A cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement

A technology of semi-flexible pavement and emulsified asphalt, which is used in new road and bridge engineering materials and highway engineering application fields, can solve the problems that semi-flexible pavement materials cannot be poured, and the fluidity requirements are far from each other, so as to achieve extended working time and fatigue. The effect of improved life and shear resistance, moderate elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

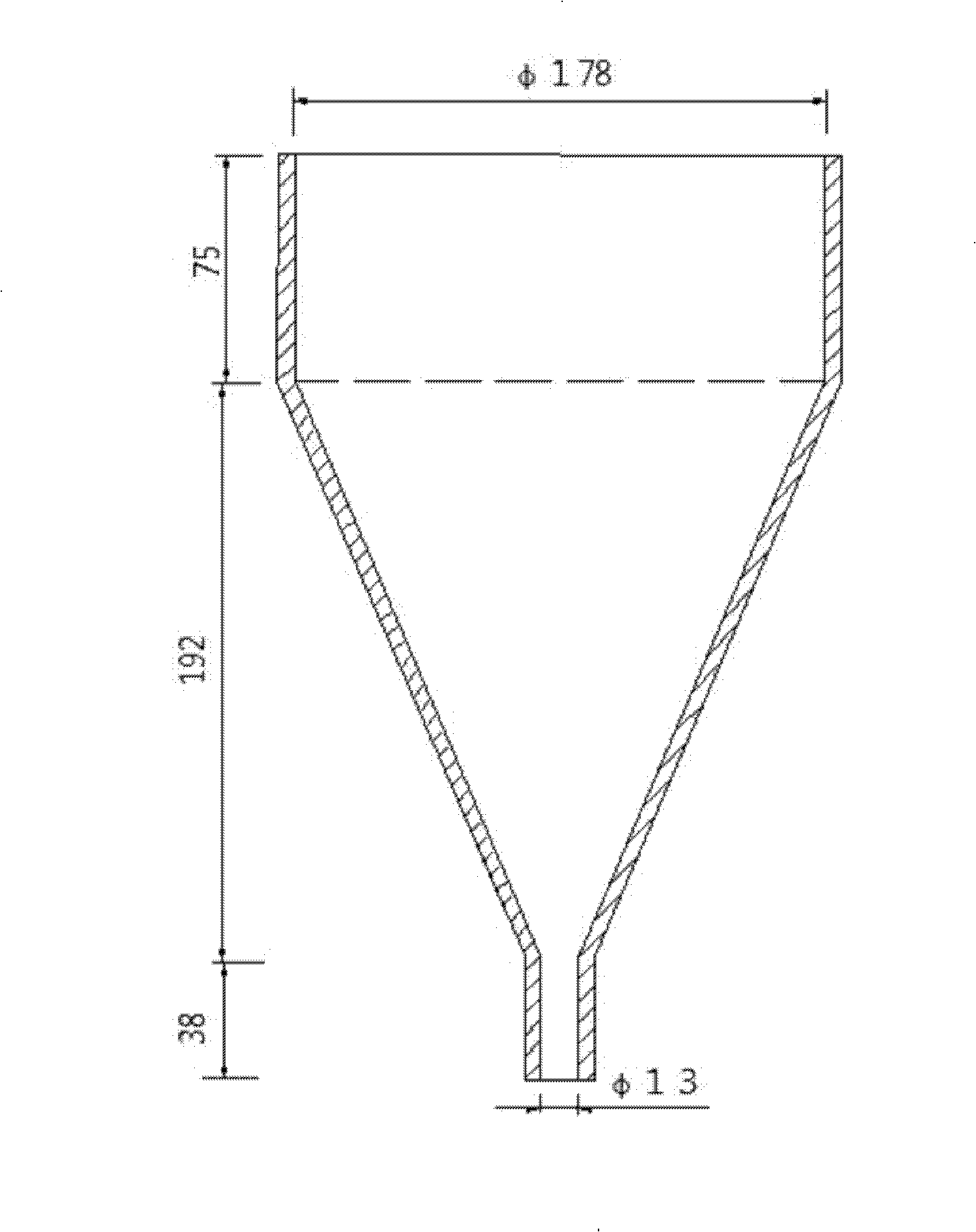

Image

Examples

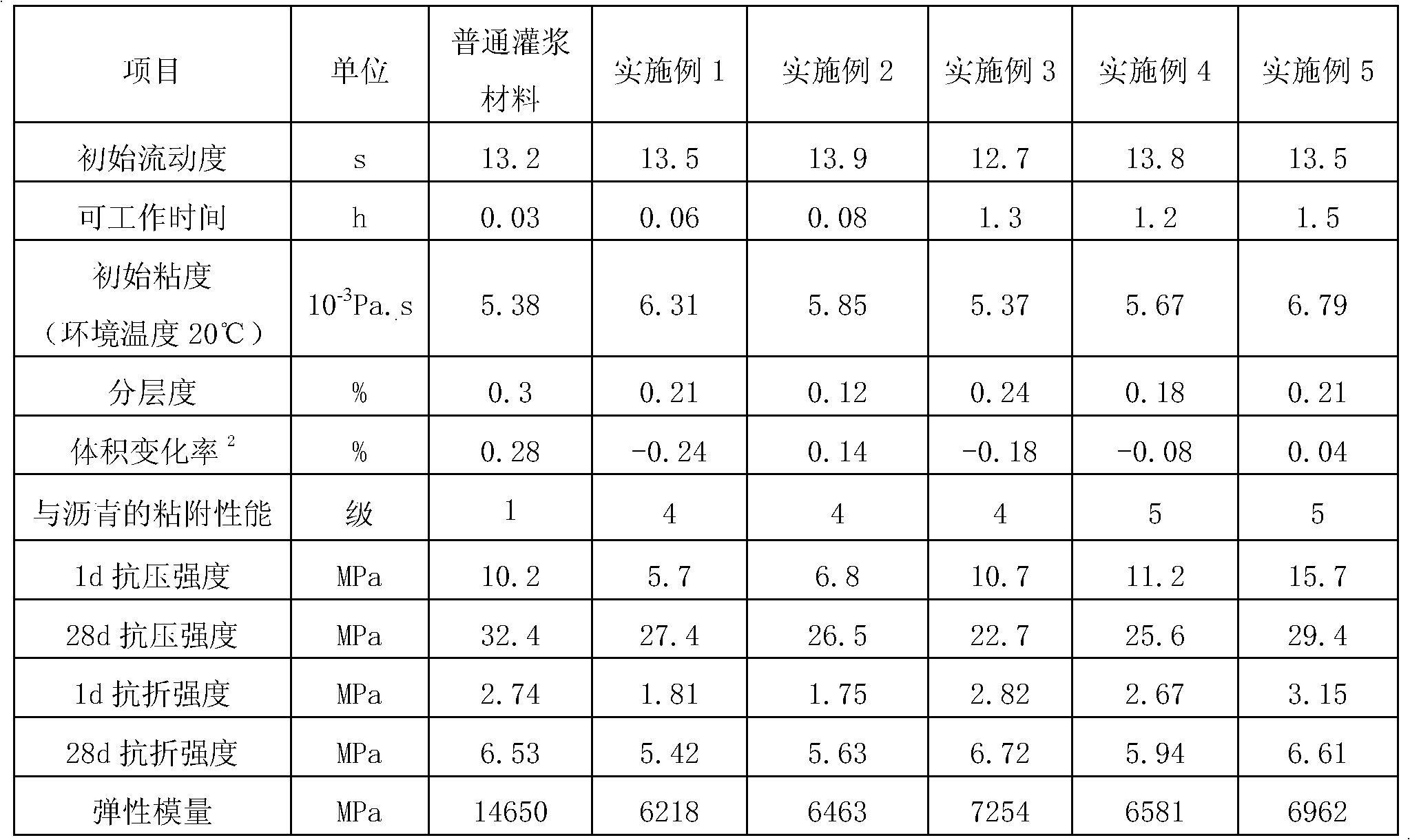

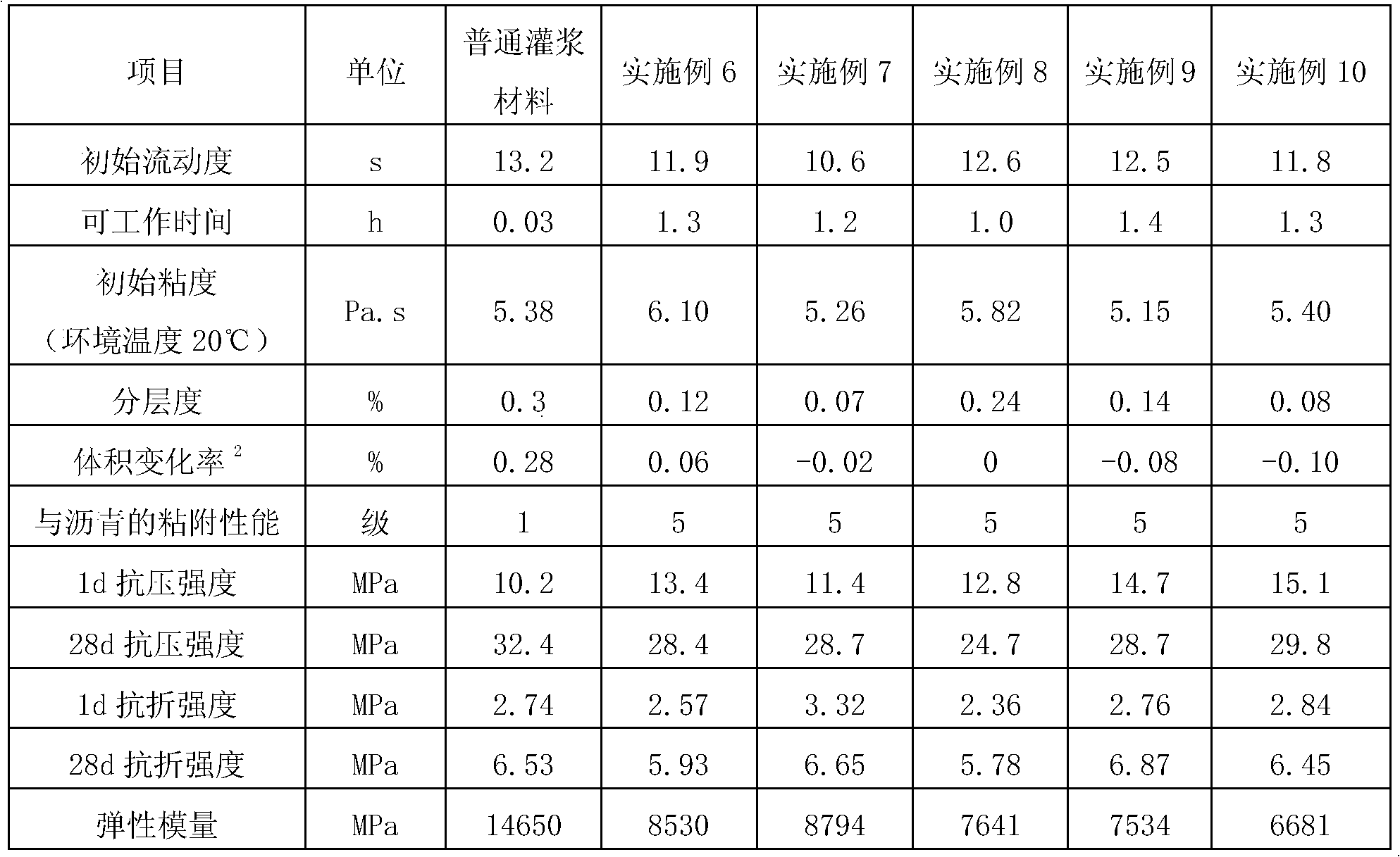

Embodiment 1

[0043]100 parts of cement, 130 parts of mineral admixture, 40 parts of expansion agent, 67 parts of river sand, 15 parts of water reducing agent, 128 parts of water, and 130 parts of emulsified asphalt. Among them, the cement is composed of ordinary 52.5 Portland cement of China Resources Cement Holdings Co., Ltd. and 52.5 sulfoaluminate cement of Nanjing Conch Cement Co., Ltd. in a mass ratio of 100:25; the mineral admixture is composed of kaolin, silica fume and slag. The mass ratio is a mixture of 58:27:15, among which kaolin comes from Jiangsu Runyu