Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Good fuel resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser markable high-shading polyester composite material for LED (Light Emitting Diode), and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to a laser markable high-shading polyester composite material for an LED (Light Emitting Diode), and a preparation method thereof. The laser markable high-shading polyester composite material for the LED comprises the following raw materials in parts by weight: 40-60 parts of polyester, 15-20 parts of glass fiber, 15-20 parts of main fire retardant, 3-5 parts of auxiliary fire retardant, 4-8 parts of flexibilizer, 0.1-0.2 part of antioxidant, 10-15 parts of opacifier, 0.3-1.0 part of laser marking powder and 0.5-1.0 part of other accessory ingredients. The laser markable high-shading polyester composite material for the LED has the advantages of good shading effect, good anti-flaming effect, good temperature tolerance and weather fastness, high intensity, excellent shock resistance, good processability and excellent overall performance, can be used for laser marking and can pass a high and low temperature (40DEG C below-120DEG C) impact test.

Owner:东莞市东翔塑胶有限公司

Hydrogenated nbr composition

ActiveUS20090258980A1Meet cost performance requirementsDistinguished heat resistanceSpecial tyresCross-linkAcrylonitrile

A hydrogenated NBR composition, which comprises 100 parts by weight of a blend of a hydrogenated NBR having an acrylonitrile content of 25-44% by weight and an iodine number of 32-65, with such an amount of an NBR as to make the iodine number of the blend of 40-160, 2-23 parts by weight of an ester-based plasticizer, and 0.5-10 parts by weight of an organic peroxide, preferably which further contains 0.5-10 parts by weight of a polyfunctional, unsaturated compound, has a distinguished cost performance because of blending an expensive hydrogenated NBR with a cheap NBR, can give cross-linked products having a distinguished oil resistance (resistance to such oil as No. 3 oil and other general-purpose, commercially available engine oil, etc.) and a distinguished fuel oil resistance (resistance to such fuel oil as fuel oil C, and other general-purpose, commercially available gasoline, etc.) and thus can serve as suitable molding materials for intake manifold gaskets of automobile engine or automobile sealing parts, particularly sealing parts around engines and transmission systems.

Owner:NOK CORP

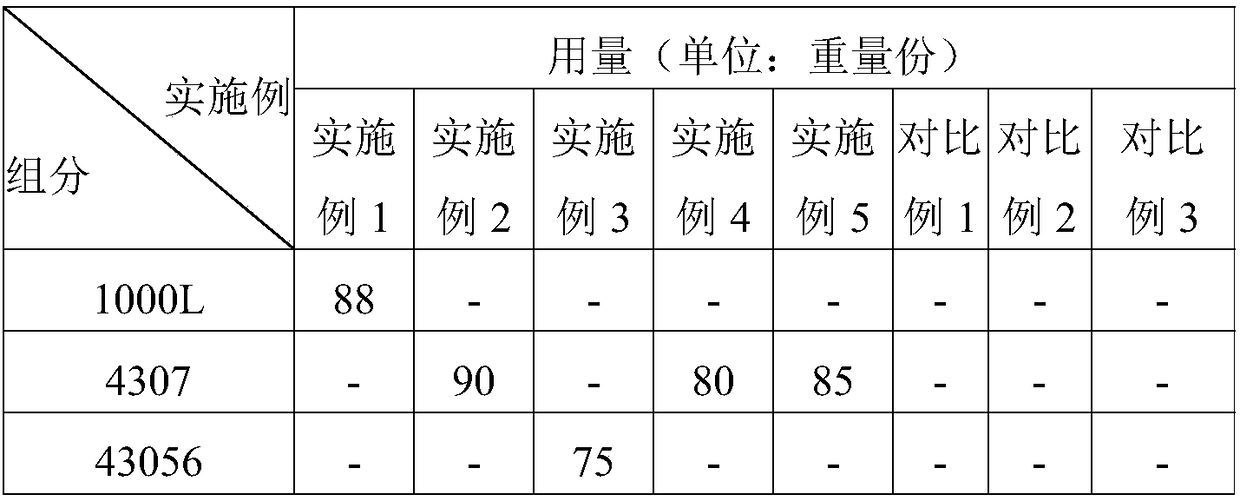

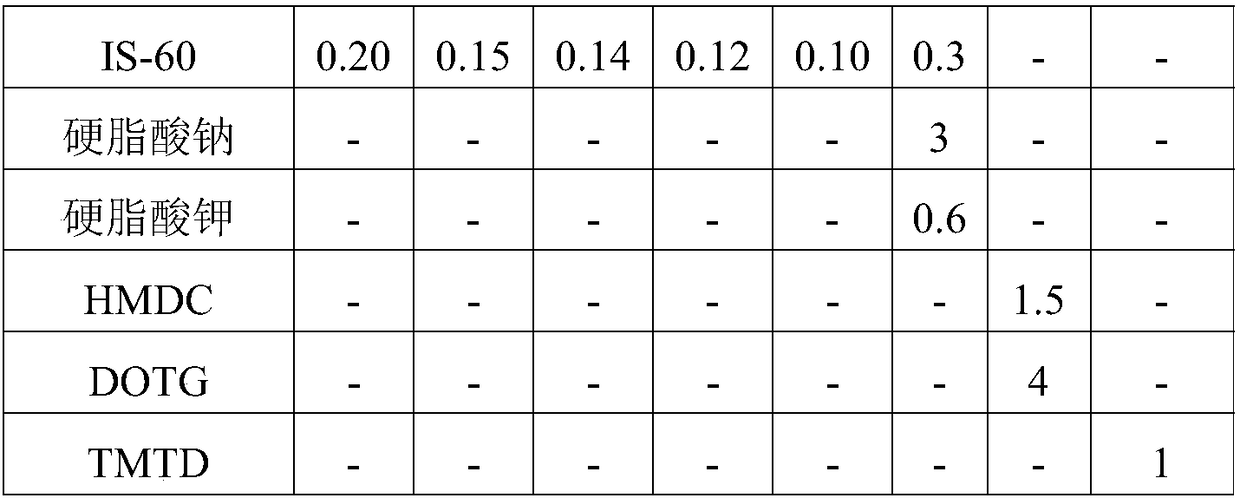

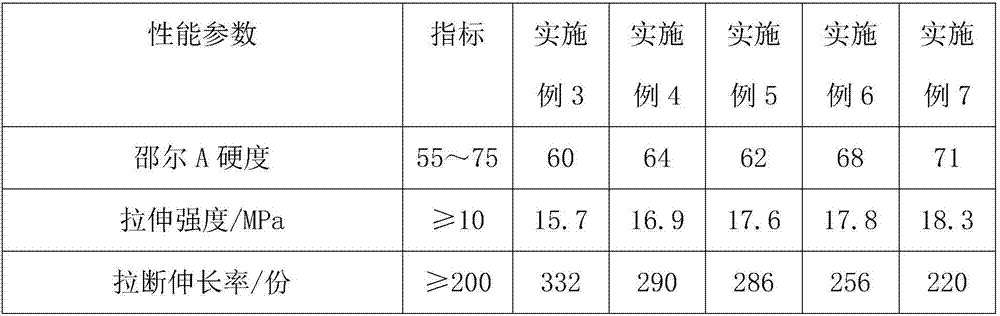

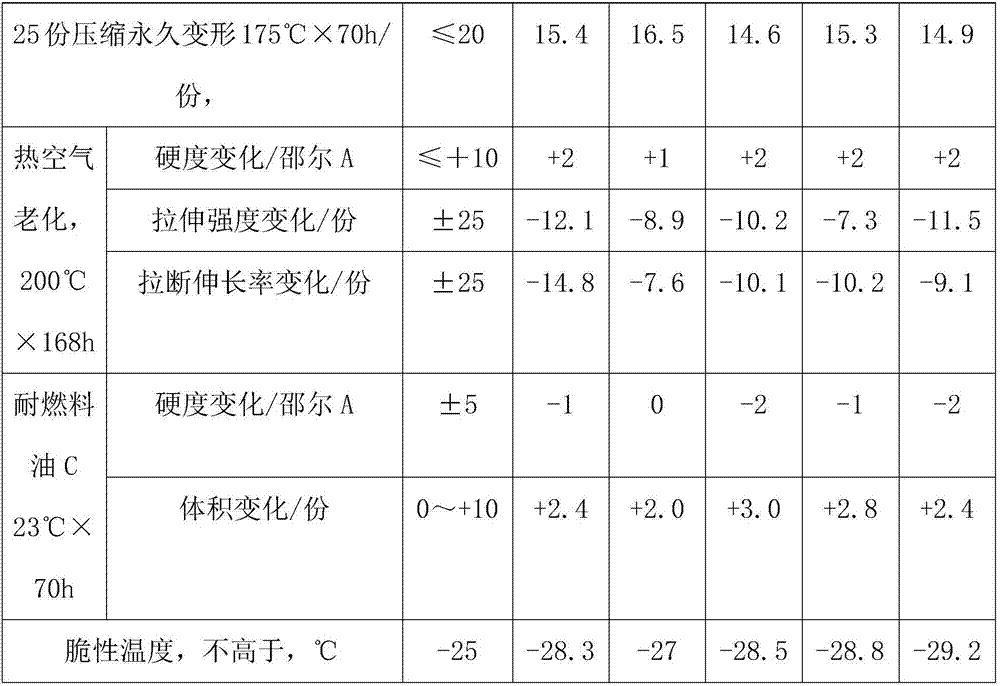

Hydrogenated butadiene-acrylonitrile rubber composition material and preparation method and application thereof

The invention discloses a hydrogenated butadiene-acrylonitrile rubber composition material, and a preparation method and application thereof. The hydrogenated butadiene-acrylonitrile rubber composition material is prepared from the following raw material components in parts by weight: 100 parts of hydrogenated butadiene-acrylonitrile rubber, 4-10 parts of zinc oxide, 0.5-2.5 parts of stearic acid,1-4 parts of an anti-ageing agent, 20-30 parts of carbon black with a particle size of 26-30 nm, 25-35 parts of carbon black with a particle size of 40-48 nm, 5-15 parts of white carbon black, 5-15 parts of a polyester polyether plasticizer, 2-4 parts of a vulcanizing agent and 1-3 parts of an auxiliary crosslinking agent. The acrylonitrile content of the hydrogenated butadiene-acrylonitrile rubber is 41.3-43.1%, the saturation degree of the hydrogenated butadiene-acrylonitrile rubber is 99% or more, and the Mooney viscosity ML(1+4) at a temperature of 100 DEG C of the hydrogenated butadiene-acrylonitrile rubber is 60-70. The composition material is relatively good in breaking strength, tearing strength and elastic ductility; the composition material has relatively good high-temperature resistance, low-temperature resistance and oil resistance; the composition material has a relatively long service life; and the composition material has excellent performance as an oil-seal material for an engine oil dipstick sleeve of an automobile. The preparation method of the composition material is simple in steps, easy in operation, and suitable for industrial production.

