Magnesia-carbon modifier prepared from tundish residual linings

A modifier, magnesia-carbon technology, applied in the field of refractory materials, can solve the problems of low carbon content, affecting the life of the converter, and low magnesia content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the embodiments of the present application, the preparation method of the magnesium-carbon modifier specifically includes the following steps:

[0036] 1) Ingredients: put the residual lining, coke powder, sintered magnesia and flake graphite in the raw material into the mixing mill according to the above weight ratio;

[0037] 2) Mixing: After dry mixing for 1-2 minutes, add binder according to the above weight ratio, stir for 8-10 minutes, so that the binder is evenly distributed in the mud, add 15-20wt% water of raw materials, and wait for the mud to Mix evenly, discharge without floating fine powder and white material, and ensure that the discharge temperature is 10-40°C;

[0038] 3) Ball pressing: put the mixed mud into the ball pressing machine, 1000t high pressure ball forming;

[0039] 4) Natural drying: natural drying for 24 hours, and then bagged.

[0040] The present invention will be described in detail below, but it should be noted that the implementat...

Embodiment 1

[0042] A magnesium-carbon modifying agent prepared by tundish residual lining is composed of the following raw materials in parts by weight:

[0043] 60 parts of tundish residual lining with particle size ≤ 10mm;

[0044] 10 parts of coke powder with particle size ≤ 1mm;

[0045] 12 parts of sintered magnesia with particle size ≤0.074mm;

[0046] 15 parts of flake graphite with particle size ≤0.074mm;

[0047] The binder is 2 parts of magnesium sulfate heptahydrate and 1 part of magnesium chloride.

[0048] The preparation method of magnesium carbon modifier comprises the following steps:

[0049] 1) Ingredients: according to the ratio, put the residual lining, coke powder, sintered magnesia and flake graphite in the raw material into the mixer;

[0050] 2) Mixing: After 2 minutes of dry mixing, add the binder in proportion and stir for 10 minutes to make the binder evenly distributed in the mud, add 15wt% water of the raw material, and wait until the mud is mixed evenly w...

Embodiment 2-5

[0054] The preparation method of Examples 2-5 is the same as that of Example 1, and the ratio of each raw material is changed to prepare a magnesium-carbon modifier.

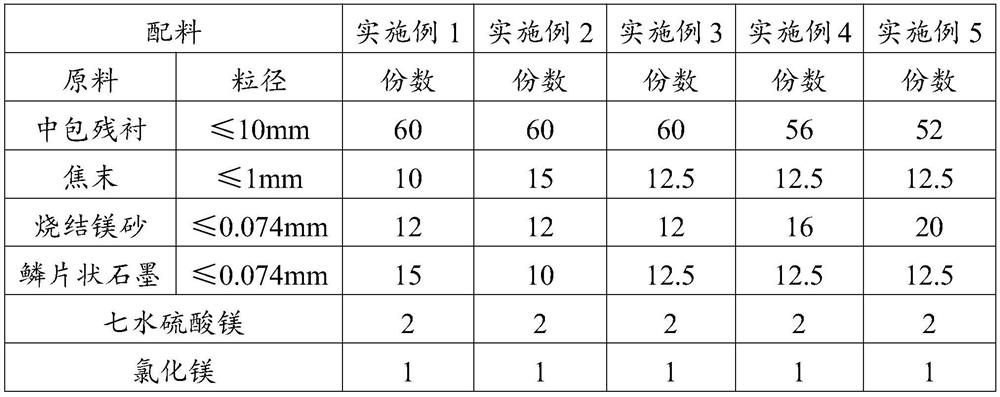

[0055] The raw material ratio of embodiment 1-5 is as shown in table 1:

[0056] Table 1

[0057]

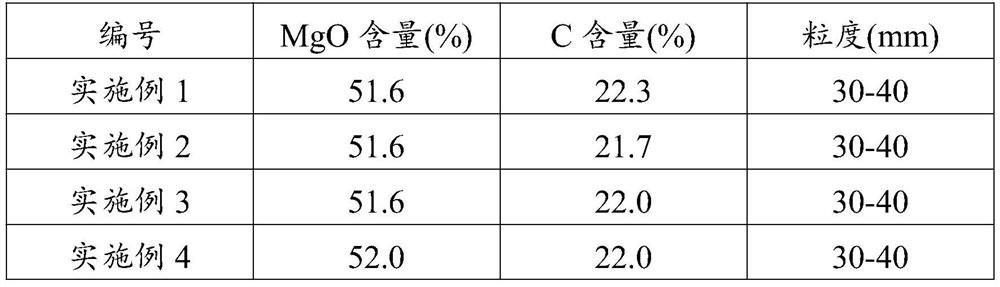

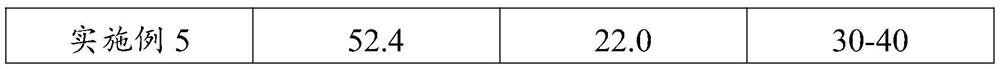

[0058] The physical and chemical indicators of the magnesium-carbon modifier prepared in Examples 1-5 are shown in Table 2:

[0059] Table 2

[0060]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com