Chemical Products Co., Ltd. with a mesh size of 1200 mesh, silica fume comes from Shandong Shanmei Silicon Materials Co., Ltd. with a mesh number of 200 mesh, and slag comes from Wuhan Iron and Steel Group , the mesh number is 200 mesh; the expansion agent is HME-I expansion agent (magnesium oxide expansion agent) of Jiangsu Bote New Material Co., Ltd.; the river sand is ordinary river sand with a fineness modulus of 1.2; the wa...

Embodiment 2

[0047] 100 parts of cement, 120 parts of mineral admixture, 35 parts of expansion agent, 58 parts of river sand, 12 parts of water reducing agent, 124 parts of water, and 110 parts of emulsified asphalt. Among them, the cement is composed of ordinary 52.5 Portland cement of Nanjing Conch Cement Co., Ltd. and 52.5 sulfoaluminate cement of China Resources Cement Holdings Co., Ltd. in a mass ratio of 100:20; the mineral admixture is composed of first-grade kaolin, Silica fume and slag are mixed in a mass ratio of 60:17:23. Among them, the kaolin comes from the No. 4 kaolin mine of Shanxi Yangmei Group with a mesh size of 2500 mesh, the silica fume comes from Beijing Youya / SF85 with a mesh number of 150 mesh, and the slag comes from Baosteel Group, the mesh is 300 mesh; the expansion agent is