Oxygen lance nozzle with concentrated streams

A technology of oxygen lance nozzles and concentrated streams, which is applied in the manufacture of converters, etc., can solve the problems of low resource recovery and utilization rate, difficulty in suppressing jet black slag splashing, and low economic furnace life, so as to improve the adaptability of raw materials and improve the efficiency of gas The effect of early recovery time and small attenuation of oxygen flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

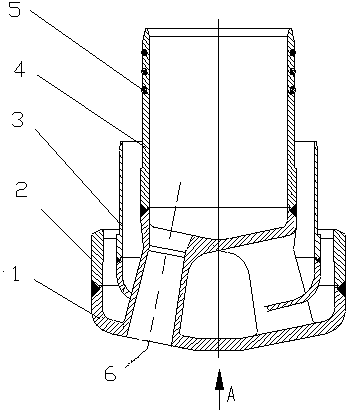

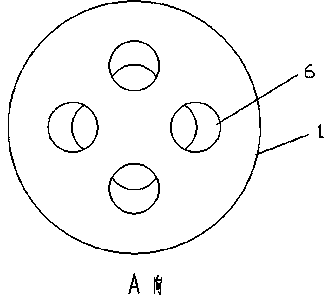

[0026] The principle of the cluster oxygen lance is to increase the outer surrounding accompanying flow around the traditional oxygen lance, so that the expansion and attenuation of the supersonic jet in the center is smaller, the supersonic jet is longer, and the penetration depth and stirring intensity of the oxygen jet to the molten pool are improved. Due to the delayed decay of the jet velocity, the blowing lance position of the oxygen lance can be increased without affecting the impact depth of the jet on the molten steel. This oxygen lance nozzle refers to the design idea of clustering oxygen lances to reduce jet attenuation, but does not adopt the method of surrounding the accompanying flow on the outer layer, but achieves the purpose of reducing oxygen jet attenuation through a more concentrated oxygen stream than conventional oxygen lances. To achieve the effect of micro-bundling. The oxygen lance nozzle designed with the concept of micro cluster adopts the design m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com