Efficient dephosphorization process for converter

A converter and dephosphorization technology, applied to the improvement of process efficiency, manufacturing converters, lime production, etc., can solve the problems of difficult to achieve dephosphorization effect and slow dephosphorization speed, and achieve good dephosphorization effect and dephosphorization efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

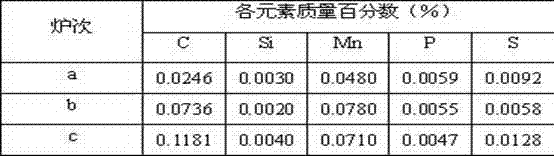

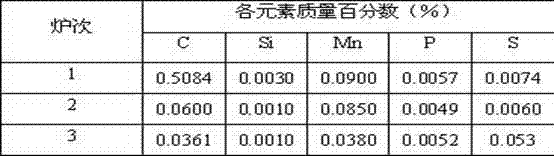

Examples

Embodiment Construction

[0017] Main technique of the present invention comprises the following contents:

[0018] (1) After the converter is tapped, no slag is dumped, and the slag remains in the brick furnace for dephosphorization in the blowing stage of the next furnace;

[0019] (2) The dephosphorization stage of the converter adopts low lance position operation, and the top blowing oxygen lance position is controlled according to the following formula: H=3.23×h -2 +1.3, where: H is the position of the lance, m; h is the depth of the molten pool, m; in the actual production process, the position of the lance is related to the design parameters of the oxygen lance, the gas pressure of the oxygen lance, and the shape of the converter. The oxygen lance and the eigenvalues of the relevant parameters of the converter, after the regression, the relationship between the lance position and the depth of the molten pool is obtained when the conventional process is used for converter steelmaking: H=3.23×h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com