powder thick material layer sintering technology

The invention discloses a vanadium-titanium concentrate powder thick material layer sintering technology. The vanadium-titanium concentrate powder thick material layer sintering technology comprises the following steps that sintering raw materials are mixed to be uniform, and the sintering raw materials comprise, by weight, 50-60 parts of vanadium-titanium concentrate powder, 5-8 parts of iron oreconcentrate powder, 10-20 parts of a fluxing agent and 3-5 parts of fuel; the sintering raw materials are crushed; the powder is infiltrated with water and then prepared into pellets; the pellets aredistributed on sintering equipment, and the distributing thickness is 720-740 mm; the pellets are sintered into pellet ore; and the pellet ore is cooled. By changing the component proportion of the sintering raw materials and adding the fluxing agent to improve the air flow fluidity, therefore, the large sintering material distributing thickness is achieved, and the sintered ore quality is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

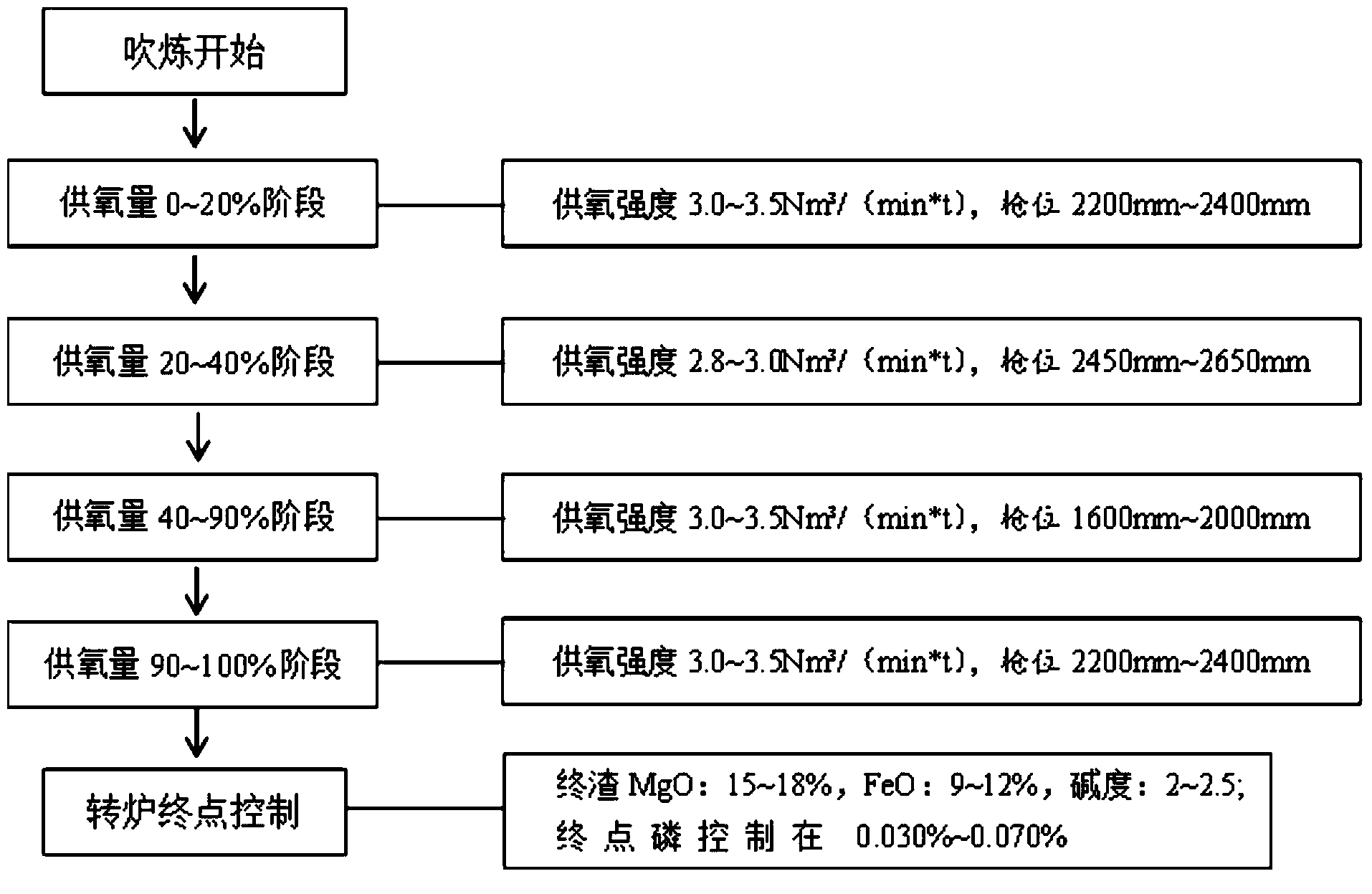

Smelting method of steel with high phosphorus content

The invention relates to a smelting method of steel with high phosphorus content. The smelting method is suitable for a converter of 180-250t. The smelting method comprises the following steps: in the converter blowing process, adjusting the oxygen lance position and the oxygen supply strength according to the oxygen supply amount; and carrying out endpoint control on the converter, wherein the endpoint control comprises the following steps: on the basis of the percentage by mass, controlling MgO to be 15-18%, FeO to be 9%-12% and endpoint phosphorus to be 0.030%-0.070%, and controlling the alkalinity of slag at the endpoint to be 2.0-2.5. According to the smelting method, the endpoint phosphorus content of the converter can be increased, consumption of ferro-phosphorus alloy is reduced, and on the basis of the percentage by mass, the method is suitable for smelting the grade of steel, of which the phosphorus content in a finished product is greater than or equal to 0.070%.

Owner:SHOUGANG CORPORATION

Compound slag-forming constituent for converters

