Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Small volume change rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement

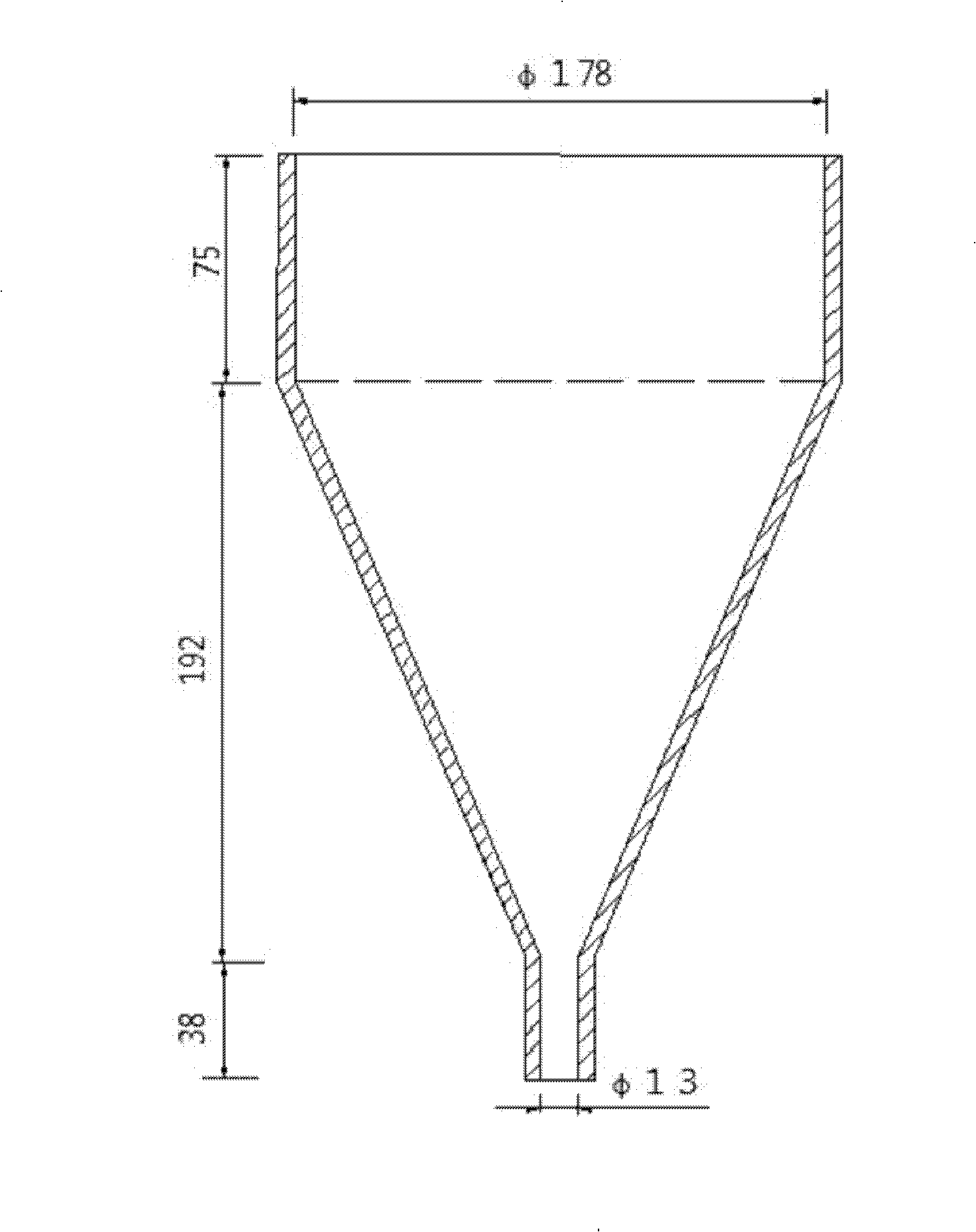

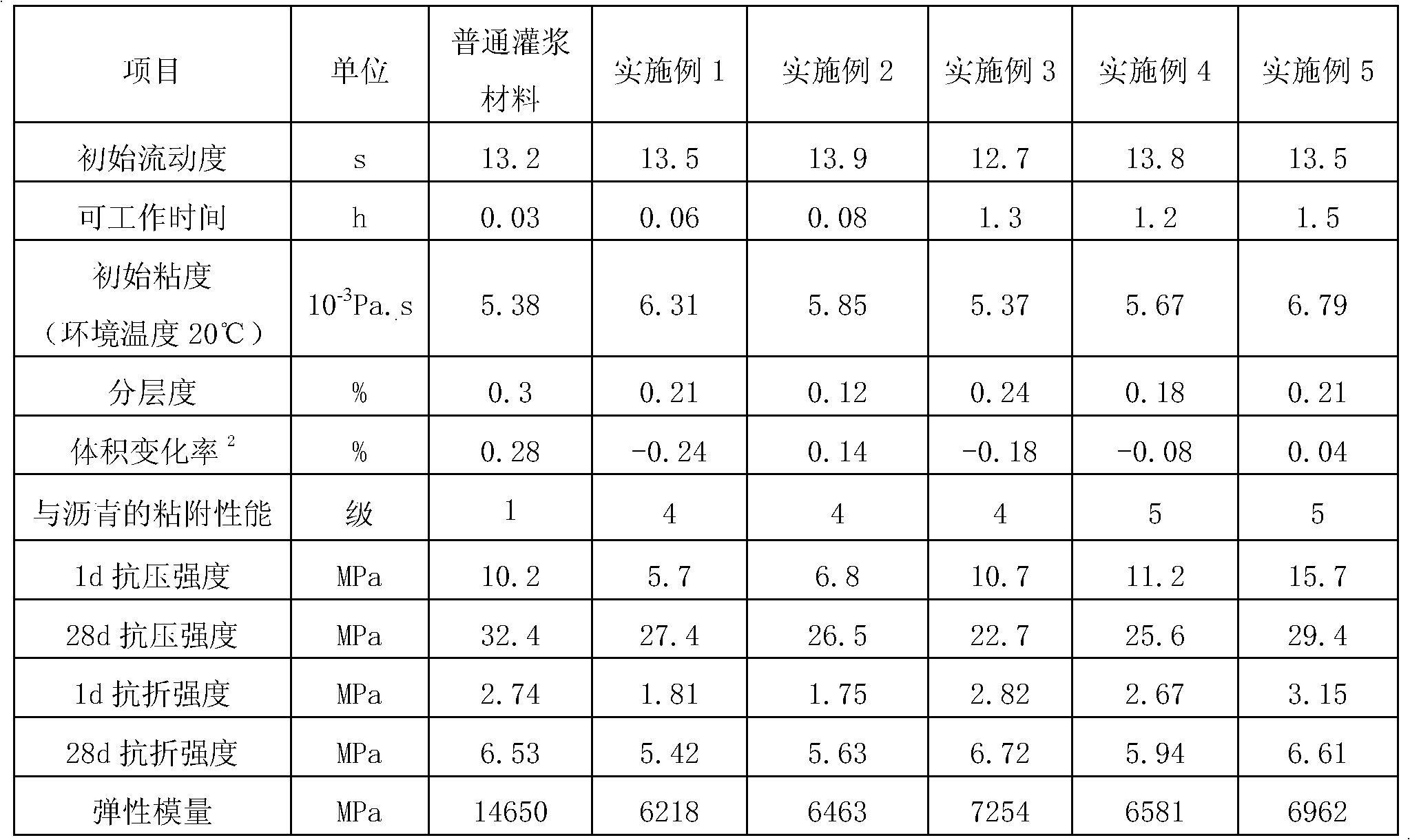

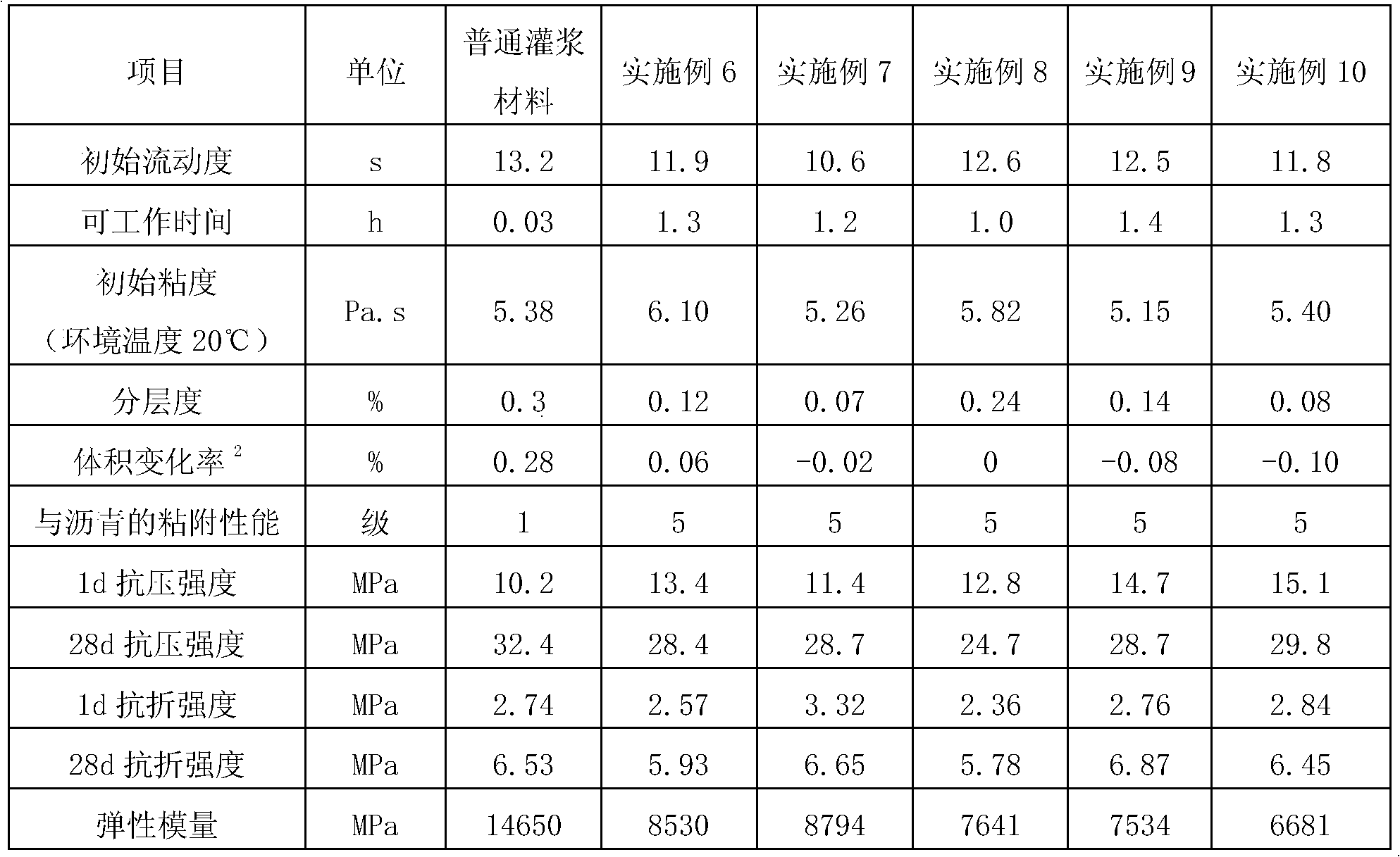

The invention discloses a cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement, which comprises 100 parts of cement, 50-150 parts of mineral admixture, 15-40 parts of expansion agent, 0-80 parts of river sand, 0.5-20 parts of water agent, 60-140 parts of water, and 50-150 parts of emulsified asphalt, all of which are parts by weight. The grouting material of the present invention is low in cost, good in fluidity, long in working time, and satisfies the grouting characteristics of self-permeation of slurry; has good interfacial bonding performance with asphalt, and has a certain early strength function; the volume change rate is small, and the degree of delamination is less than 0.3%, with good volume stability; both cationic emulsified asphalt and anionic emulsified asphalt can be used, with a wide range of applications; applying this grouting material to semi-flexible pavement can greatly improve the fatigue life of flexible pavement The shear performance is effectively improved.

Owner:JIANGSU SUBOTE MATERIAL +4

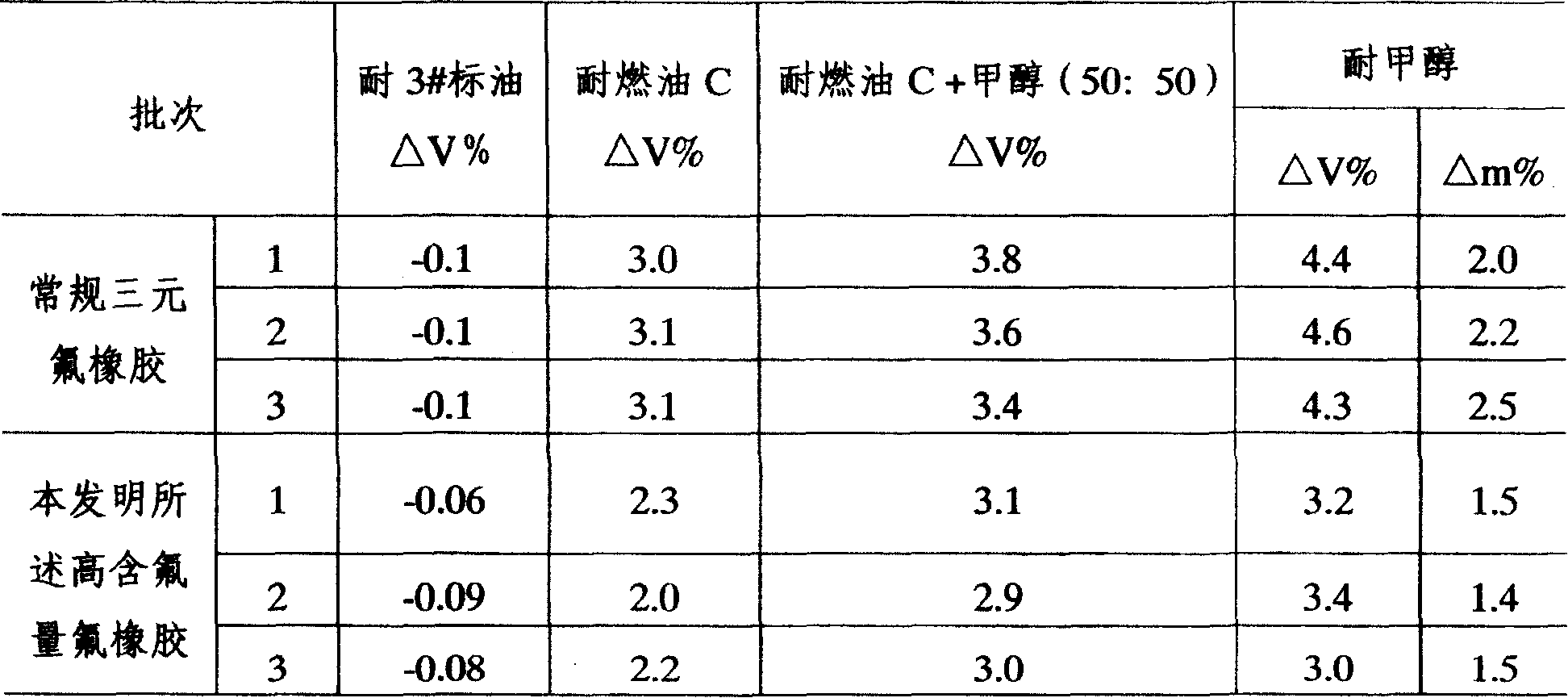

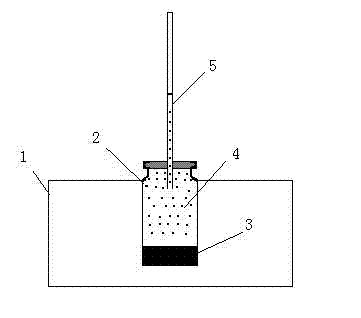

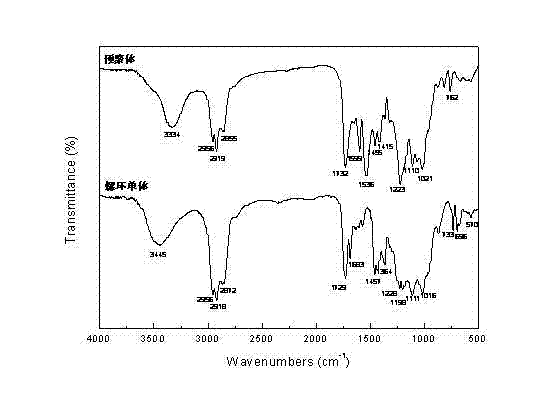

Fluorine elastomer containing high fluorine content and preparation process thereof

The present invention is fluoric elastomer with fluorine content higher than 70 %. The fluoric elastomer consists of the following copolymerized units: 1, 1-difluoro ethylene 30-60 wt%, perfluoro propylene 20-40 wt% and tetrafluoro ethylene 20-40 wt%. The present invention also relates to the preparation process of the fluoric elastomer with high fluorine content, and the preparation process is one emulsion polymerization process with water as medium, low molecular weight esters as chain transferring agent, persulfate as initiator, perfluoro caprylate as dispersant and borax as pH regulator.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