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

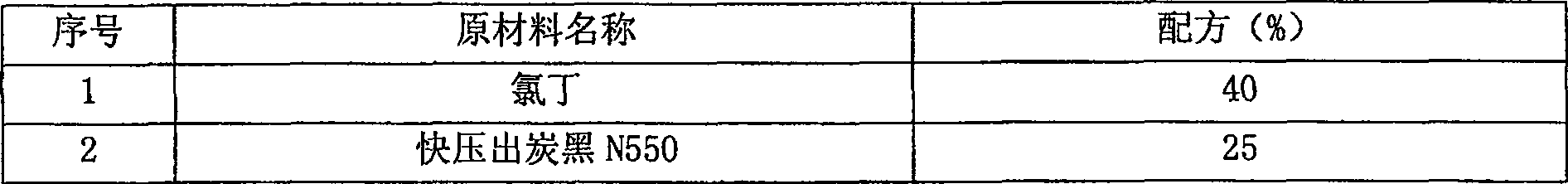

Fluororubber and epichlorophdrin rubber formulation

ActiveCN101081916AHigh electronegativityGood fuel resistanceSynthetic resin layered productsPolymer scienceLead(II,IV) oxide

The present invention is one kind of rubber pipe comprising one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber. The fluororubber consists of polyfluoroprene, thermal black N990, 2, 5-dimethyl-2, 5-dihexane, triallyl cyanourate and carnauba wax; and the chlorohydrin rubber consists of chlorohydrin rubber C, chlorohydrin rubber H, black N550, anti-ager NBC, processing aid R-300, stearic acid, plasticizer RS-107, red lead, ethylene thiourea NA-22, plasticizer W-305ELS and scorch retarder CTP-80. The rubber pipe with one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber has high heat resistance, high oil tolerance, high ozone tolerance and high fuel oil osmosis resistance.