The invention relates to the type of metallurgy, in particular to a compound slag-forming constituent for converters, which are used for slag-forming during steel-making of the converters, and improve the smelting efficiency of the converters, the raw material component of the compound slag-forming constituent mainly comprises ferric oxide and manganese oxide, wherein compound slag-forming constituent comprises the following components in percentage by weight: 60%-80% of the ferric oxide, not more than 20% of the manganese oxide, and the other component is additive. The compound slag-forming constituent has the advantages that the content of FeO is high, and the content of MnO is low, which is more convenient for the initial stage slag-smelting of converters, simultaneously the loss of molten iron is reduced, since the compound slag-forming constituent adopts steel-making industrial waste which has low cost, and is difficult to recover, such as OG sludge, dust-removing powder, ferric oxide sheets and the like, as raw materials, the cost of products is low, and the compound slag-forming constituent is green, environment-friendly, and economical.

Owner:上海盛宝冶金科技有限公司

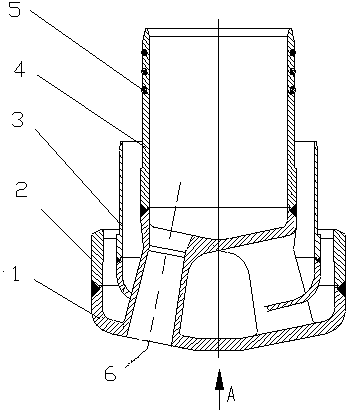

Oxygen lance nozzle with concentrated streams

ActiveCN103993127ASolve the flow of black slagSolve the problem of serious splatterManufacturing convertersSteelmakingJet flow

The invention relates to an oxygen lance nozzle with concentrated streams, which belongs to the technical field of converter oxygen lance equipment and is used for improving indexes of top-blown oxygen steelmaking of a converter. According to the technical scheme, four oxygen lance spray holes are uniformly distributed around the center of the end surface of the nozzle to form a circle, the diameter of the circle is 140-150mm and the included angles between the spray holes of the nozzle are 11.5 degrees-13.5 degrees. According to the oxygen lance nozzle provided by the invention, the diameter of the circle formed by the oxygen lance spray holes and the included angles between the oxygen lance spray holes are changed, more concentrated oxygen jet flows are obtained, an impact region formed by four streams has a small total heat dissipation area and concentrated reaction points; and the oxygen lance nozzle has the advantages of capability of fast entering in a C-O reaction period, high recovery of coal gas, high residual manganese in molten steel, balanced erosion to a furnace liner, low consumption of steel and iron material and the like; simultaneously, due to the concentrated streams, the position of the lance is higher than that of a conventional oxygen lance in the blowing process and far away from a reaction area, the risk of erosion or burning loss of the nozzle is greatly reduced and the service life of the nozzle is prolonged.

