Ceramic crucible matched with intermediate frequency furnace and preparation method of ceramic crucible

A technology for a ceramic crucible and an intermediate frequency furnace, which is applied in the field of ceramic crucibles for intermediate frequency furnaces and its preparation, can solve the problems of slag inclusion and pores, poor thermal shock resistance, pollution of precision castings, etc., and achieve stable chemical properties, prevent pollution or Effects of slag inclusion, improved performance and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

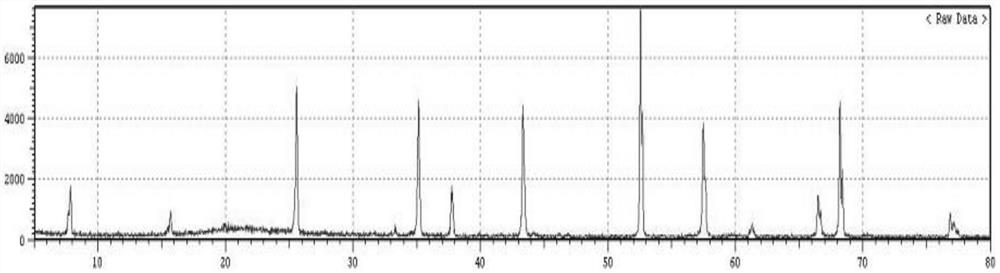

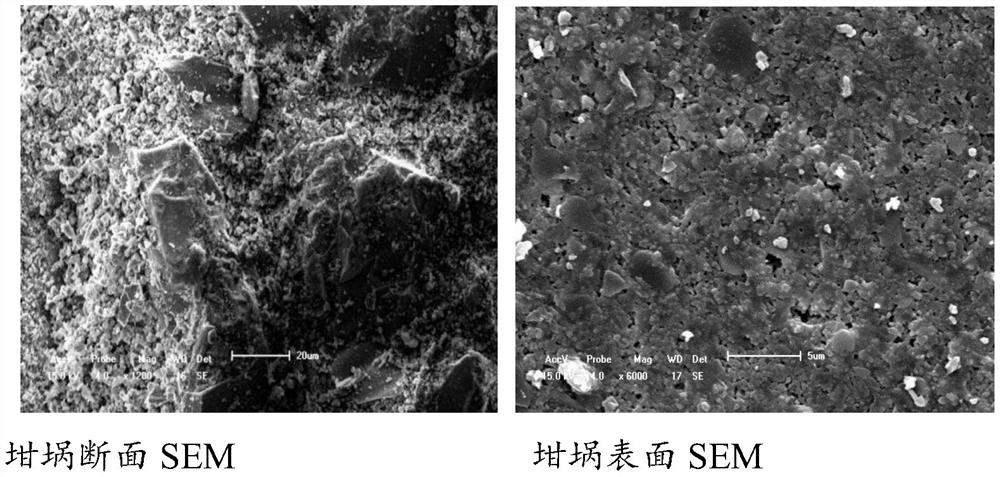

Embodiment 1

[0033] To prepare a ceramic crucible for an intermediate frequency furnace, the specific steps are as follows:

[0034] a) Mixing of main ingredients: by weight, take 40 parts of fused silica powder between 120 mesh and 350 mesh, 10 parts of white corundum powder between 120 mesh and 350 mesh, 30 parts of α-alumina powder below 325 mesh, 30 μm grain 28 parts of diameter γ-alumina powder and 2 parts of white carbon black are sent into the gravity-free mixing equipment, and the raw materials are mixed evenly for 15 minutes before use;

[0035] b) Mixing of auxiliary materials: according to the total weight of main materials, take 0.2 parts of boric acid, 0.6 parts of sodium polyacrylate, 1.25 parts of silane coupling agent (KH-570), and 8 parts of silica sol, put them into a mixer and stir for 3 minutes, and set aside;

[0036] c) Mixing of main ingredients and auxiliary materials: send the fully mixed main ingredients into the blender, divide the fully dissolved auxiliary mater...

Embodiment 2

[0044] Prepare a ceramic crucible for an intermediate frequency furnace, the specific steps are as follows:

[0045] a) Mixing of main ingredients: by weight, take 50 parts of fused silica powder between 120 mesh and 350 mesh, 0 parts of white corundum powder between 120 mesh and 350 mesh, 28 parts of α-alumina powder below 325 mesh, 30 μm grain 18 parts of diameter γ-alumina powder and 4 parts of white carbon black are sent into the gravity-free mixing equipment, and the raw materials are mixed evenly for 10 minutes before use;

[0046] b) Mixing of auxiliary materials: according to the total weight of main materials, take 0.4 parts of boric acid, 1 part of sodium polyacrylate, 1 part of silane coupling agent (KH-570), and 10 parts of silica sol, put them into a mixer and stir for 5 minutes, and set aside;

[0047]c) Mixing of main ingredients and auxiliary materials: Send the fully mixed main ingredients into the blender, divide the fully dissolved auxiliary materials into 2...

Embodiment 3

[0055] To prepare a ceramic crucible for an intermediate frequency furnace, the specific steps are as follows:

[0056] a) Mixing of main ingredients: by weight, take 20 parts of fused silica powder between 120 mesh and 350 mesh, 30 parts of white corundum powder between 120 mesh and 350 mesh, 28 parts of α-alumina powder below 325 mesh, 30 μm grain 20 parts of diameter γ-alumina powder and 2 parts of white carbon black are sent into the gravity-free mixing equipment, and the raw materials are mixed evenly for 20 minutes before use;

[0057] b) Mixing of auxiliary materials: according to the total weight of main materials, take 0.6 parts of boric acid, 1.25 parts of sodium polyacrylate, 0.6 parts of silane coupling agent (KH-570), and 10 parts of silica sol, put them into a mixer and stir for 5 minutes, and set aside;

[0058] c) Mixing of main ingredients and auxiliary materials: Send the fully mixed main ingredients into the blender, divide the fully dissolved auxiliary mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com