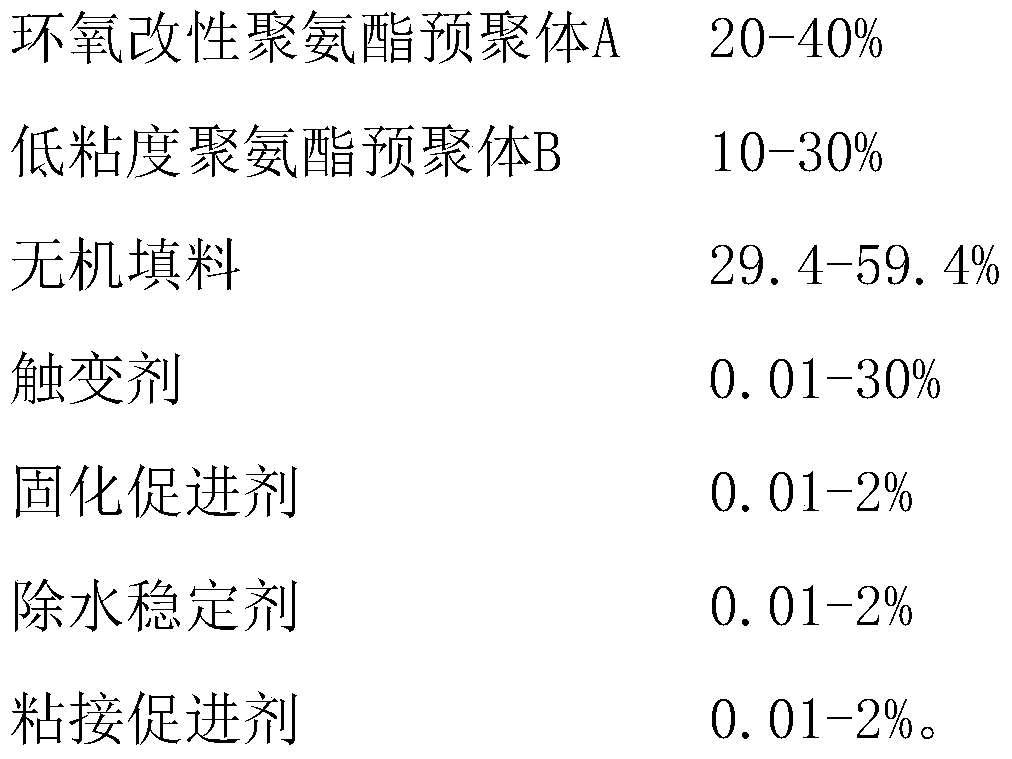

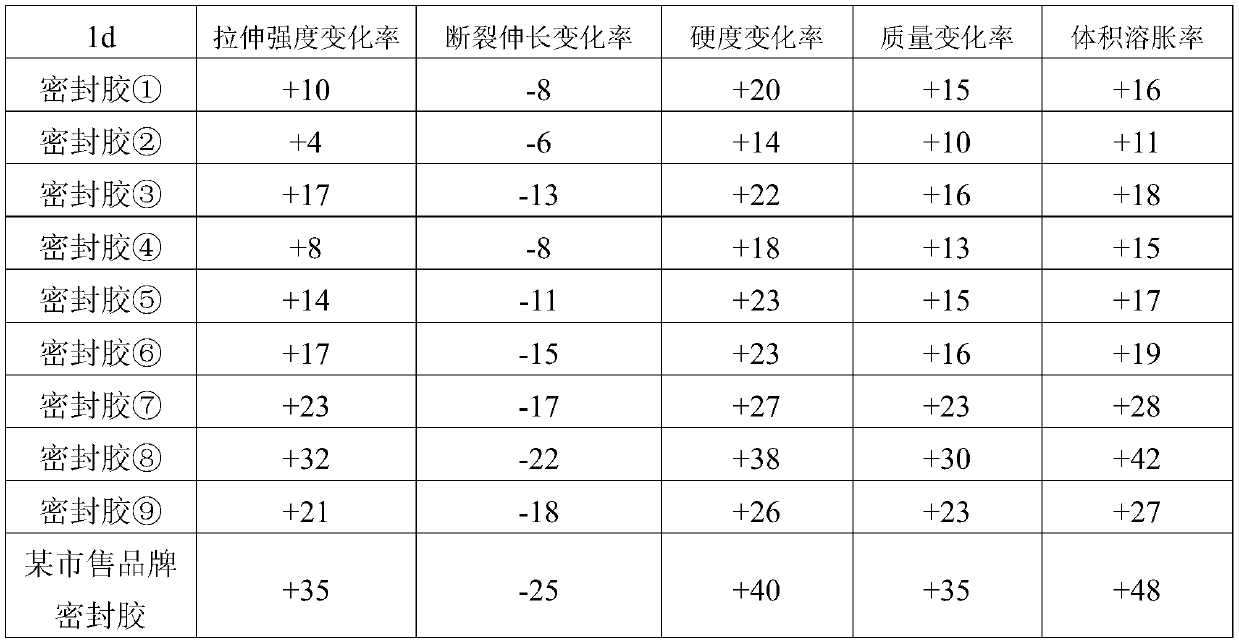

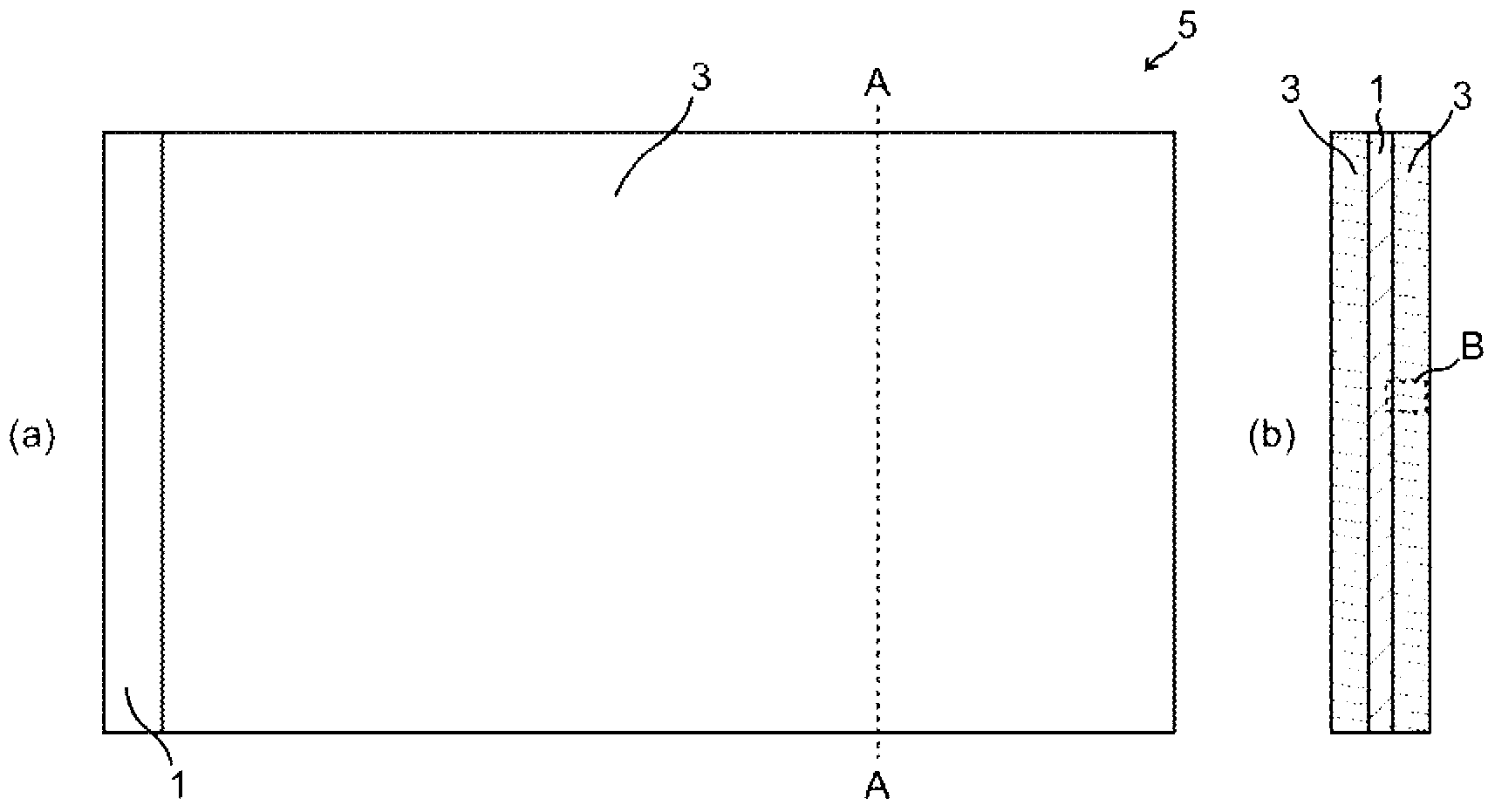

Solvent-resistant epoxy modified polyurethane sealant and preparation method thereof

ActiveCN110172323AGood chemical resistanceGood mechanicalNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySolvent

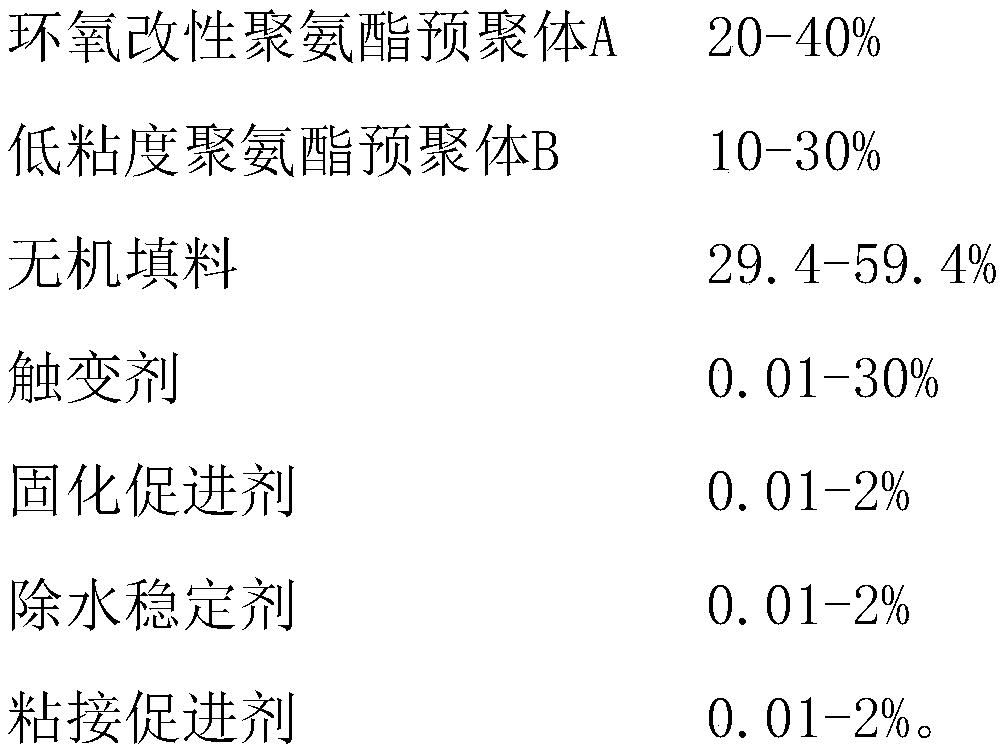

The invention relates to the technical field of sealants, in particular to a solvent-resistant epoxy modified polyurethane sealant and a preparation method thereof. The sealant is prepared from, by weight, 20-40% of an epoxy modified polyurethane prepolymer A, 10-30% of a low-viscosity polyurethane prepolymer B, 29.4-59.4% of an inorganic filler, 0.01-30% of a thixotropic agent, 0.01-2% of a curing promoter, 0.01-2% of a water removal stabilizer and 0.01-2% of an adhesion promoter. The epoxy modified polyurethane sealant has excellent chemical corrosion resistance and mechanical properties, through a chemical corrosion test in the industry standard of a membrane-type gas meter, after liquid immersion, the mechanical properties, mass change rate and volume change rate of the sealant can allbe kept at a very small change rate, the adhesive sealing effect is good, and the sealant can keep the good adhesive sealing function during long-term use in the gas meter.