Owner:HEBEI TANGYIN IRON & STEEL

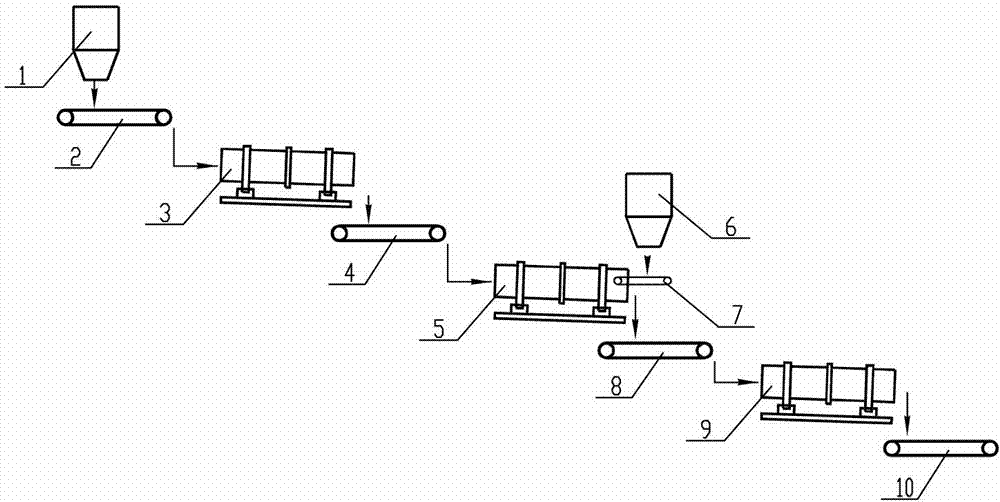

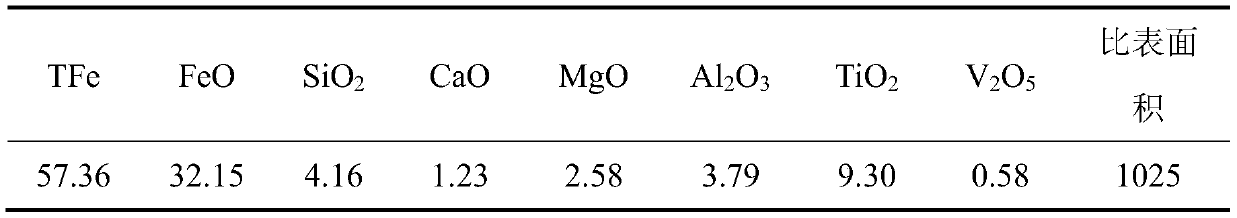

Preparation method based on high-pressure roll-grinding pretreatment and used for low-energy-consumption and high-quality vanadium-titanium pellet ores

The invention discloses a preparation method based on high-pressure roll-grinding pretreatment and used for low-energy-consumption and high-quality vanadium-titanium pellet ores. According to the method, the specific surface area and the particle size composition of vanadium-titanium magnetite are improved by controlling the conditions of high-pressure roll-grinding, and meanwhile, the compact structure of vanadium-titanium magnetite particles are broken by virtue of the high-pressure roll-grinding, so that favorable conditions are provided for pelletization and oxidation-solidification for the vanadium-titanium magnetite; pelletization and roasting methods suitable for the vanadium-titanium magnetite subjected to the high-pressure roll-grinding are developed according to the structure andsurface characteristics of the vanadium-titanium magnetite subjected to the high-pressure roll-grinding; and uniform oxidation and efficient solidification for the vanadium-titanium magnetite are realized through the coupling action of the high-pressure roll-grinding pretreatment, pellet particle size control, thermal process optimization and the like, so that the strength of the vanadium-titanium ore pellets is greatly increased, the energy consumption of the roasting process is reduced, and then the high-quality vanadium-titanium pellet ores are prepared.

