Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Promote decarbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-silicon high-carbon chromium bearing steel and hot rolling production method thereof

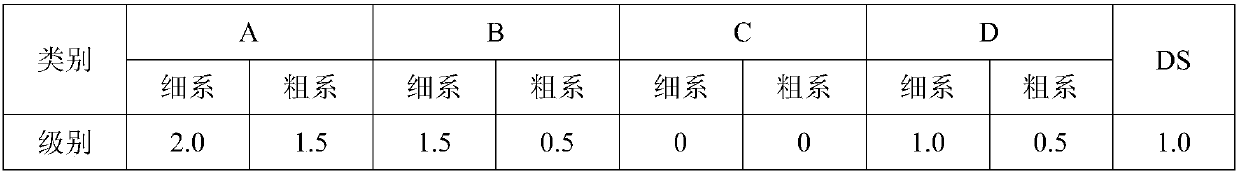

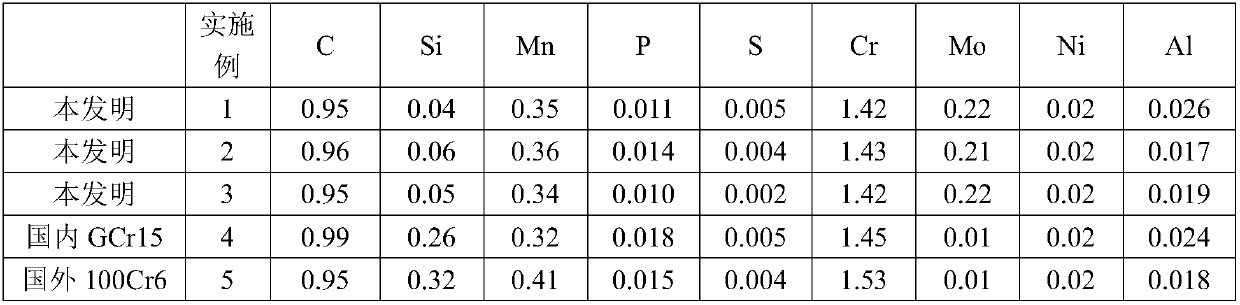

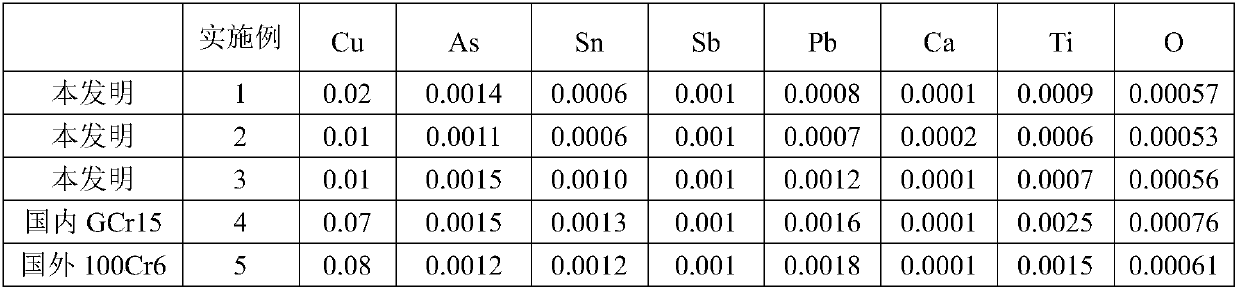

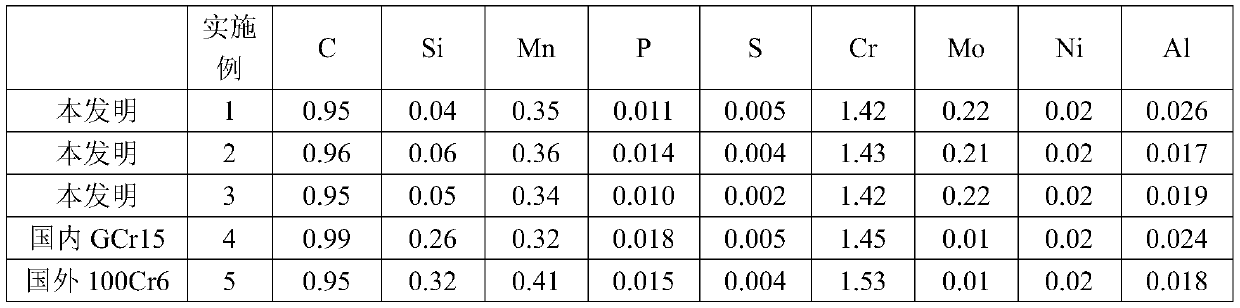

The invention relates to low-silicon high-carbon chromium bearing steel. The low-silicon high-carbon chromium bearing steel is prepared from the following chemical components in percentage by mass: 0.80-1.10% of C, 0.01-0.15% of Si, 0.20-0.60% of Mn, 1.20-1.60% of Cr, 0.15-0.50% of Mo, less than or equal to 0.05% of Al, less than or equal to 0.025% of P, less than or equal to 0.020% of S, less than or equal to 0.001% of Ca, less than or equal to 0.003% of Ti, less than or equal to 0.0008% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb and the balance of Fe and unavoidable impurities. A production flow comprises the following steps: electric furnace or converter smelting; external refining; VD or RH vacuum degassing; continuous casting; continuous rolling; shearing; stack cooling; finishing; flaw detection; and packaging. A low silicon technology is adopted based on existing high-carbon chromium bearing steel GCr15, and the chemical components are re-designed, so that not only are the demands on strength, hardness, toughness, wear resistance, hardenability and the like of a steel product met, but also the overheating sensitivity and decarburizing and cracking tendency of the steel product are improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD +1

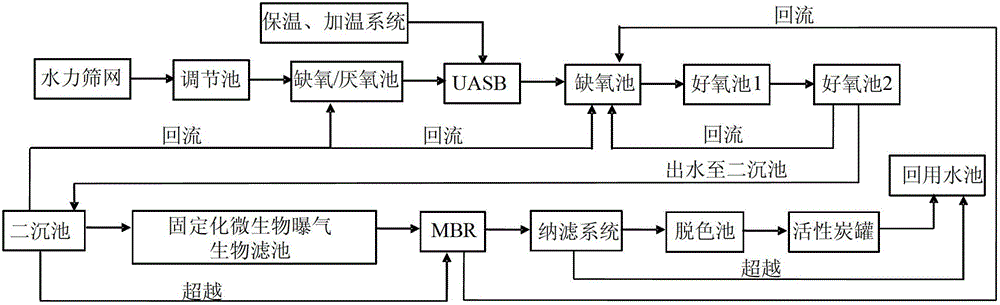

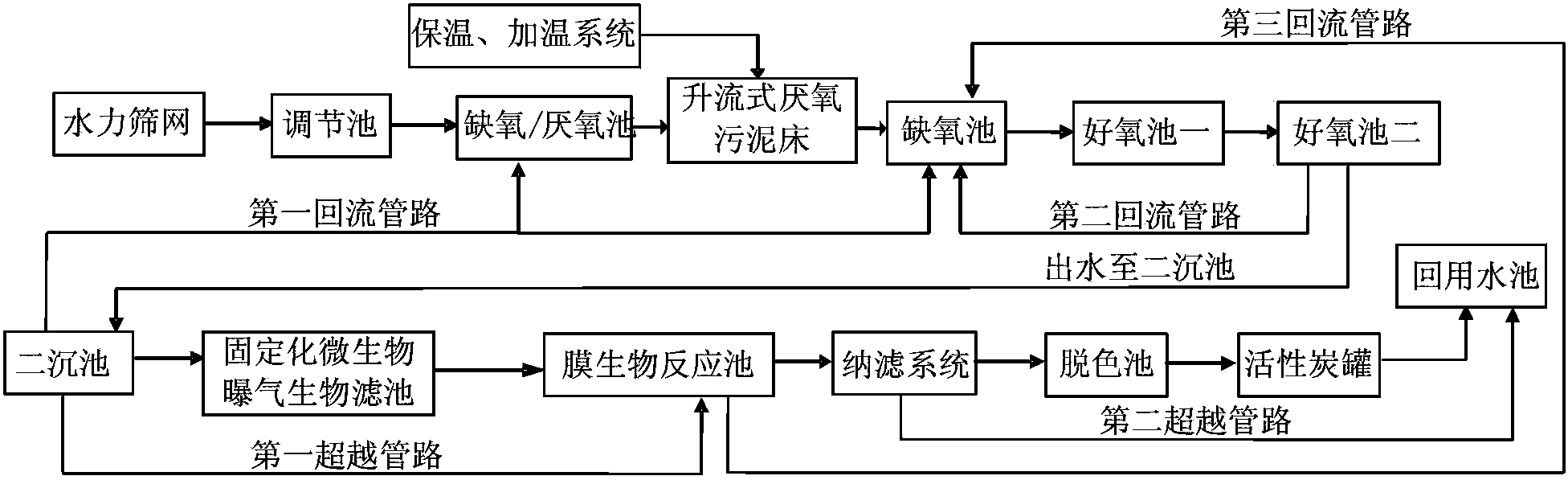

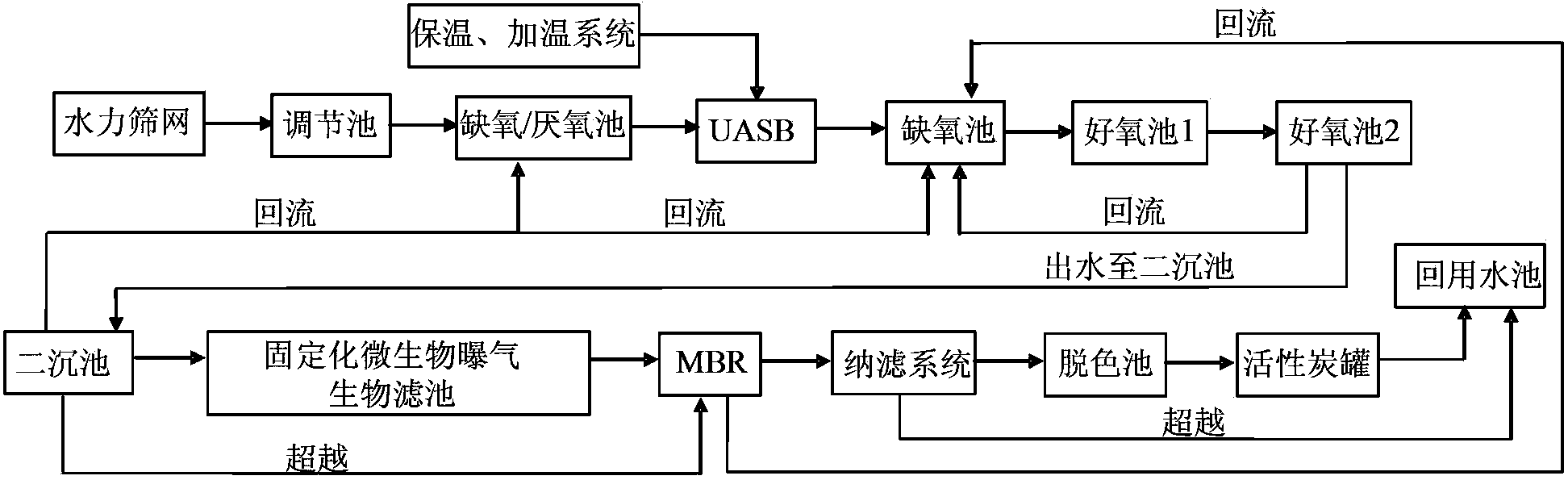

System and method for treating high-concentration landfill leachate in aerobic composting site

InactiveCN102976566AExtended service lifeIncrease alkalinityMultistage water/sewage treatmentHigh concentrationBiological filter

The invention discloses a system and a method for treating the high-concentration landfill leachate in an aerobic composting site. The system comprises a hydraulic screen, a regulation pool, an anoxic and anaerobic pool, an upflow anaerobic pool, an anoxic pool, a first aerobic pool, a second aerobic pool, a secondary sedimentation pools, an immobilized microorganism aerating biological filtering pool, an MBR (membrane biological reaction) pool, a nanofiltration system, a decolourising pool and a charcoal canister which are connected in sequence. The raw landfill leachate is treated by the hydraulic screen, the regulation pool, the anoxic and anaerobic pool, the upflow anaerobic pool, the anoxic pool, the first aerobic pool, the second aerobic pool, the secondary sedimentation pools, the immobilized microorganism aerating biological filtering pool, the MBR pool, the nanofiltration system, the decolourising pool and the charcoal canister of the system in sequence so that the effluent can be recovered. The effluent can meet the requirement for the limit of the discharge concentration of the water pollutant in the special region in the Domestic Waste Landfill Site Pollution Control Standard GB16889-2008.