Owner:广东盛业化学科技有限公司

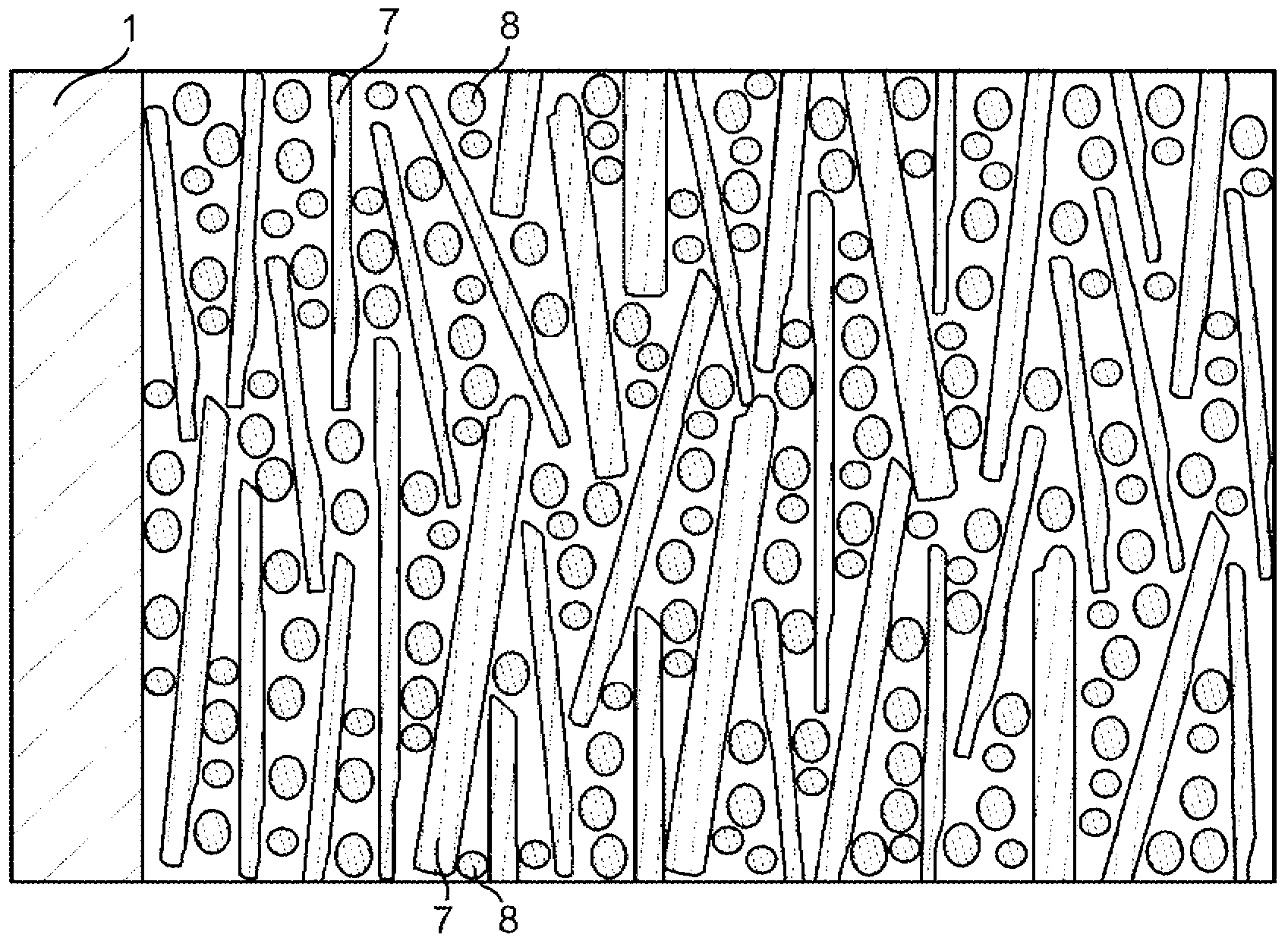

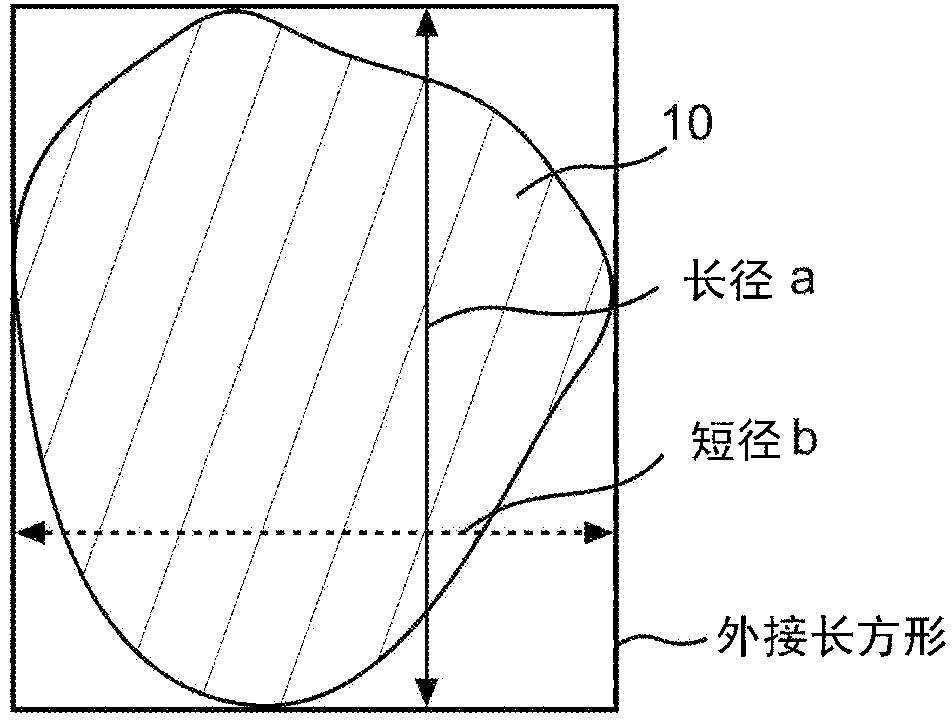

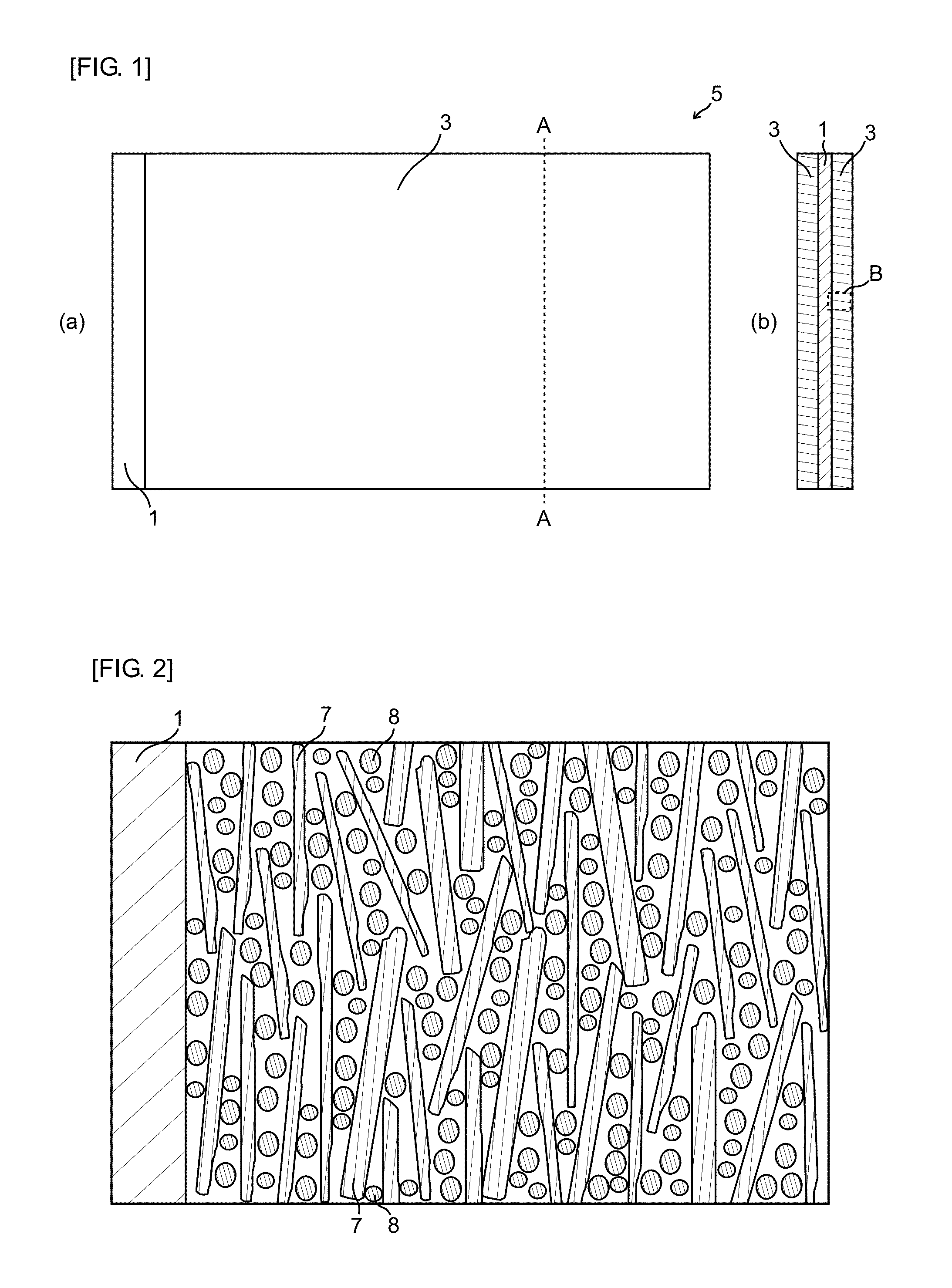

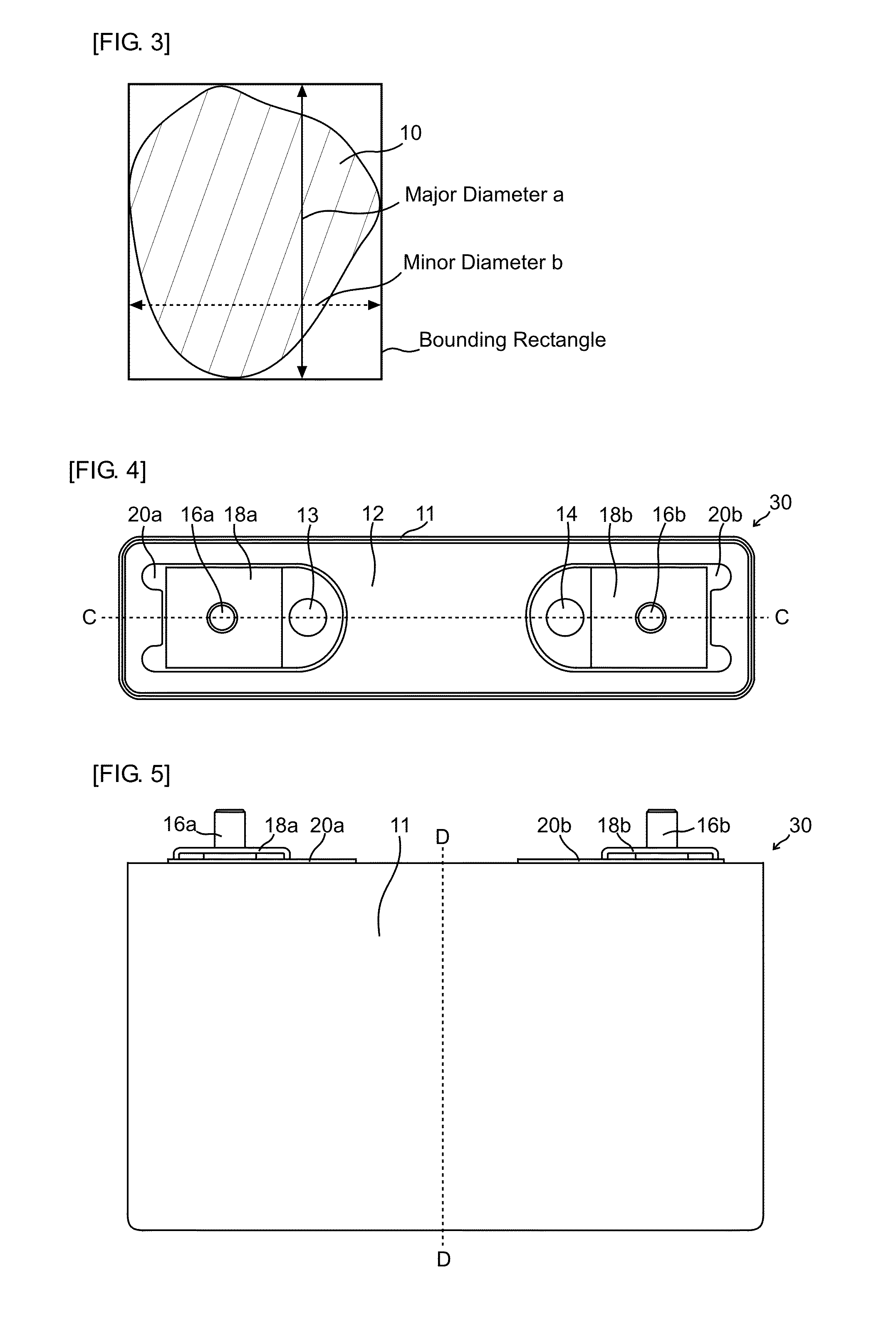

Negative electrode for non-queous electrolyte secondary battery, non-aqueous electrolyte secondary battery and production method for negative electrode for non-aqueous electrolyte secondary battery

ActiveCN103262306AIncreased ion storage capacityHigh filling densityCell electrodesLi-accumulatorsGraphiteMaterials science

The present invention provides a negative electrode for a non-aqueous electrolyte secondary battery which can be produced at a reduced cost and has a high graphite packing density and consistent quality. The negative electrode for a non-aqueous electrolyte secondary battery is characterized by comprising a negative-electrode current collector and a negative-electrode active material layer disposed on the negative-electrode current collector, and in that the negative-electrode active material layer contains flaky graphite formed through the graphitization of needle coke, granular graphite formed through the graphitization of coke, and a binder.

Owner:ELIIY POWER

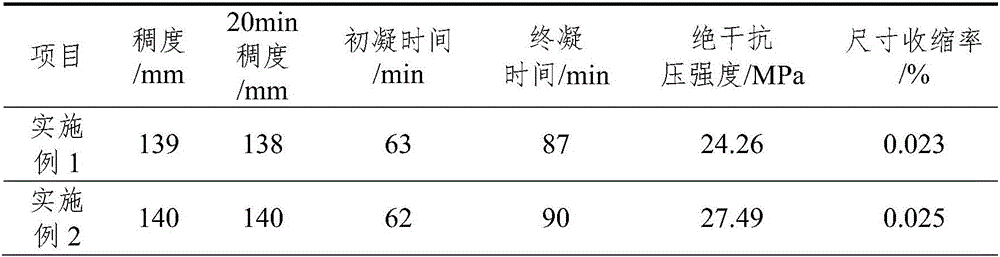

Gypsum-based self-leveling mortar prepared by taking molybdenum tailings as filler

The invention relates to gypsum-based self-leveling mortar prepared by taking molybdenum tailings as filler. The gypsum-based self-leveling mortar is prepared from the following components in parts by weight: 50-70 parts of alpha gypsum, 30-45 parts of the molybdenum tailings, 0.1-0.2 part of a defoaming agent, 0.3-0.5 part of a water reducing agent, 1-3 parts of a volume stabilizer, 0-1 part of a coagulation time regulator, 0-1 part of a thickening agent and 0-1 part of a water repellent agent. The gypsum-based self-leveling mortar prepared by taking the molybdenum tailings as the filler has better strength and leveling property, and is lower in rate of volume change; the performance of the gypsum-based self-leveling mortar is improved, and the utilization rate of the molybdenum tailings is increased. The industrial solid waste-molybdenum tailings is utilized on the one hand, and the high-performance gypsum-based self-leveling mortar which meets the demands of grade level engineering is prepared on the other hand while the rapid development market demand of gypsum-based self-leveling is combined. The gypsum-based self-leveling mortar both meets the demand of comprehensive resource utilization and the demand of the grade level market.

Owner:河北睿索固废工程技术研究院有限公司 +1

Negative electrode for nonaqueous electrolyte secondary battery, nonaqueous electrolyte secondary battery and method for producing negative electrode for nonaqueous electrolyte secondary battery

InactiveUS20130266849A1High bulk densityIncreased ion storage capacityActive material electrodesNon-aqueous electrolyte accumulator electrodesGraphite particleMaterials science

The present invention provides a negative electrode for a nonaqueous electrolyte secondary battery, the negative electrode being produced at reduced costs, having a high graphite packing density, and having stable quality. The negative electrode according to the present invention includes a negative-electrode current collector; and a negative-electrode active material layer provided on the negative-electrode current collector, wherein the negative-electrode active material layer includes: flaky graphite particles formed by graphitizing needle coke; particulate graphite particles formed by graphitizing coke; and a binder.

Owner:ELIIY POWER

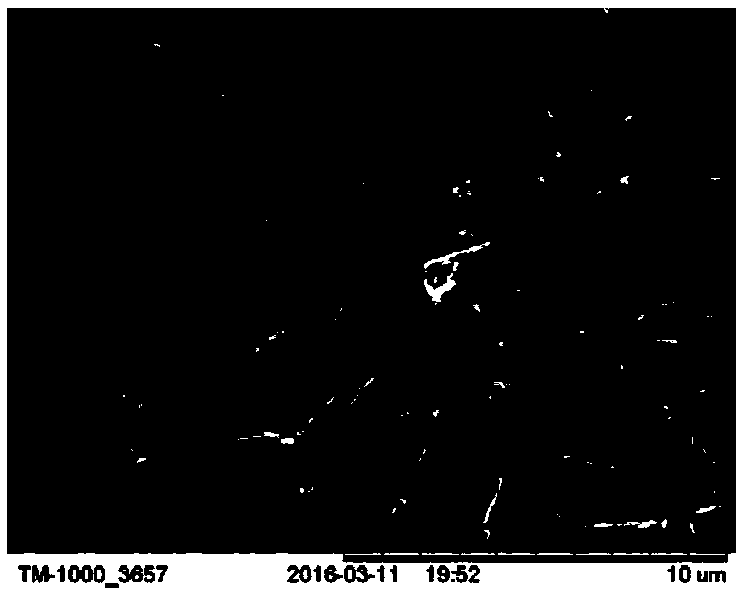

Composite silicon based electrode material, preparation method and application thereof

InactiveCN107394161AImprove stabilitySmall volume change rateCell electrodesSecondary cellsWater basedSolvent

Relating to the field of electrode materials, the invention in particular provides a composite silicon based electrode material, a preparation method and application thereof. The composite silicon based electrode material is mainly composed of a pre-lithiated silicon based core and a graphene layer coating the pre-lithiated silicon based core. The composite silicon based electrode material has the advantages of high environmental stability, good inertness to solvent, high initial coulomb efficiency and good cyclic stability, has no change after storage in the air for 24h or more, has initial coulomb efficiency up to 90% or more, shows good inertness to water based solvents and oil based solvents, and has a capacity retention ratio up to92% or more after 20 cycles.