Owner:TIANJIN PENGYI GRP CO LTD

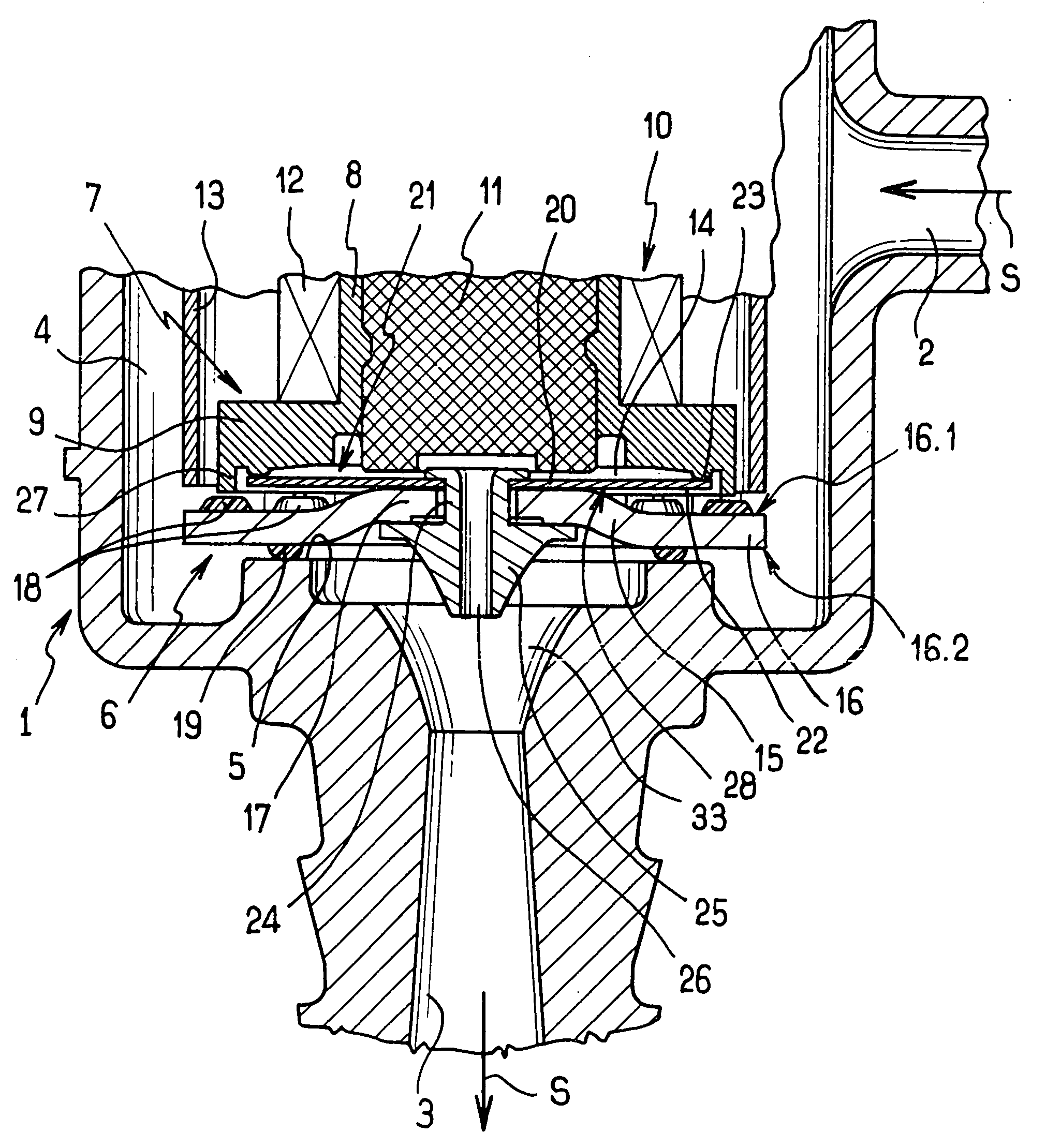

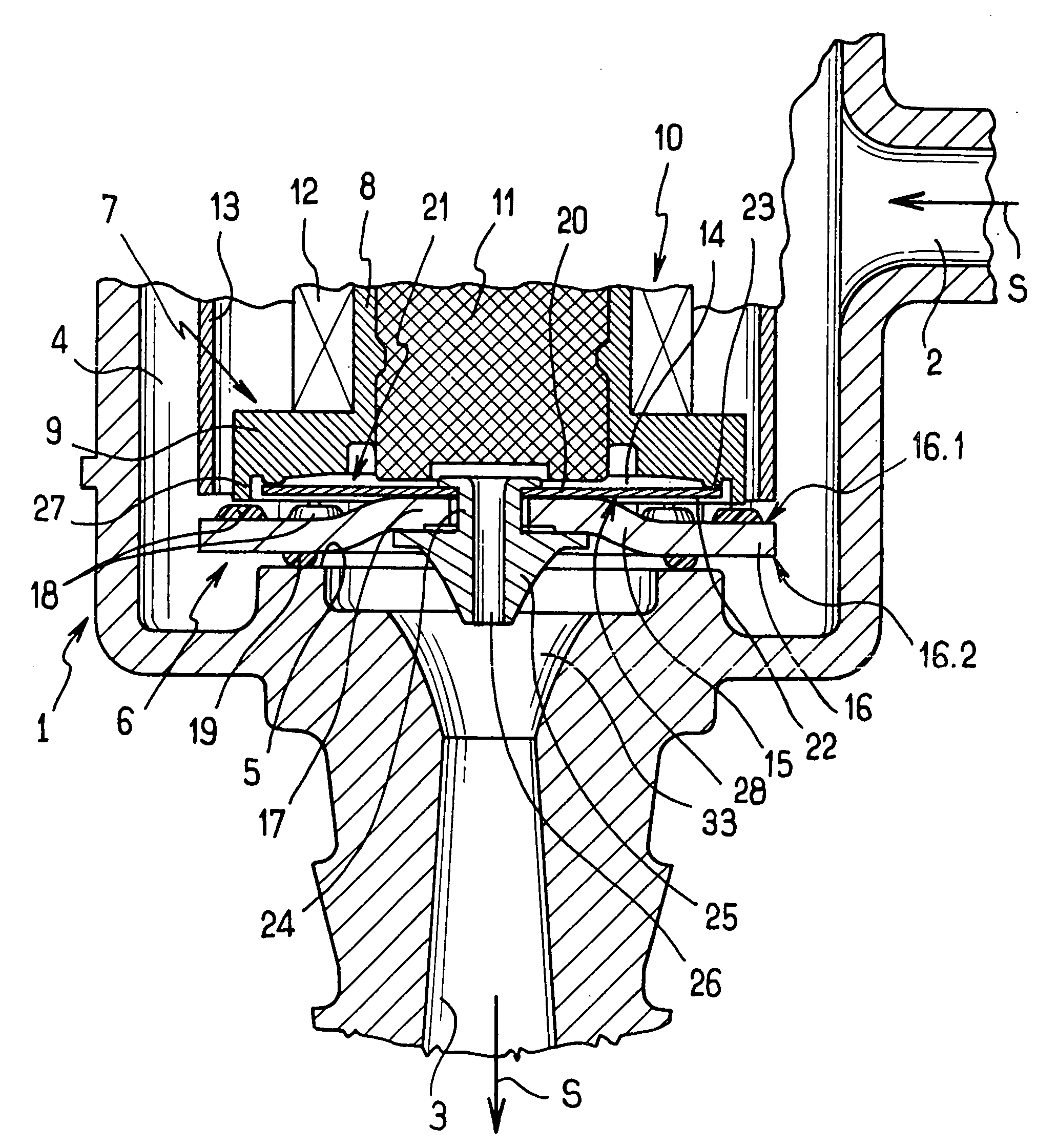

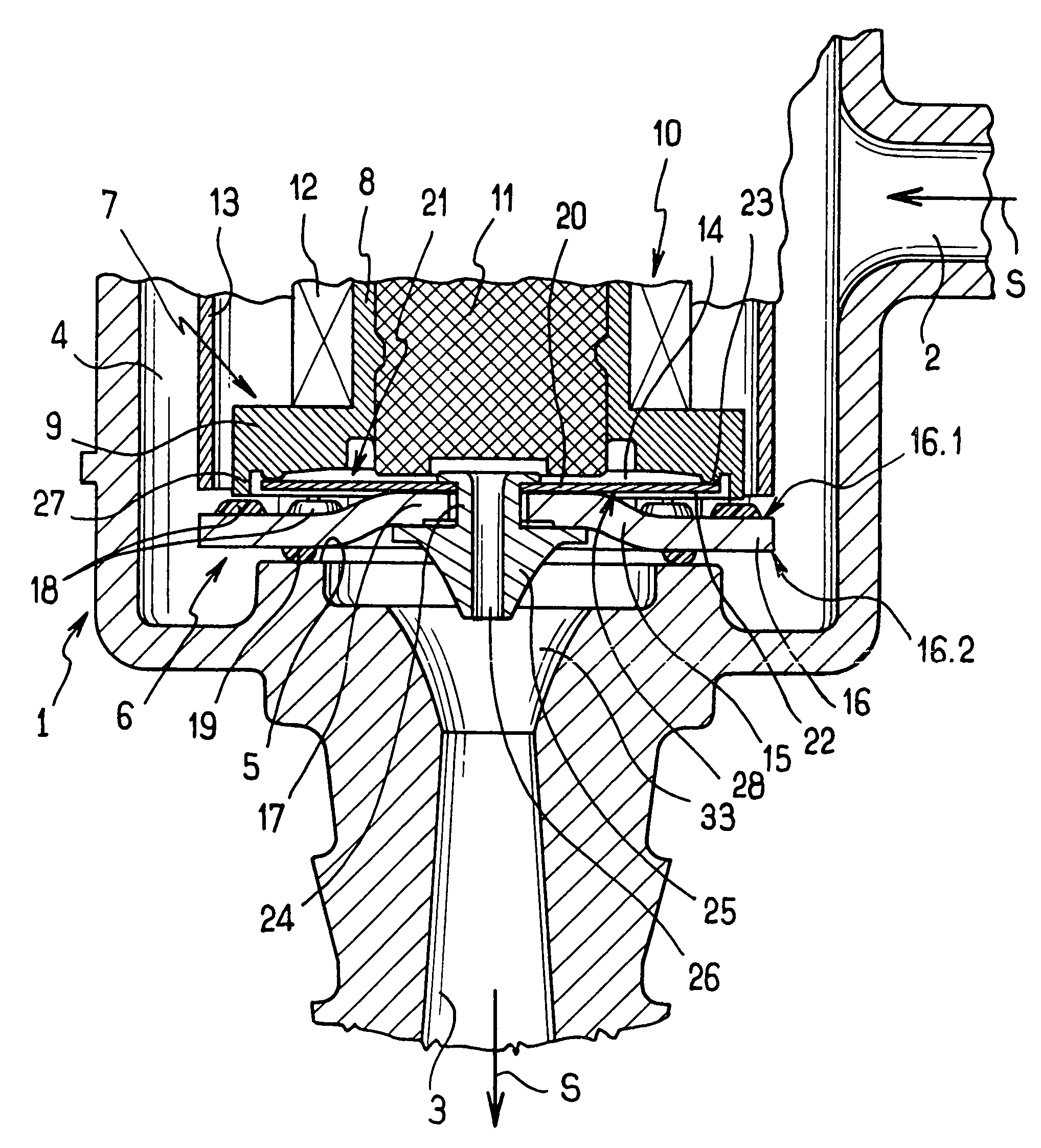

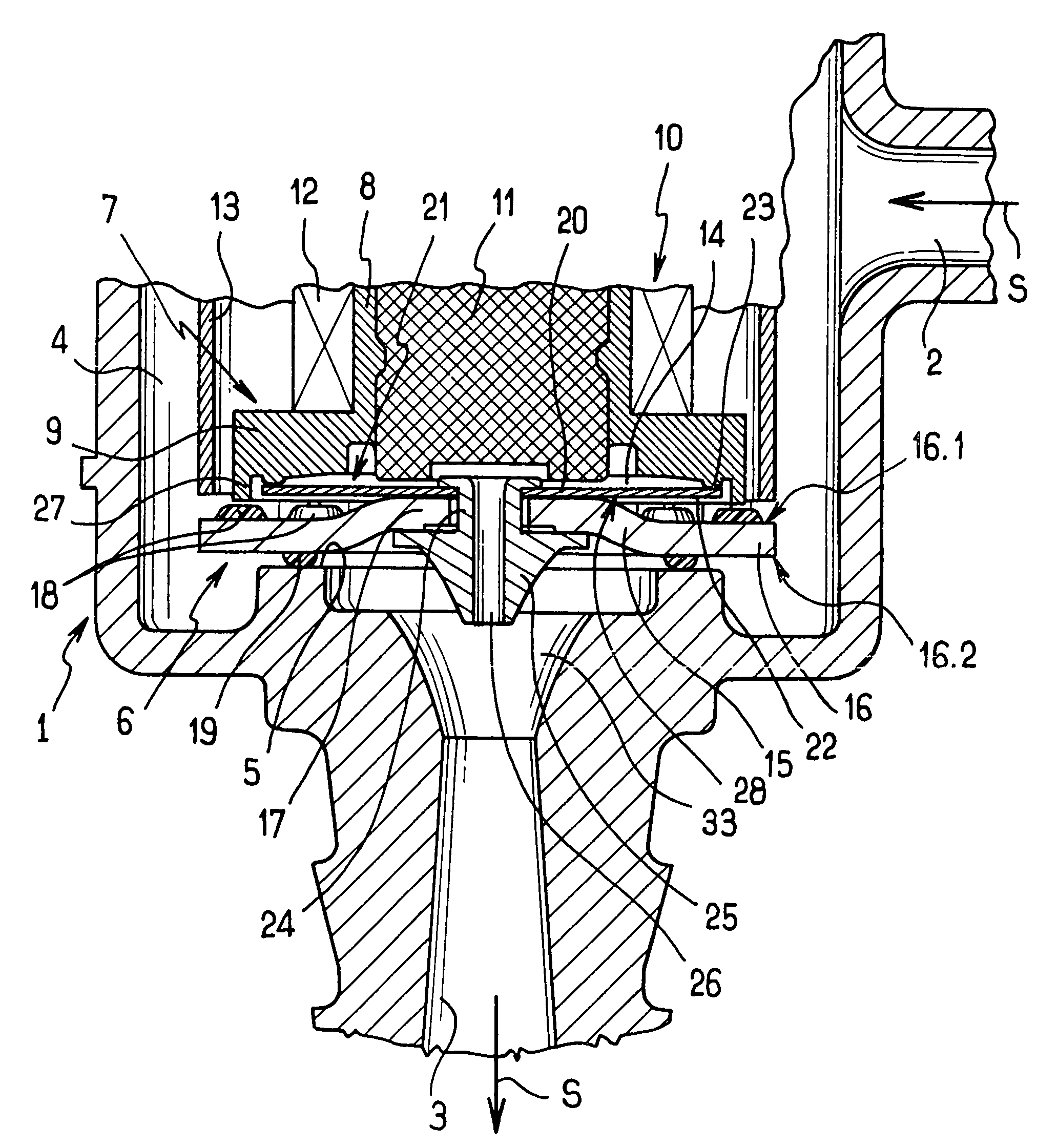

Valve Incorporating Means for Balancing Pressures on Either Side of a Valve Member

InactiveUS20080116409A1Sacrificing effectivenessCompact structureOperating means/releasing devices for valvesNon-fuel substance addition to fuelVALVE PORTActuator

The disclosure relates to a valve comprising a body defining at least an admission duct and an outlet duct for a fluid and receiving a valve member that is movable by means of an actuator member fastened to the body to move between a closed position closing the outlet duct and an open position leaving it open, the valve member having a central portion secured to a central portion of a substantially plane diaphragm that has a peripheral portion associated in leaktight manner with a support element secured to the body in such a manner as to co-operate with the support element to define a chamber, the valve member and the diaphragm being pierced by an opening providing permanent communication between the chamber and the outlet duct, the diaphragm being elastically deformable and being dimensioned to urge the valve member into its closed position.

Owner:VALEO SYST DE CONTROLE MOTEUR

Hydrogenated NBR Composition

InactiveUS20090062445A1Good oil resistanceHeat resistance is deterioratedEmulsion paintsPlasticizerHeat resistance

A hydrogenated NBR composition, which comprises 100 parts by weight of a hydrogenated NBR having an acrylonitrile content of 25-44% by weight and an iodine number of 32-65, or a blend of the hydrogenated NBRs themselves, 2-23 parts by weight of an ester-based plasticizer, and 0.5-10 parts by weight of an organic peroxide, and preferably further contains 0.5-10 parts by weight of a polyfunctional unsaturated compound, can give molding products having distinguished oil resistance and fuel oil resistance as well as distinguished heat resistance and cold resistance, and thus can be used as suitable molding materials for intake manifold gaskets of automobile engines.

Owner:NOK CORP

Valve incorporating means for balancing pressures on either side of a valve member

InactiveUS8308130B2Compact structureSuppress noiseOperating means/releasing devices for valvesNon-fuel substance addition to fuelActuator

The disclosure relates to a valve comprising a body defining at least an admission duct and an outlet duct for a fluid and receiving a valve member that is movable by means of an actuator member fastened to the body to move between a closed position closing the outlet duct and an open position leaving it open, the valve member having a central portion secured to a central portion of a substantially plane diaphragm that has a peripheral portion associated in leaktight manner with a support element secured to the body in such a manner as to co-operate with the support element to define a chamber, the valve member and the diaphragm being pierced by an opening providing permanent communication between the chamber and the outlet duct, the diaphragm being elastically deformable and being dimensioned to urge the valve member into its closed position.

Owner:VALEO SYST DE CONTROLE MOTEUR

Special rubber alloy elastomer for sealing members and preparation method thereof

The invention discloses a special rubber alloy elastomer for sealing members and a preparation method thereof. The special rubber alloy elastomer comprises the following raw materials in parts by weight: 40 to 60 parts of raw rubber of fluororubber, 5 to 20 parts of raw rubber of hydrogenated butadiene-acrylonitrile rubber, 5.01 to 50 parts of filling reinforcing agent, 0.3 to 2 parts of polyperfluoro isopropyl ether oil, 1 to 3 parts of zinc oxide, 0.6 to 1.4 parts of organic peroxides, 0.5 to 2.5 parts of triallyl isocyanurate, and 0.5 to 1 part of lubricant. During the preparation process, technologies of synthetic rubber preparation, moulding and vulcanization of rubber, post treatment, and examination are adopted, and the obtained special rubber alloy elastomer for sealing members has an excellent performance on resisting high temperature, low temperature, low pressure change, fuel oil, engine oil, acids, alkalines, and mixed oil gas, and has a long service life.