Owner:BEIJING SOUND ENVIRONMENTAL ENG

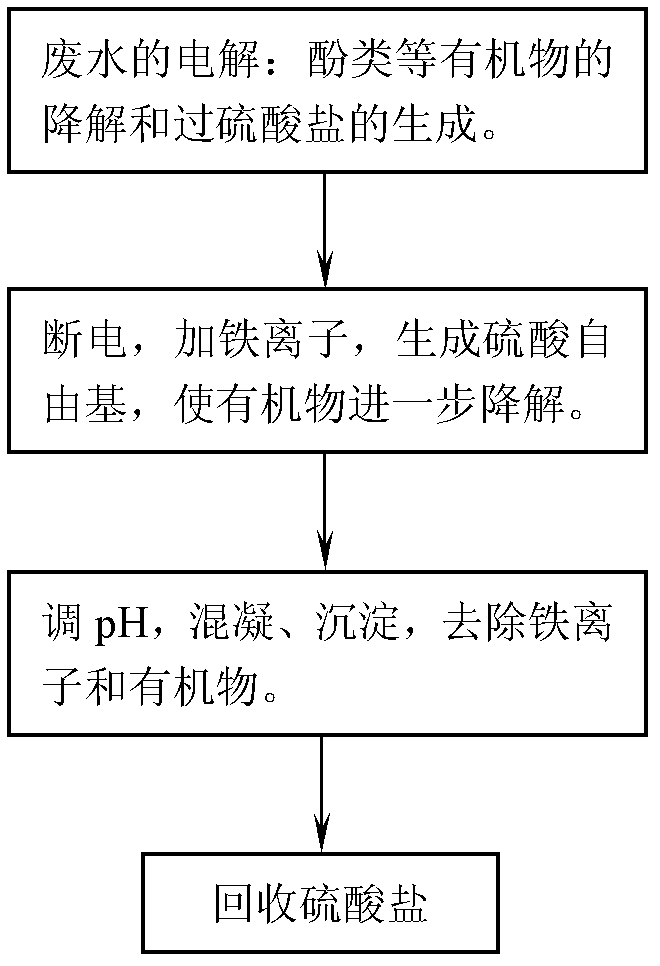

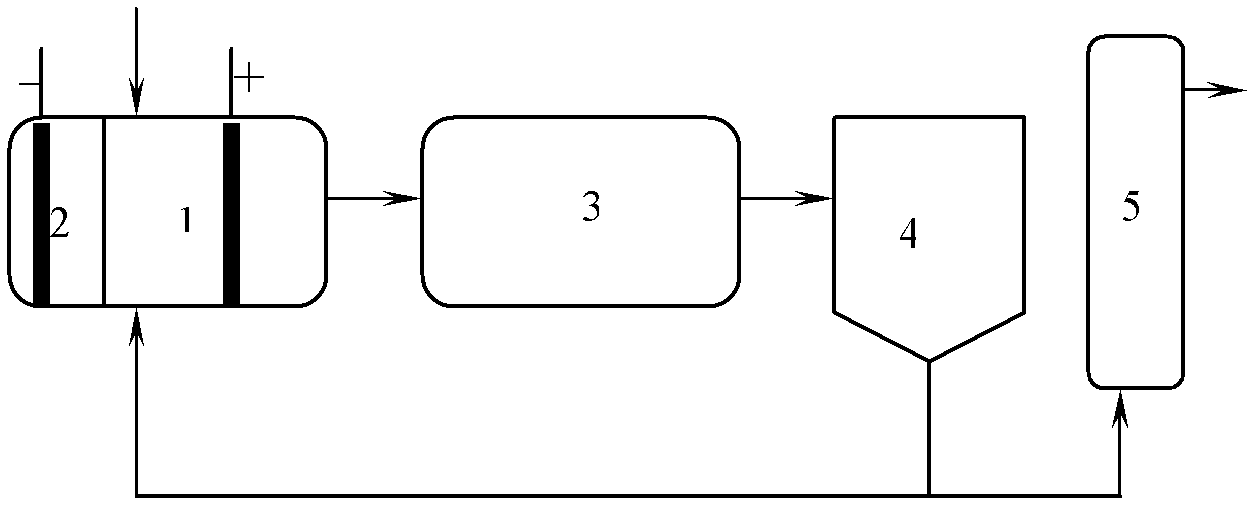

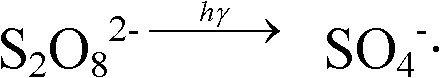

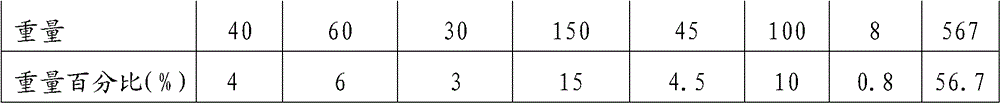

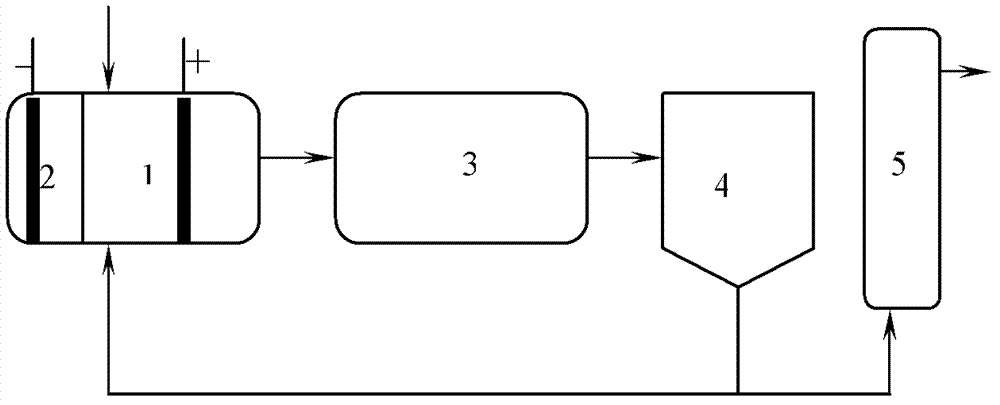

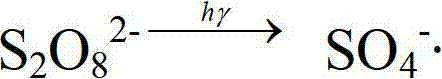

Method for pre-degrading high-concentration oil refining organic wastewater by synergism of sulfuric acid free radical and anodic oxidation

InactiveCN102311191ARaise the ratioSuitable for biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh concentrationSulfate radicals

The invention discloses a method for pre-degrading organic high-concentration oil refining organic wastewater by synergism of sulfuric acid free radical and anodic oxidation. The method comprising the following steps: building an electrolytic cell by taking a Ti / SnO2-Sb-Pt oxide electrode as an anode; adding wastewater to be degraded and SO4<2->; switching on a power supply for electrolysis; while the wastewater is degraded, generating HSO5<-> and S2O8<2-> in a system; sampling and measuring the concentration of S2O8<2-> every 10 minutes; when the concentration of S2O8<2-> reaches a certain degree, filling the wastewater into a reaction tank; and adding catalysts Fe<2+> and Co<2+> to catalyze the generation of the sulfuric acid free radical so as to further degrade the wastewater. With the method, the sulfuric acid free radical and the anodic oxidation are organically combined, and a sulfate radical serves as an auxiliary electrolyte, HSO5<-> and S2O8<2-> can be automatically generated in the system while the wastewater is oxidized and degraded in an anodic area; and then the catalysts are added to catalyze the generation of the sulfuric acid free radical, thereby degrading organic matters in oil refining wastewater, which are difficult to degrade, and improving the biological property of the wastewater.

Owner:DALIAN MARITIME UNIVERSITY

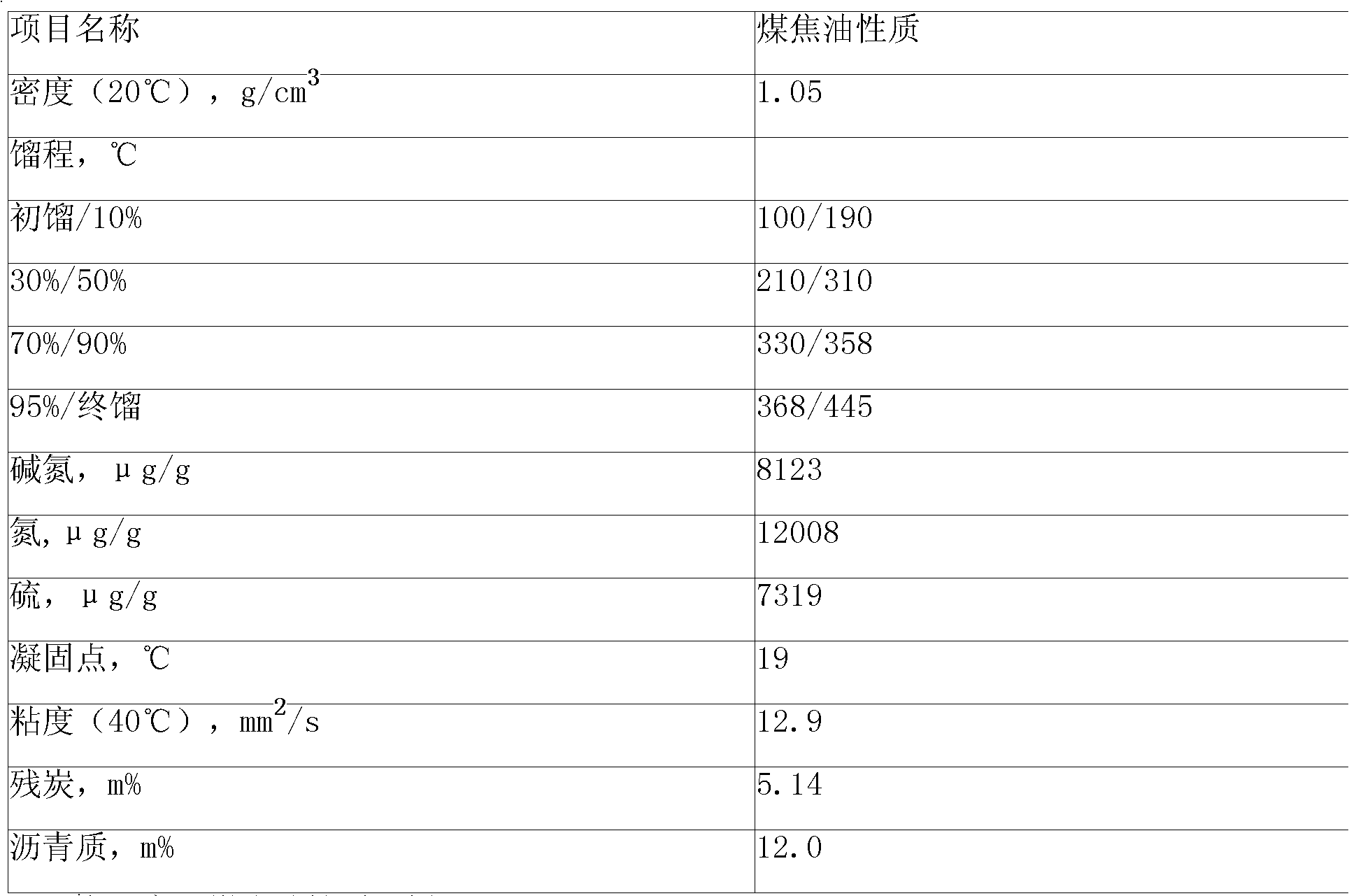

Method for preparing diesel component by catalytic cracking of coal tar light fraction

ActiveCN101629094AExtend your lifeQuality improvementCatalytic crackingChemistryFluid catalytic cracking

The invention discloses a method for preparing a diesel component by catalytic cracking of coal tar light fraction, which comprises the following step: placing a coal tar light fraction in a catalytic cracking device under conditions of a temperature of between 400 and 450 DEG C, a pressure of 0.05and 0.4MPa and an oil gas airspeed of 0.5 to 2.5 hour<-1> to obtain the diesel component. The method has the advantages of simple flow, high conversion rate and stable operation and belongs to the field of coal tar deep processing.

Owner:HANERGY TECH

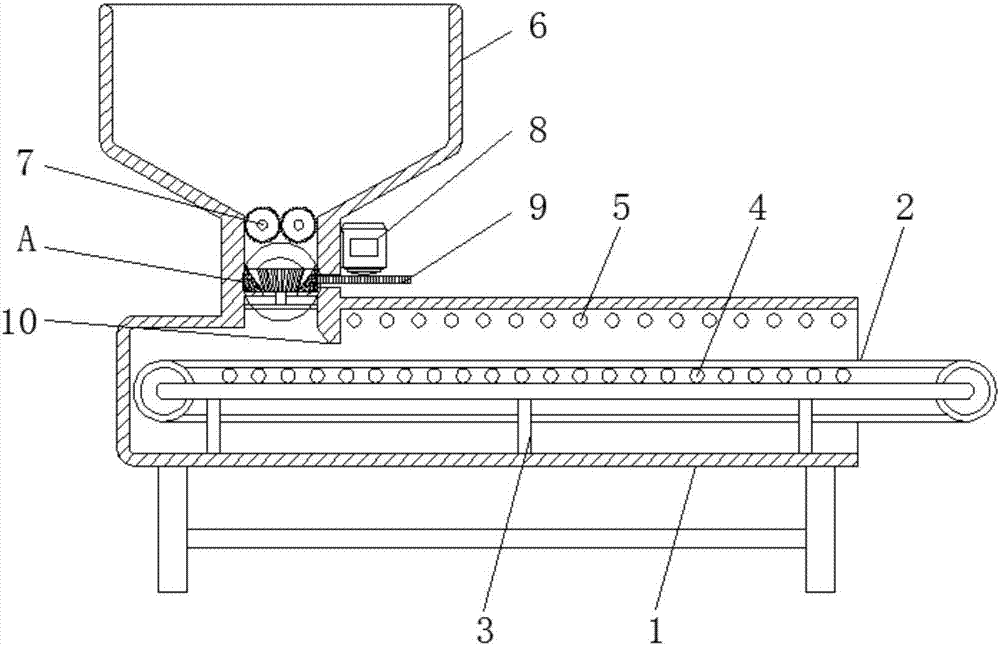

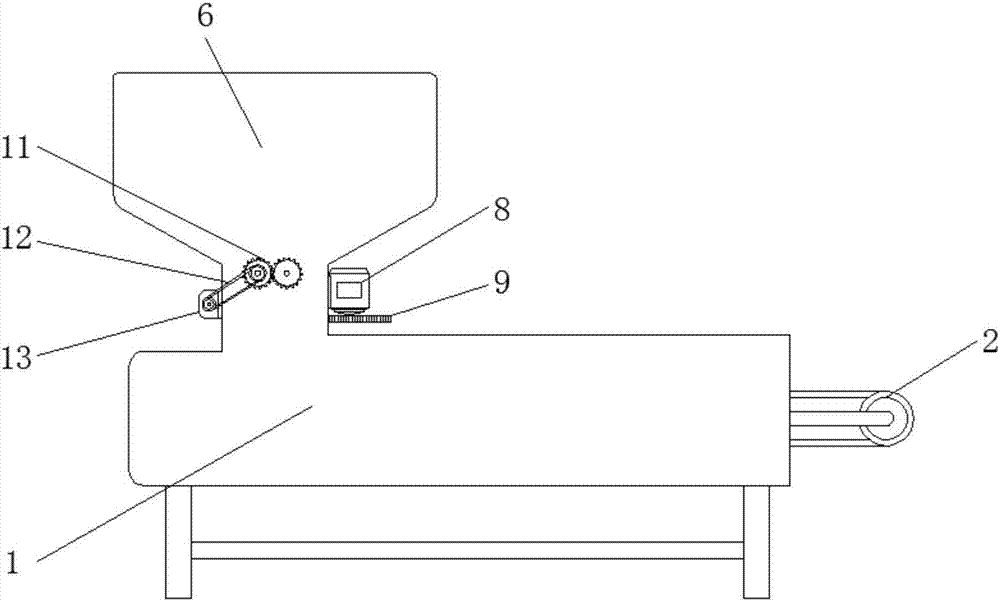

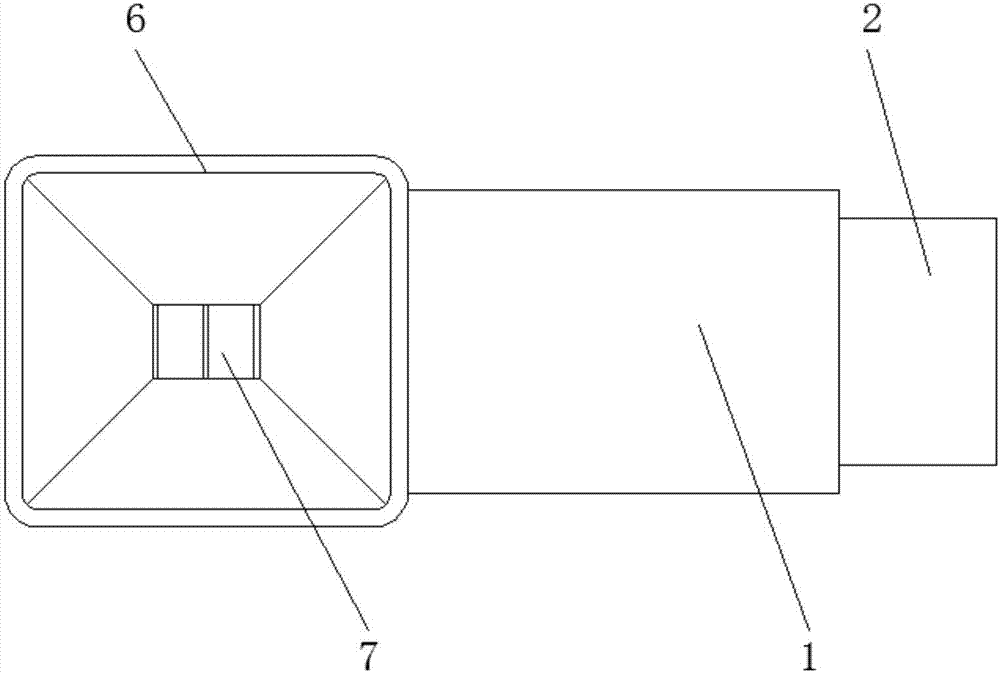

Coal chemical gasification furnace slag decarburization device

InactiveCN107321765AEasy to decarbonizePromote decarbonizationTransportation and packagingSolid waste disposalSlagDecarburization