Owner:PEKING UNIV

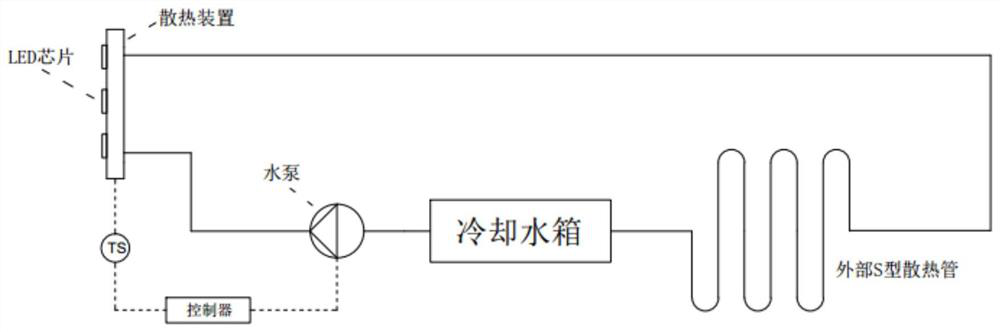

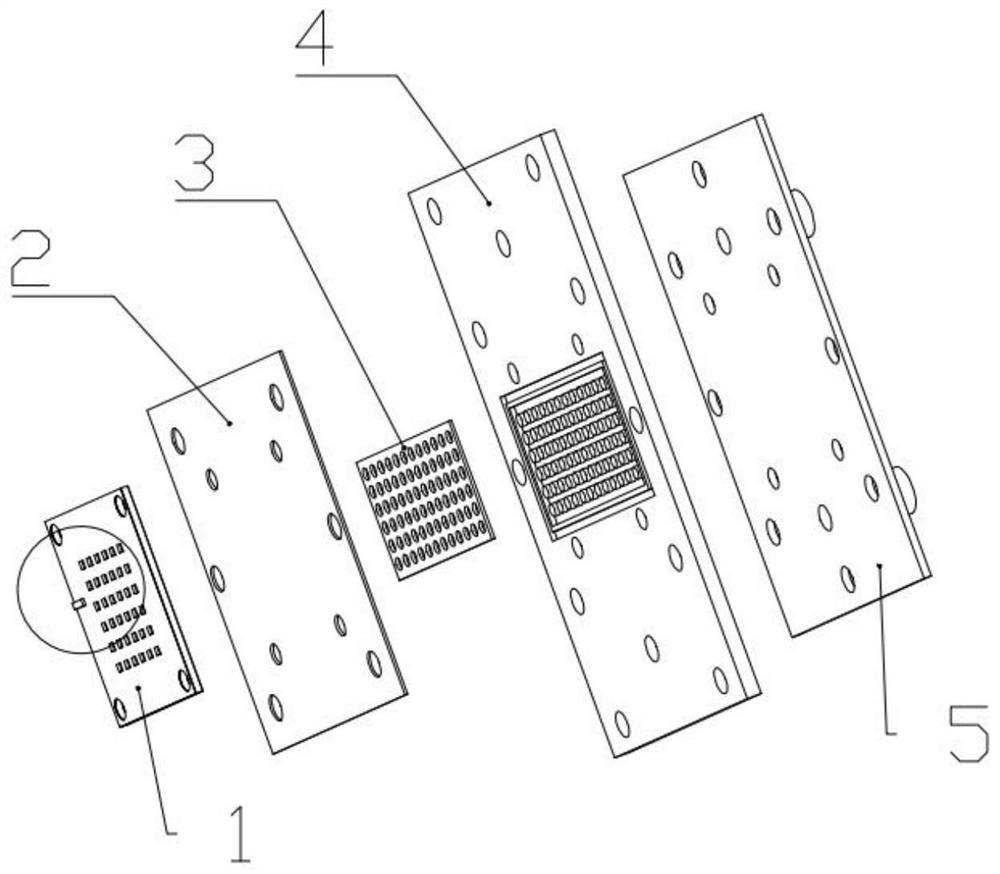

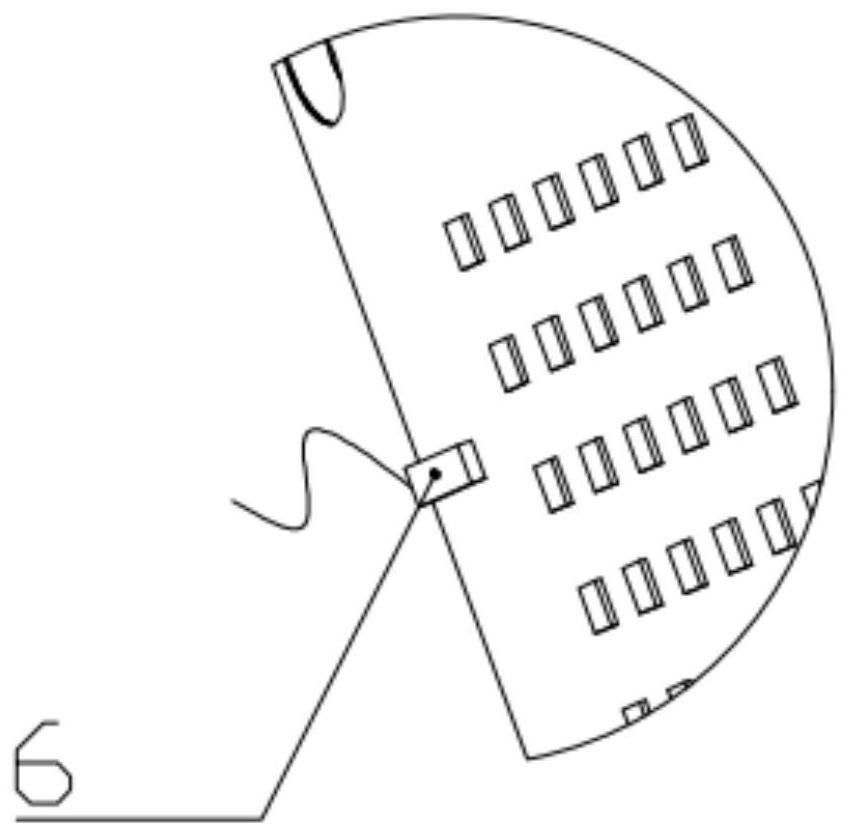

Composite heat dissipation device adopting composite phase change materials and micro-channel liquid cooling

PendingCN111911892ASimple structural designCompact structureLighting heating/cooling arrangementsSemiconductor devices for light sourcesCooling fluidHeat spreader

The invention discloses a composite heat dissipation device adopting composite phase change materials and micro-channel liquid cooling, relates to the field of cold heat dissipation, in particular tothe heat dissipation device adopting combination of the phase change materials and the liquid cooling. The heat dissipation device comprises a phase change area cover plate, the phase change materials, a radiator and a liquid cooling area cover plate; the radiator is of a plate-shaped structure, a concave area for containing the phase change materials is formed in one side of the radiator, and a micro-channel is formed in the other side corresponding to the concave area; the phase change materials are packaged by the phase change area cover plate, the micro-channel is packaged by the liquid cooling area cover plate, and a liquid injection port and a liquid outlet of cooling liquid are formed in one side, which is not packaged, of the liquid cooling area cover plate; and the heat source isarranged on the unpackaged side of the phase change area cover plate. The composite heat dissipation device is characterized in that a plurality of columnar protrusions made of foamed aluminum materials are arranged in the concave area of the radiator in an array mode, gaps among the columnar protrusions in the concave area are filled with the phase change materials, and a circle of sealing grooveis formed in the outer side of the concave area. The composite heat dissipation device has the advantages of uniform heat dissipation and high heat dissipation efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Amorphous alloy dental pulp file and manufacture method thereof

The invention provides an amorphous alloy dental pulp file and a manufacture method thereof. Compared with the traditional dental pulp file prepared from a titanium-nickel memory alloy, the novel dental pulp file has excellent properties such as high strength, high hardness, high elasticity, high surface smoothness, high fatigue strength and the like as well as corrosion resistance; meanwhile, the manufacture method of the dental pulp file is simple, machining can be performed at a lower temperature, and the dental pulp file can be manufactured with methods such as twisting, rolling, weaving, impressing and the like.

Owner:盘星新型合金材料(常州)有限公司

Thermosetting liquid optical adhesive composition and application thereof

ActiveCN111154451AStable PenetrationImprove heat stabilityNon-macromolecular adhesive additivesNeedle penetrationPolymer science

The invention provides a thermosetting liquid optical adhesive composition and an application thereof; the thermosetting liquid optical adhesive composition is tested according to a GB / T 4509-2010 asphalt needle penetration determination method, and the needle penetration of the thermosetting liquid optical adhesive composition is 160-250 mm. The thermosetting liquid optical adhesive provided by the invention has proper needle penetration after being cured, is easy to repair, does not greatly fluctuate along with the influence of temperature, humidity, UV aging irradiation and the like, and has higher cohesion strength, better binding power and excellent binding power for a binding material of a display module.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Oil seal for automobile rear axle assembly

The invention discloses an oil seal for an automobile rear axle assembly. The oil seal comprises a metal skeleton and a rubber layer coating the surface of the metal skeleton. The ingredients of the metal skeleton include, by weight percentages: 3.0 to 3.1% of C, 2.2 to 2.4% of Mn, 4.8 to 5.0% of Cr, 1.4 to 1.6% of Si, 0.4 to 0.6% of Mo, 1.2% to 1.4% of Ba, not smaller than 0.02% of S, not smaller than 0.02% of P, and the balance of Fe. The ingredients of the rubber layer include, by weight ratios: 34 to 36 parts of acrylonitrile butadiene rubber 40, 16 to 18 parts of acrylonitrile butadiene rubber 18, 10 to 12 parts of PVC, 1.8 to 2 parts of antioxidant RD, 1.4 to 1.6 parts of DTDM, 4.2 to 4.4 parts of zinc oxide, 2 to 4 parts of graphite, 1.6 to 1.8 parts of stearic acid, 35 to 38 parts of white carbon black, 1.2 to 1.4 parts of accelerator DM and 1.4 to 1.6 parts of accelerator CZ. The rubber layer has high heat resistance, wear resistance, corrosion resistance and hardness, the fracture strength is larger than 16 MPa, the volume change rate is lower than 8%, the hardness ranges from 82 to 85 degrees, the metal skeleton has high hardness and wear resistance, and the service life of the oil seal is prolonged by 2 to 2.5 times.

Owner:宁国天运橡塑制品有限公司

Fluorine-silicon sealant for fuel oil-resisting solvent part and preparation method for fluorine-silicon sealant

InactiveCN105086473ASolve processing problemsGood fuel resistanceOther chemical processesCross-linkFuel oil

The invention discloses a fluorine-silicon sealant for a fuel oil-resisting solvent part. The fluorine-silicon sealant is characterized by comprising the following components in parts by weight: 100 parts of hydroxyl end-capping fluorinated silicone rubber, 5-20 parts of white carbon black, 0-100 parts of nano calcium carbonate, 10-20 parts of a cross-linking agent, 1-5 parts of an accelerant, and 0.2-0.5 part of a curing agent. A preparation method for the sealant is characterized by comprising: preparing a base stock: adding the hydroxyl end-capping fluorinated silicone rubber, the white carbon black and the active nano calcium carbonate according to a formula, and stirring the mixture for one hour at a high speed in vacuum; preparing an auxiliary agent: uniformly mixing the tetraethylortho silicate, the accelerant and the catalyst according to the formula; and in use, adding 1 part of the auxiliary agent into 10 parts of the base stock, and uniformly stirring the mixture in vacuum to obtain the sealant. The product has good fuel oil resistance and excellent mechanical properties.

Owner:SUZHOU DATONG ADVANCED MATERIAL

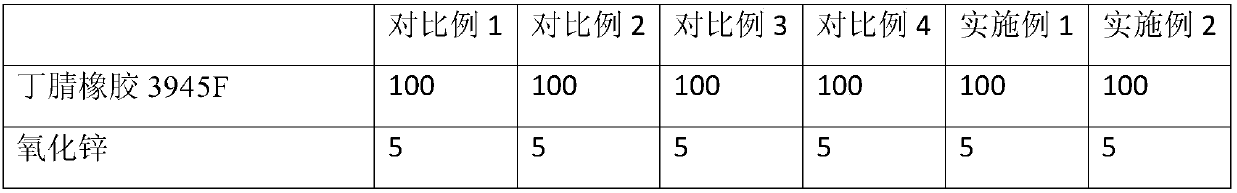

Heat-conductive rubber material for drilling tools and preparation method thereof

ActiveCN109535511AImprove thermal conductivityImprove temperature resistanceHeat-exchange elementsCarbon blackPlasticizer

The invention relates to a heat-conductive rubber material for drilling tools and a preparation method thereof. The heat-conductive rubber material is composed of the following raw materials by weight: 90 to 100 parts of hydrogenated nitrile or nitrile rubber, 20 to 70 parts of carbon black, 5 to 15 parts of amorphous silica, 3 to 9 parts of an activator, 2 to 20 parts of a plasticizer, 2 to 10 parts of a vulcanizing agent, 1 to 5 parts of an anti-aging agent, 1 to 6 parts of a dispersing agent, 1 to 50 parts of a heat-conductive material and 10 to 15 parts of an ionic liquid. The rubber material provided by the invention has the advantages of excellent physical and mechanical properties, excellent heat conduction performance and dielectric barrier properties and low volume change rate inmud, and can effectively improve the temperature resistance of a main rubber material.

Owner:KINGDREAM PLC CO +1

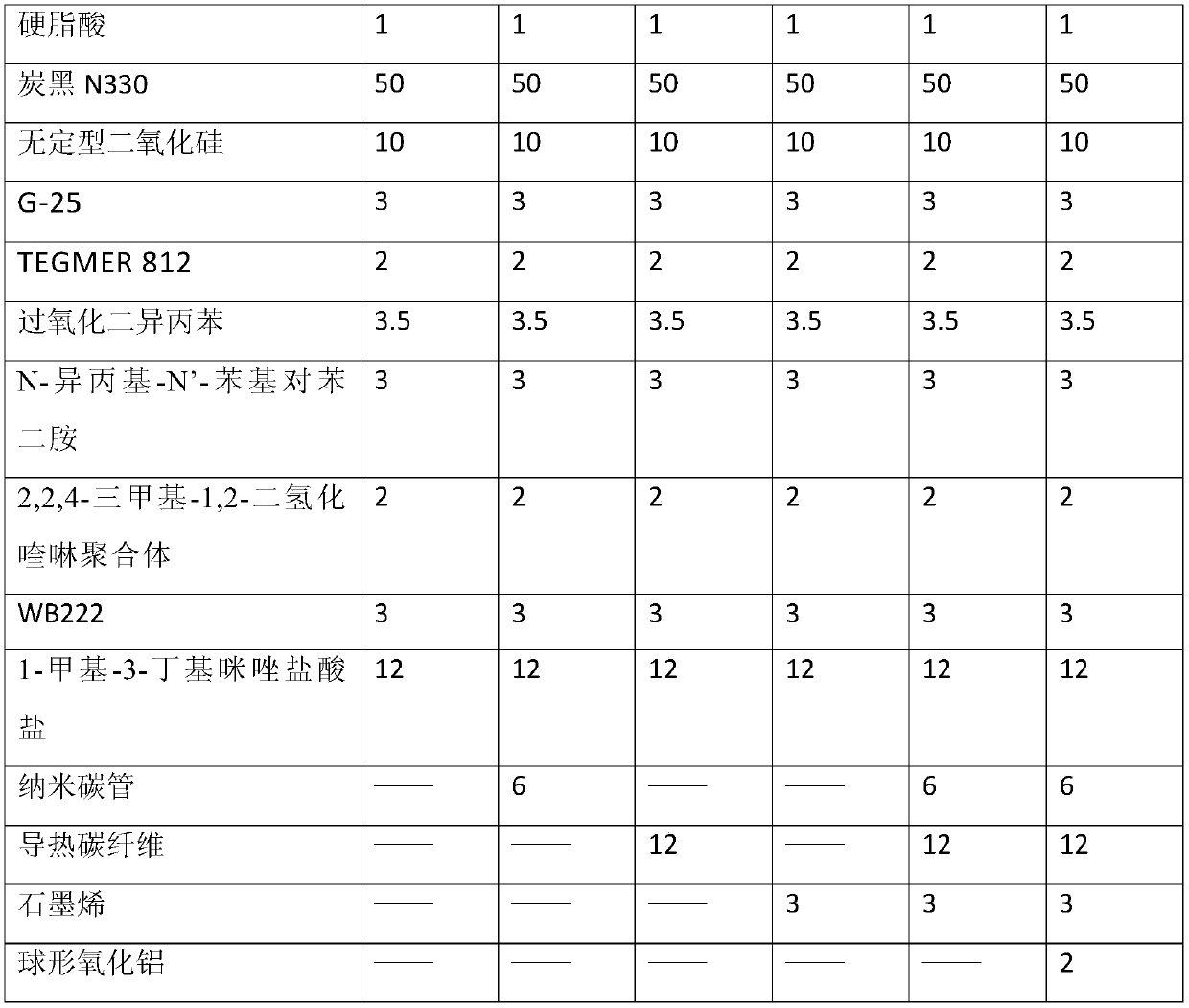

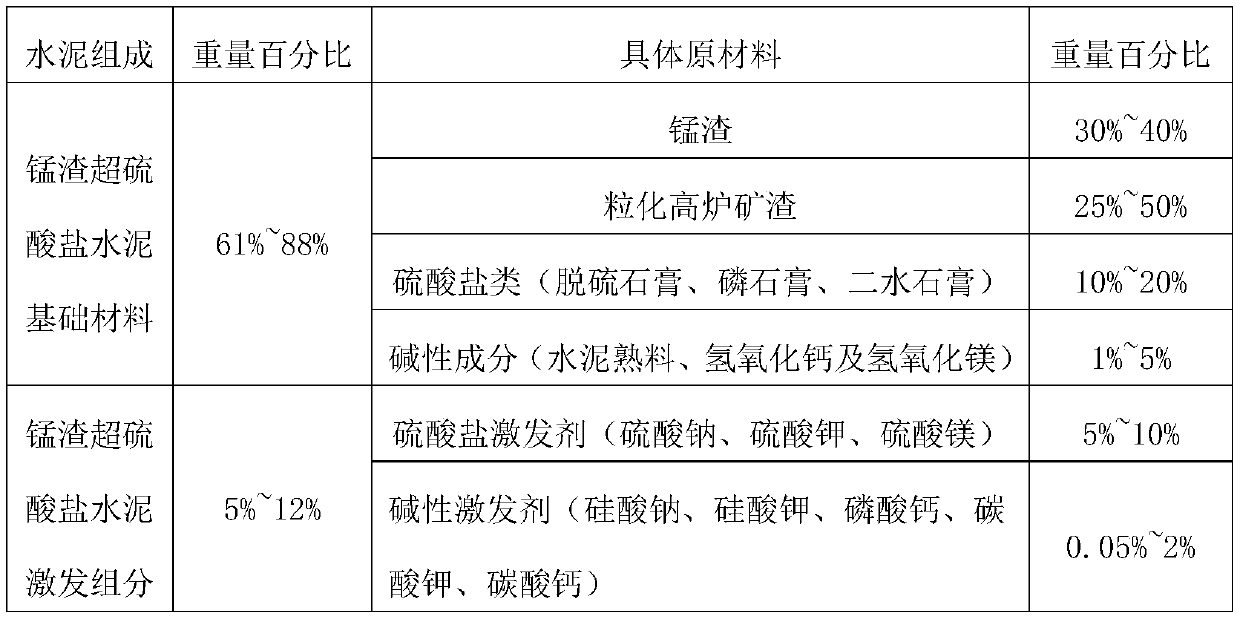

Manganese slag supersulfate cement and preparation method thereof

The invention belongs to the technical field of special cement, and particularly relates to a manganese slag supersulfate cement and a preparation method thereof. The manganese slag supersulfate cement is prepared from the components in percentage by weight: 30-40% of manganese slag, 25%-50% of granulated blast furnace slag powder, 10-20% of sulfates, 5%-10% of a sulfate activator, 1-5% of an alkaline component and 0.05-2% of an alkaline activator. The manganese slag which is a high-temperature slag waste discharged during the blast furnace smelting process of manganese iron or silicomaganeseis used as a main raw material, a material science principle is combined, the mineral characteristics of manganese slag and slag are taken as a basis, the potential hydration activity of the manganeseslag is activated by using sulfates and alkaline environment to form the initial strength, and novel manganese slag supersulfate cement with excellent properties is further designed.