Owner:CENT SOUTH UNIV

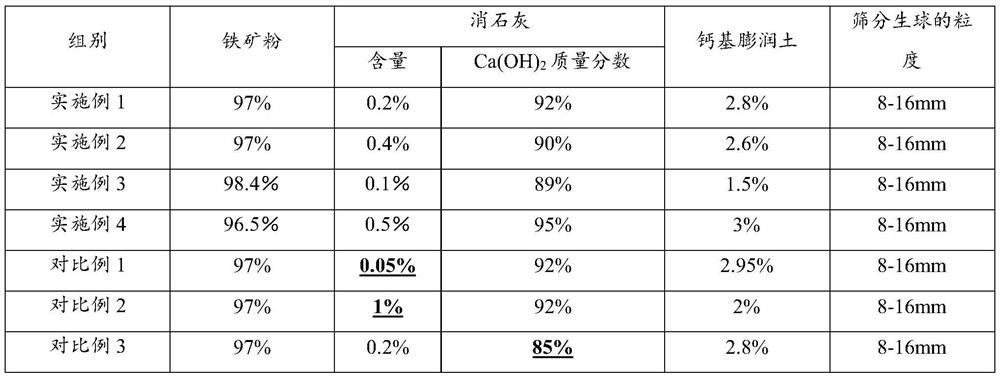

Finished pellet and preparation method thereof

The invention discloses a finished pellet. The finished pellet comprises, by mass: 96.5%-98.4% of iron ore powder, 0.1%-0.5% of slaked lime and 1.5%-3% of calcium bentonite, and the mass fraction of Ca(OH)2 in the slaked lime is more than 88%. The invention also discloses a preparation method of the finished pellet. The preparation method comprises the steps of uniformly mixing the proportioned iron ore powder with the slaked lime and the calcium bentonite to obtain a mixture; and carrying out pelletizing, screening and roasting on the mixture to obtain the finished pellet. According to the finished pellet and the preparation method thereof, through adding the small amount of slaked lime, the specific surface area of the mixture can be improved, the falling strength and granularity uniformity of green pellets are further improved, and the quality of the green pellets is improved; the improvement of the quality of the green pellets is beneficial to the improvement of the circulation ofthe hot gas flow in a material layer, and sufficient oxidizing atmosphere is provided for the pellets in the roasting process, so that the content of FeO in the finished pellets is reduced; and the small amount of slaked lime plays a role of sulfur fixation, and the influence of the combination of sulfur and oxygen on the oxidation of ferrous iron is reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Method for smelting clean steel by supplementation and decarburization with CO2 at end of converter blowing

The invention discloses a method for smelting clean steel by supplementation and decarburization with CO2 at the end of converter blowing. In the method, when the clean steel is smelted by using a converter, the oxygen consumption is about 80%-95% of total theoretical calculation amount and the decarburization speed is reduced to below 50% of that in a severe decarburization period, a certain proportion of CO2 gas is mixed in oxygen for decarburization, and the content of carbon in a molten bath is controlled by a furnace gas analysis system. The method has the advantages and effects that CO2 is added in the decarburization gas at the end of converter blowing, thus a decarburization purpose can be achieved and the blowing amount of oxygen can be reduced, so that the content of oxygen in steel is reduced, the loss of the temperature in the tapping process is decreased, and the increase of the oxygen activity in the molten steel is effectively controlled, thereby achieving the purposes of reducing iron loss, lowering the dosage of alloy, decreasing the quantity of impurities in the molted steel and improving the quality of the molten steel.