Owner:ANHUI ZHONGDING SEALING PARTS

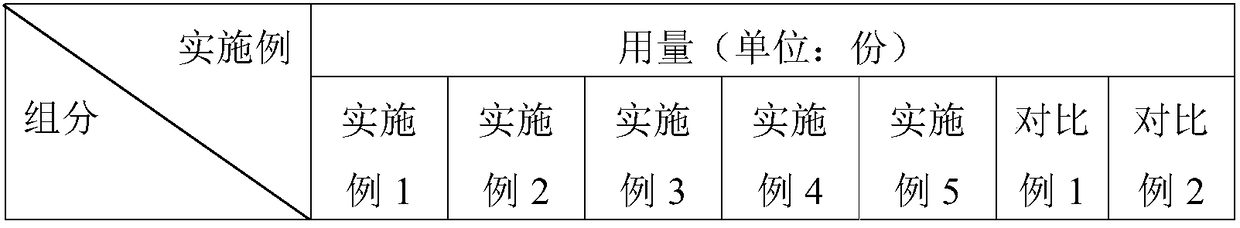

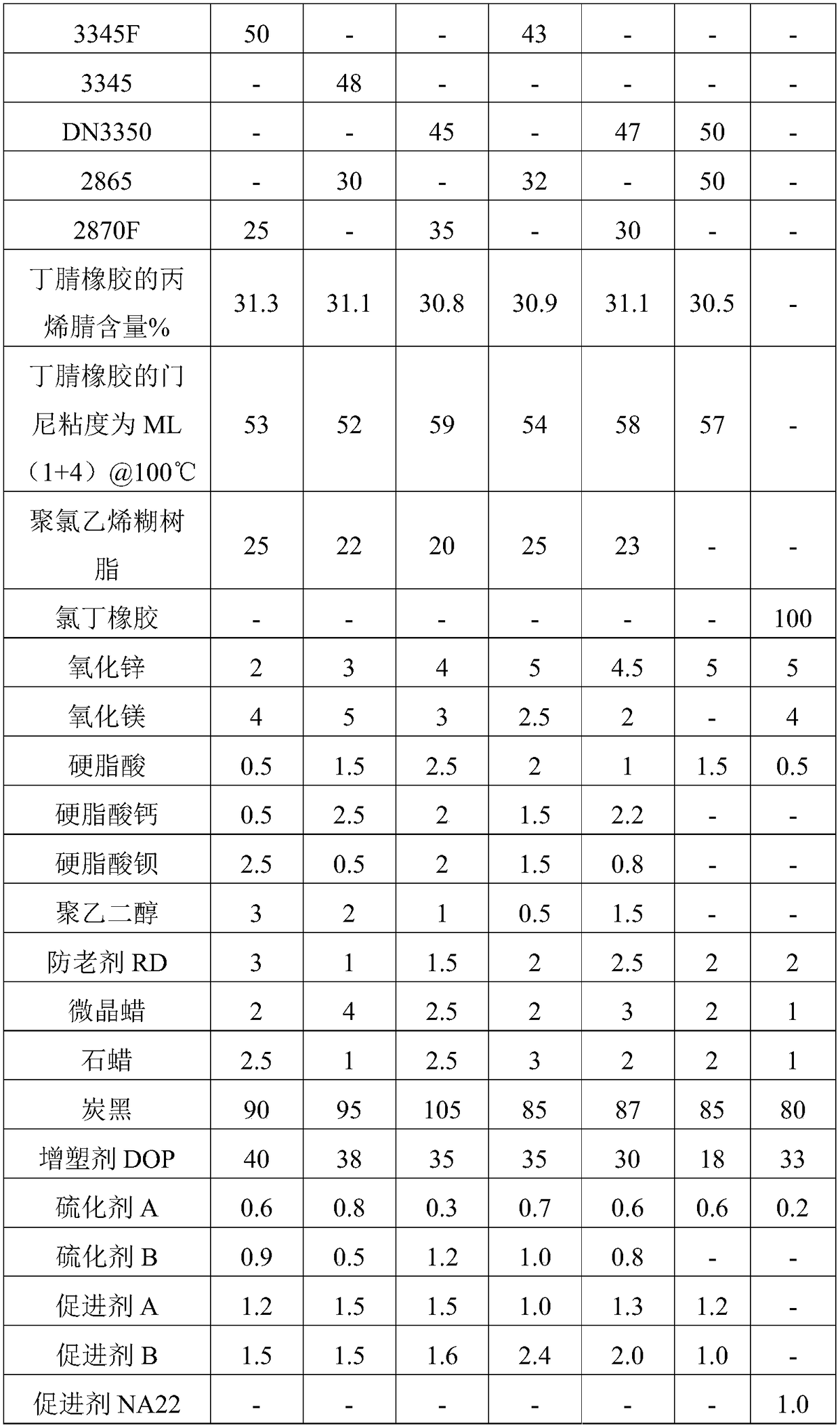

NBR-PVC (nitrile butadiene rubber-polyvinyl chloride) blended rubber-plastic alloy material, preparation method and application

The invention discloses an NBR-PVC (nitrile butadiene rubber-polyvinyl chloride) blended rubber-plastic alloy material, a preparation method and an application. The NBR-PVC blended rubber-plastic alloy material is prepared from raw materials in parts by weight as follows: 75-80 parts of NBR, 20-25 parts of PVC paste resin, 4-10 parts of an activator A, 0.5-2.5 parts of an activator B, 1-5 parts ofa heat stabilizer, 1-3 parts of an anti-ageing agent RD, 3-6.5 parts of protective wax, 85-105 parts of carbon black, 30-40 parts of a plasticizer, 0.3-0.8 parts of a vulcanizing agent A, 0.5-1.2 parts of a vulcanizing agent B, 0.9-1.5 parts of an accelerator A and 1.5-2.5 parts of an accelerator B. The preparation method is simple, lower in cost and suitable for industrial production; the obtained product has excellent comprehensive performance and wide working temperature range, is resistant to fuel, lubricating oil and ozone and good in mixing dispersity and can be widely applied to materials of gas inlet hoses of engines.

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

Fluorine-silicon sealant for fuel oil-resisting solvent part and preparation method for fluorine-silicon sealant

InactiveCN105086473ASolve processing problemsGood fuel resistanceOther chemical processesCross-linkFuel oil

The invention discloses a fluorine-silicon sealant for a fuel oil-resisting solvent part. The fluorine-silicon sealant is characterized by comprising the following components in parts by weight: 100 parts of hydroxyl end-capping fluorinated silicone rubber, 5-20 parts of white carbon black, 0-100 parts of nano calcium carbonate, 10-20 parts of a cross-linking agent, 1-5 parts of an accelerant, and 0.2-0.5 part of a curing agent. A preparation method for the sealant is characterized by comprising: preparing a base stock: adding the hydroxyl end-capping fluorinated silicone rubber, the white carbon black and the active nano calcium carbonate according to a formula, and stirring the mixture for one hour at a high speed in vacuum; preparing an auxiliary agent: uniformly mixing the tetraethylortho silicate, the accelerant and the catalyst according to the formula; and in use, adding 1 part of the auxiliary agent into 10 parts of the base stock, and uniformly stirring the mixture in vacuum to obtain the sealant. The product has good fuel oil resistance and excellent mechanical properties.