Owner:中建西部建设新疆有限公司 +1

High-elasticity, corrosion-resistant, wear-resistant and oil-resistant rubber material

The invention discloses a high-elasticity, corrosion-resistant, wear-resistant and oil-resistant rubber material, and belongs to the technical field of rubber materials. The rubber material comprisesnitrile rubber, MgO, thermoplastic polyurethane, polyvinyl chloride, stearic acid, paraffin, carbon black N550, carbon black N330, paraffin oil, a promotor CZ, a promotor TRA, a promotor BZ, a promotor TMTD, an anti-aging agent 4010NA, anti-aging agent BLE, silicone master batch and sulfur. Through a modification process, the heat resistance, corrosion resistance, environment stress crack resistance and wear resistance of the rubber material are improved, and the rubber material has the advantages of superior aging resistance, particular outdoor aging resistance, ultraviolet light irradiationresistance, insusceptibility to decomposition and yellowing, and capability of keeping original luster and color. Meanwhile, the rubber material has high corrosion resistance, can resist chemical products such as acids, alkalis, salts and grease, and has excellent oil resistance, cold resistance and high temperature resistance, and the cost is lowered.

Owner:合肥旭亚新材料科技有限公司

Material for sealing cathode steel bar of aluminum electrolytic tank

The invention discloses a material for sealing a cathode steel bar of an aluminum electrolytic tank, which is prepared by mixing refractory particles, mixture of aluminum oxide powder and a refractory material, a binding agent and water according to a certain proportion, wherein the refractory particles account for 30-60% by weight, the mixture of the aluminum oxide powder and the refractory material accounts for 25-55% by weight, the binding agent accounts for 5-18% by weight and the water accounts for 7-15% by weight; the refractory particles adopt aluminum silicate particles or silicon oxide particles, and the binding agent adopts high aluminum cement or water glass; the required materials are poured into a stirring machine according to the proportion during the production, the stirring is firstly carried out for 3-5min for uniformly mixing and stirring the added materials, then an appropriate amount of the water is added for stirring for 5-10min, the stirring is stopped after confirming that the stirred materials have good flowability through visual observation, and then the materials are pouring into a container for preparation; and the material has simple production, good self-flowing property, convenient construction, good sealing performance and high temperature resistance.

Owner:HENAN ZHONGFU IND

Fluorine elastomer containing high fluorine content and preparation process thereof

The present invention is fluoric elastomer with fluorine content higher than 70 %. The fluoric elastomer consists of the following copolymerized units: 1, 1-difluoro ethylene 30-60 wt%, perfluoro propylene 20-40 wt% and tetrafluoro ethylene 20-40 wt%. The present invention also relates to the preparation process of the fluoric elastomer with high fluorine content, and the preparation process is one emulsion polymerization process with water as medium, low molecular weight esters as chain transferring agent, persulfate as initiator, perfluoro caprylate as dispersant and borax as pH regulator.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Preparation method of modified epoxy resin

A preparation method of a modified epoxy resin includes synthesis of spiro orthocarbonate performed polymer and a subsequent preparation of the modified epoxy resin. Prepared performed polymer with a synthesis molar ratio of 2:1, 3:2, 4:3 and epoxy resin are mixed in a beaker at room temperature, added and mixed well with a boron trifluoride ethylamine curing agent 3wt% of the resin; the beaker with the mixture in is mixed in an supersonic wave washer and placed in a vacuum baking oven for 2 h bubble removal. An expanding monomer performed polymer synthesized by the invention can effectively reduce volume contraction in the epoxy resin solidification process and has good expansion effect; besides a volumetric change rate in the epoxy resin solidification process decreases as a performed polymer content and a spiromonomer content in the performed polymer increase.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

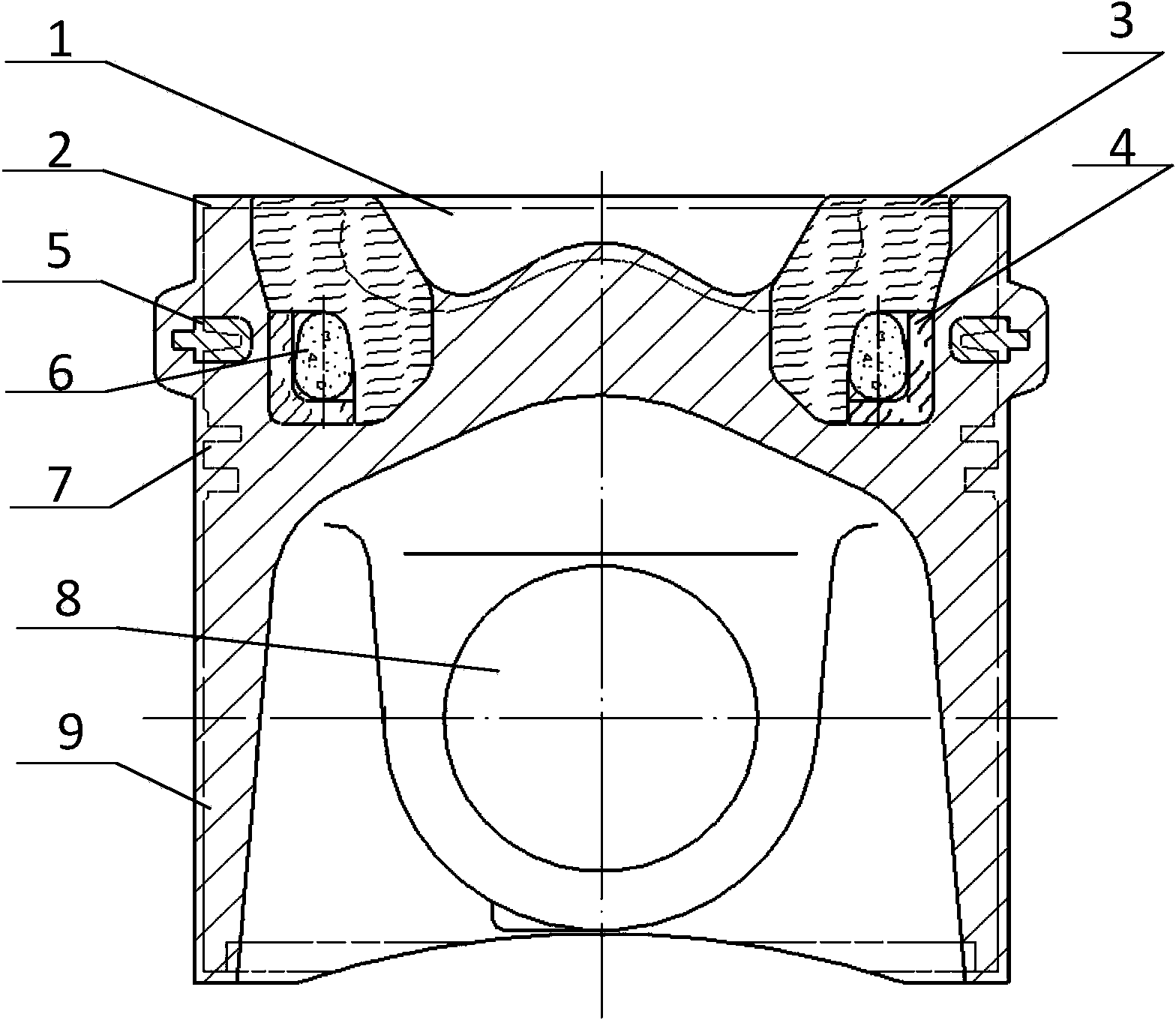

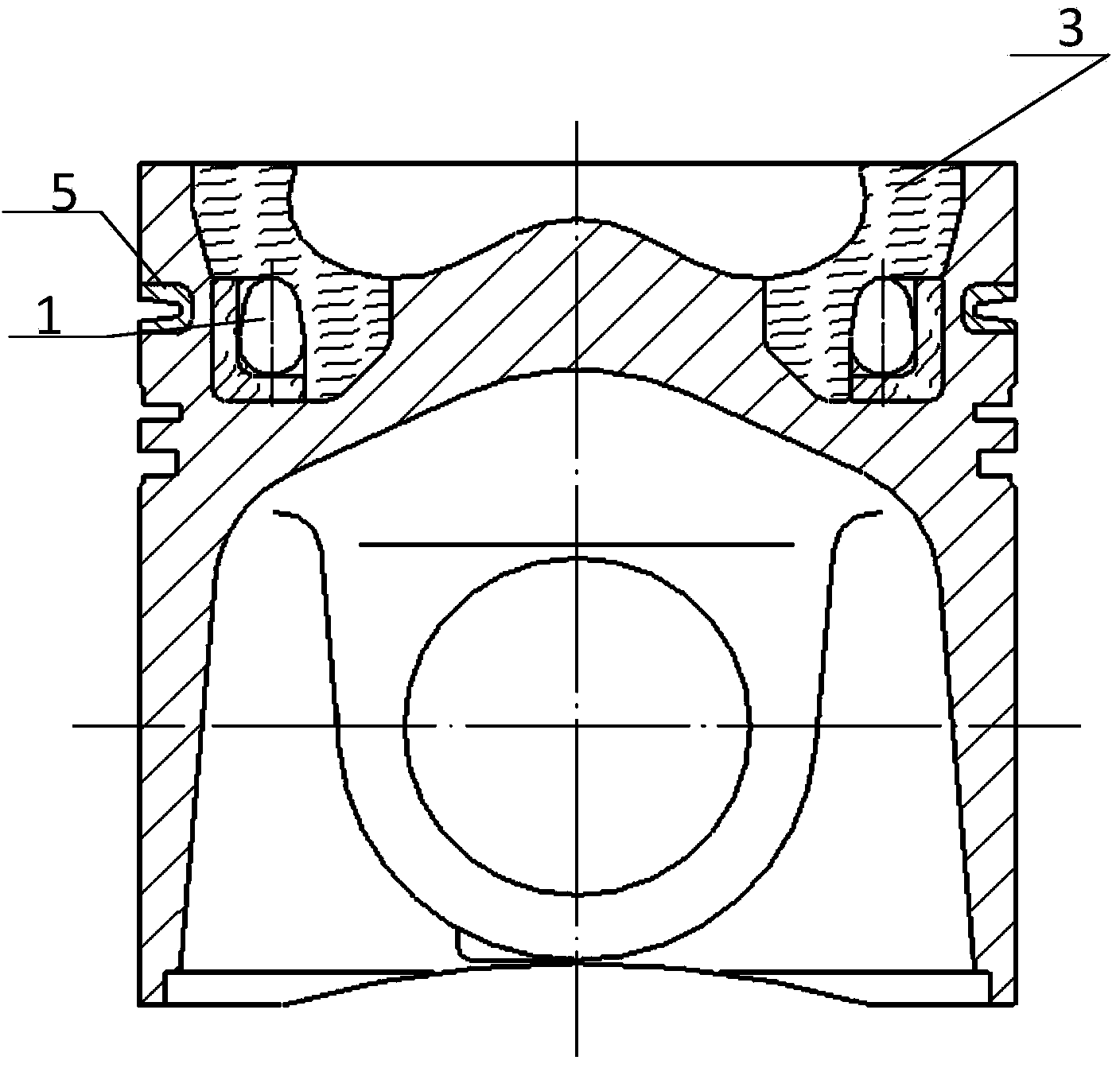

Method for manufacturing alumina fiber and titanium oxide particle-reinforced inner-cooling insert ring piston blanks

ActiveCN104353814AImprove stabilityImprove high temperature fatigue strengthPistonsFiberWear resistant

The invention discloses a method for manufacturing alumina fiber and titanium oxide particle-reinforced inner-cooling insert ring piston blanks. The method comprises the following steps: (1) manufacturing an upper fabricated part and a lower fabricated part of alumina ceramic fiber and titanium oxide particles, wherein the volume fraction of alumina ceramic fibers is 8-25 percent, the volume fraction of titanium oxide particles is 1-9 percent, and the rest is gaps; (2) preparing a soluble core by using salt and aluminum titanate ceramics as raw materials; (3) putting a wear resistant cast iron insert ring after aluminum diffusion treatment in a casting mould, and fixing; (4) preheating the upper fabricated part and the lower fabricated part of alumina ceramic fiber and titanium oxide particles; (5) after preheating the soluble core, taking out the upper fabricated part and the lower fabricated part of alumina ceramic fiber and titanium oxide particles, putting the soluble core in the lower fabricated part of alumina ceramic fiber and titanium oxide particles, and then combining the upper fabricated part and the lower fabricated part of alumina ceramic fiber and titanium oxide particles and quickly putting in the mould; (6) pouring an aluminum alloy solution into the casting mould, and carrying out pressure forming.

Owner:BINZHOU BOHAI PISTON CO LTD

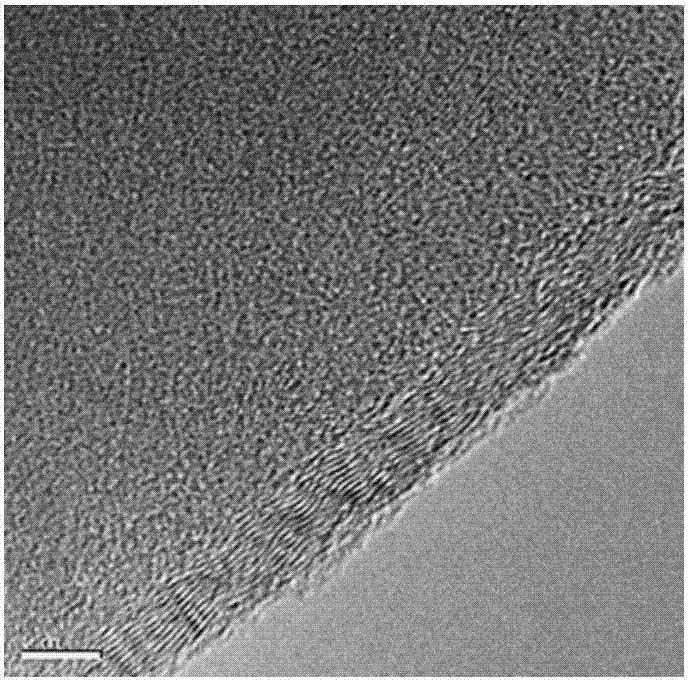

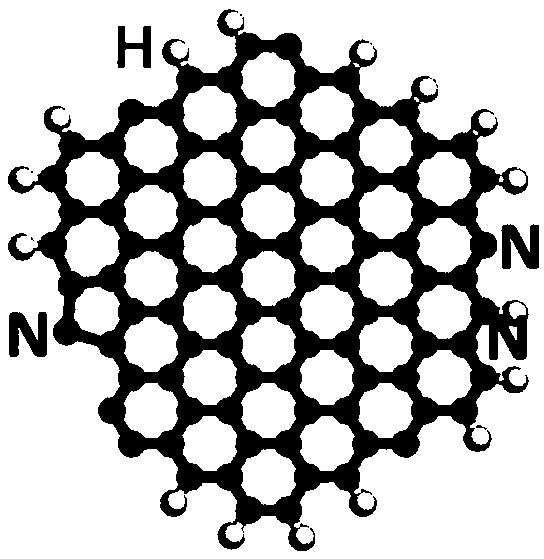

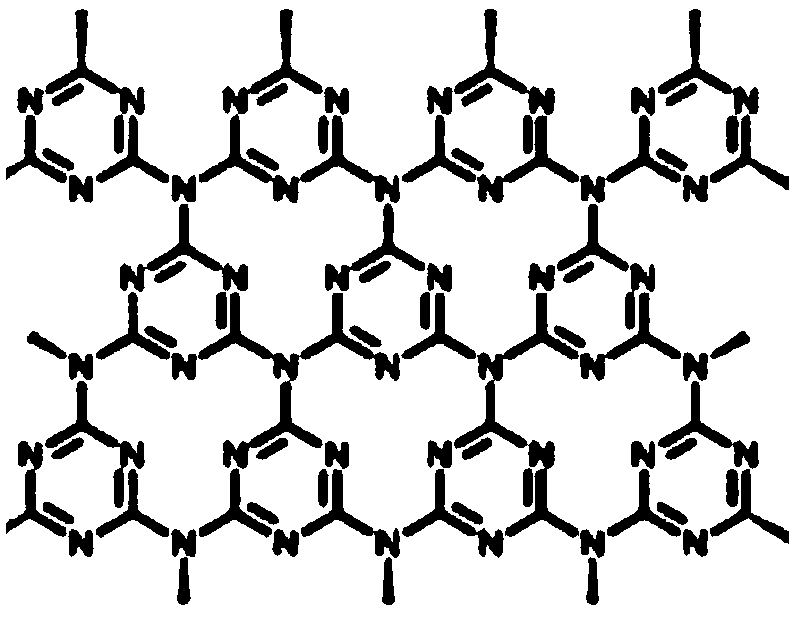

Carbon-nitrogen material, preparation method thereof, lithium-sulfur battery cathode material containing carbon-nitrogen material and lithium-sulfur battery

ActiveCN108821249AReduces the chance of dissolving in the electrolyteReduce the amount of dissolutionMaterial nanotechnologyCell electrodesSodium–sulfur batteryCarbon nitrogen

The invention provides a carbon-nitrogen material, a preparation method thereof, a lithium-sulfur battery cathode material containing the carbon-nitrogen material and a lithium-sulfur battery, and relates to the technical field of new energy batteries. The preparation method of the carbon-nitrogen material comprises the following steps: sintering a mixture of a catalyst and melamine in an inert atmosphere to obtain the carbon-nitrogen material. A carbon-nitrogen nanotube obtained with the preparation method can solve the technical problem of poor cycle stability of the lithium-sulfur battery due to high dissolubility of an intermediate product lithium polysulfide of the lithium-sulfur battery in an electrolyte in the prior art, and achieves the technical effect of improving cycle stabilityof the lithium-sulfur battery.