The invention discloses a coal chemical gasification furnace slag decarburization device which comprises a shell, a first heating electric wire and a rotary grinding sleeve, wherein a conveyer belt is arranged inside the shell; the conveyer belt and the shell are fixed through a supporting frame; the first heating electric wire is installed above the interior of the conveyor belt; a second heating electric wire is arranged above the interior of shell, a feeding box is installed on the upper left portion of the shell, a smashing shaft is embedded inside the feeding box, a first motor is installed on the right side of the feeding box, and a fixed frame is connected below a grinding shaft, and the fixed frame is connected with the feeding box. According to the coal chemical gasification furnace slag decarburization device, furnace slag is smashed and ground twice, slag grinding and decarburization are more full; the width of a scraping plate is equal to the width of the shell, therefore the furnace slag can be flattened, accordingly, uniform decarburization of the furnace slag is facilitated, and the problem that the furnace slag is decarburized incompletely due to excessively-thick furnace slag is avoided.

Owner:开阳浩洋环保科技开发有限公司

Stainless steel refining method

The invention relates to a stainless steel refining method sequentially comprising the steps that: 1, molten steel satisfying requirements of argon oxygen furnace smelting is added into an argon oxygen furnace; 2, decarburization is carried out, wherein in a blowing decarburization process in which oxygen and nitrogen are both blown by using a top gun and a bottom gun, lime and light-calcined magnesium balls are added, wherein an MgO content in slag is 6-8%; sintered nickel, high-carbon ferromanganese, and chromium-and-nickel-containing stainless steel are added in batches according to the component of the type of steel; and carbon content in steel is removed to a value no higher than 0.05%; 3, a reductive bottom gun only blows argon, and stirring is carried out; ferrosilicon is added for reduction; fluorite and lime are added, wherein CaO / SiO2 is 1.7-2.2, and a MgO content is 6-8%; and molten steel components are analyzed; 4, molten steel components are adjusted according to analysis result and the components of the steel type; and 5, tapping molten steel analysis is carried out; when molten steel component mass percentages reach the requirements of the steel type, tapping is carried out. With the stainless steel refining method provided by the invention, corrosion of furnace slag to furnace lining is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Novel technology for producing medium/low carbon manganese iron by air three-times blowing method

InactiveCN103572057AGood production process controllabilityGood product quality controllabilityFurnace temperatureHigh carbon

The invention provides a novel technology for producing medium / low carbon manganese iron by an air three-times blowing method. The novel technology comprises the following steps: blowing primary air into a high carbon manganese iron flux, which is different from blowing oxygen by which high temperature evaporation manganese is generated and blowing components are damaged, and completely decarburizing through powerful dynamics stirring; blowing secondary air on a high carbon manganese iron flux liquid level so as to burn carbon monoxide generated by primary-air blowing for increasing heat, and adding more manganese ores so as to increase manganese oxide solid oxygen which facilitates decarburization and the recovery of manganese metal; blowing tertiary air and fuel gas into a furnace at the same time so as to provide external heat for increasing the furnace temperature, conditionally adding more manganese ores in an oxidation period and more reducing agent in a reduction period, conditionally adding a refinement period and meanwhile adding the manganese ores and the reducing agent so as to ensure the blowing technological operation and adjust product components for ensuring the quality.

Owner:王洪东

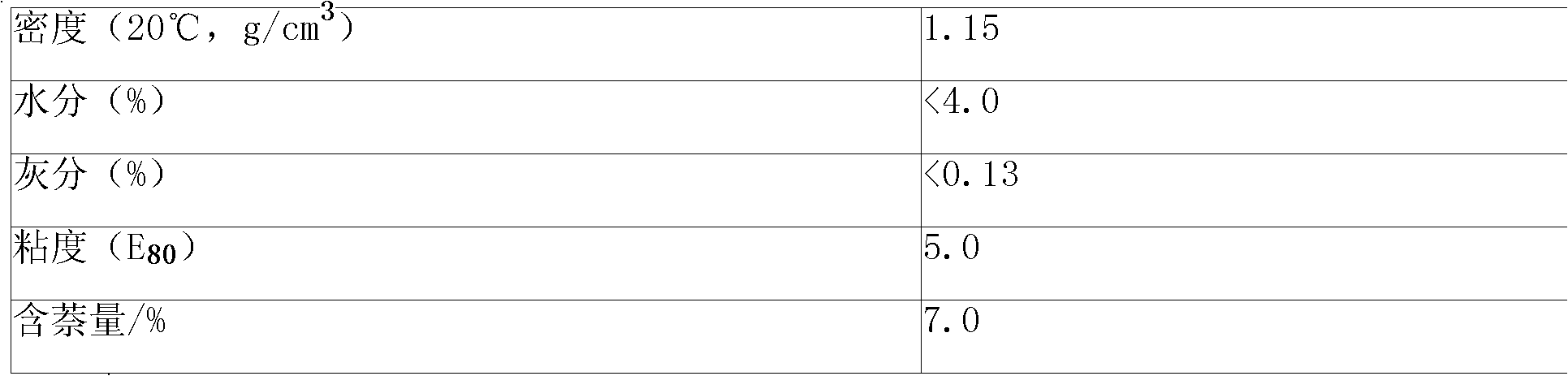

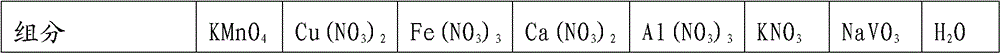

Liquid combustion-supporting sulfur-fixing coal additive and using method thereof

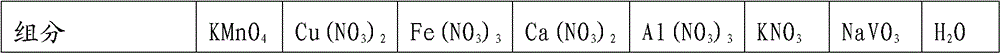

The invention discloses a liquid combustion-supporting sulfur-fixing coal additive and a using method of the additive; the liquid combustion-supporting sulfur-fixing coal additive comprises the following components in percentage by weight: 3-7.5% of KMnO4, 3-8% of Cu(NO3)2, 2-7.5% of Fe(NO3)3, 8-18% of Ca(NO3)2, 3.5-6% of Al(NO3)3, 8-18% of KNO3, 0.5-2.5% of NaVO3, and the balance of H2O. The liquid combustion-supporting sulfur-fixing coal additive provided by the invention uses water as a solvent and each component is at an ionic state, has relatively high reaction activity at a high temperature and has high combustion efficiency and an excellent sulfur fixing effect, and the sulfur fixing efficiency is more than 40%.

Owner:唐山干诚工程管理有限公司

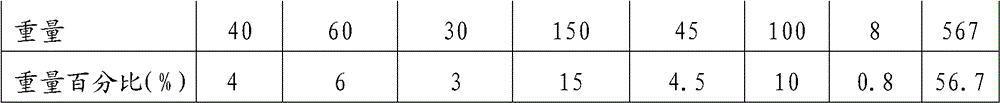

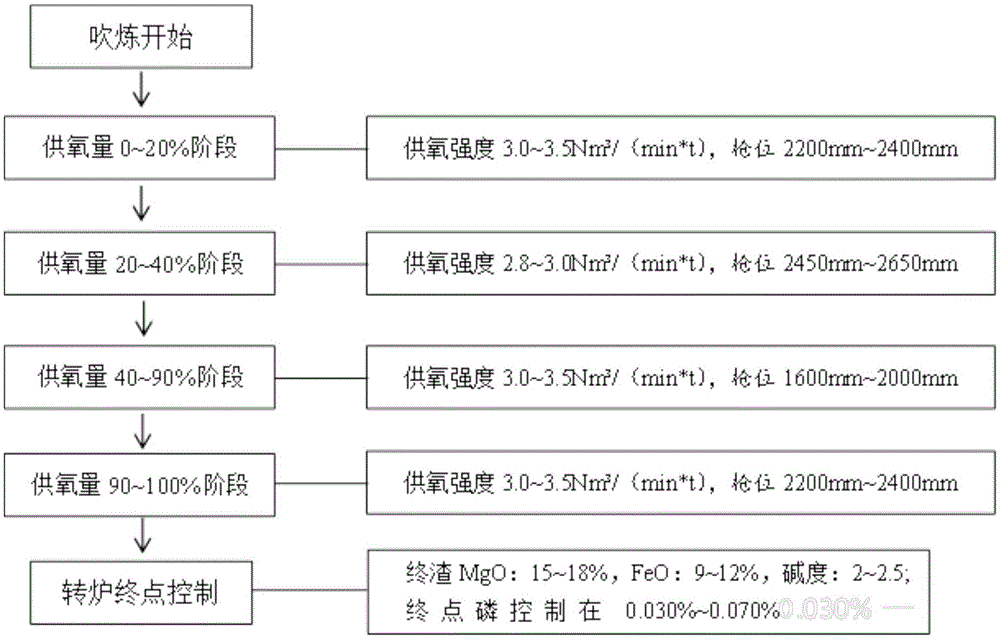

Smelting method of steel with high phosphorus content

The invention relates to a smelting method of steel with high phosphorus content. The smelting method is suitable for a converter of 180-250t. The smelting method comprises the following steps: in the converter blowing process, adjusting the oxygen lance position and the oxygen supply strength according to the oxygen supply amount; and carrying out endpoint control on the converter, wherein the endpoint control comprises the following steps: on the basis of the percentage by mass, controlling MgO to be 15-18%, FeO to be 9%-12% and endpoint phosphorus to be 0.030%-0.070%, and controlling the alkalinity of slag at the endpoint to be 2.0-2.5. According to the smelting method, the endpoint phosphorus content of the converter can be increased, consumption of ferro-phosphorus alloy is reduced, and on the basis of the percentage by mass, the method is suitable for smelting the grade of steel, of which the phosphorus content in a finished product is greater than or equal to 0.070%.

Owner:SHOUGANG CORPORATION

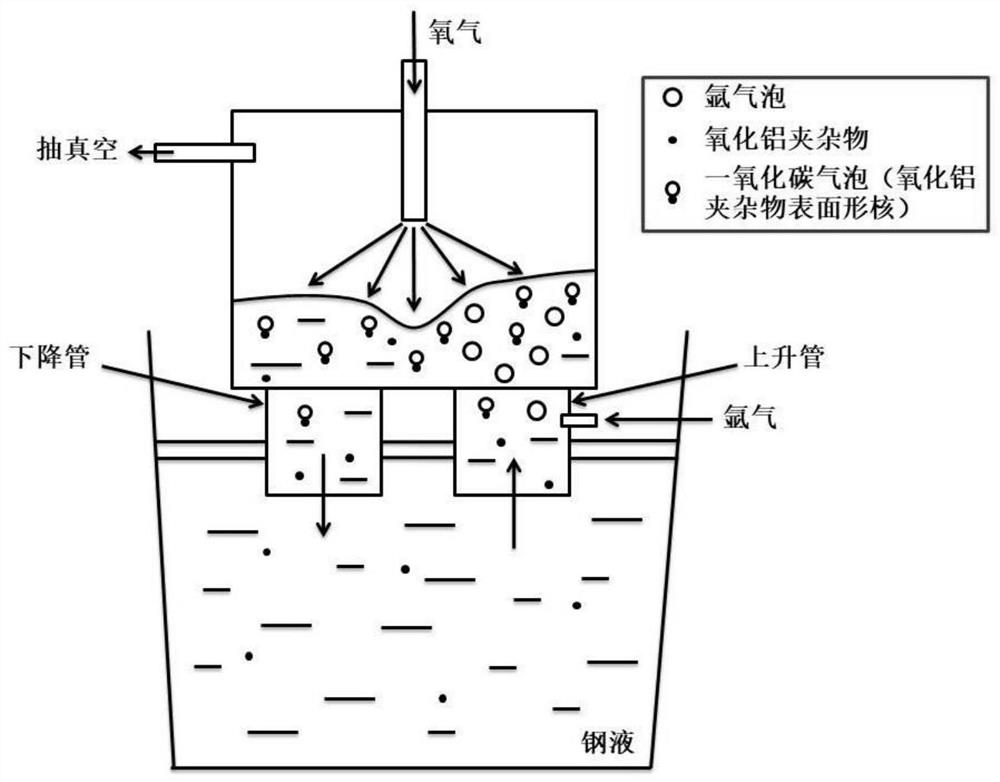

Method for promoting RH decarburization

The invention discloses a method for promoting RH decarburization. Before or during RH decarburization of ultra-low carbon steel, aluminum or aluminum alloy is added into molten steel, an aluminum oxide reaction is used for forming dispersed Al2O3 inclusions in the molten steel, wettability of the generated Al2O3 inclusions and the molten steel is poor, the wetting angle is large, the Al2O3 inclusions become a heterogeneous nucleation core of carbon monoxide bubbles generated by an RH decarburization reaction, nucleation of the carbon monoxide bubbles is promoted, the nucleation depth of the carbon monoxide bubbles in the molten steel is increased, the thickness of a reaction layer of a carbon-oxygen reaction in an RH vacuum tank is increased, and the ability of RH deep decarburization isimproved. According to the method, the RH decarbonization rate can be effectively increased, the end point carbon content is reduced by (1-10)*10<-6>. The generated carbon monoxide bubbles have smallsizes and a strong ability to catch the inclusions, the removal of the previously generated Al2O3 inclusions can be promoted without polluting the molten steel.