Owner:ANGANG STEEL CO LTD

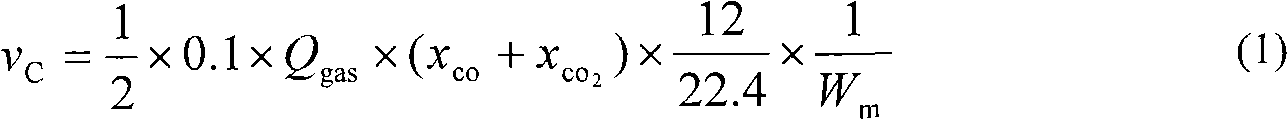

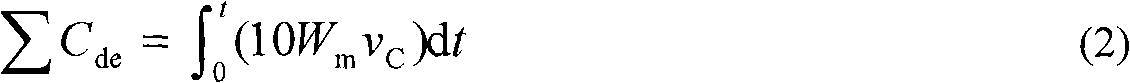

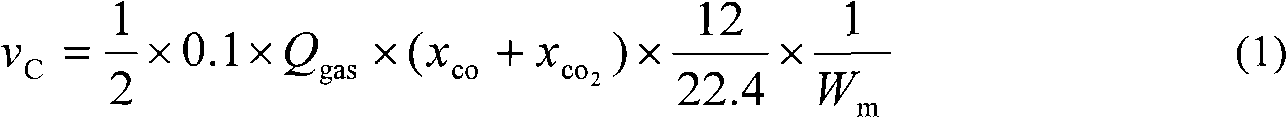

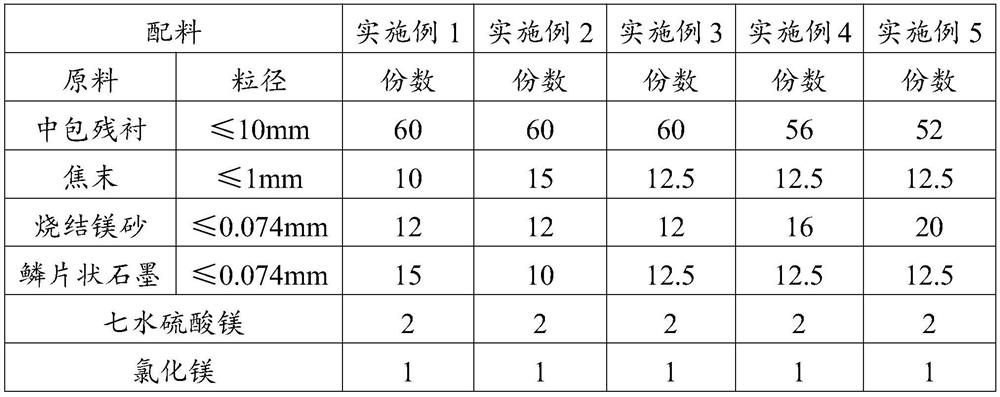

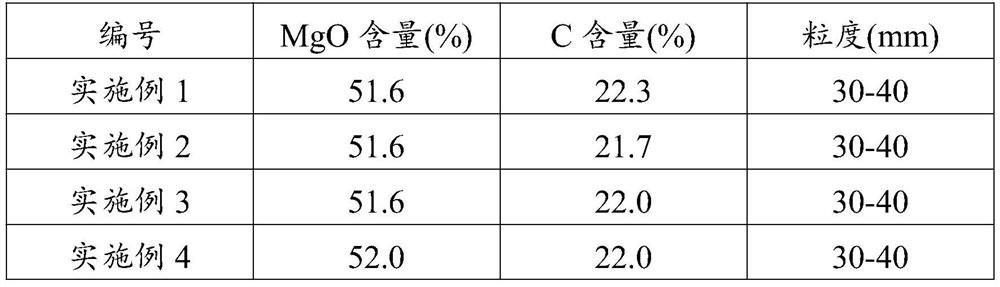

Magnesia-carbon modifier prepared from tundish residual linings

InactiveCN112811884AIncreased magnesium oxide contentHigh in magnesiumCeramic materials productionClaywaresIron(II) oxideSlag

The invention provides a magnesia-carbon modifier prepared from tundish residual linings. The modifier is prepared by taking tundish residual linings, coke breeze, flaky graphite and magnesite clinker as main raw materials, adding a binding agent and carrying out the processes of mixing, ball pressing, natural drying and the like. The magnesia-carbon modifier has the characteristics of high magnesia content, high carbon content and good slag adjusting effect, and can effectively adjust the final slag components of a converter, improve the MgO content in the slag, reduce the FeO content in the slag, and improve the melting point and viscosity of the slag by applying the magnesia-carbon modifier to the converter and combining the dissolution of magnesia and the reaction between carbon and ferrous oxide. The combination state of a slag bonding layer and a furnace lining is effectively improved, and the slag splashing furnace protection effect is optimized. The magnesia-carbon modifier can effectively prolong the service life of a converter, and has important significance for saving energy, reducing consumption, protecting the environment and increasing economic benefits.