Owner:桑德新能源技术开发有限公司 +1

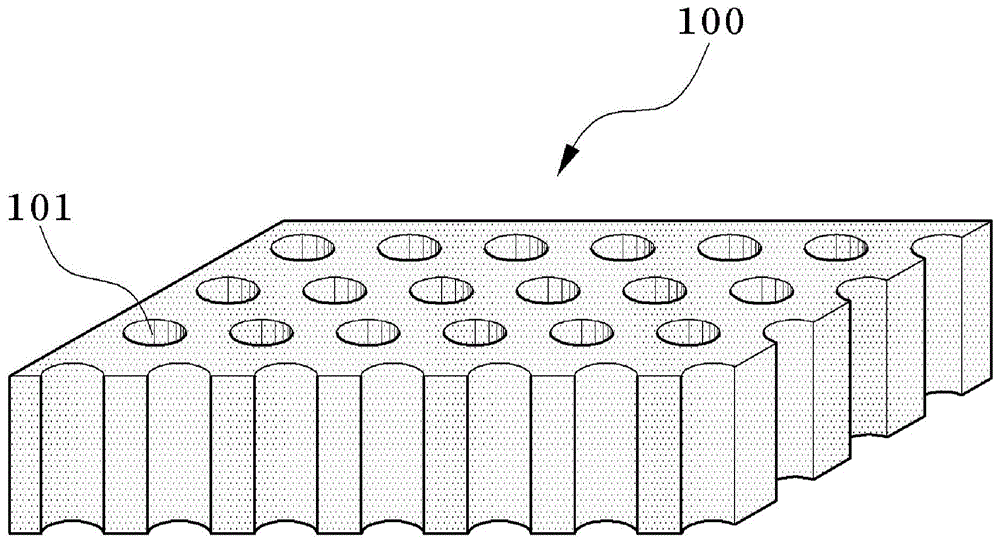

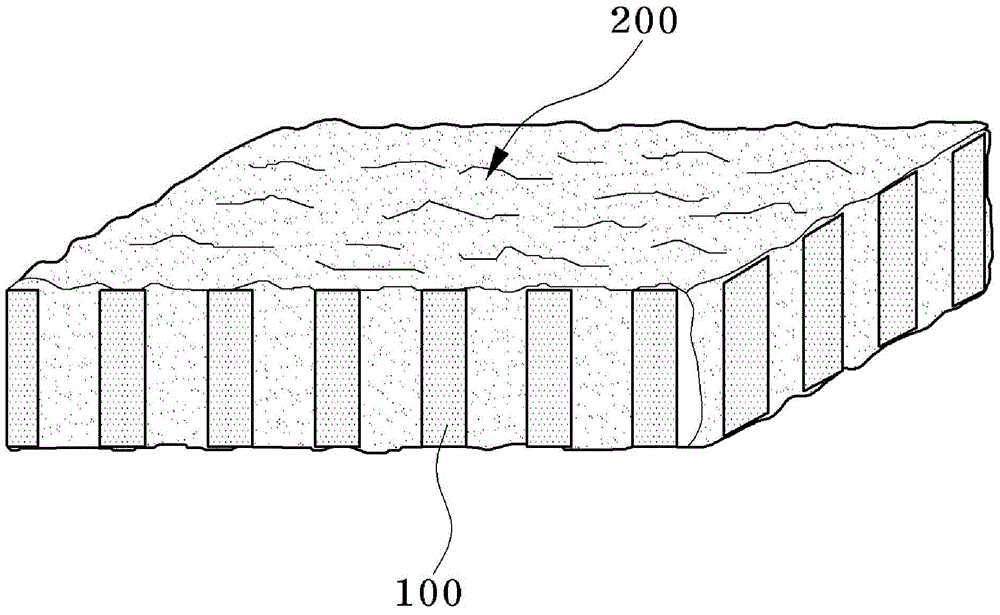

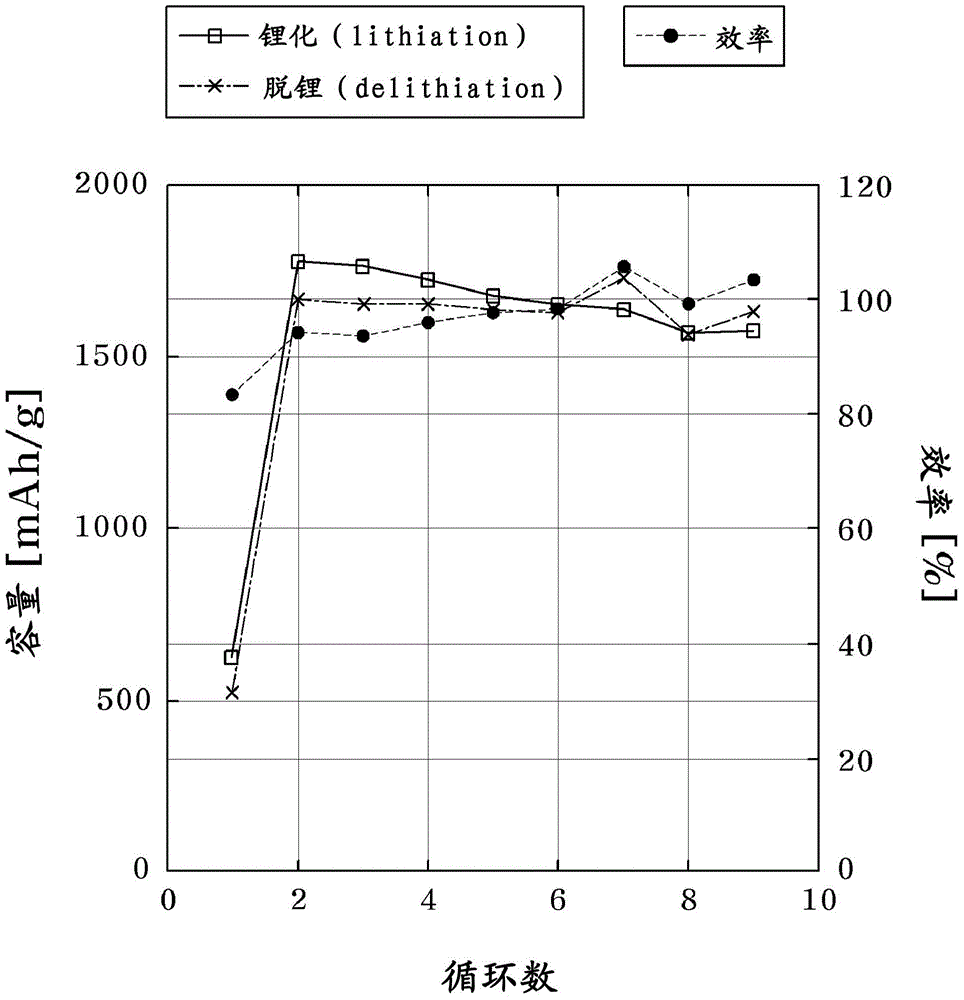

Film-Type Negative Electrode Filled With Active Material And Method For Manufacturing Same

InactiveCN104011903ASmall volume change rateGuaranteed electrical conductivityElectrode carriers/collectorsPrinted batteriesCharge and dischargeMaterials science

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method of lithium manganate battery

InactiveCN111816924ALarge specific surface areaIncrease energy densityFinal product manufactureCell electrodesElectrical batteryMaterials science

The invention provides a preparation method of a lithium manganate battery. A positive electrode active substance of the lithium manganate battery is spinel lithium manganate, and the molecular formula of the spinel lithium manganate is LiMn2-xMxO4, wherein x ranges from 0.01 to 0.1, M is a doped metal element; and a negative electrode active substance of the lithium manganate battery is a carbon-based material. The preparation method comprises the following steps: sieving the spinel lithium manganate material; respectively pulping the active substances under the screen and the active substances on the screen; coating the surface of a current collector with the obtained pulps in sequence; drying to obtain a positive electrode; putting the positive electrode and a counter electrode lithiumsheet into an electrolyte tank; discharging to a first preset voltage; taking out the positive electrode; assembling the positive electrode and a negative electrode clamping diaphragm into a batterycell; putting the battery cell into a shell, and carrying out injection molding to obtain the lithium manganate battery. The battery obtained by the preparation method disclosed by the invention is high in energy density, good in cycle performance and high in capacity retention ratio.

Owner:陆信甫

Novel insulated sealing material for chemical pump

The invention discloses a novel insulated sealing material for a chemical pump and a manufacturing method of the novel insulated sealing material. The novel insulated sealing material is prepared fromthe following raw material components in parts by weight: 89-113 parts of an organic fluorine thermoplastic elastomer, 8.5-13.5 parts of Al2O3, 45.5-61.6 parts of methicone, 27-49.5 parts of polypropylene, 17-27.5 parts of barium sulfate, 0.05-0.2 part of tetraethylenepentamine, 0.1-0.2 part of hexafluorobisphenol A, and 0.05-0.2 part of sulfonated-1,3-dibenzyl-2-methylimidazole. The novel insulated sealing material does not need to be vulcanized or only needs to be locally vulcanized, and can be machined in a circulating mode to form a thermoplastic vulcanized rubber system. The novel insulated sealing material has the active effects that by adjusting a formula and a manufacturing process, the breakdown voltage of a blend rubber material is increased, and meanwhile, it is ensured that indexes such as the hardness, mechanical performance, corrosion resistance and insulation resistance of the material meet the using requirements of the chemical pump.

Owner:安徽江南泵阀集团有限公司

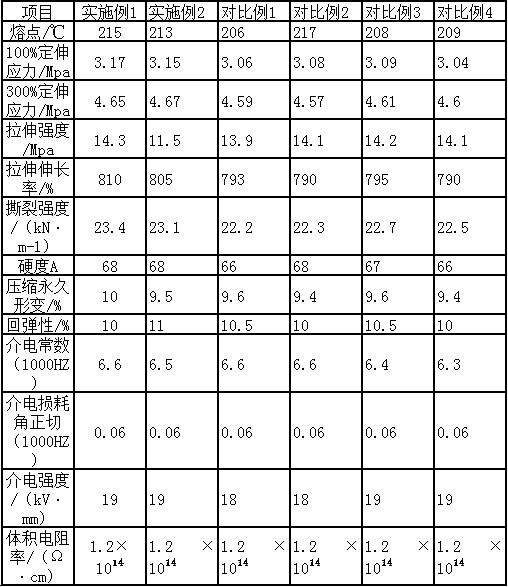

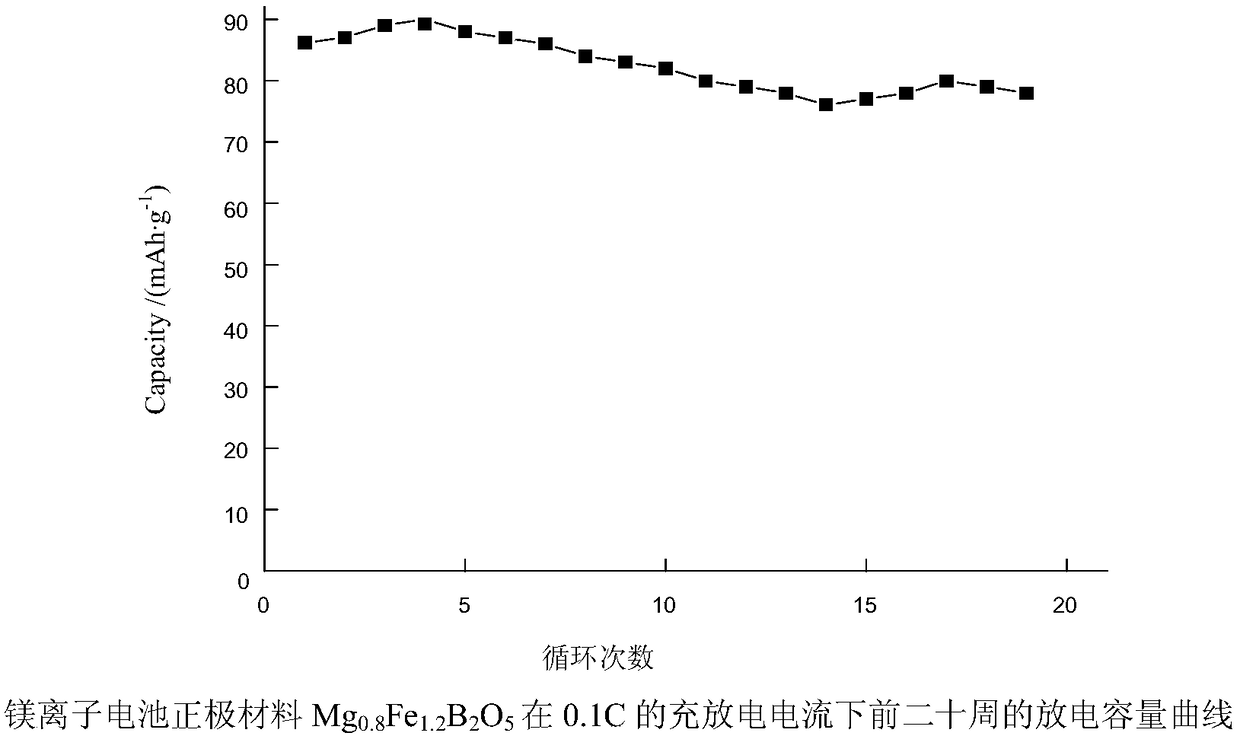

Method for preparing magnesium ion battery positive electrode material

The invention belongs to the technical field of battery materials, and concretely relates to a method for preparing a magnesium ion battery positive electrode material. The magnesium ion battery positive electrode material is carbon coated magnesium ferrous borate, wherein the magnesium ferrous borate mainly comprises a magnesium source compound, a ferrous source compound and a borate radical compound. The magnesium ferrous borate synthesized from common raw materials in the invention is a novel magnesium ion battery positive electrode material having an extremely rich source and an excellentapplication prospect. Compared with currently widely studied phosphate polyanion compound magnesium ion battery positive electrode materials, the positive electrode material in the invention achievesa higher theoretic specific capacity by replacing a phosphate radical having a large mole with a borate radical having a small mole from structural analysis. The electric conduction capability of ferrous borate is stronger than that of ferrous phosphate, the volume change rate of the ferrous borate before and after discharge is lower than that of the ferrous phosphate before and after discharge and is less than half of that of the ferrous phosphate, so the magnesium ferrous borate positive electrode material has good rate performances and a good cycle stability.

Owner:NINGBO POLYTECHNIC

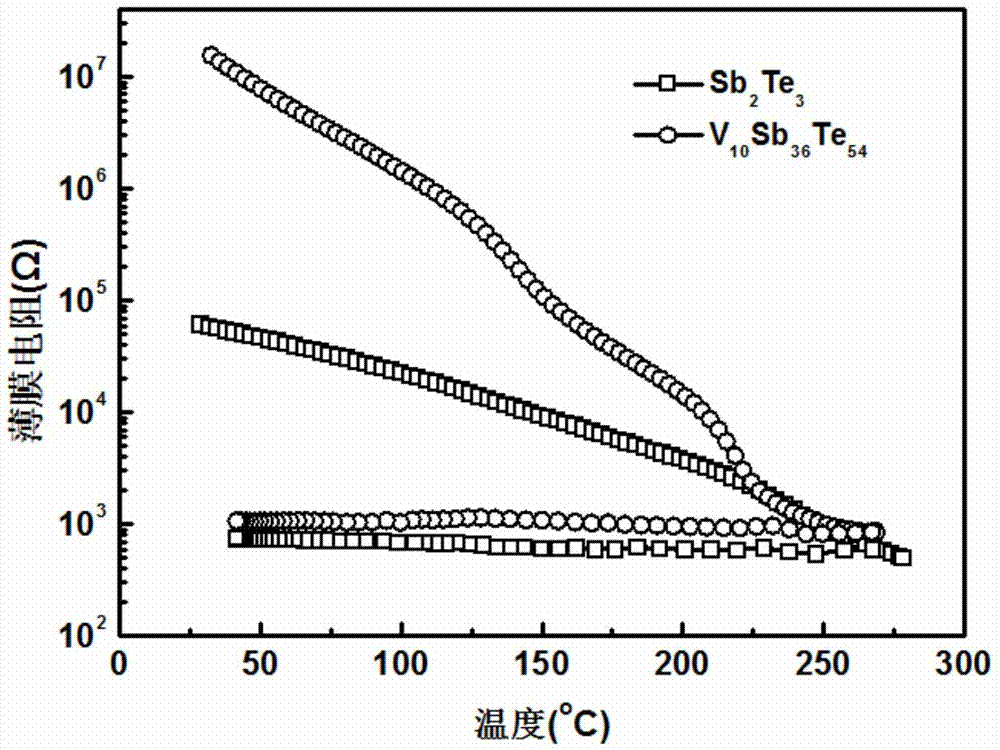

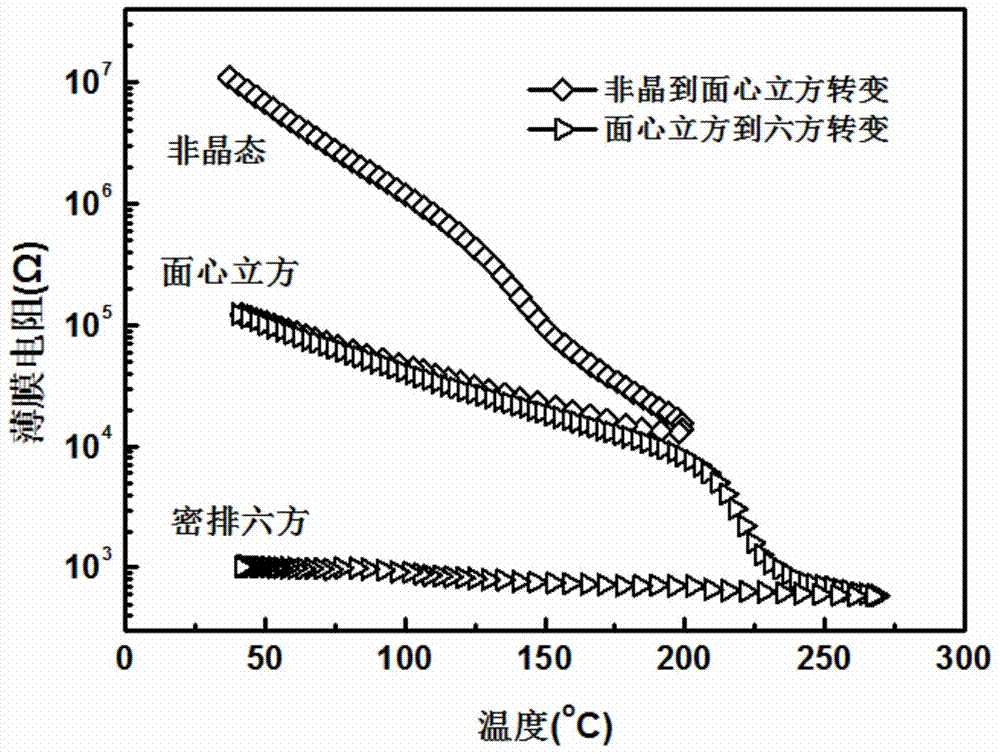

Phase change memory V-Sb-Te phase change material system and preparing method thereof