Owner:SUZHOU DATONG ADVANCED MATERIAL

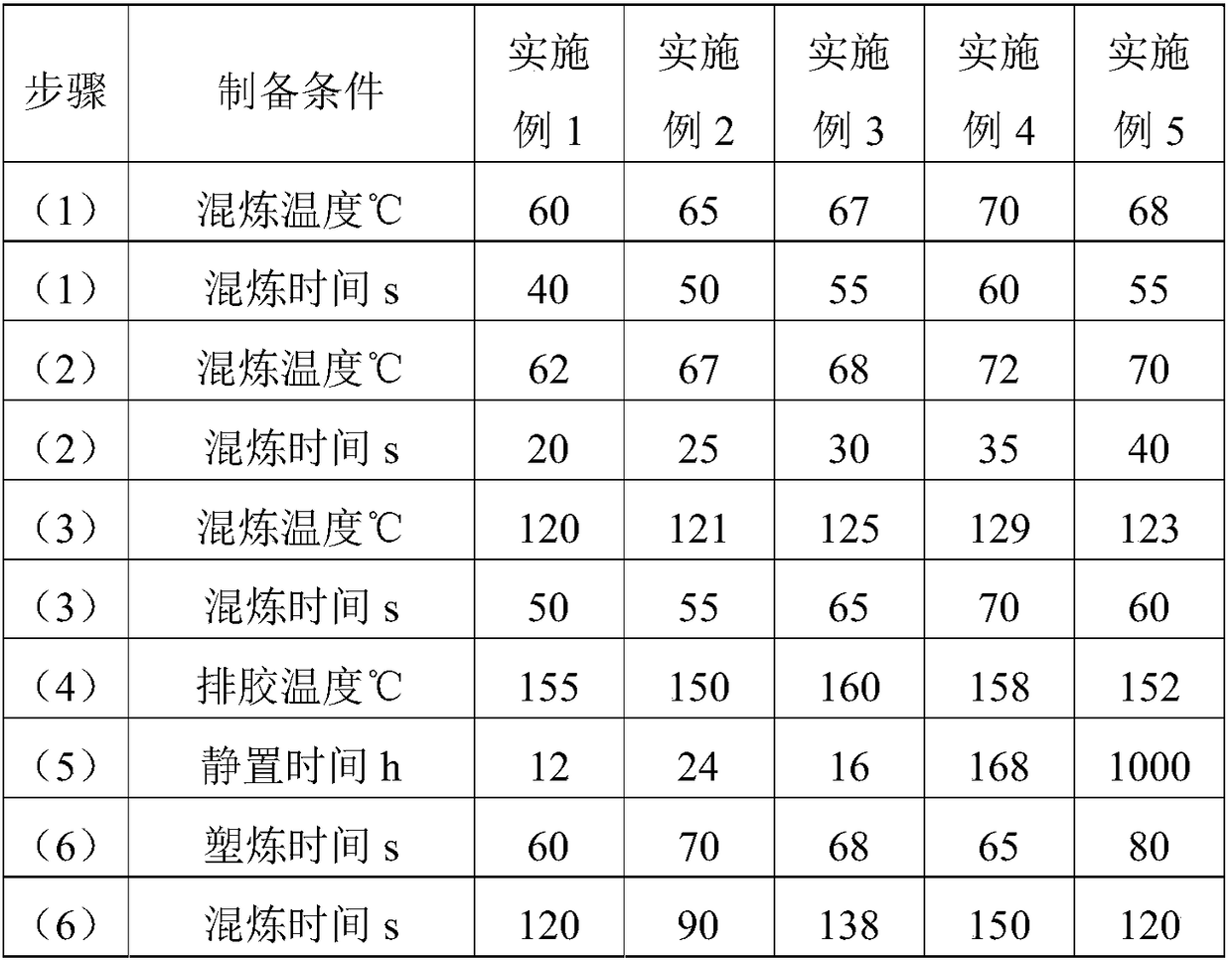

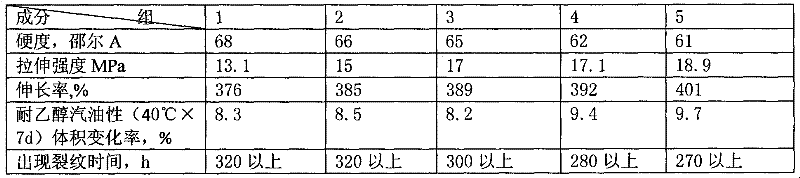

Rubber alloy material of ethanol-resisting gasoline diaphragm of fuel pressure regulator and preparation method of rubber alloy material

The invention provides a rubber alloy material of an ethanol-resisting gasoline diaphragm of a fuel pressure regulator and relates to a preparation method of the rubber alloy material of the ethanol-resisting gasoline diaphragm of the car fuel pressure regulator, which overcome the defects that the diaphragm which is used by the existing car fuel system regulator and takes butadiene-acrylonitrile rubber as a main material does not resist an ethanol solvent, and the cold resistance and the ozone aging resistance of the diaphragm are poor. The rubber alloy material is prepared from the butadiene-acrylonitrile rubber and chlorine ether rubber in an alloying way. The rubber alloy material is composed of the butadiene-acrylonitrile rubber, the chlorine ether rubber, a filling reinforcing agent, a vulcanizing system, a protection system, an activating agent and a plasticizer. The preparation method of the rubber alloy material comprises the following steps of: (1) plastifying; (2) mixing; and (3) vulcanizing and molding. The rubber alloy material of the ethanol-resisting gasoline diaphragm of the fuel pressure regulator, provided by the invention, has excellent oil resistance and solvent resistance and also has the cold resistance and the ozone aging resistance. The preparation method of the rubber alloy material has the advantages of simplicity, easiness in operation and less equipment investment.

Owner:HEILONGJIANG INST OF TECH

Hydrogenated NBR composition

ActiveUS7847008B2Meet cost performance requirementsGood oil resistanceSpecial tyresCross-linkAcrylonitrile

A hydrogenated NBR composition, which comprises 100 parts by weight of a blend of a hydrogenated NBR having an acrylonitrile content of 25-44% by weight and an iodine number of 32-65, with such an amount of an NBR as to make the iodine number of the blend of 40-160, 2-23 parts by weight of an ester-based plasticizer, and 0.5-10 parts by weight of an organic peroxide, preferably which further contains 0.5-10 parts by weight of a polyfunctional, unsaturated compound, has a distinguished cost performance because of blending an expensive hydrogenated NBR with a cheap NBR, can give cross-linked products having a distinguished oil resistance (resistance to such oil as No. 3 oil and other general-purpose, commercially available engine oil, etc.) and a distinguished fuel oil resistance (resistance to such fuel oil as fuel oil C, and other general-purpose, commercially available gasoline, etc.) and thus can serve as suitable molding materials for intake manifold gaskets of automobile engine or automobile sealing parts, particularly sealing parts around engines and transmission systems.

Owner:NOK CORP

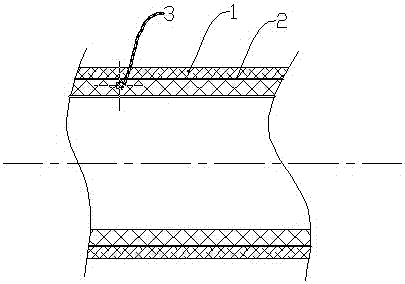

Fuel-resistant anti-static oil delivery pipe

The invention relates to an oil delivery pipe structure containing high polymer materials, in particular to a fuel-resistant anti-static oil delivery pipe. A pipeline of the fuel-resistant anti-static oil delivery pipe is divided into three layers sequentially including a reinforced layer, an adhesive layer and a fuel-resistant anti-static layer from outside to inside; the reinforced layer is a high polymer material, and the fuel-resistant anti-static layer is a fuel-resistant anti-static high polymer material. The fuel-resistant anti-static oil delivery pipe disclosed by the invention has fuel-resistant and anti-static functions, and is simple in manufacturing process.

Owner:江苏法利沃环保科技有限公司

Hydrogenated NBR Composition

InactiveUS20090062444A1Good fuel resistanceHeat resistance is deterioratedOther chemical processesPlasticizerHeat resistance

A hydrogenated NBR composition, which comprises a 100 parts by weight of hydrogenated NBR having an acrylonitrile content of 25-45% by weight and an iodine number of 20-65, or a blend of the hydrogenated NBRs themselves, 10-70 parts by weight of furnace black having a nitrogen adsorbable specific surface area of 30-130 (×103 m2 / kg), 10-80 parts by weight of thermal black having a nitrogen adsorbable specific surface area of 5-15 (×103 m2 / kg), 2-23 parts by weight of an ester-based plasticizer, and 0.5-10 parts by weight of an organic peroxide, and preferably further contains 0.5-10 parts by weight of a polyfunctional unsaturated compound, can give molding products having distinguished oil resistance and fuel oil resistance as well as distinguished heat resistance and cold resistance, even if a hydrogenated NBR having an iodine number of 20 to less than 32, and thus can be used as suitable molding materials for intake manifold gaskets of automobile engines.

Owner:NOK CORP

Automobile fuel hose cover rubber and preparation method thereof

The invention discloses an automobile fuel hose cover rubber and a preparation method thereof, belonging to the technical field of automobile hoses. The automobile fuel hose cover rubber is prepared from the following raw materials in parts by weight: 100 parts of ethylene-acrylate rubber, 20-30 parts of quick-extrusion carbon black, 10-15 parts of cracking-process carbon black, 8-12 parts of talcum powder, 1-5 parts of magnesium oxide, 5-8 parts of stearic acid, 2-4 parts of polyamide, 3-5 parts of ethylenediamine, 0.5-0.8 part of trithiocyanuric acid and 5-10 parts of calcium hydroxide. Compared with the prior art, the automobile fuel hose cover rubber disclosed by the invention has the advantages of favorable high-temperature resistance, favorable aging resistance, favorable fuel resistance and low fuel permeability.

Owner:柳州市中橡科技有限公司

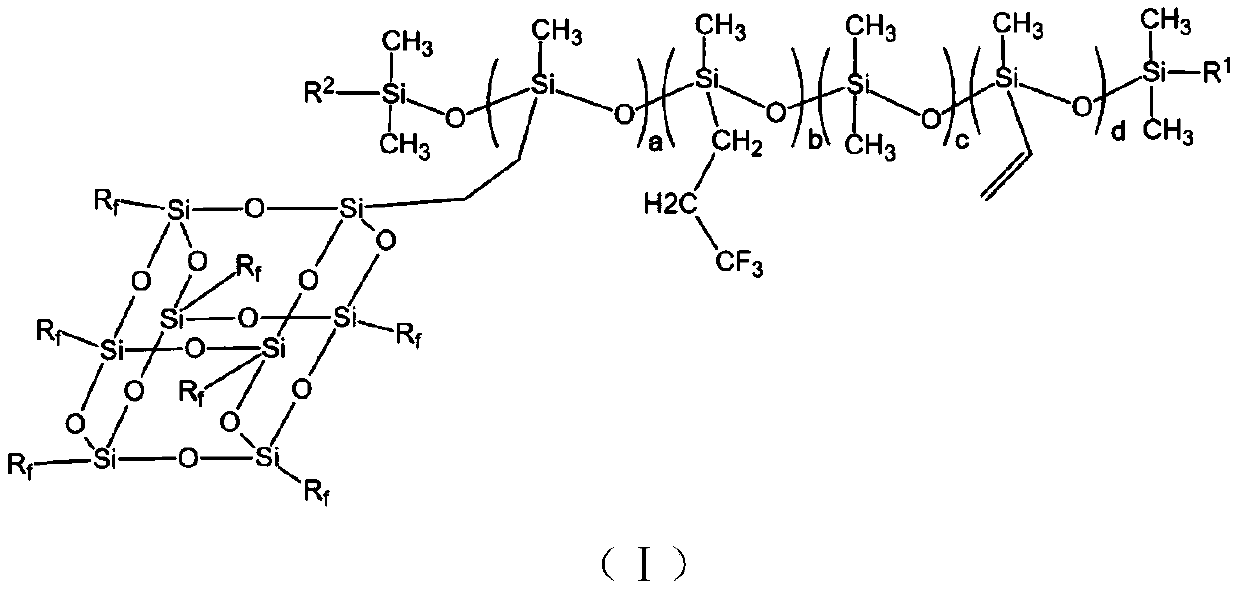

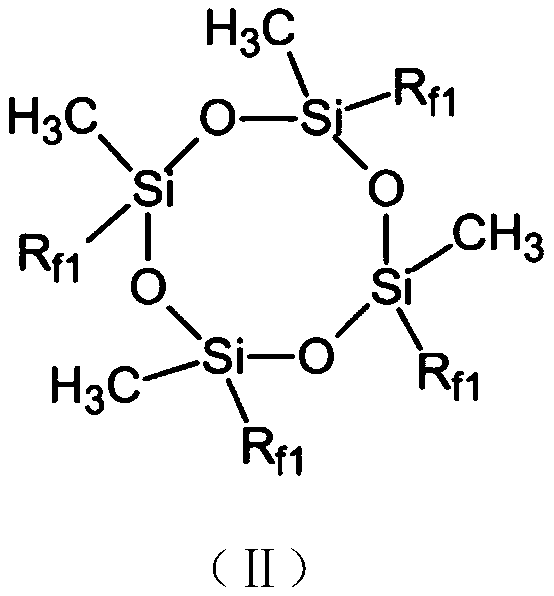

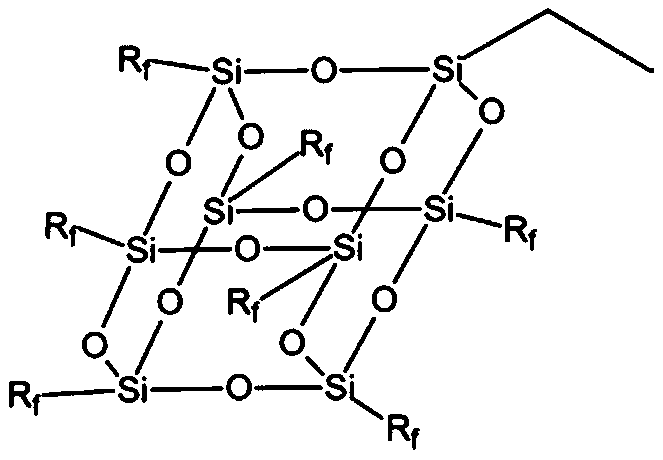

High-strength copolymerized fluorinated silicone rubber composition and preparation method thereof