Owner:北京利尔高温材料股份有限公司

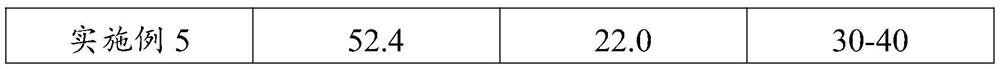

Method for preparing reduced titanium for welding electrodes from ilmenite placer

ActiveCN109097576ARestore fastReduce production difficultyCarbon compoundsActivated carbonActive carbon

The invention relates to a method for preparing reduced titanium for welding electrodes from ilmenite placer. The method comprises three steps of material mixing, heating reaction and cooling-separation. Compared with the prior art, ilmenite reducing speed is increased greatly, production difficulty is reduced, and reduced titanium with low FeO content can be obtained; low-sulfur reduced titaniumcan be obtained without addition of a sulfur removal agent; reactivity of ilmenite can be improved, removal speed of coal volatile matter is increased, a loose and porous structure is formed by remaining fixed carbon, and follow-up reduction is better facilitated; reactivity of raw materials is improved, a reduction reaction can be performed at lower temperature, and sintering in a kiln is avoidedeffectively; an activated carbon product with high added value can be obtained simultaneously, and overall earnings are high.

Owner:CENT SOUTH UNIV +1

Method for reducing FeO content of final slag in modification of molten converter slag

ActiveCN108504799AReduce alkalinityHigh recovery rateRecycling and recovery technologiesIron oxideSilicon dioxide

The invention discloses a method for reducing the FeO content of final slag in modification of molten converter slag. The composition of silicon dioxide in iron tailings is used for reducing the basicity of slag, and blast furnace dusting ash carbon is used for reducing iron oxide in molten slag; and according to the foam slag theory, by adopting the method of grading proportion, grading raw material mixing preheating and grading upper feeding, the use efficiency of blast furnace dusting ash is improved, the FeO content of the final slag in the modification of the molten converter slag is reduced, finally, the use performance of the final slag can be improved, the recovery of iron is improved and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

Dephosphorizing slag pressing agent and method thereof for inhibiting steel slag bubbles

ActiveCN106755739AIncrease FeO contentExtend your lifeManufacturing convertersChemical compositionMoisture

The invention discloses a dephosphorizing slag pressing agent and method thereof for inhibiting steel slag bubble, and belongs to the technical field of steel-making. The dephosphorizing slag pressing agent comprises the following components in mass percent: 45-55% of SiO2, 25-30% of Al2O3, 1.5-3.0% of Fe2O3, 0.5-1.0% of CaO, 2.5-4.5% of MgO, 0.7-1.1% of TiO2, 10-15% of C, less than 5% of total moisture. The slag pressing agent is added after the dephosphorizing blowing is finished, thereby effectively inhibiting the production of the steel slag bubble; the direct tapping can be realized without performing fore-deslagging in dephosphorizing smelting, the smelting period is greatly shortened, the steel and iron consumption can be effectively lowered at the same time, the lining life of a converter is improved, the production target of low cost, high efficiency, energy-conservation and environmental protection of the semi-steel smelting through a dephosphorizing furnace is realized, the environment cannot be influenced, and the chemical component and temperature requirements of the semi-steel are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Method for reducing aluminum-containing steel inclusions

InactiveCN110453028AHigh strengthImprove toughnessManufacturing convertersProcess efficiency improvementSteelmakingAfter treatment

The invention relates to the technical field of ferrous metallurgy, in particular to a method for reducing aluminum-containing steel inclusions. The process route of converter smelting, steel ladle top slag modification behind a converter, top slag modification of a vacuum degassing furnace and casting of a continuous casting machine is adopted. In the tapping process, lime granules for steelmaking are added, after the lime granules are spread, a slag modification agent is added into a steel ladle, and after treatment of the vacuum degassing furnace is finished, the slag modification agent isadded into the steel ladle. The slag modification agent of the steel ladle is used for removing slag oxidization molten steel inclusions, through top slag deoxidization behind the converter and in thesteel ladle of the vacuum degassing furnace, the FeO content of slag in the steel ladle is reduced to 12% from original 20% when the slag just enters the vacuum degassing furnace, the FeO content ofthe slag is reduced to 8% from original 15% when the slag moves out of the vacuum degassing furnace, and the cold rolling inclusion rate is reduced by 50%. The strength, toughness and machining performance of steel are improved, the mechanical performance and anti-fatigue performance of the steel are improved, and then the quality of aluminum-containing steel is improved.