ActiveCN104241527AReduced operating power consumptionGood operating power consumptionElectrical apparatusVacuum evaporation coatingPhase-change memoryVolume variation

The invention provides a phase change memory V-Sb-Te phase change material system and a preparing method thereof. The V-Sb-Te phase change material system is formed by doping V on the basis of an Sb-Te phase change material system and is of a chemical general form as V<100-x-y>Sb<x>Te<y>, wherein 0.5= / <x / y< / =4 and 50< / =x+y< / =99.99. The V-Sb-Te phase change material system has high phase change speed, low operating consumption, excellent data holding capacity and phase stability and can expand application range of the Sb-Te phase change material system greatly. Meanwhile, the element V has an effect of greatly reducing grain size of the Sb-Te material system to improve the scalability thereof, so that volume rate of change of the material before and after phase change is reduced and fatigue resistance thereof is improved. In addition, the element V is compatible with the Sb-Te phase change material system well, so that the overall V-Sb-Te phase change material is uniform in phase.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

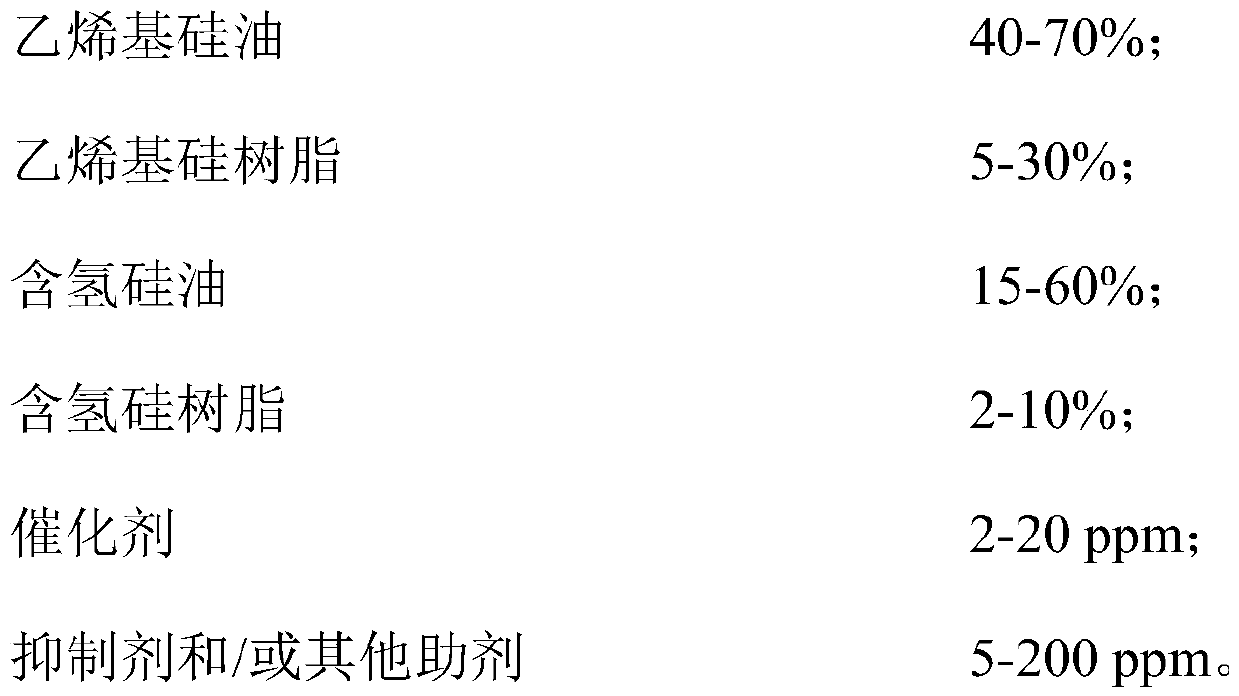

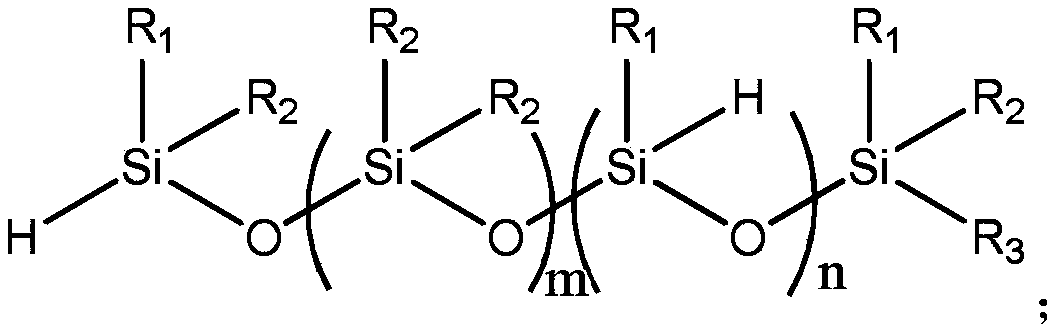

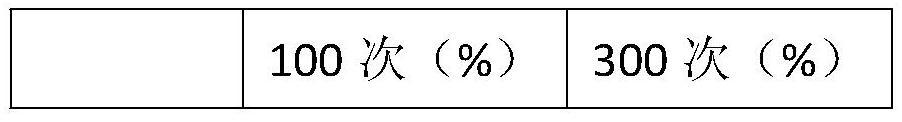

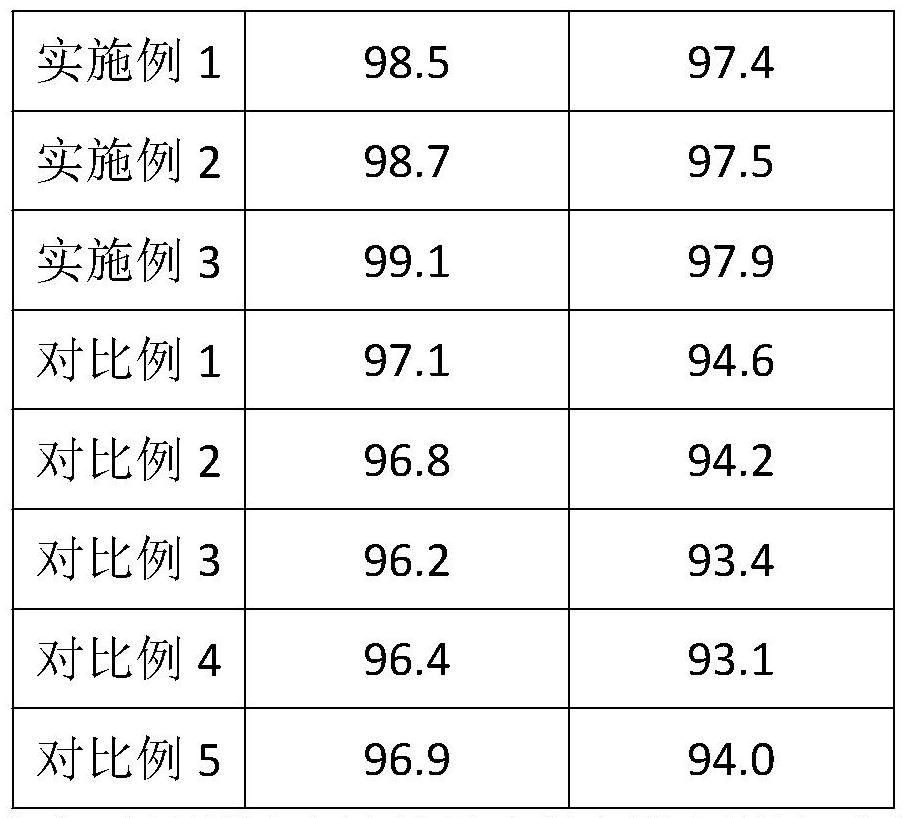

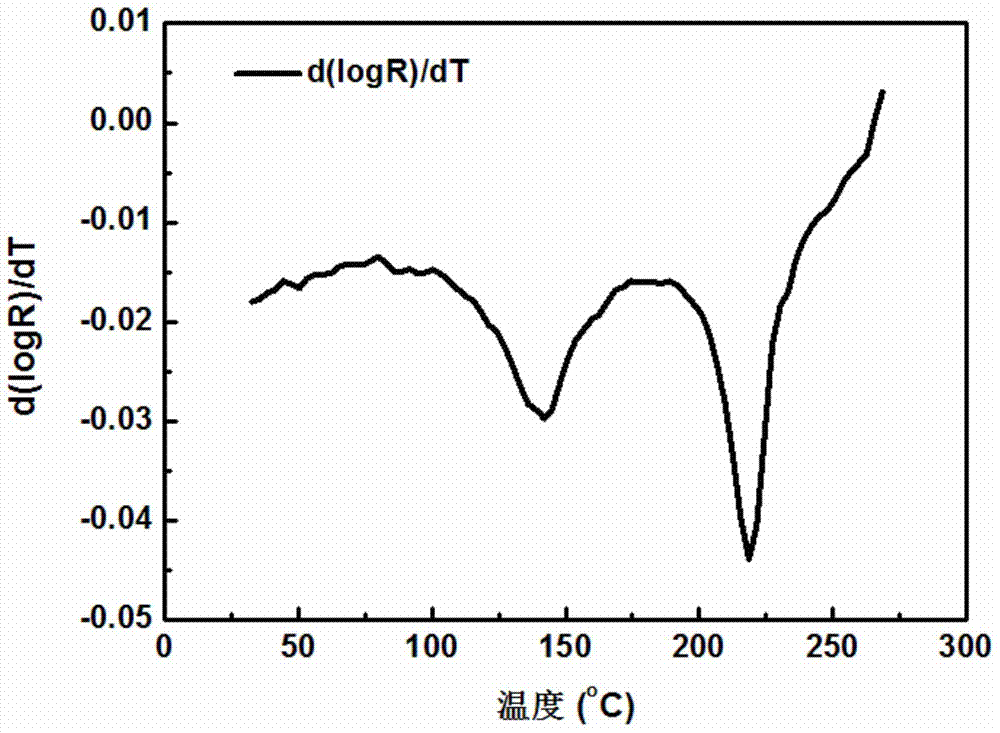

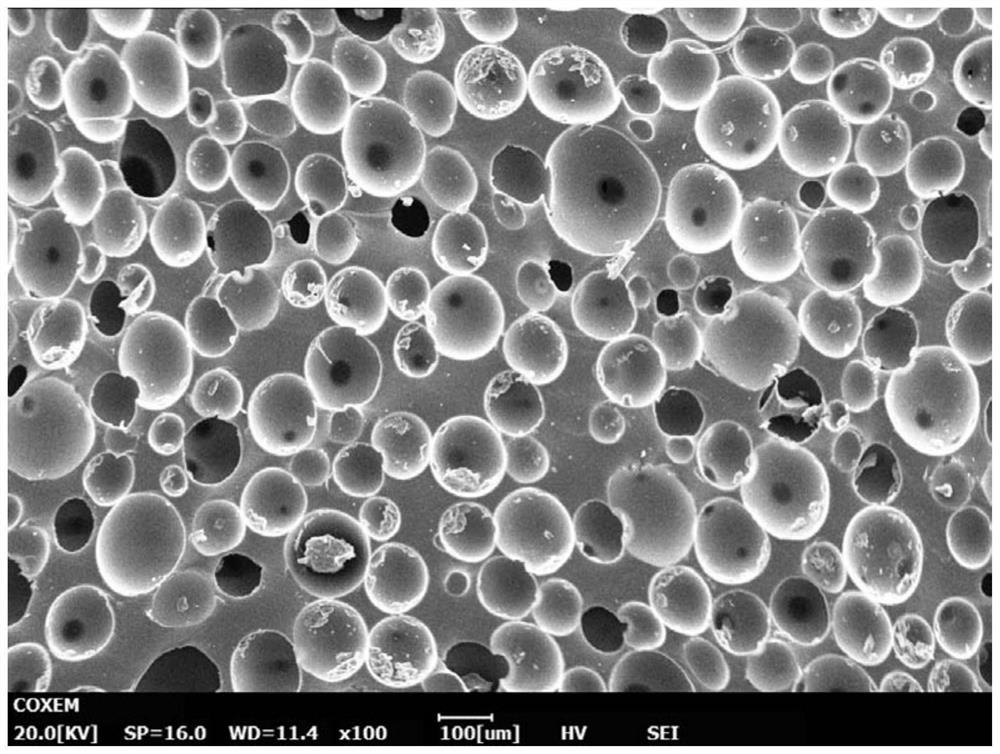

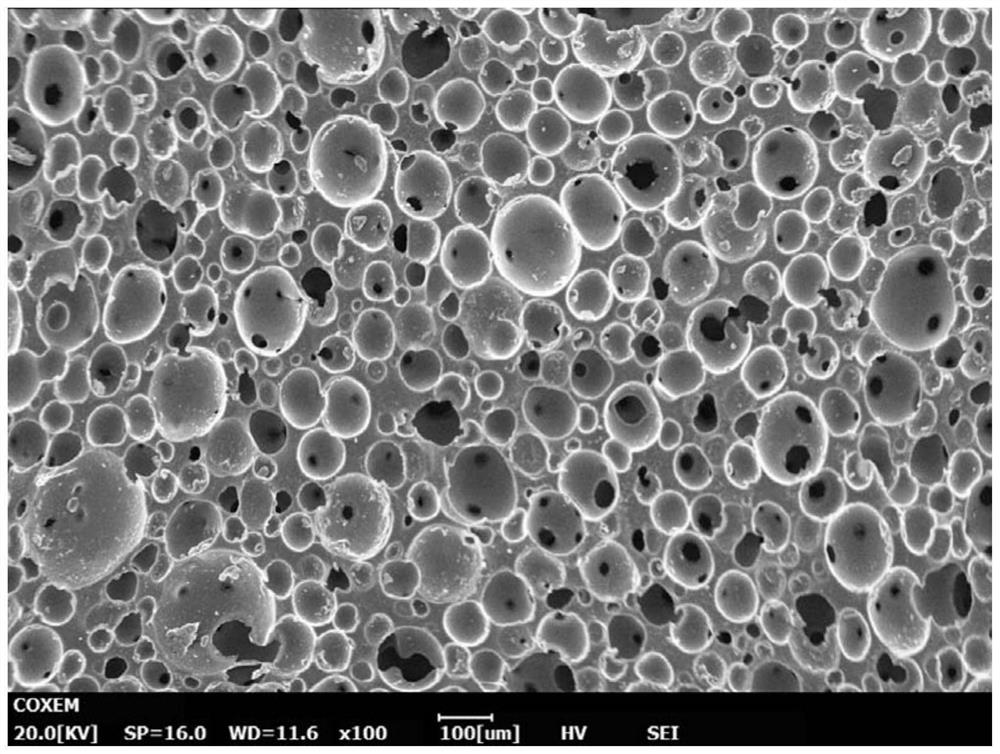

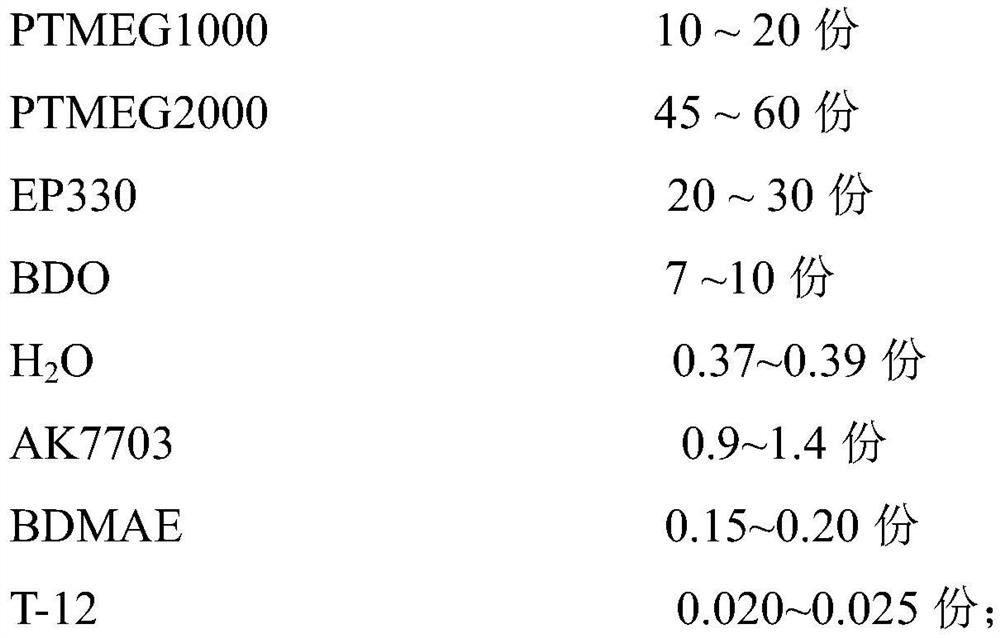

Low-static-stiffness polyurethane microporous elastic backing plate with low low-temperature static stiffness change rate