Owner:UNIV OF SCI & TECH BEIJING

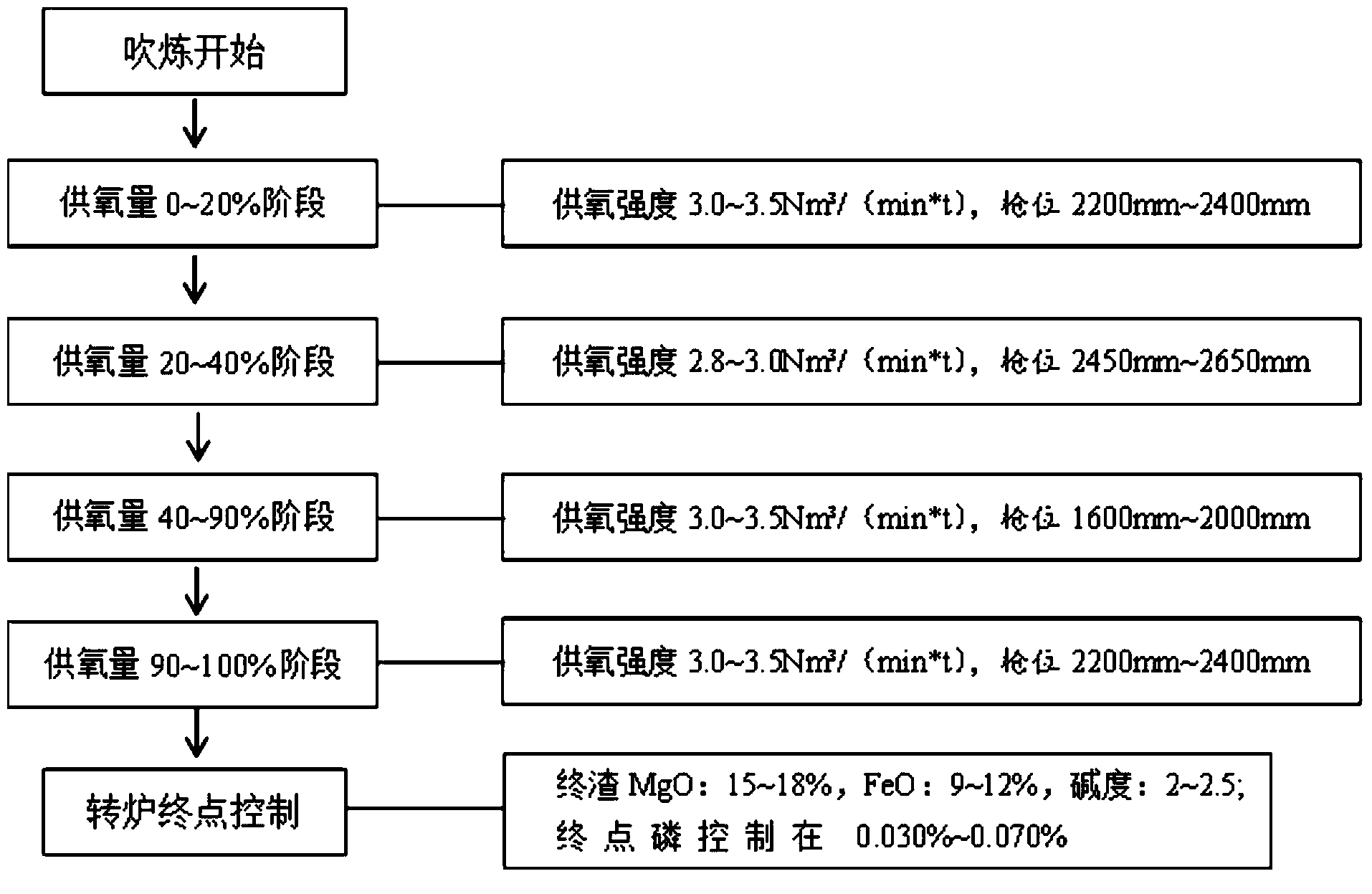

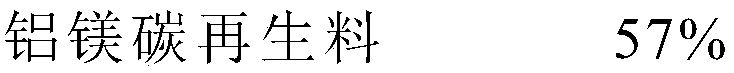

Al-Mg-C brick for steel ladle lining

The invention discloses an Al-Mg-C brick for a steel ladle lining. The Al-Mg-C brick is prepared from 50%-70% by weight of Al-Mg-C reclaimed materials, 5%-20% by weight of magnesia, 10%-25% by weightof alpha-Al2O3, 3%-10% by weight of AlN, 2%-6% by weight of crystalline flake graphite, 2%-3% by weight of SiC and 2.5%-3.5% by weight of phenolic resin. Due to addition of AlN, compared with a traditional Al-Mg-C brick, the Al-Mg-C brick is more resistant to high-temperature scouring, expansion coefficient of a brick body is reduced at the use temperature, volume stability is maintained, AlN is not corroded by molten metal, and slag resistance of the material is improved; a small amount of graphite is added, so that molten steel decarburization is facilitated, and the type of ultra-low carbonsteel is smelted; a large quantity of the Al-Mg-C reclaimed materials are adopted, therefore, the use quantity of high-bauxite clinkers or corundum particles is greatly reduced, the production cost is lower, and the Al-Mg-C brick has better social benefits and economic benefits.

Owner:WUGANG REFRACTORY CO LTD

Production method for smelting low-phosphorus steel from vanadium-containing molten iron

ActiveCN112226566AImprove dephosphorization efficiencyGuaranteed dephosphorization effectManufacturing convertersSlagDecarburization

The invention relates to the technical field of metallurgy, and particularly discloses a production method for smelting low-phosphorus steel from vanadium-containing molten iron. The production methodcomprises the following steps of carrying out desulfurization pretreatment on the vanadium-containing molten iron; feeding the desulfurized vanadium-containing molten iron into a dephosphorizing converter, adding a calcium dephosphorizing agent for dephosphorizing, and pouring out slag; carrying out coarse oxygen vanadium extraction on the dephosphorized vanadium-containing molten iron; and feeding semisteel into the dephosphorizing converter after deslagging for decarburization treatment, and conducting steel tapping. In the steel tapping process, small-particle lime and low-silicon refiningslag are added along with deoxidized alloy materials, and slag is reserved after steel tapping. According to the production method provided by the invention, desulfurization pretreatment is firstly carried out, then the alkalinity and oxidability of the slag are adjusted by utilizing the calcium dephosphorizing agent, the fluidity of the slag is improved, phosphorus is converted into 3CaO.P2O5 or4CaO.P2O5, the dephosphorizing efficiency is improved, vanadium extraction and decarburization are carried out after dephosphorizing, the grade of vanadium slag can be improved, residual vanadium inthe semisteel is reduced, the difficulty of smelting the low-phosphorus steel from the vanadium-containing molten iron is greatly reduced, and the low-phosphorus steel of which P is less than or equalto 0.005% is obtained.

Owner:HEBEI IRON AND STEEL

Combustion-supporting coal additive and application method thereof

The invention discloses a combustion-supporting coal additive and an application method thereof. The coal additive comprises the following components in percentage by weight: 3-7.5% of KMnO4, 3-8% of Cu(NO3)2, 2-7.5% of Fe(NO3)3, 1.5-6% of Zn(NO3)2, 6-14% of KNO3, 5-10% of NaNO3, 0.5-1.5% of NaVO3 and the balance of H2O. The combustion-supporting coal additive disclosed by the invention uses water as a solvent, and the components are in an ionic state, so the combustion-supporting coal additive has high reaction activity; the combination of the components in the additive can promote the decarburization and cracking reactions of the coal as well as the sufficient combustion of volatile compounds and fixed carbon, enhance the combustion efficiency of the coal, and save the coal by 4-10%.

Owner:国家电投集团协鑫滨海发电有限公司

Silicon steel heat treatment method

The invention relates to a silicon steel heat treatment method. A silicon steel annealing furnace is composed of an inlet sealing chamber, a preheating furnace, a non-oxidation furnace, a first furnace throat, a radiant tube heating furnace, a soaking furnace, a second furnace throat, a circulating gas spray cooler and an outlet sealing chamber. The silicon steel heat treatment method comprises the following steps: 1) heating the preheating furnace, non-oxidation furnace and radiant tube heating furnace in a coke oven gas heating mode, and controlling the furnaces to achieve the required temperatures; 2) heating the soaking furnace in a resistance heating mode, and controlling the furnace to achieve the required temperature; 3) charging argon-hydrogen mixed protective gas into the annealing furnace to perform furnace cleaning; and 4) sequentially passing a silicon strip through the inlet sealing chamber, preheating furnace, non-oxidation furnace, first furnace throat, radiant tube heating furnace, soaking furnace, second furnace throat and outlet sealing chamber at a certain operating speed, wherein the circulating gas spray cooler continuously sprays the argon-hydrogen mixed protective gas in the process. The heat treatment process can not easily form the oxide film protection layer, is beneficial to decarbonization, and enhances the performance indexes of the silicon steel.

Owner:ANGANG STEEL CO LTD

Rolled steel bar for machine structural use and method of producing the same

ActiveUS20170137904A1Low costImprove fatigue resistanceFurnace typesMetal rolling arrangementsChemical compositionSurface layer

A rolled steel bar for machine structural use includes a predetermined chemical composition. In the rolled steel bar for machine structural use, K1 obtained from “K1=C+Si / 7+Mn / 5+1.54×V” is 0.95 to 1.05, K2 obtained from “K2=139−28.6×Si+105×Mn−833×S−13420×N” is more than 35, K3 obtained from “K3=137×C−44.0×Si” is 10.7 or more, a Mn content and a S content satisfy Mn / S≧8.0, and a total decarburized depth in a surface layer is 500 μm or less.

