Preparation method based on high-pressure roll-grinding pretreatment and used for low-energy-consumption and high-quality vanadium-titanium pellet ores

A technology of high-pressure roller milling and pelletizing, which is applied in the preparation of high-quality vanadium-titanium pellets with low energy consumption and in the field of pellet production. Effect of improving specific surface area and improving spheroidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

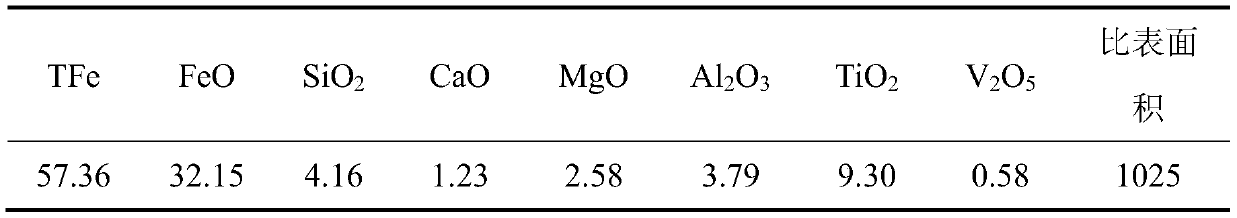

Embodiment 1

[0039] Adopt the vanadium-titanium magnetite of table 1, with it under the condition of pressure 2.5MPa, iron concentrate moisture 7.5% high-pressure roller mill, the specific surface area relative change η of vanadium-titanium magnetite concentrate after roller milling S 0.23, the increase ratio of particle crack rate ΔL 5%; after roller milling, the water pressure is pressurized to 1.2MPa through the pipeline booster pump during the pelletizing process, and the water is dispersed by compressed air to form a particle size of 20-30μm The water mist beads within the range are added to the growing area of the pelletizing disc to make pellets, and the proportion of particle size 13-15mm reaches 88%; the adjusted material height is 180mm×(1+0.23 2 )=190mm, machine speed 2.5 / (1+0.23 2 )=2.37m / min, adjust the preheating temperature 970-0.23×80-0.05×120=946°C, and the calcination temperature 1275-0.23×100=1252°C. After roasting, the pellet oxidation rate is 97%, the residual FeO c...

Embodiment 2

[0041] Adopt the vanadium-titanium magnetite of table 1, with it under the condition of pressure 3MPa, iron concentrate moisture 7.0% high-pressure roller mill, the specific surface area relative change η of vanadium-titanium magnetite concentrate after roller milling S 0.30, the increase ratio of particle crack rate ΔL 7%; after roller milling, pressurize the water pressure to 1MPa through the pipeline booster pump, and disperse the water through compressed air to form water mist with a particle size in the range of 30-40μm Beads are added to the growing area of the pelletizing disk, and it is made into pellets, and the proportion of particle size 13-15mm reaches 90%; the adjustment material height is 180mm×(1+0.3 2 )=196mm, machine speed 2.5 / (1+0.3 2 )=2.29m / min, adjust the preheating temperature 970-0.3×80-0.07×120=938°C, and the calcination temperature 1275-0.3×100=1245°C. After roasting, the pellet oxidation rate is 98%, the residual FeO content is 0.6%, the pellet str...

Embodiment 3

[0043] Adopt the vanadium-titanium magnetite of table 1, with it under the condition of pressure 2.75MPa, iron concentrate moisture 6.5% high-pressure roller mill, the specific surface area relative change η of vanadium-titanium magnetite concentrate after roller milling S 0.25, the increase ratio of particle crack rate ΔL 4%; after roller milling, the water pressure is pressurized to 1.1MPa through the pipeline booster pump during the pelletizing process, and the water is dispersed by compressed air to form a particle size of 30-40μm The water mist beads within the range are added to the growing area of the pelletizing disc to make pellets, and the proportion of particle size 13-15mm reaches 87%; the adjustment material height is 180mm×(1+0.25 2 )=191mm, machine speed 2.5 / (1+0.25 2 )=2.35m / min, adjust the preheating temperature 970-0.25×80-0.04×120=945°C, and the calcination temperature 1275-0.25×100=1250°C. After roasting, the pellet oxidation rate is 97%, the residual Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com