The invention relates to the technical field of rubber, specifically to a high-strength copolymerized fluorinated silicone rubber composition and a preparation method thereof. The fluorosilicone rubber composition comprises, in parts by weight, 100 parts of raw copolymerized fluorinated silicone rubber, 30 to 70 parts of fumed silica, 4 to 12 parts of hydroxyl fluorosilicone oil with a viscosityof 90 to 120 mPa.s (at 25 DEG C), 0 to 10 parts of high-vinyl fluorosilicone oil, 1 to 2 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane and 0 to 2 parts of pigment, wherein the side chain of a polymer chain of the raw copolymerized fluorinated silicone rubber contains trifluoropropyl polyhedral oligomeric silsesquioxane. The high-strength copolymerized fluorinated silicone rubber compositiondisclosed by the invention has better mechanical strength and improved high-temperature resistance after being vulcanized; and the fuel oil resistance of the composition can be obviously improved byintroducing a small amount of trifluoropropyl polyhedral oligomeric silsesquioxane, and the comprehensive performance of the composition is better.

Owner:深圳市森薄材料科技有限公司

Synthesis method of 2-hydroxyl-3-chloropropyl-2'-chloroethyl ether, and application thereof

ActiveCN102757314AGood mechanicsGood fuel resistanceEther preparation from oxiranesPolysulfide rubberSynthesis methods

The invention provides a synthesis method of 2-hydroxyl-3-chloropropyl-2'-chloroethyl ether, and an application thereof. The method comprises the steps of: firstly, mixing 2-chlorohydrin and a catalyst, and heating up to be at 45 DEG C; maintaining the temperature of 45 DEG C, and slowly dripping epoxy chloropropane into the mixture within 1-1.5 hours; then, controlling the reaction temperature to be within the range of 45-80 DEG C and the reaction time to be within the range of 3-5 hours, wherein the molar ratio between the 2-chlorohydrin and the epoxy chloropropane is 1.5-5.0, and the mass fraction of the catalyst accounts 0.2-1.5% of that of the epoxy chloropropane; and finally, carrying out vacuum distillation on reaction liquid, and collecting fraction under 1.33kPa at 114-117 DEG C. The 2-hydroxyl-3-chloropropyl-2'-chloroethyl ether synthesized by using the method can be taken as a comonomer for preparing polysulfide rubber, and the prepared polysulfide rubber has relatively good mechanical property and fuel resistance.

Owner:锦西化工研究院有限公司

Hydrogenated NBR composition

A hydrogenated NBR composition, which comprises 100 parts by weight of a hydrogenated NBR having an acrylonitrile content of 25-44% by weight and an iodine number of 32-65, or a blend of the hydrogenated NBRs themselves, 2-23 parts by weight of an ester-based plasticizer, and 0.5-10 parts by weight of an organic peroxide, and preferably further contains 0.5-10 parts by weight of a polyfunctional unsaturated compound, can give molding products having distinguished oil resistance and fuel oil resistance as well as distinguished heat resistance and cold resistance, and thus can be used as suitable molding materials for intake manifold gaskets of automobile engines.

Owner:NOK CORP

Fluorine-containing elastomer composition and molded article made of same

ActiveUS8481140B2Good fuel resistanceIncrease speedClosuresOther chemical processesPolyolFluorine containing

Owner:DAIKIN IND LTD

Food-grade polyvinyl chloride film and calendaring process thereof

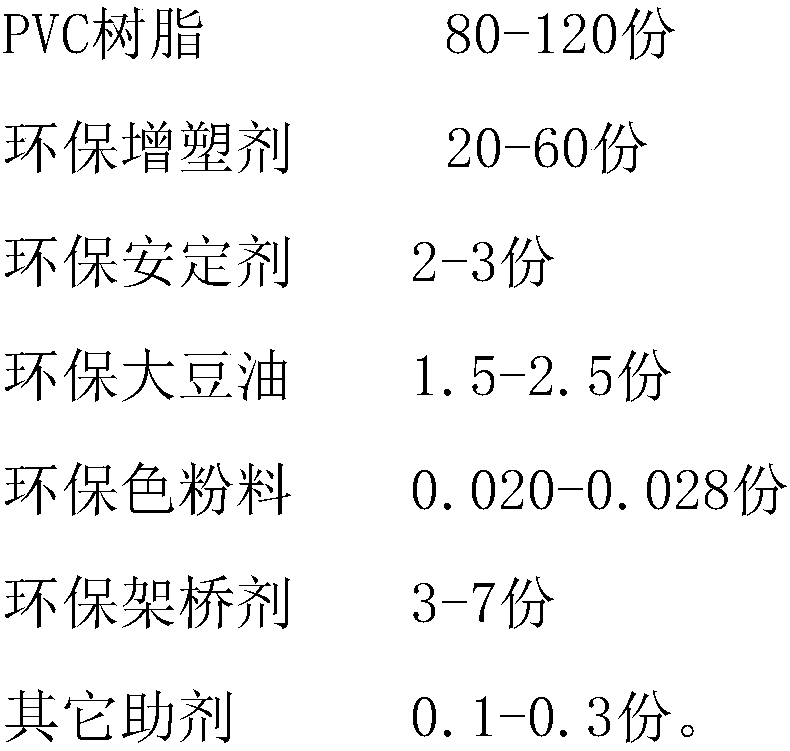

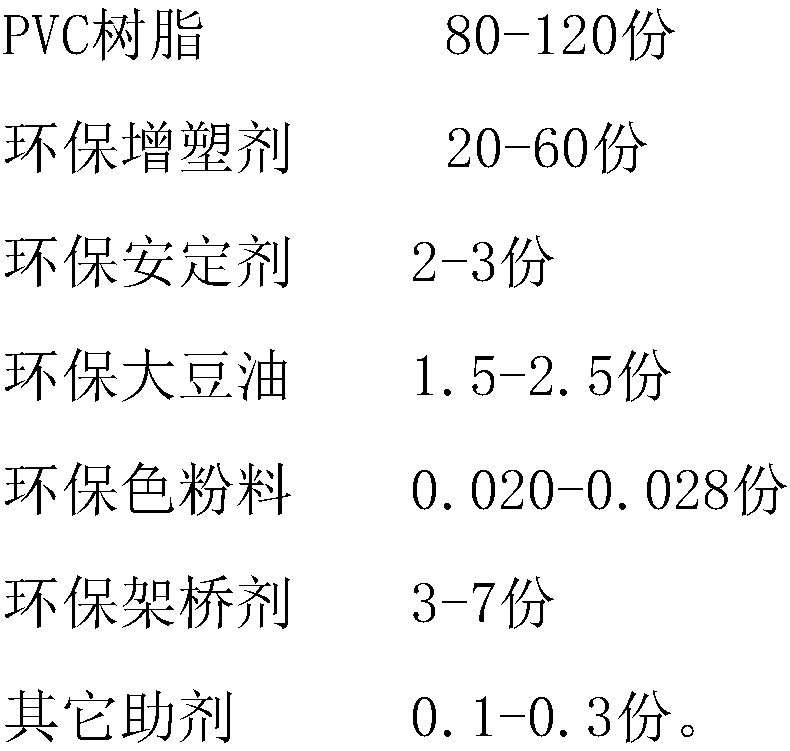

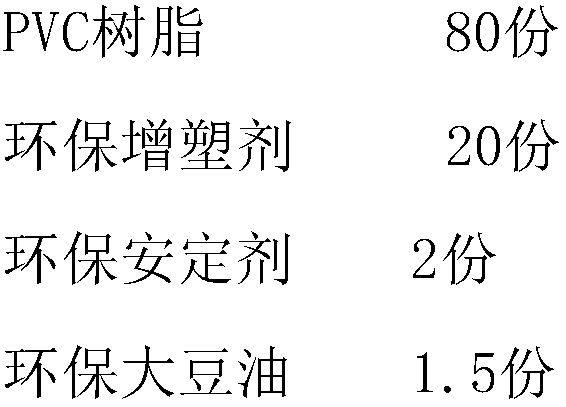

InactiveCN107698891AFeel goodImprove visual effectsFlat articlesEnvironmental resistancePolyvinyl chloride

The invention relates to the technical field of films, in particular to a food-grade polyvinyl chloride film and a calendaring process thereof. The food-grade polyvinyl chloride film is prepared from,by weight, 80-120 parts of PVC (polyvinyl chloride) resin, 20-60 parts of an environment-friendly plasticizer, 2-3 parts of an environment-friendly stabilizing agent, 1.5-2.5 parts of environment-friendly soybean oil, 0.020-0.028 part of environment-friendly toner, 3-7 parts of an environment-friendly bridging agent and 0.1-0.3 part of other additives. The food-grade polyvinyl chloride film is environmentally friendly, great in handfeel and visual effects and excellent in ultraviolet resistance and water resistance and has advantages of flame retardation, insulation, alkali and acid resistance, cold and mould proofing, corrosion resistance, static resistance, tensile resistance, aging resistance and the like, thereby being excellent in comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Preparation method of outer-layer rubber of automobile fuel rubber hose

The invention discloses a preparation method of outer-layer rubber of an automobile fuel rubber hose, belonging to the technical field of automobile rubber hoses. The preparation method comprises the steps of firstly, placing the prepared raw materials into an open mill to mix and synthesize rubber, and then, extruding at the pressure of 0.6-0.8MPa and the temperature of 55-60 DEG C for 15-20 minutes; after ending the extruding operation, placing the rubber into an extruder, and extruding the rubber out of the extruder at a certain temperature to obtain an outer-layer rubber hose blank; and placing the prepared outer-layer rubber hose blank into vulcanization equipment to carry out vulcanization treatment at the pressure of 205-210Kgf / cm<2> and the temperature of 150-160 DEG C for 5-10 minutes. Compared with the outer-layer rubber of the automobile fuel rubber hose, which is prepared in the prior art, the outer-layer rubber of the automobile fuel rubber hose, prepared by using the preparation method disclosed by the invention, is good in high temperature resistance, ageing resistance and fuel resistance and low in fuel permeability.