Owner:NIPPON STEEL CORP

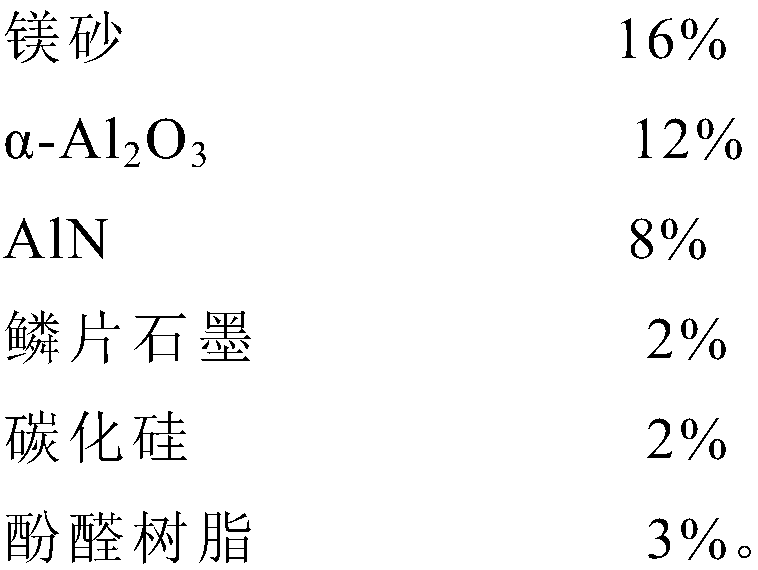

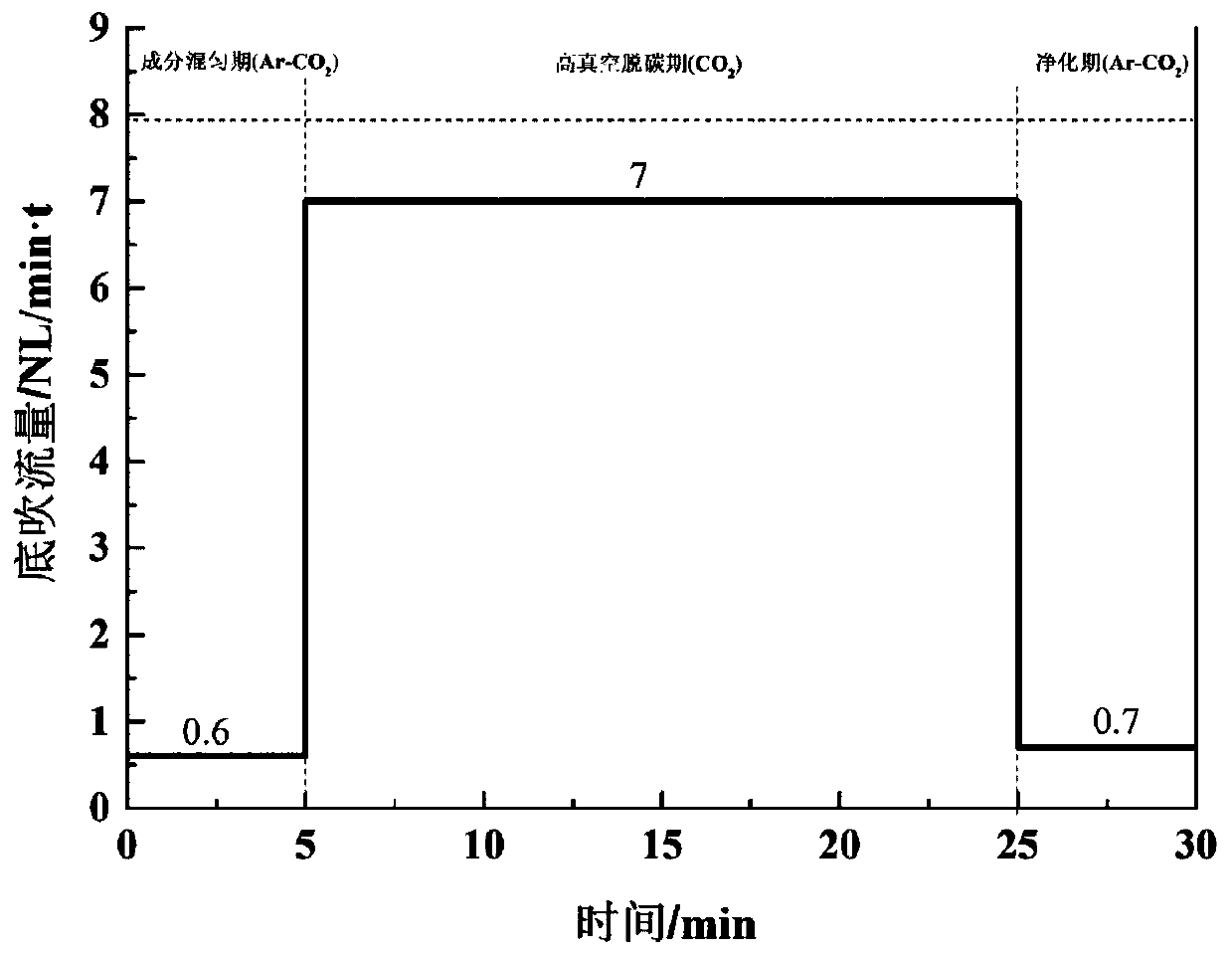

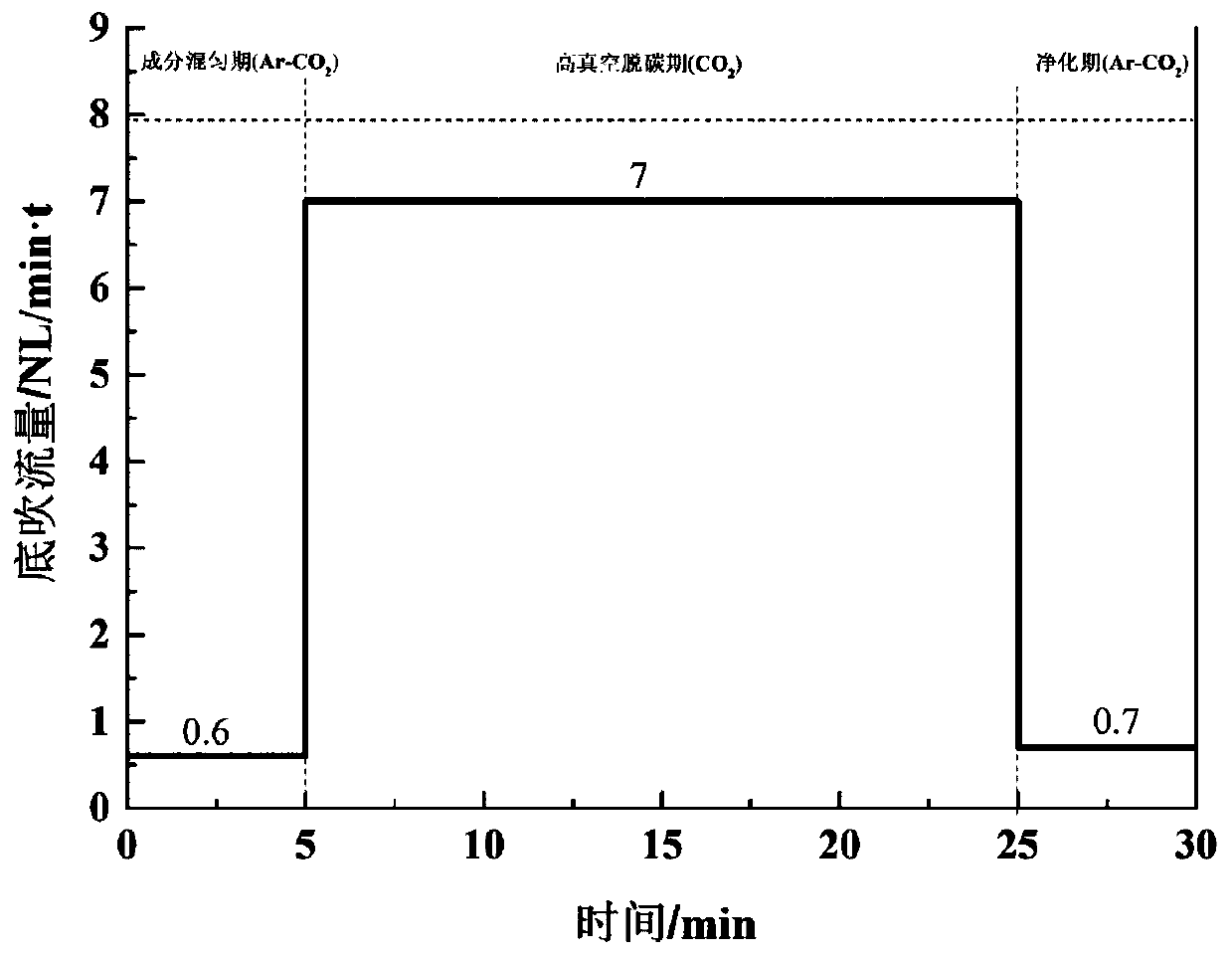

A method for denitrification in vd furnace using CO2 steelmaking

The invention relates to the technical field of the steelmaking industry, in particular to a method for steelmaking and denitrification of a VD furnace through CO2. The method for steelmaking and denitrification of the VD furnace through CO2 is suitable for the VD refinement of 30-350 t of steel ladles. According to the refinement process, bottom blowing of CO2 or CO2-Ar is performed through the steel ladles; different bottom blowing modes are adopted in all stages, the small-flow gas mixing bottom blowing is adopted in the liquid steel composition even-mixing stage, and liquid steel oxidationis prevented and the vacuumizing speed is increased; the high-flow bottom blowing of pure CO2 is adopted in the high vacuum decarburization stage, decarburization of CO2 is promoted, and then deep denitrification is achieved and dehydrogenation is enhanced; normal operation of a bottom blowing component is ensured by switching bottom blowing of Ar and high-pressure spraying and blowing in the bottom blowing repetition stage; and in the liquid steel purifying stage, bottom soft blowing of CO2-Ar mixed gas is performed, rapid flotation of nonmetal inclusions is promoted, and at the same time, CO2 gas is the main part of blowing, heat impact on a bottom blowing nozzle is reduced, the bottom blowing service life is prolonged, and finally low-cost smelting of low-nitrogen steel through the VDfurnace is achieved.

Owner:UNIV OF SCI & TECH BEIJING

A liquid combustion-supporting sulfur-fixed coal additive and its application method

The invention discloses a liquid combustion-supporting sulfur-fixing coal additive and a using method of the additive; the liquid combustion-supporting sulfur-fixing coal additive comprises the following components in percentage by weight: 3-7.5% of KMnO4, 3-8% of Cu(NO3)2, 2-7.5% of Fe(NO3)3, 8-18% of Ca(NO3)2, 3.5-6% of Al(NO3)3, 8-18% of KNO3, 0.5-2.5% of NaVO3, and the balance of H2O. The liquid combustion-supporting sulfur-fixing coal additive provided by the invention uses water as a solvent and each component is at an ionic state, has relatively high reaction activity at a high temperature and has high combustion efficiency and an excellent sulfur fixing effect, and the sulfur fixing efficiency is more than 40%.

Owner:唐山干诚工程管理有限公司

Method for pre-degrading high-concentration oil refining organic wastewater by synergism of sulfuric acid free radical and anodic oxidation

InactiveCN102311191BEfficient degradationPromote decarbonizationMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh concentrationSulfate radicals

The invention discloses a method for pre-degrading organic high-concentration oil refining organic wastewater by synergism of sulfuric acid free radical and anodic oxidation. The method comprising the following steps: building an electrolytic cell by taking a Ti / SnO2-Sb-Pt oxide electrode as an anode; adding wastewater to be degraded and SO4<2->; switching on a power supply for electrolysis; while the wastewater is degraded, generating HSO5<-> and S2O8<2-> in a system; sampling and measuring the concentration of S2O8<2-> every 10 minutes; when the concentration of S2O8<2-> reaches a certain degree, filling the wastewater into a reaction tank; and adding catalysts Fe<2+> and Co<2+> to catalyze the generation of the sulfuric acid free radical so as to further degrade the wastewater. With the method, the sulfuric acid free radical and the anodic oxidation are organically combined, and a sulfate radical serves as an auxiliary electrolyte, HSO5<-> and S2O8<2-> can be automatically generated in the system while the wastewater is oxidized and degraded in an anodic area; and then the catalysts are added to catalyze the generation of the sulfuric acid free radical, thereby degrading organic matters in oil refining wastewater, which are difficult to degrade, and improving the biological property of the wastewater.

Owner:DALIAN MARITIME UNIVERSITY

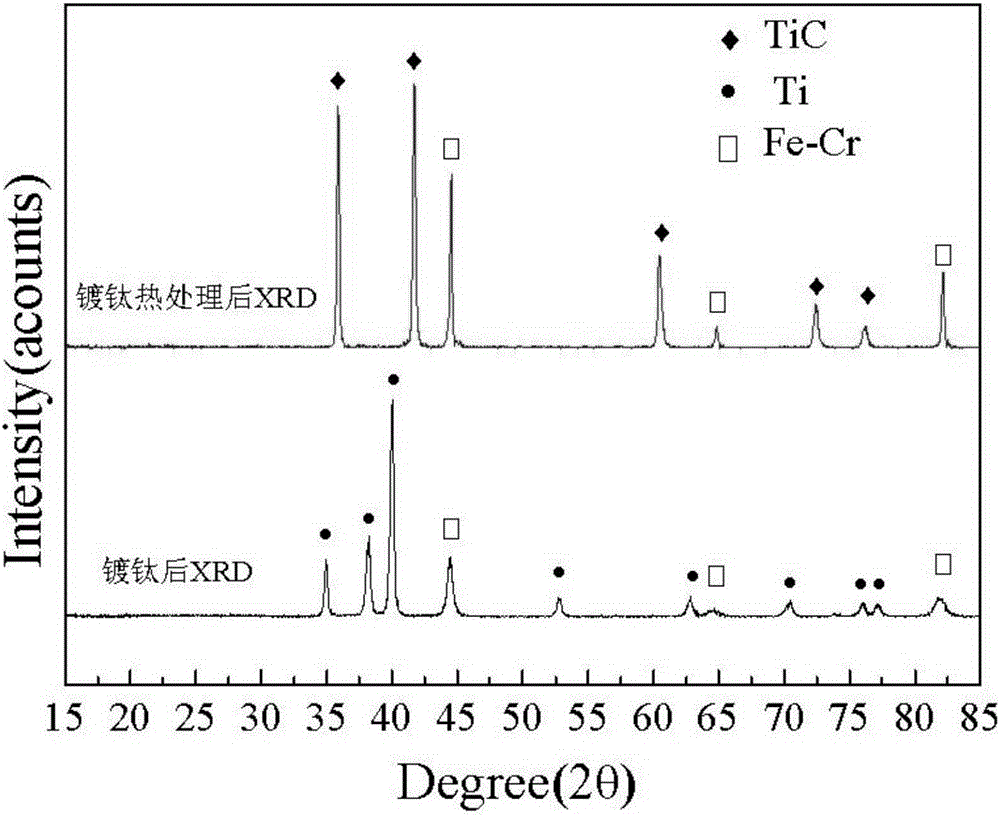

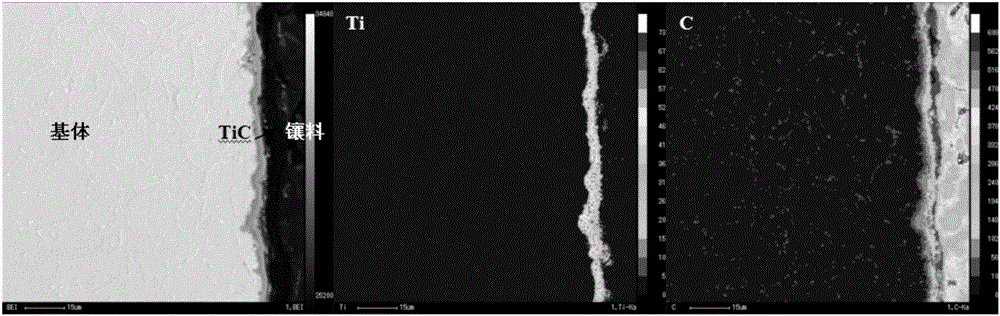

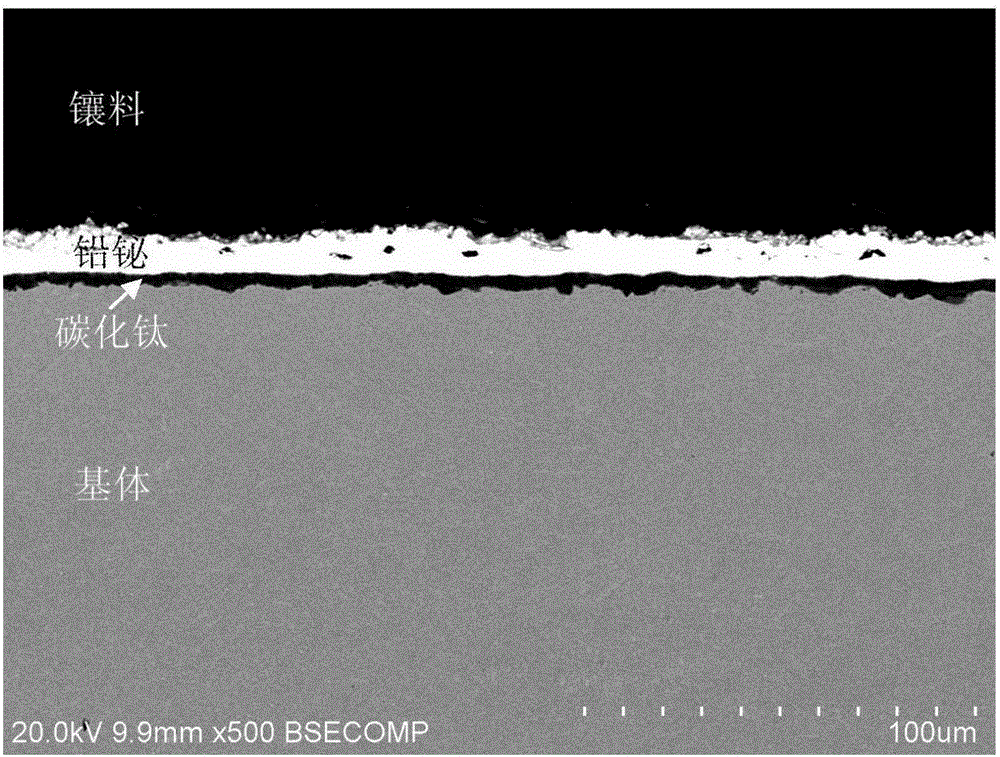

A method for improving the resistance to liquid metal corrosion of martensitic heat-resistant steel

ActiveCN103993271BImprove liquid metal corrosion resistanceAccelerated corrosionVacuum evaporation coatingSputtering coatingSurface layerCeramic coating

The invention aims to provide a method for improving the liquid metal corrosion resistance of martensitic heat-resistant steel. The method is characterized by: firstly pre-plating a titanium layer on the surface of martensitic heat-resistant steel, then making the carbon on the surface layer of the martensitic heat-resistant steel react with the pre-plated titanium layer on the surface by means of vacuum heat treatment, thus finally forming a ceramic coating of titanium carbide. By employing the method to treat the surface of martensitic heat-resistant steel, the liquid metal corrosion resistance of metal can be effectively improved, and the service life of metal materials can be prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

