Smelting method of steel with high phosphorus content

A high-phosphorus-content steel and smelting method technology, applied in the manufacture of converters, etc., can solve the problems of increasing smelting costs and wasting resources, and achieve the effects of increasing phosphorus content, reducing consumption, and increasing FeO content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A 210-ton top-bottom combined blowing converter is used for smelting, and the specific steps are:

[0037] S1: Put the hot metal from the blast furnace into the converter, and add 15t of steel scrap at the same time. The mass percentages of the hot metal are C: 4.30%, Si: 0.35%, Mn: 0.21%, P: 0.10%.

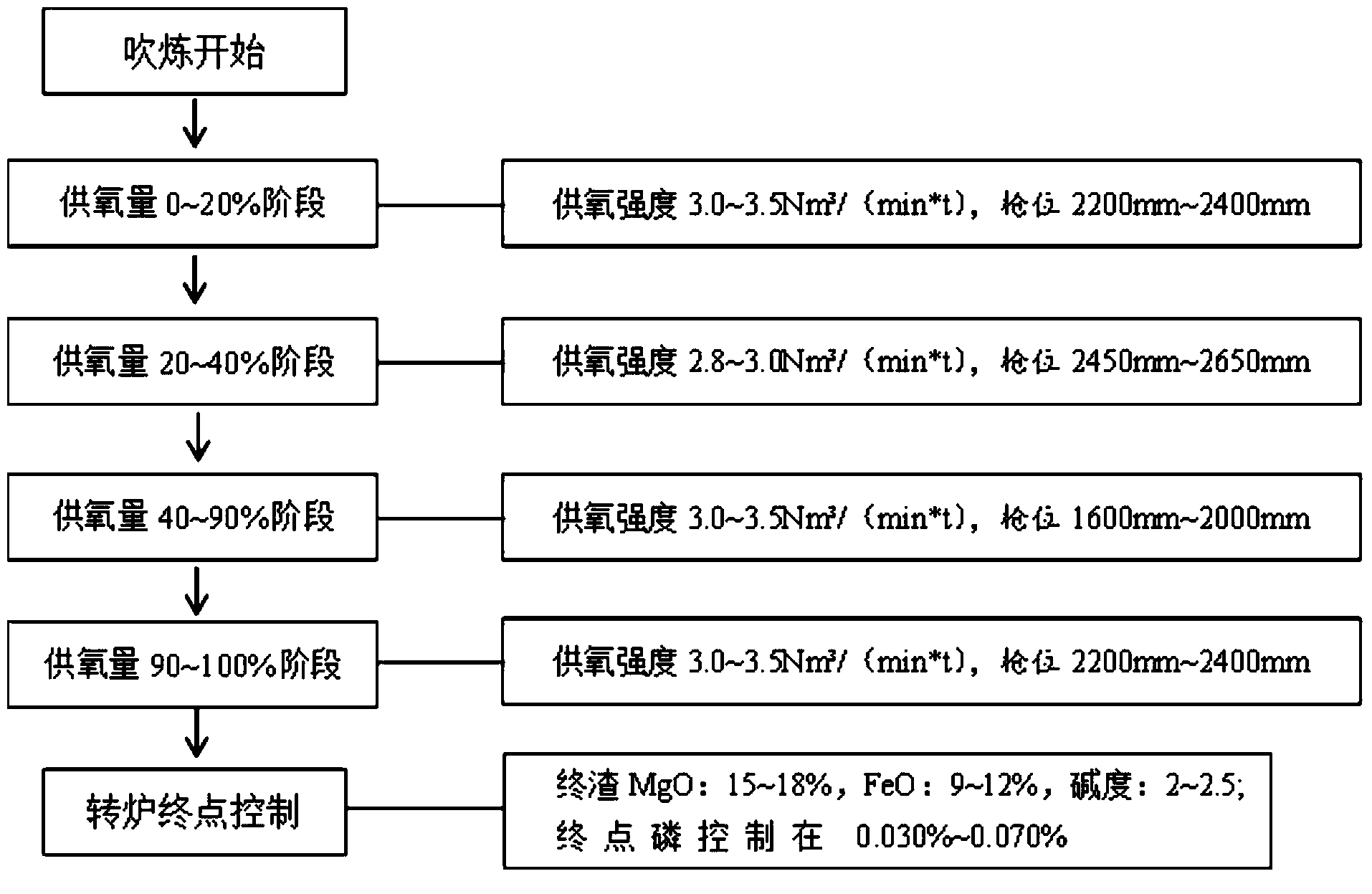

[0038] S2: The blowing oxygen lance position and oxygen supply intensity are controlled as follows in the converter smelting process: at the stage of oxygen supply 0-20%, the oxygen supply intensity is controlled to 3.3Nm 3 / (min*t), the gun position is controlled at 2300mm; at the stage of oxygen supply 20-40%, the oxygen supply intensity is controlled at 2.9Nm 3 / (min*t), the gun position is controlled at 2500mm; at the stage of oxygen supply 40-90%, the oxygen supply intensity is controlled at 3.2Nm 3 / (min*t), the gun position is controlled at 1800mm; at the stage of 90-100% oxygen supply, the oxygen supply intensity is controlled at 3.2Nm 3 / (min*t), gun position co...

Embodiment 2

[0043] A 210-ton top-bottom combined blowing converter is used for smelting, and the specific steps are:

[0044] S1: Put the hot metal from the blast furnace into the converter, and add 15t of steel scrap at the same time. The mass percentages of the hot metal are C: 4.20%, Si: 0.30%, Mn: 0.14%, P: 0.08%.

[0045] S2: The blowing oxygen lance position and oxygen supply intensity are controlled as follows in the converter smelting process: at the stage of oxygen supply 0-20%, the oxygen supply intensity is controlled at 3.0Nm 3 / (min*t), the gun position is controlled at 2200mm; at the stage of oxygen supply 20-40%, the oxygen supply intensity is controlled at 2.8Nm 3 / (min*t), the gun position is controlled at 2450mm; the oxygen supply intensity is controlled at 3.0Nm at the stage of 40-90% oxygen supply 3 / (min*t), the gun position is controlled at 1600mm; at the stage of oxygen supply 90-100%, the oxygen supply intensity is controlled at 3.0Nm 3 / (min*t), gun position con...

Embodiment 3

[0050] A 210-ton top-bottom combined blowing converter is used for smelting, and the specific steps are:

[0051] S1: Put the hot metal from the blast furnace into the converter, and add 15t of steel scrap at the same time. The mass percentages of the hot metal are C: 4.40%, Si: 0.40%, Mn: 0.25%, P: 0.20%.

[0052] S2: The blowing oxygen lance position and oxygen supply intensity are controlled as follows in the converter smelting process: at the stage of oxygen supply 0-20%, the oxygen supply intensity is controlled at 3.5Nm 3 / (min*t), the gun position is controlled at 2400mm; at the stage of oxygen supply 20-40%, the oxygen supply intensity is controlled at 3.0Nm 3 / (min*t), the gun position is controlled at 2650mm; at the stage of oxygen supply 40-90%, the oxygen supply intensity is controlled at 3.5Nm 3 / (min*t), the gun position is controlled at 2000mm; at the stage of oxygen supply 90-100%, the oxygen supply intensity is controlled at 3.5Nm 3 / (min*t), gun position co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com