Process for mixing materials and making external-rolled coal through sintering machine

The technology of mixing material and sintering machine is applied in the field of agglomeration of iron-making raw material pellets and sintered ore, which can solve the problems affecting the quality of sintered ore, fuel segregation, and decrease of sintered ore output, and achieves saving solid fuel consumption, uniform fuel distribution, The effect of high calcium oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

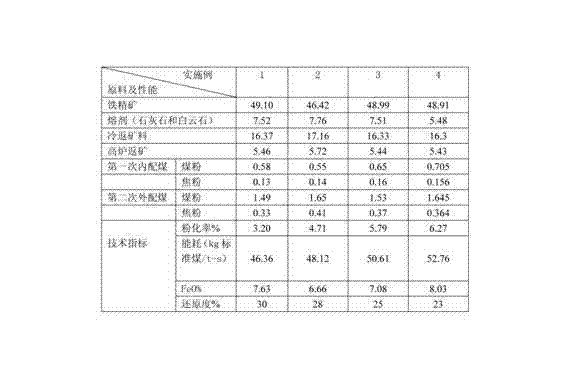

Examples

Embodiment Construction

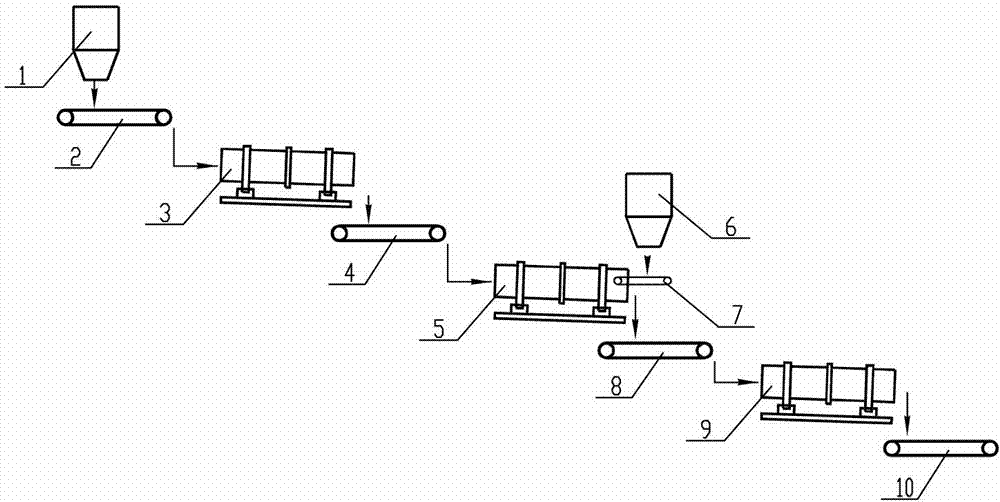

[0019] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, according to the sintering machine mixture rolling coal process of the present invention, including batching, mixing, pelletizing, it is characterized in that: adopt the following mixed pelletizing technology of adding solid fuel and rolling fuel,

[0021] Filled with solid fuel:

[0022] (1) Batching and mixing: add solid fuel that is 25% to 35% by weight of the amount of solid fuel added to the raw material mixture into the raw material mixture in the fuel mine tank 1 of the batching room,

[0023] Mixing: Send the above-mentioned raw material mixture and solid fuel from the primary feeding belt conveyor 2 to the mixer 3 for mixing, and the mixing time is 2 to 3 minutes; the primary internal mixture is prepared;

[0024] (2) Pelletizing: feed the first-time internal mixture prepared in step (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com