Jiangsu Bote New Material Co., Ltd. HME-I expansion agent (magnesium oxide expansion agent); the river sand is ordinary river sand with a fineness modulus of 1.1; the water reducing agent is J...

Embodiment 3

[0051] 100 parts of cement, 100 parts of mineral admixture, 30 parts of expansion agent, 40 parts of river sand, 10 parts of water reducing agent, 15 parts of early strength penetrant, 90 parts of water, 125 parts of emulsified asphalt, among which, the cement is controlled by China Resources Cement Co., Ltd.'s ordinary 52.5 Portland cement and 52.5 sulfoaluminate cement are mixed in a mass ratio of 100:5; the mineral admixture is composed of kaolin, silica fume and slag in a mass ratio of 40:30:30, of which kaolin Kaolin No. 4 Mine of Shanxi Yangmei Group, 2500 mesh, silica fume from Beijing Youya / SF85, 150 mesh, slag from Wuhan Iron and Steel Group, 200 mesh; expansion agent Tianjin Baoming UEA expansion agent (calcium sulfoaluminate expansion agent); the river sand is ordinary river sand with a fineness modulus of 0.7; the water reducing agent is PCA-I polycarboxylate water reducing agent of Jiangsu Bote New Material Co., Ltd.; early strength penetrating agent It is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com