Owner:广西颖航科技有限公司

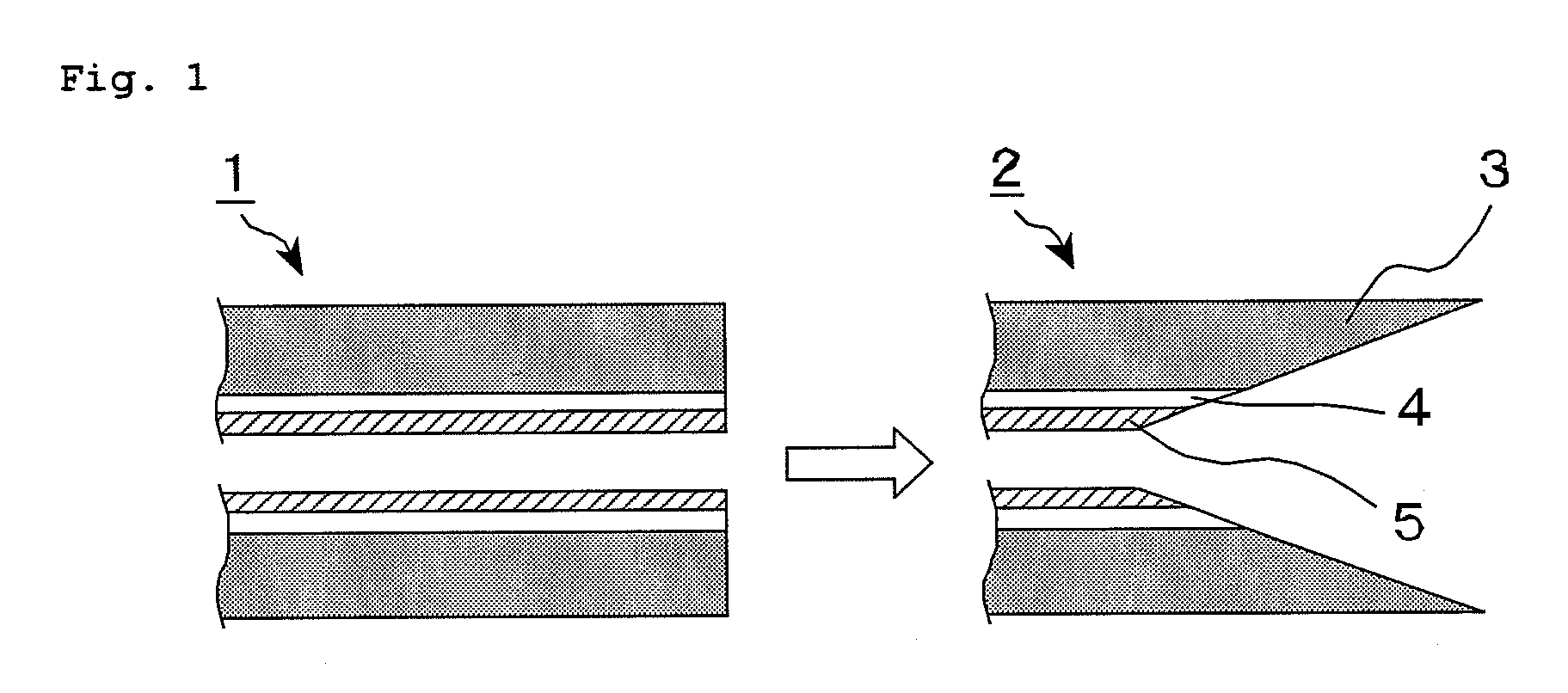

Blow molded body

ActiveUS20100075089A1Good chemical resistanceGood fuel resistanceBottlesSynthetic resin layered productsPolymer sciencePolyolefin

The present invention provides a hollow molded article which is excellent in chemical resistance, fuel resistance, weathering resistance and low fuel permeability and can be produced at low cost.The hollow molded article comprising a polyolefin resin-based layer (A), a modified polyolefin resin-based layer (B) and a fluororesin-based layer (C), wherein the fluororesin-based layer (C) constitutes at least one of the innermost and outermost layers.

Owner:DAIKIN IND LTD

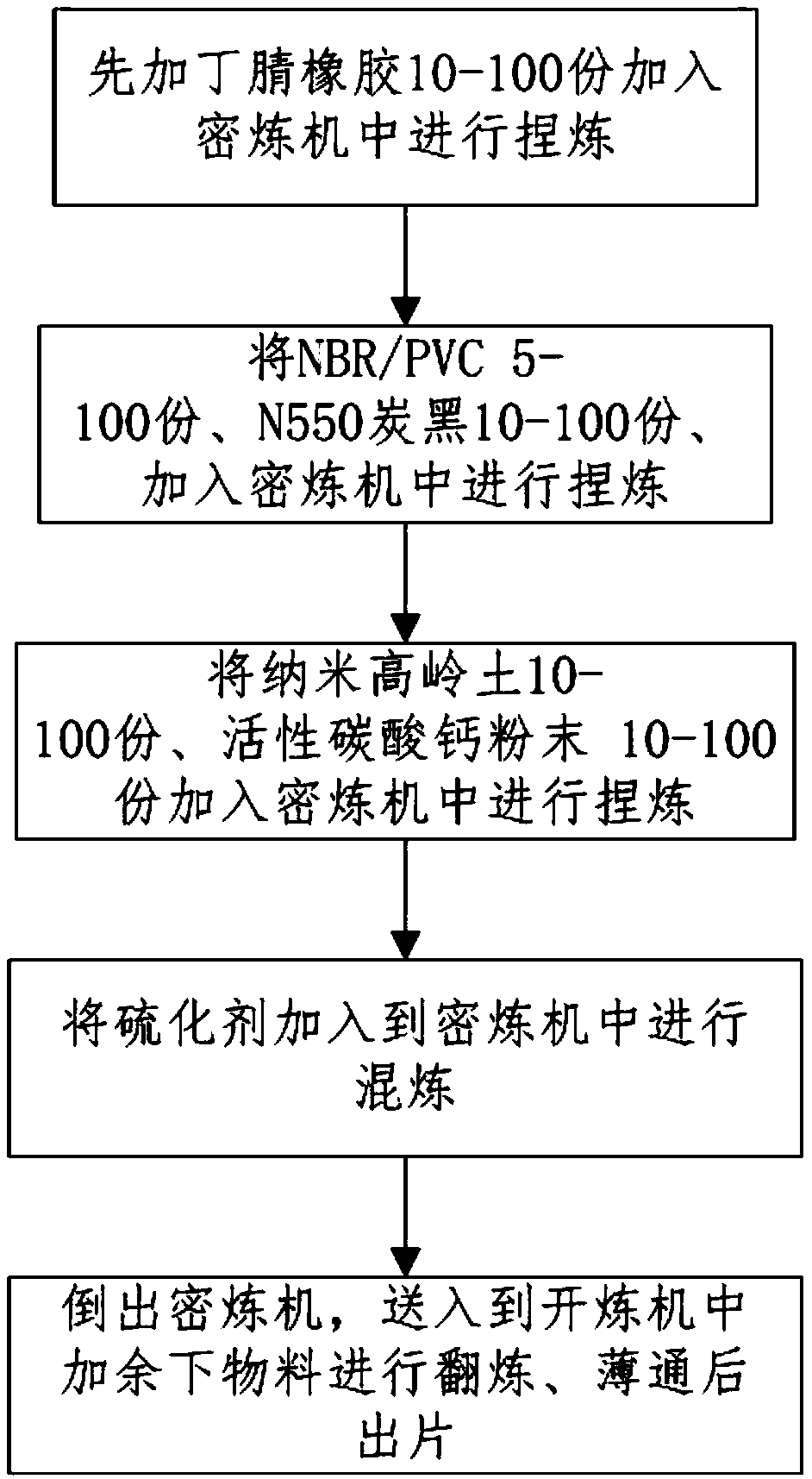

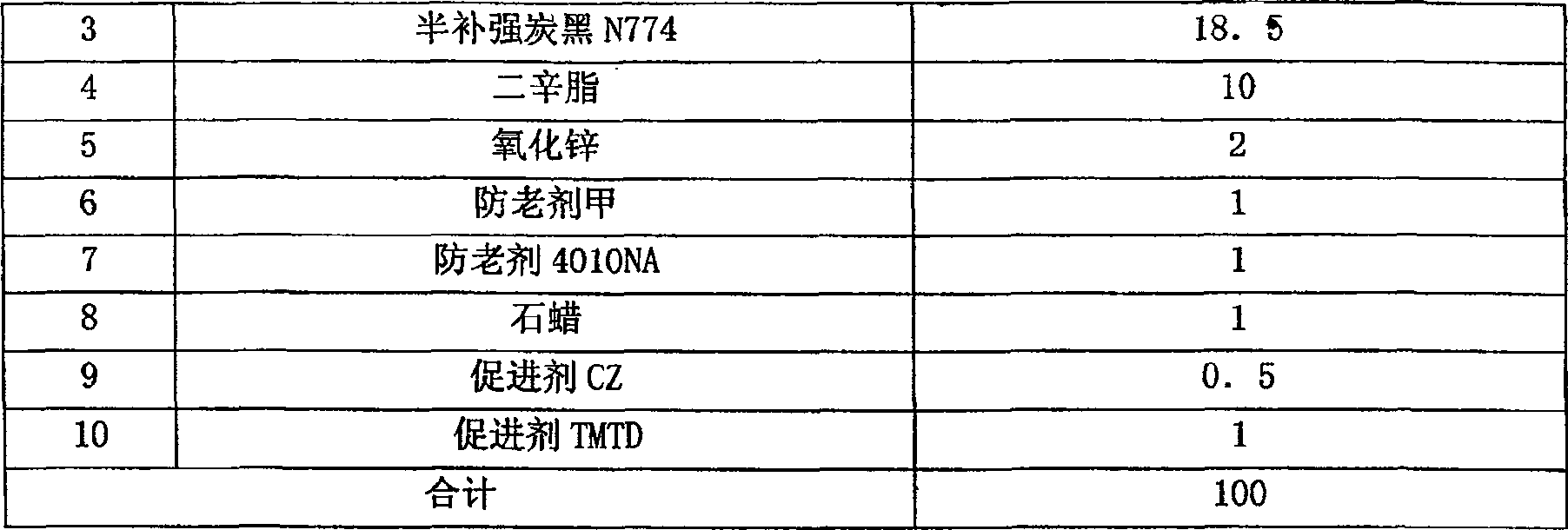

Dustproof cover of charge port of new energy vehicle and preparation method thereof