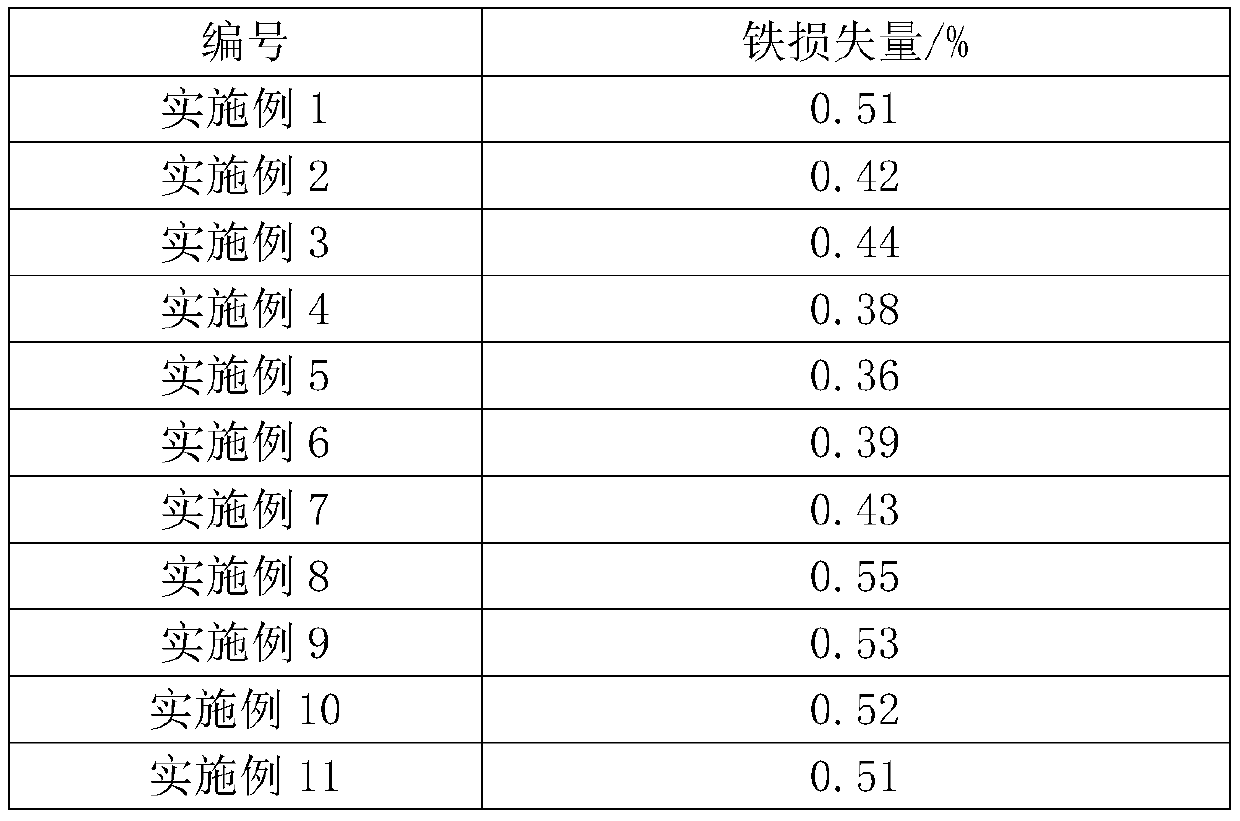

A kind of low-silicon high-carbon chromium bearing steel and its hot rolling production method

The invention relates to low-silicon high-carbon chromium bearing steel. The low-silicon high-carbon chromium bearing steel is prepared from the following chemical components in percentage by mass: 0.80-1.10% of C, 0.01-0.15% of Si, 0.20-0.60% of Mn, 1.20-1.60% of Cr, 0.15-0.50% of Mo, less than or equal to 0.05% of Al, less than or equal to 0.025% of P, less than or equal to 0.020% of S, less than or equal to 0.001% of Ca, less than or equal to 0.003% of Ti, less than or equal to 0.0008% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb and the balance of Fe and unavoidable impurities. A production flow comprises the following steps: electric furnace or converter smelting; external refining; VD or RH vacuum degassing; continuous casting; continuous rolling; shearing; stack cooling; finishing; flaw detection; and packaging. A low silicon technology is adopted based on existing high-carbon chromium bearing steel GCr15, and the chemical components are re-designed, so that not only are the demands on strength, hardness, toughness, wear resistance, hardenability and the like of a steel product met, but also the overheating sensitivity and decarburizing and cracking tendency of the steel product are improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD +1

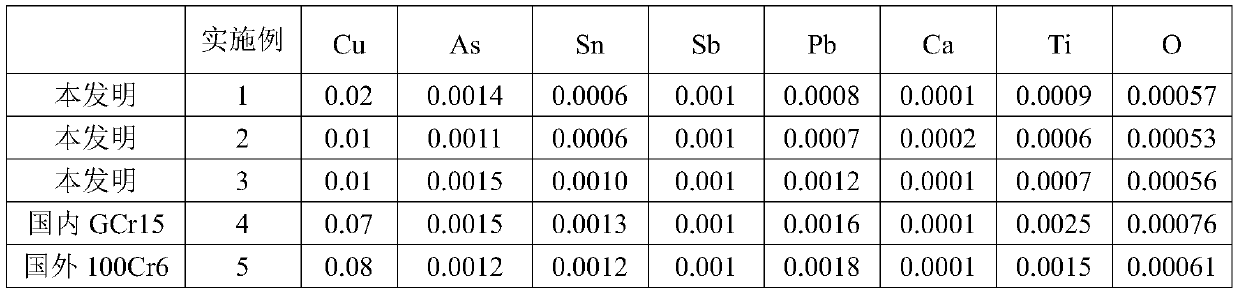

A Composite Steelmaking Process for Improving Steelmaking Precision

ActiveCN108330241BImprove dynamic conditionsRapid responseManufacturing convertersProcess efficiency improvementSteelmakingCaking

The invention discloses a composite steel-making technology with a function of improving steel-making precision, relates to the technical field of steel-making and solves the problems of unstable molten steel composition and low precision. The method comprises the steps of converter steel-making and LF (ladle furnace) steel-making. With adoption of an oxygen supply mode based on constant lance position and variable pressure, slag making and slag melting are facilitated, dynamic conditions of reaction in the furnace are greatly improved, and decarburization, dephosphorization and desulfurization are promoted, besides, ultrasonic waves are introduced during adding of a first slag-making material, fast reaction of the slag-making material and molten steel is promoted, and precision of the molten steel composition is improved; by means of introduction of the ultrasonic waves, argon flow can be reduced during addition of the slag-making material, consumption of argon is reduced, and steel-making cost is reduced; the ultrasonic waves are introduced during adding of the slag-making material, so that the slag-making material is dispersed uniformly and prevented from caking, and the impurities in the slag-making material are prevented from remaining in the molten steel.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

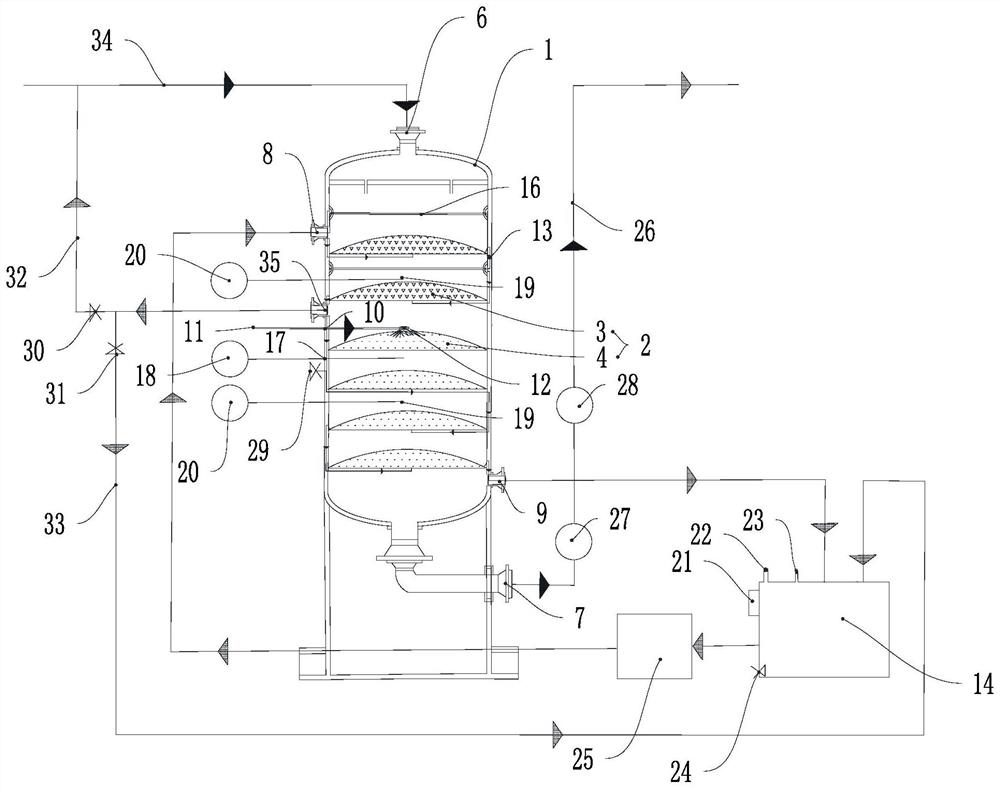

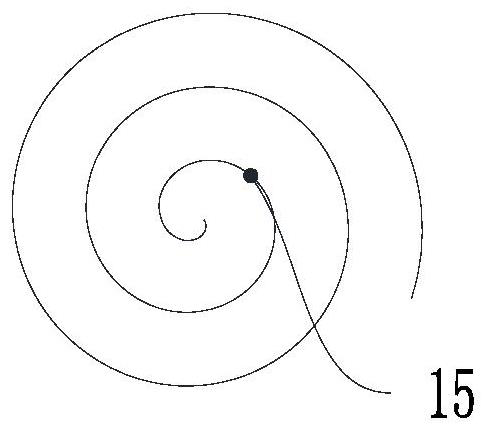

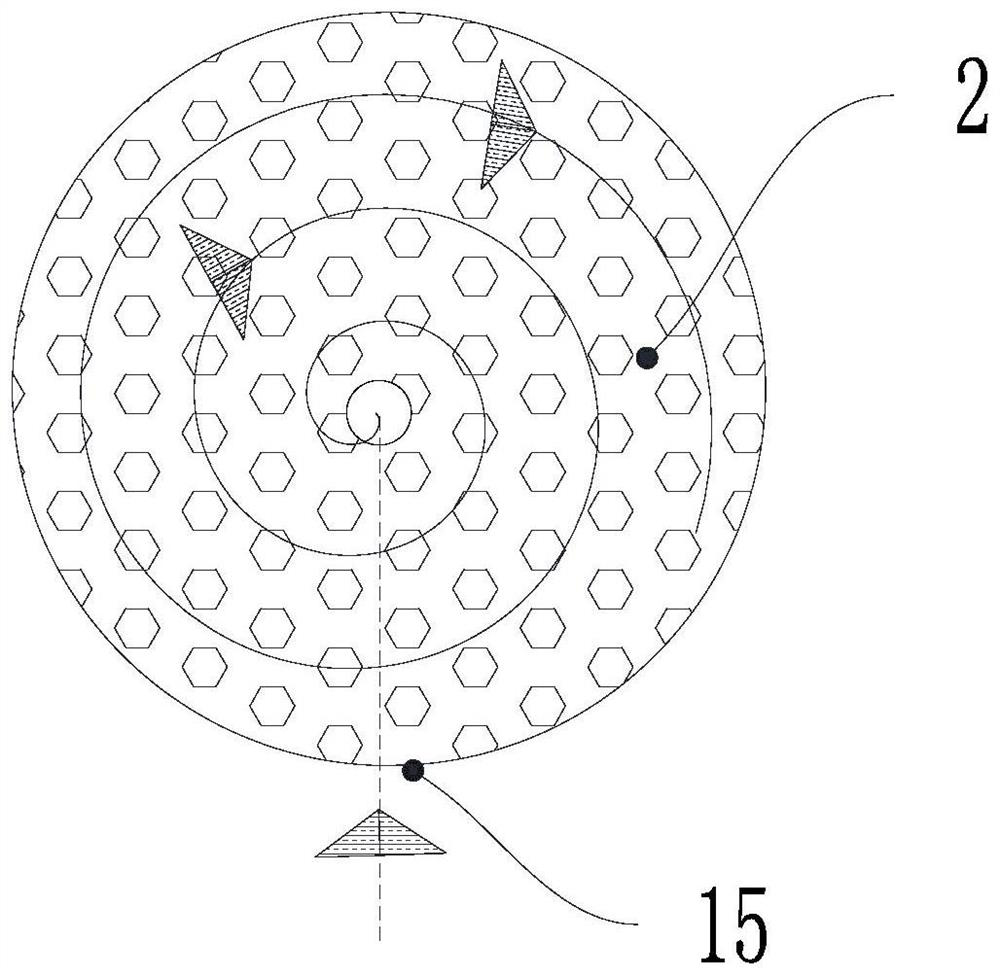

Impurity removal process and device for scintillation rotary flotation calcining furnace

PendingCN114777482APromote decarbonizationGood fluidization effectCombination devicesFurnace typesGas solidEconomic benefits

The invention discloses an impurity removal process and device for a scintillation rotary-floating calcining furnace. The process comprises the following steps that materials calcined in the scintillation rotary-floating calcining furnace enter a high-temperature cyclone separator from an outlet of the scintillation rotary-floating calcining furnace to be subjected to gas-solid separation; gas separated by the high-temperature cyclone separator enters a preheating system; and materials separated by the high-temperature cyclone separator are conveyed to fluidization impurity removal equipment through a discharge valve. The method has the technical effects that impurities in the product can be more effectively removed, the purity of the product is improved, and the economic benefit is increased.