Owner:ANGANG STEEL CO LTD

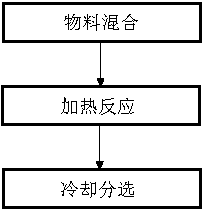

Atmosphere control process of high-magnetic-induction oriented silicon steel with excellent magnetism

PendingCN112626447AImprove the accuracy of atmosphere controlReduce FeO contentSolid state diffusion coatingHeat treatment process controlSmelting processNitrogen gas

The invention relates to the technical field of oriented silicon steel, and discloses an atmosphere control process of high-magnetic-induction oriented silicon steel with excellent magnetism. The atmosphere control process comprises the following steps of 1, smelting, specifically, smelting in a converter and RH refining to obtain molten steel, introducing air in the smelting process, and setting the total air inflow to be 100-300Nl / min and the oxygen content in the introduced air to be 20-21%. According to the atmosphere control process of the high-magnetic-induction oriented silicon steel with the excellent magnetism, the content of oxygen and the content of nitrogen in a certain proportion are added in different processes, the atmosphere control precision of each stage is effectively improved, therefore the obtained final high-magnetic-induction oriented silicon steel is excellent, the influence of air pressure, flow and other factors on the magnetic effect of the final high-magnetic-induction oriented silicon steel is avoided, the FeO content in the slag is reduced, the steel recovery rate is increased, the service life of a furnace lining is prolonged, the effect of reducing the production cost is achieved, accurate atmosphere control is conducted, the smelting effect is better in the smelting process of the high-magnetic-induction oriented silicon steel, and the magnetism of the smelted high-magnetic-induction oriented silicon steel is more excellent.

Owner:海安华诚新材料有限公司

Method for preparing high-titanium slag by directly reducing titanium concentrate in gas-based shaft furnace

InactiveCN109136588ARaise the gradeHigh activityElectric furnaceShaft furnaceIntermediate frequencyShaft furnace

The invention relates to the technical field of direct reduction in the metallurgical technology, in particular to a method for preparing high-titanium slag by directly reducing titanium concentrate in a gas-based shaft furnace. According to the method, titanium concentrate oxidized pellets are used as a raw material, put into the gas-based shaft furnace, directly reduced with reducing gas, then delivered to an intermediate frequency induction furnace, and melted to obtain pig iron and high-titanium slag, wherein the recovery rate of iron in the pig iron is greater than 97%, and the recovery rate of TiO2 in the high-titanium slag is greater than 95%. The method is short and compact in process, high in production efficiency and low in comprehensive energy consumption, and is a new method for efficient, clean and comprehensive utilization of titanium concentrate.

Owner:NORTHEASTERN UNIV

A kind of low-carbon low-silicon steel manufacturing method

ActiveCN103627853BGuaranteed low silicon content requirementsReduce oxidationManufacturing convertersCastabilitySilicon

Owner:SGIS SONGSHAN CO LTD

Method for smelting clean steel by supplementation and decarburization with CO2 at end of converter blowing

ActiveCN102146491BContinuous decarburizationReduce blowing volumeManufacturing convertersGas analysisMolten bath

The invention discloses a method for smelting clean steel by supplementation and decarburization with CO2 at the end of converter blowing. In the method, when the clean steel is smelted by using a converter, the oxygen consumption is about 80%-95% of total theoretical calculation amount and the decarburization speed is reduced to below 50% of that in a severe decarburization period, a certain proportion of CO2 gas is mixed in oxygen for decarburization, and the content of carbon in a molten bath is controlled by a furnace gas analysis system. The method has the advantages and effects that CO2 is added in the decarburization gas at the end of converter blowing, thus a decarburization purpose can be achieved and the blowing amount of oxygen can be reduced, so that the content of oxygen in steel is reduced, the loss of the temperature in the tapping process is decreased, and the increase of the oxygen activity in the molten steel is effectively controlled, thereby achieving the purposes of reducing iron loss, lowering the dosage of alloy, decreasing the quantity of impurities in the molted steel and improving the quality of the molten steel.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com