ActiveCN113461900AGuaranteed damping effectSmall volume change rateRail fastenersElastomerPolymer science

The invention relates to a low-static-stiffness polyurethane microporous elastic backing plate with a low low-temperature static stiffness change rate, and belongs to the technical field of polyurethane microporous elastomers. The elastic base plate is a polyurethane microporous elastic base plate which is obtained by curing and forming a component A and a component B, the density of the polyurethane microporous elastic base plate is 400-450 kg / m<3>, and the static rigidity of the polyurethane microporous elastic base plate is (8 + / -0.8) kN / mm under the loading of 1-35 kN, the component A is prepared by uniformly mixing PTMEG 1000, PTMEG 2000, EP330, BDO, H2O, AK7703, BDMAE and T12, and the component B is a prepolymer which is formed by stirring and reacting a compound containing -NCO groups and polytetrahydrofuran ether polyol at the temperature of 80-100 DEG C for 4-6 h and has the NCO value of 12-15. By optimizing the raw material components and the component content in the elastic base plate and properly increasing the pressure in micropores in the elastic base plate, the elastic base plate has good cold resistance on the premise of meeting the use requirements of other indexes such as static rigidity, dynamic and static rigidity ratio and the like; therefore, the low-static-stiffness polyurethane microporous elastic base plate for the urban railway passenger transport line, which meets various index requirements, is obtained.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

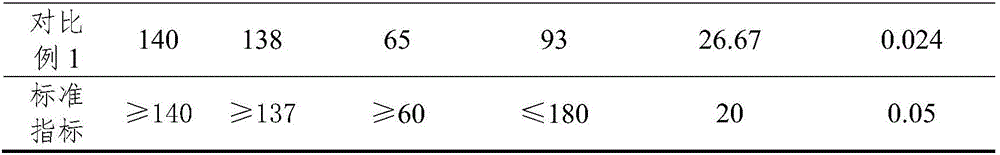

Lithium ion battery diaphragm prepared from inorganic-organic composite material

PendingCN112531292AGood electrochemical stabilityImprove high temperature thermal stabilityMaterial nanotechnologySecondary cellsPorous membranePolyolefin

The invention relates to a lithium ion battery diaphragm prepared from an inorganic-organic composite material. The lithium ion battery diaphragm comprises at least two layers of polyolefin-based porous membranes which are stacked in sequence, and two adjacent layers of polyolefin-based porous membranes are bonded and fixed through an inorganic-organic composite material liquid; wherein the inorganic-organic composite material liquid is prepared from the following components in parts by weight: 30 to 50 parts of polyolefin emulsion, 5 to 10 parts of adhesive, 3 to 8 parts of nanoscale modifiedcomposite fiber, 0.2 to 0.5 part of dispersing agent and 0.1 to 0.5 part of plasticizer. The prepared lithium ion battery diaphragm is relatively stable in performance, is particularly applied to a lithium ion battery for an electric vehicle, and can tolerate relatively high temperature in the working process of the electric vehicle, and the diaphragm shrinkage rate is remarkably reduced comparedwith that of an existing polyolefin-based diaphragm, so that the overall service life of the battery is remarkably prolonged, and the safety is greatly improved; and the use convenience, the safety and the stability of the electric product are also improved.

Owner:宁波启新精合新能源研究院有限公司

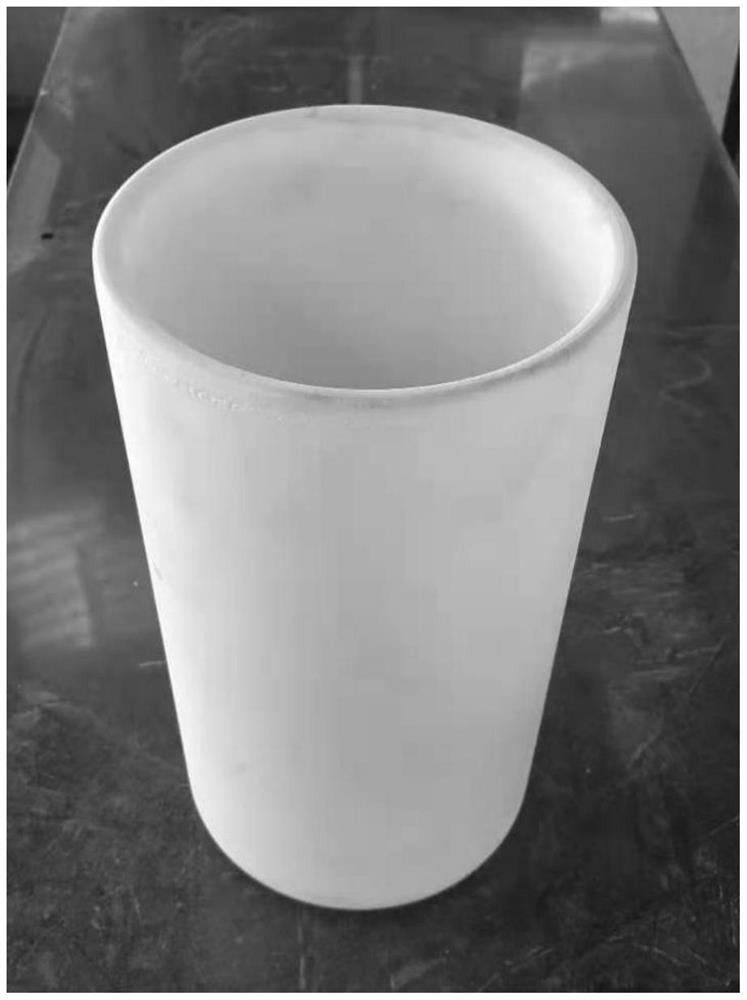

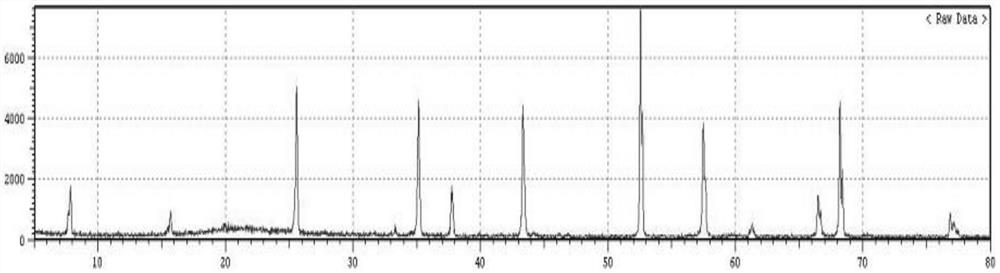

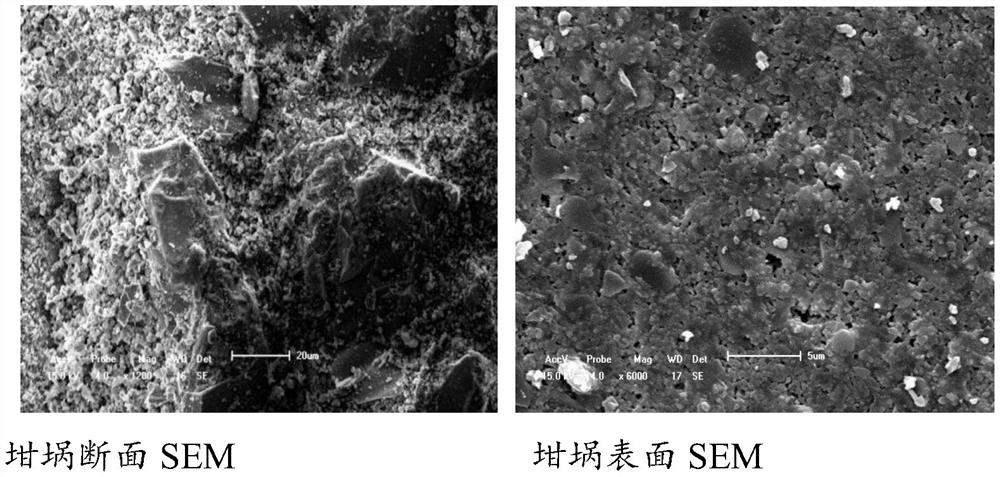

Ceramic crucible matched with intermediate frequency furnace and preparation method of ceramic crucible

The invention discloses a ceramic crucible matched with an intermediate frequency furnace and a preparation method of the ceramic crucible, the ceramic crucible matched with the intermediate frequency furnace is stable in chemical property, and the main components of the ceramic crucible are only SiO2 and Al2O3, so that the ceramic crucible cannot react with molten steel in the casting use process, meanwhile, harmful free substances cannot be separated out, and the risks of pollution or slag inclusion pores and the like of castings are completely eradicated. Besides, the fused quartz is a substance with the thermal expansion coefficient almost being 0 and has extremely low volume change rate and extremely high thermal shock resistance, smooth casting is guaranteed on the basis that the use strength is met, and the performance and production efficiency of the high-temperature alloy precision casting can be greatly improved through the fused quartz and the preparation method thereof.

Owner:LIAONING SILICATE RES INST

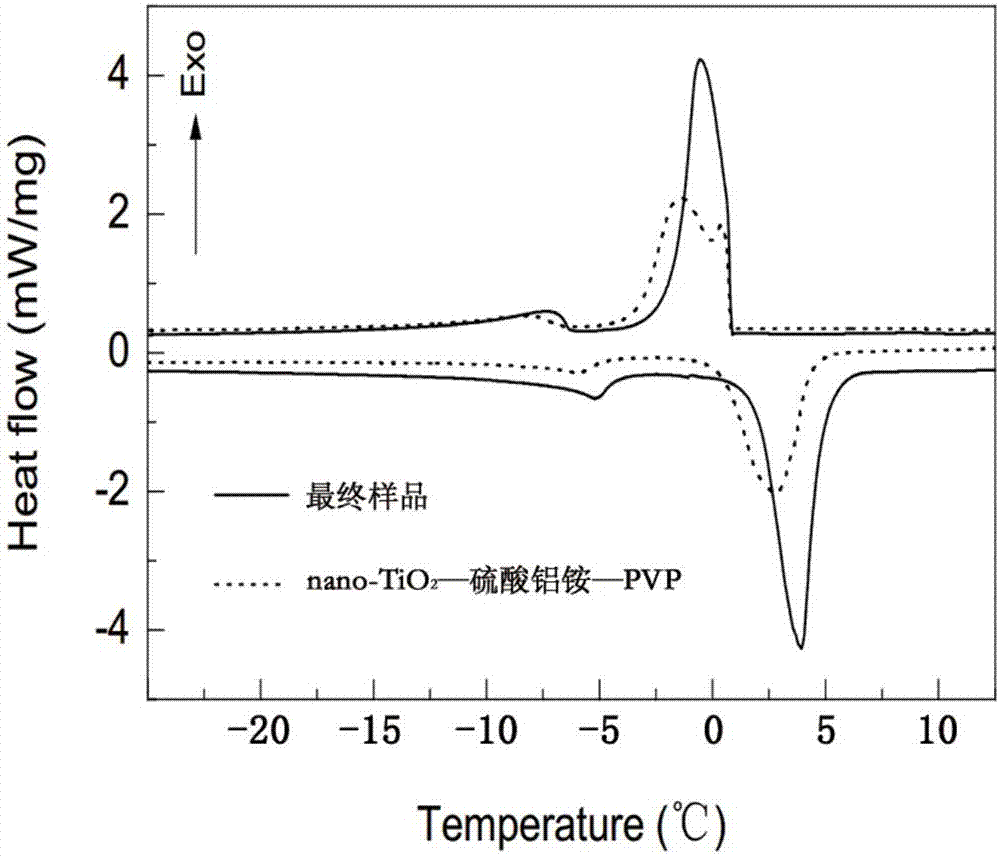

Phase change cold-storage composite material and preparation method thereof

ActiveCN107325793AImprove thermal conductivityTo achieve the purpose of strengthening heat transferHeat-exchange elementsAluminum ammonium sulfatePhase change

The invention provides a preparation method of a phase change cold-storage composite material, and belongs to the technical field of a phase change material. The preparation method comprises the following steps of taking and scattering nanometer titanium dioxide, aluminum ammonium sulfate and polyvinylpyrrolidone into de-ionized water; after the stirring and mixing, performing ultrasonic treatment for 1 to 1.5h for preparing sol; uniformly mixing the sol with pelargonic acid / phytol solution; performing scattering; obtaining the phase change cold-storage composite material. The invention simultaneously provides the phase change cold-storage composite material. The preparation method is simple; the operation is easy; the prepared finished product rate is high; the stability of the phase change cold-storage composite material is high.

Owner:HEBEI MILSON TITANIUM DIOXIDE

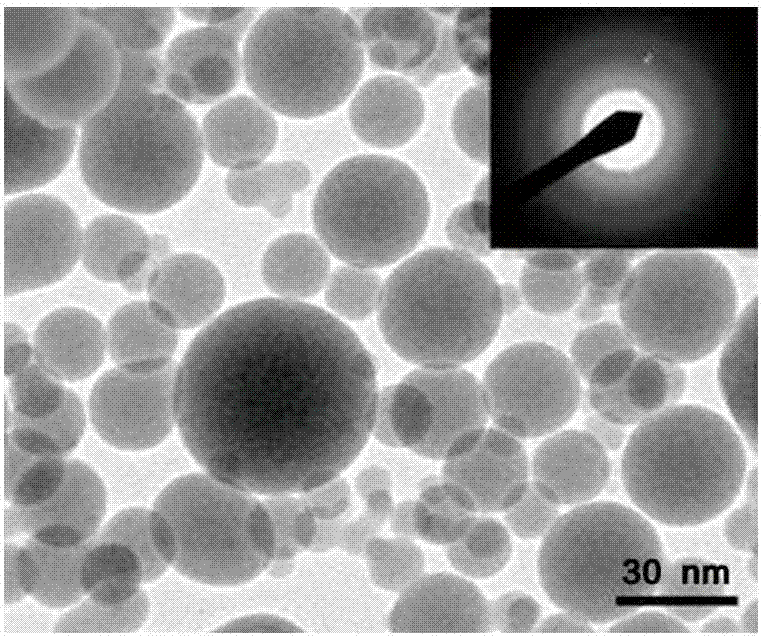

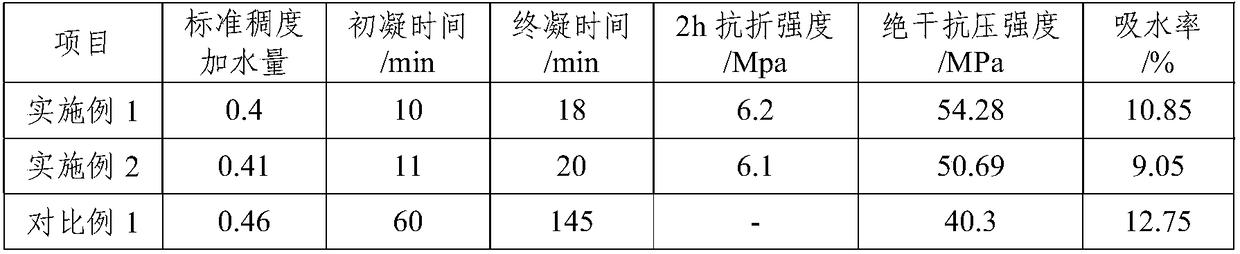

Gypsum powder and application thereof

ActiveCN108373307AHigh strengthImprove fire performanceFireproof doorsDoor leavesCompressive strengthFire resistance

The invention relates to gypsum powder and application thereof. The gypsum powder is prepared from, by weight, 100 parts of alpha gypsum, 1-3 parts of a reinforcing agent, 1-3 parts of a volume stabilizing agent, 0-1 part of a setting time adjusting agent, 0.1-1 part of a foam stabilizer, 0.1-4 parts of a waterproof agent and 0.1-1 part of a toughening agent. The gypsum powder has advantages of short initial setting time and final setting time, high absolute dry compression strength, low water absorption and the like. Fireproof door core plates made from the gypsum powder overcome defects of magnesite fireproof door core plates, fire resistance of the door core plates is improved is by taking the advantage of the characteristic that the gypsum powder releases crystal water under a high-temperature condition, and the door core plates have advantages of high fire resistance, environmental friendliness and the like.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com