Method for preparing reduced titanium for welding electrodes from ilmenite placer

A technology for welding electrodes and ore, which is applied in the field of reducing titanium, can solve problems such as difficult reduction, high tar content in flue gas, excessive S content in products, etc., and achieve the effect of promoting reduction speed, high overall profit, and reduced production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

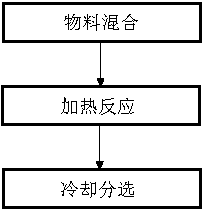

[0020] like figure 1 Shown, a kind of ilmenite placer prepares the method for reducing titanium for welding rod, comprises the following steps:

[0021] S1, the TiO2 content of ilmenite used in this case is 49%, S and P content are 0.02%, the volatile content of bituminous coal added at the kiln tail is 29%, and the proportion of particle size <5 mm is 1%, and the volatile content of coal is added at the kiln head was 34%. After mixing 2 parts of bituminous coal and 10 parts of ilmenite evenly, they are put into the rotary kiln from the kiln tail, and 1 part of coal and 0.5 parts of sodium bicarbonate are added into the kiln from the kiln head through a spray gun.

[0022] S2. By adjusting the secondary air and primary air of the kiln body, the temperature distribution of each section of the rotary kiln is controlled. The temperature of the kiln tail is 800°C, the temperature of the middle and front of the kiln is controlled between 1050-1150°C, and the temperature of the kil...

Embodiment 2

[0025] like figure 1 Shown, a kind of ilmenite placer prepares the method for reducing titanium for welding rod, comprises the following steps:

[0026] S1, the TiO2 content of ilmenite used in this case is 56%, the content of S and P is 0.03%, the volatile content of bituminous coal added at the kiln tail is 35%, and the proportion of particle size <5 mm is 2%, and the volatile content of coal added at the kiln head 37%. After mixing 4 parts of bituminous coal and 10 parts of ilmenite evenly, they are put into the rotary kiln from the kiln tail, and 3 parts of coal and 0.0 part of sodium bicarbonate are added into the kiln from the kiln head through the spray gun.

[0027] S2, by adjusting the secondary air and primary air of the kiln body, the temperature distribution of each section of the rotary kiln is controlled. The temperature at the kiln tail is 900°C, the temperature at the middle and front of the kiln is controlled between 1050-1150°C, and the temperature at the ki...

Embodiment 3

[0030] like figure 1 Shown, a kind of ilmenite placer prepares the method for reducing titanium for welding rod, comprises the following steps:

[0031] S1, the TiO2 content of ilmenite used in this case is 52%, S and P content are 0.01%, the volatile content of bituminous coal added at the kiln tail is 30%, and the proportion of particle size <5 mm is 1.5%, and the volatile content of coal is added at the kiln head 35%. After mixing 3 parts of bituminous coal and 10 parts of ilmenite evenly, they are put into the rotary kiln from the kiln tail, and 2.5 parts of coal and 0.3 parts of sodium bicarbonate are added into the kiln from the kiln head through the spray gun.

[0032] S2, by adjusting the secondary air and primary air of the kiln body, the temperature distribution of each section of the rotary kiln is controlled, in which the temperature of the kiln tail is 880°C, the temperature of the middle and front of the kiln is controlled between 1050-1150°C, and the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com