Owner:沈阳宇能机械工程科技有限公司

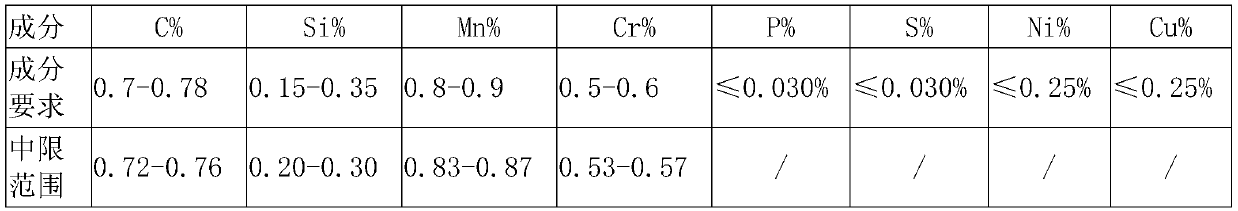

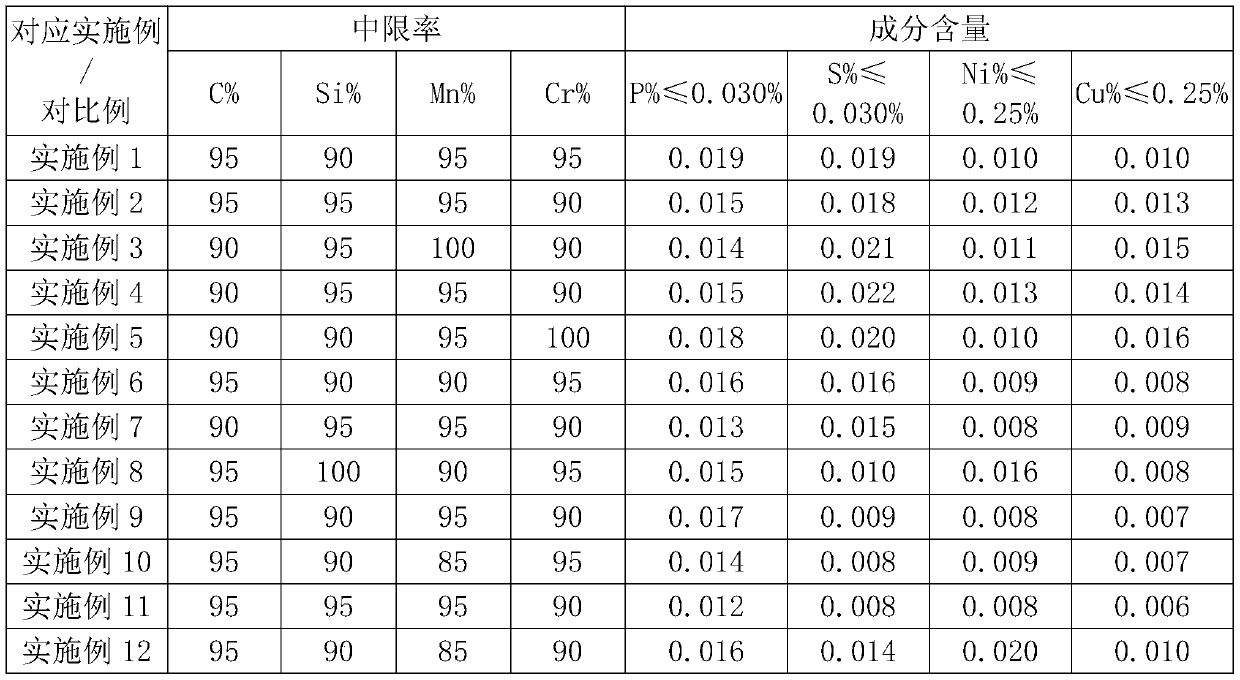

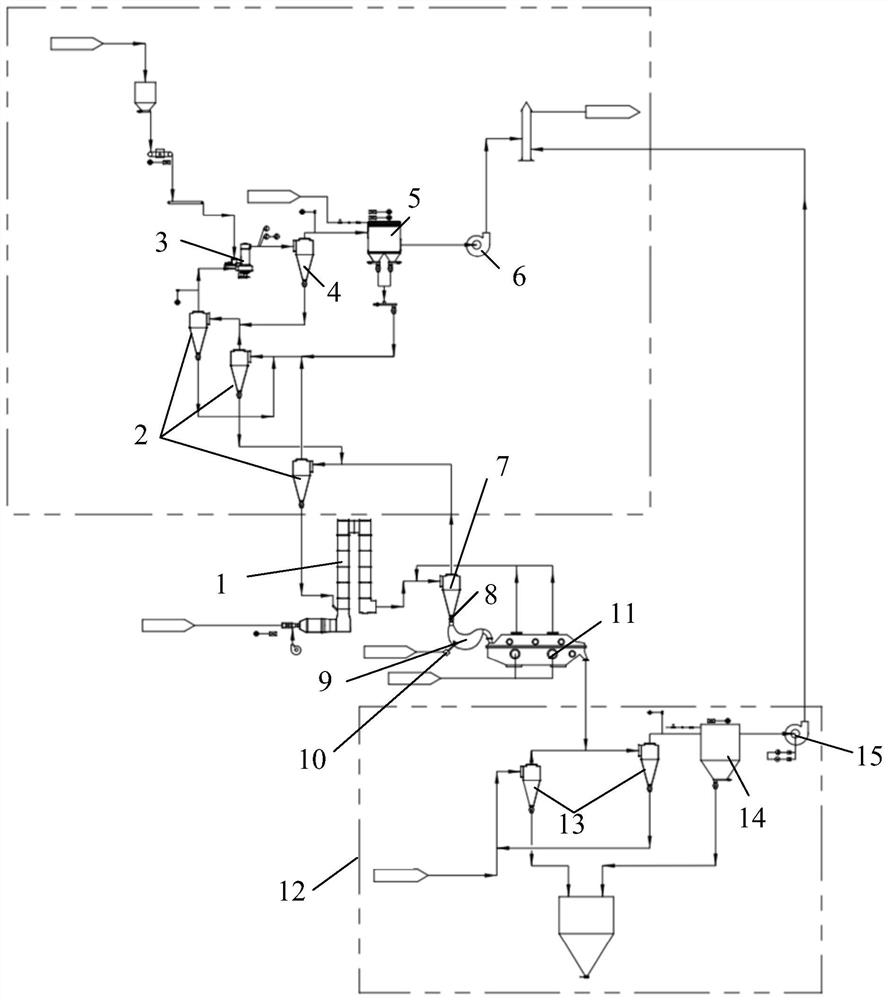

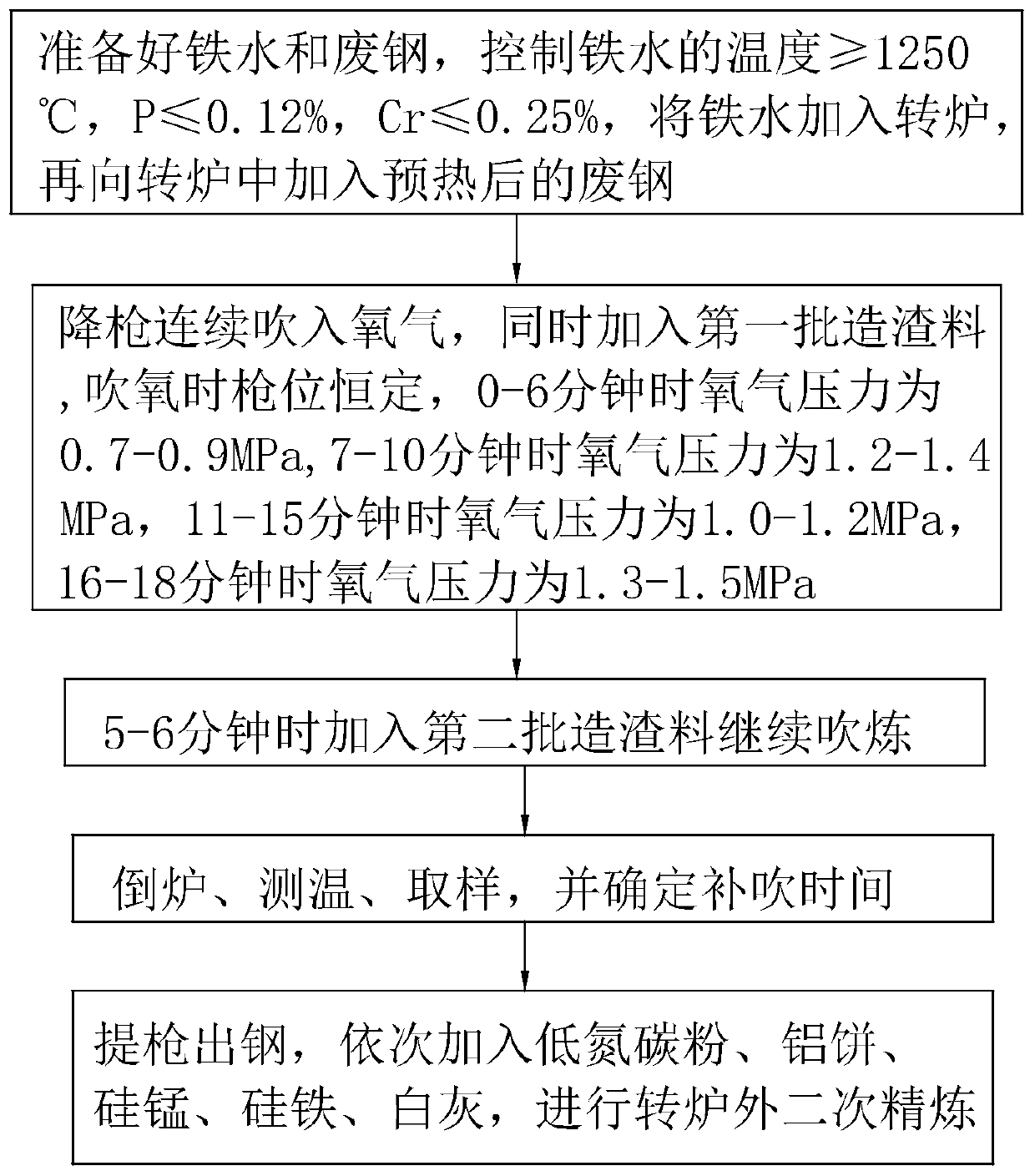

A converter steelmaking process

ActiveCN107988456BChange kinetic energyChange depthManufacturing convertersProcess efficiency improvementSteelmakingFerrosilicon

The invention discloses a converter steelmaking process, and relates to the technical field of steelmaking in order to solve the problem of metal loss during constant-pressure variable gun position oxygen supply. The converter steelmaking process comprises the following steps that firstly, molten iron and scrap steel are prepared, the molten iron is added into a converter, and then the preheated scrap steel is added into the converter; secondly, a gun is lowered to blow oxygen inwards, a first batch of slagging materials are added at the same time, and during oxygen blowing, a constant gun position variable pressure oxygen supply mode is adopted; thirdly, a second batch of slagging materials are added after five to six minutes for continuous converting; fourthly, converter turning down, temperature measurement and sampling are conducted, and the reblowing time is determined; and fifthly, the gun is lifted up, steel is discharged, and low-nitrogen carbon powder, alumcakes, silicomanganese, ferrosilicon and lime are sequentially added, and secondary refining outside the converter is conducted. The converter steelmaking process is beneficial to slag formation and slug melting, avoidssplashing, reduces metal loss, and promotes decarburization, dephosphorization and desulfuration.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

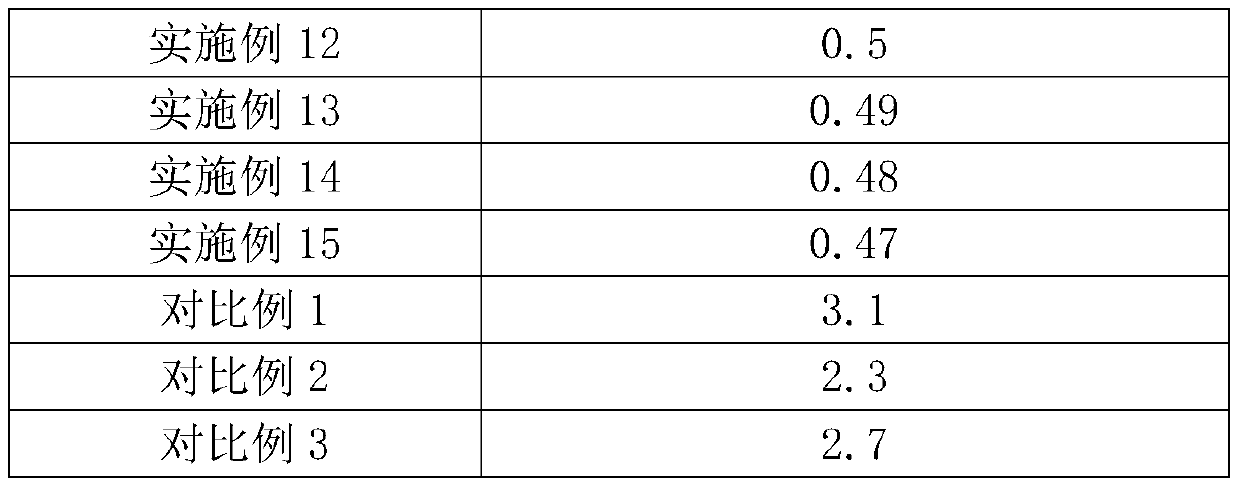

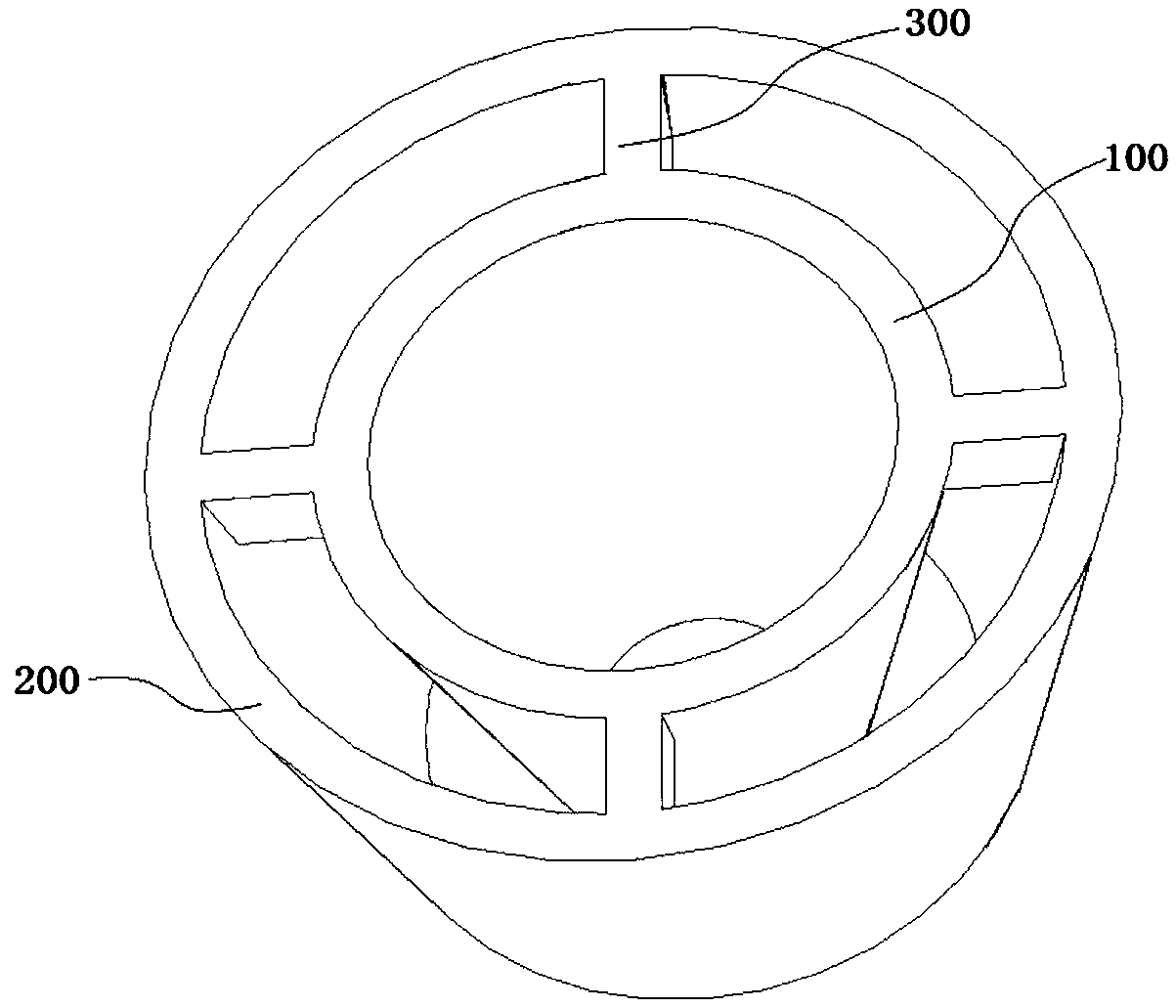

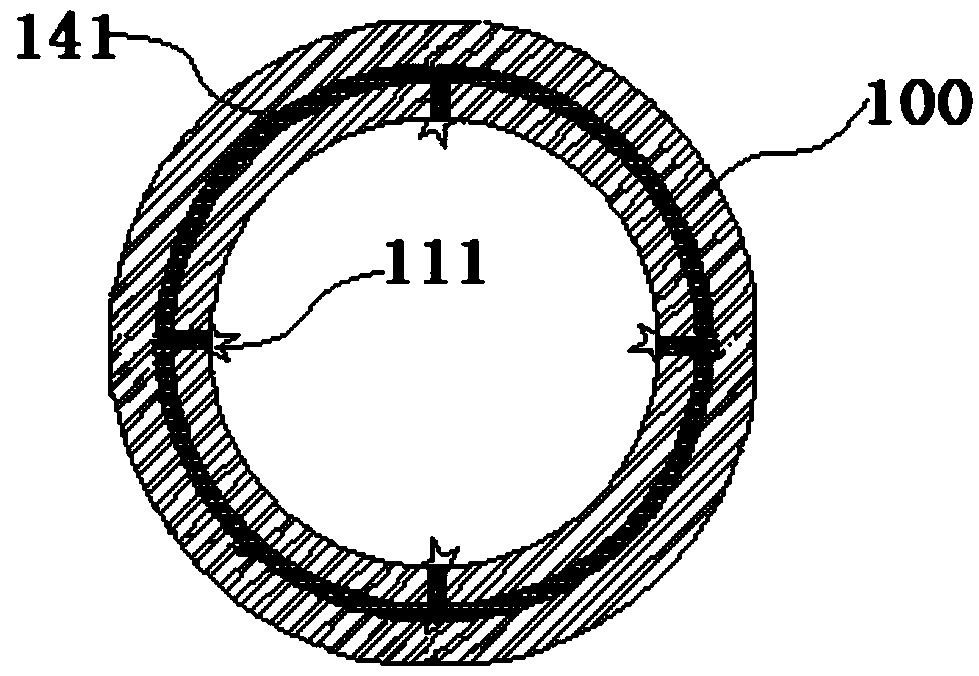

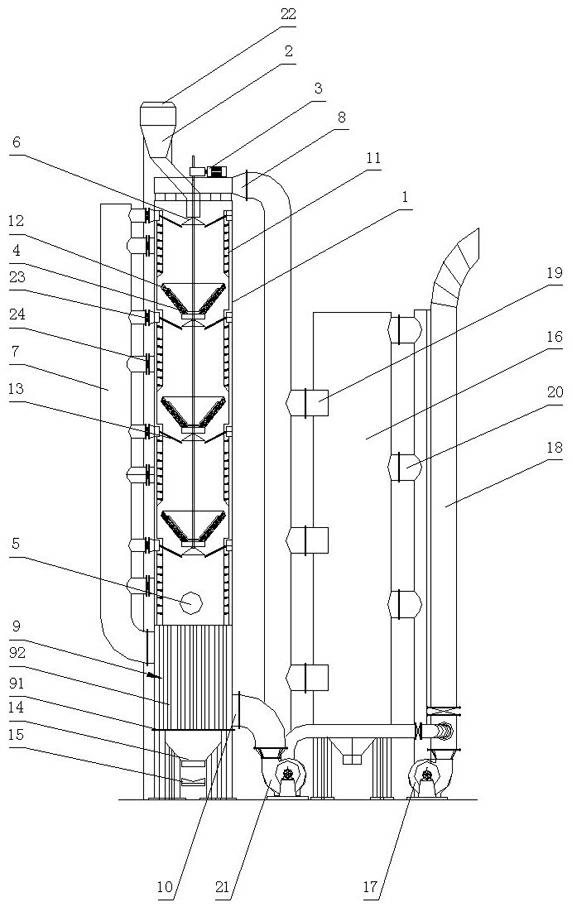

A rh vacuum refining furnace and vacuum refining system

The invention discloses an RH vacuum refining furnace and a vacuum refining system, and belongs to the technical field of secondary steelmaking of molten steel. The vacuum refining system comprises the RH vacuum refining furnace, a steel ladle base, a first air supply device, a second air supply device, a vacuum pump and an alloy hopper. The RH vacuum refining furnace comprises a vacuum chamber and a dip pipe. The dip pipe comprises a center pipe and an outer sleeve. The outer sleeve is an inverted cone frustum-shaped hollow pipe. The area of the upper bottom face of the outer sleeve is larger than that of the lower bottom face of the outer sleeve. The top of the center pipe is fixedly connected with the outer sleeve through a fixing beam, and the center pipe and the outer sleeve are located on the same axis. The center pipe is an ascending pipe and is also an inverted cone frustum-shaped hollow pipe. The area of the upper bottom face of the center pipe is larger than that of the lower bottom face of the center pipe. An annular sleeve formed by the center pipe and the outer sleeve is a descending pipe. According to the RH vacuum refining furnace and the vacuum refining system, the saturation point of gas flow in molten steel of the vacuum refining system is increased, circular flow is also increased, distribution of gas in a molten steel flow field is improved, and thus the refining effect of the molten steel is improved.

Owner:河南济源钢铁(集团)有限公司

A method to promote rh decarburization

A method to promote RH decarburization. Before or during the decarburization of ultra-low carbon steel RH, aluminum or aluminum alloy is added to the molten steel, and the aluminum-oxygen reaction is used to form dispersed Al in the molten steel. 2 o 3 Inclusions, generated Al 2 o 3 The inclusions have poor wettability and large wetting angle with molten steel, and become the heterogeneous nucleation core of carbon monoxide bubbles generated by RH decarburization reaction, which promotes the nucleation of carbon monoxide bubbles, increases the nucleation depth of carbon monoxide bubbles in molten steel, and expands The thickness of the reaction layer for the carbon-oxygen reaction in the RH vacuum tank improves the deep decarburization ability of the RH. The method can effectively increase the RH decarburization rate, and the carbon content at the end point is reduced by 1 to 10×10 ‑6 . The generated carbon monoxide bubbles are small in size and have a strong ability to capture inclusions, which can promote the formation of Al in advance. 2 o 3 Inclusions are removed without polluting molten steel.

Owner:UNIV OF SCI & TECH BEIJING

System and method for treating high-concentration landfill leachate in aerobic composting site

InactiveCN102976566BExtended service lifeIncrease alkalinityMultistage water/sewage treatmentHigh concentrationBiological filter

The invention discloses a system and a method for treating the high-concentration landfill leachate in an aerobic composting site. The system comprises a hydraulic screen, a regulation pool, an anoxic and anaerobic pool, an upflow anaerobic pool, an anoxic pool, a first aerobic pool, a second aerobic pool, a secondary sedimentation pools, an immobilized microorganism aerating biological filtering pool, an MBR (membrane biological reaction) pool, a nanofiltration system, a decolourising pool and a charcoal canister which are connected in sequence. The raw landfill leachate is treated by the hydraulic screen, the regulation pool, the anoxic and anaerobic pool, the upflow anaerobic pool, the anoxic pool, the first aerobic pool, the second aerobic pool, the secondary sedimentation pools, the immobilized microorganism aerating biological filtering pool, the MBR pool, the nanofiltration system, the decolourising pool and the charcoal canister of the system in sequence so that the effluent can be recovered. The effluent can meet the requirement for the limit of the discharge concentration of the water pollutant in the special region in the Domestic Waste Landfill Site Pollution Control Standard GB16889-2008.

Owner:BEIJING SOUND ENVIRONMENTAL ENG

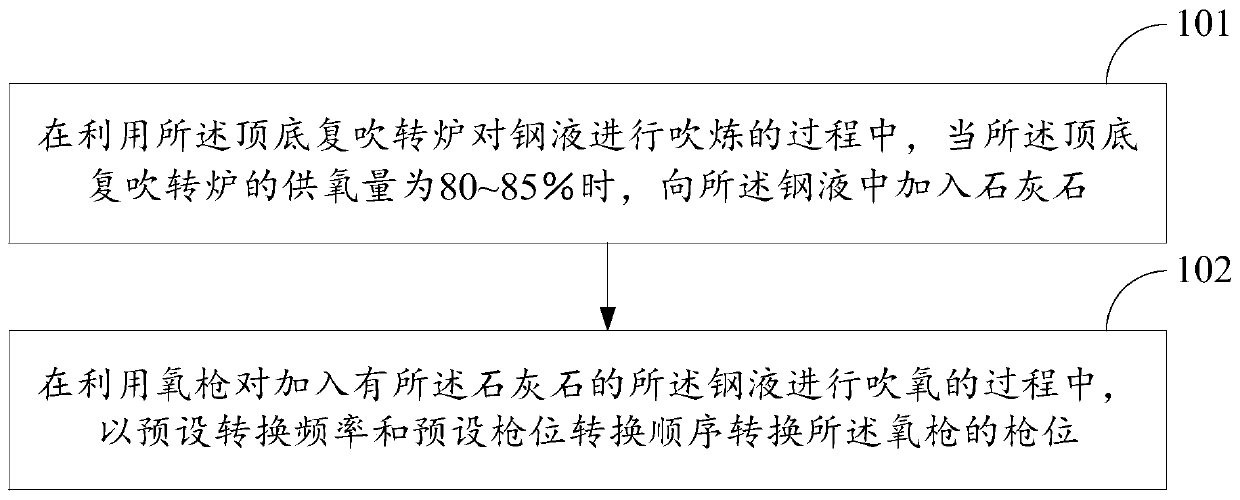

A method for smelting in a top-bottom combined blowing converter

ActiveCN107099639BImprove dephosphorization ratePromote generationManufacturing convertersSlagMolten steel

The invention relates to the technical field of converter smelting, in particular to a smelting method of a top-bottom combined blowing converter. The method comprises the steps of during a process of utilizing the top-bottom combined blowing converter for blowing molten steel, and when the oxygen supply rate of the top-bottom combined blowing converter is 80 to 85 percent, adding limestone in the molten steel; during a process of utilizing an oxygen lance for blowing oxygen to the molten steel added with the limestone, converting a the lance position of the oxygen lance according to a preset lance position conversion frequency and a preset lance position conversion sequence. According to the smelting method of the top-bottom combined blowing converter provided by the invention, when the oxygen supply rate of the top-bottom combined blowing converter is 80 to 85 percent, the limestone is added in the molten steel and is decomposed in the molten steel, the generated carbon monoxide and carbon dioxide can further play a role in stirring, and the sufficient balance between melting slags and furnace steel slags is promoted, so that carbon-oxygen equilibrium of a converter terminal can be further reduced.

Owner:SHOUGANG CORPORATION

A kind of smelting method of high phosphorus content steel

The invention relates to a method for smelting steel with high phosphorus content, which is suitable for a 180-250 ton converter, comprising: adjusting the position of the oxygen lance and the intensity of the oxygen supply according to the amount of oxygen supplied during the blowing process of the converter; End point control; the end point control includes: in terms of mass percentage, MgO is controlled at 15-18%; FeO is controlled at 9-12%; end-point phosphorus is controlled at 0.030%-0.070%; the basicity R of the slag at the end of the converter is controlled at 2.0% -2.5. The smelting method can increase the phosphorus content at the end point of the converter and reduce the consumption of the phosphorus-iron alloy, and is suitable for smelting steel types with a finished product phosphorus content ≥ 0.070% in terms of mass percentage.

Owner:SHOUGANG CORPORATION

Powder decarburization system

InactiveCN102409159APrecise Control of DecarburizationEfficient use ofEnergy inputElemental selenium/telluriumCombustorPlate heat exchanger

The invention discloses a powder decarburization system. The powder decarburization system comprises a decarburization furnace, a feed hopper, a rotating and lifting actuator, material-collecting hoppers, a combustor, material distributors, a high temperature dust remover and a main blast pipe, wherein the feed hopper is arranged on the top of the decarburization furnace; the top of the decarburization furnace is provided with a flue gas outlet, the bottom is provided with a gas-solid heat exchanger; the inside of the decarburization furnace is provided with the material-collecting hoppers, air-distributing pipes are evenly arranged on the inner wall; the combustor is arranged between the lowest material-collecting hopper and the gas-solid heat exchanger; the air outlet of the gas-solid heat exchanger is communicated with the main blast pipe, the air-distributing pipes are communicated with the main blast pipe; the material distributors are arranged below the outlets of the feed hopper and the material-collecting hoppers; and the material distributors are driven by the rotating and lifting actuator. The powder decarburization system adopts powder decarburization, mineral aggregatemoves down through the material-collecting hoppers, the heat generated through decarburization is utilized to preheat the mineral aggregate, the gas-solid heat exchanger is used to preheat air, the waste heat of the high temperature mineral aggregate is used to preheat air, the combusted flue gas is circulated to the inside of the furnace through the back part of the high temperature dust removerso as to adjust the temperature; and instant decarburization is realized in the decarburization furnace and the decarburization temperature is accurately controlled.

Owner:单文奎

Device for synchronously decarbonizing and denitrifying industrial flue gas and recycling waste heat

ActiveCN114471108ALower runLess investmentGas treatmentDispersed particle separationFlue gasEnvironmental engineering

The invention provides an industrial flue gas synchronous decarburization and denitrification and waste heat recycling device, the device comprises a decarburization and denitrification tower, ammonia spraying equipment and reaction bed layers, the decarburization and denitrification tower is provided with a flue gas inlet and a flue gas outlet, the decarburization and denitrification tower is internally provided with a plurality of reaction bed layers, and the ammonia spraying equipment is provided with ammonia spraying equipment; the plurality of reaction bed layers are located between the flue gas inlet and the flue gas outlet, a heat exchange inlet and a first heat exchange outlet are formed in the side wall of the decarburization and denitrification tower, an ammonia water inlet is formed in the side wall of the decarburization and denitrification tower, the ammonia spraying equipment is arranged in the decarburization and denitrification tower, and the ammonia water outlet is formed in the side wall of the decarburization and denitrification tower. And the ammonia water inlet is communicated with the ammonia spraying equipment. According to the technical scheme, the arrangement in the decarburization and denitration tower can be dynamically adjusted according to the temperature of the flue gas, decarburization and denitration are carried out in the decarburization and denitration tower at the same time, the equipment investment of step-by-step treatment can be greatly saved, the occupied area can be reduced, and the cost and the operation cost are saved.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com