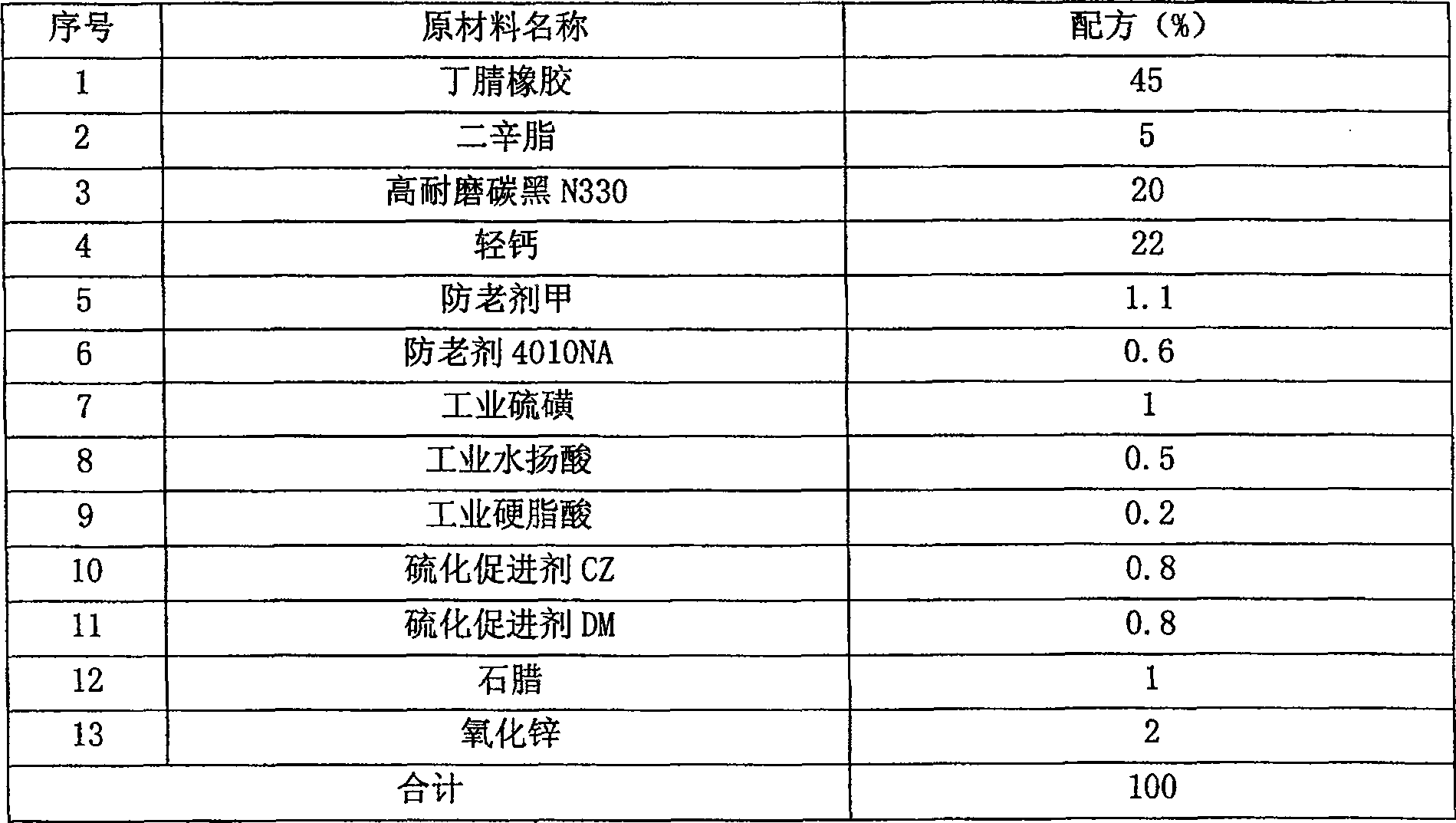

InactiveCN109400984AGood breakdown voltage performanceGood fuel resistanceWeather resistanceDioctyl terephthalate

The invention relates to a dustproof cover of a charge port of a new energy vehicle and a preparation method thereof. The dustproof cover is prepared from, by weight, 10-100 parts of nitrile butadienerubber, 5-100 parts of blend nitrile butadiene rubber / polyvinyl chloride, 10-100 parts of N550 carbon black, 10-100 parts of nano-kaolin, 10-100 parts of active CaCO3 powder, 1-50 parts of dioctyl terephthalate, and 8-12 parts of a vulcanizer. The dustproof cover is excellent in dielectic breakdown voltage performance, has excellent weather resistance, anti-tearing effect and flame-retarding property, and has great rebound resilience.

Owner:ANHUI JINGHONG SEAL TECH

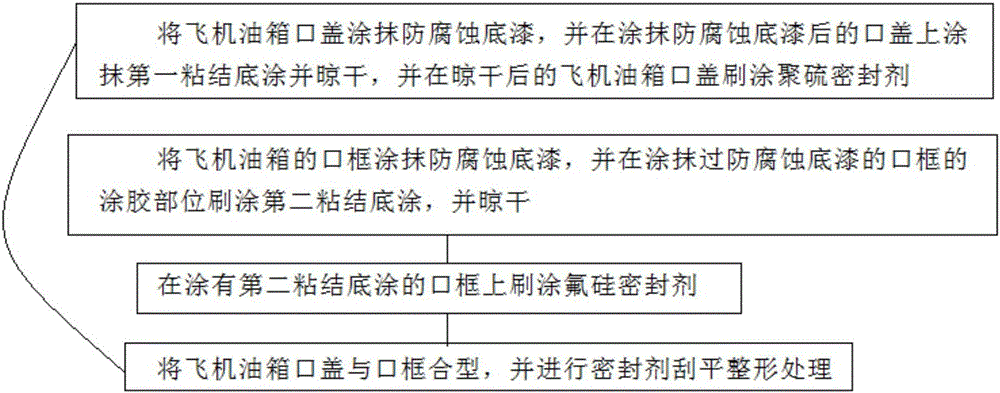

Airplane oil tank opening cap sealing method

InactiveCN106043717AImprove heat resistanceGood fuel resistanceEngine sealsPower plant fuel tanksJet aeroplaneFuel tank

The invention discloses an airplane oil tank opening cap sealing method. The airplane oil tank opening cap sealing method includes the steps that anticorrosive primer is smeared to an airplane oil tank opening cap, the opening cap smeared with the anticorrosive primer is smeared with first adhesive prime coat and aired, and the aired airplane oil tank opening cap is smeared with polysulfide sealant; an aluminum alloy opening frame of an airplane oil tank is smeared with the anticorrosive primer, and the gluing portion of the aluminum alloy opening frame smeared with the anticorrosive primer is painted with second adhesive prime coat and aired; the aluminum alloy opening frame painted with second adhesive prime coat is painted with fluorosilicone sealant; and the airplane oil tank opening cap and the aluminum alloy opening frame are combined, and sealant scraping and shaping treatment is conducted. By the adoption of the airplane oil tank opening cap sealing method, a manner that a polysulfide sealing layer and a fluorosilicone sealing layer are combined is adopted for connecting the opening cap with the opening frame, the manner has good high-temperature resistance, fuel oil resistance and low-temperature flexibility, and the opening cap can be used for a long time at the temperature from -55 DEG C to 180 DEG C.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Automobile fuel rubber pipe outer rubber and preparation method thereof

The invention discloses an automobile fuel rubber pipe outer rubber and a preparation method thereof, and relates to the rubber product technical field; the automobile fuel rubber pipe outer rubber is mainly prepared from natural latex, butadiene rubber, a garlic essential oil, stearic acid, an anti-aging agent RD, a coupling agent Si69, bisphenol A unsaturated polyester resin, diisooctyl succinate sodium sulfonate, zinc oxide, titanium carbide, waste molding sand, laterite, dioctyl phthalate, a silicon boride micro-powder, epoxidized soybean oil, a modified additive and the like. The automobile fuel rubber pipe outer rubber has good reinforcing performance; a prepared rubber pipe has the advantages of high strength, good resistance to impact toughness, difficult bubbling and deformation, good high-temperature resistance, good aging resistance, good fuel oil resistance and low fuel oil permeability; and with use of the modified additive, the rubber pipe performance is improved overall, and the service life of the rubber pipe is improved.

Owner:CHANGZHOU CHENGTIAN ELECTRONICS

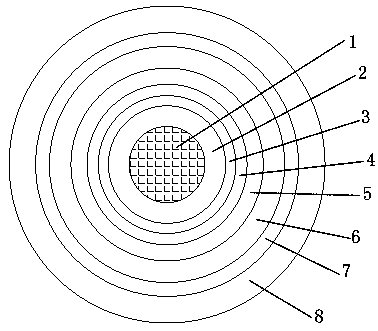

High flexibility tensile corrosion-resistant aluminum alloy aerial insulating cable

PendingCN107731376AAvoid partial dischargeImprove the effect of homogenizing electric fieldPower cables with screens/conductive layersFlexible cablesPolyesterElectrical conductor

The invention discloses a high flexibility tensile corrosion-resistant aluminum alloy aerial insulating cable. The high flexibility tensile corrosion-resistant aluminum alloy aerial insulating cable comprises an aluminum alloy conductor, and a semiconducting conductor shielding layer and an insulating layer extrude the aluminum alloy conductor in sequence to constitute a line core; a fiber belt layer winds the line core and is provided with a steel belt shielding layer, a polyester rubber isolation pad is arranged outside the steel belt shielding layer, an aramid fiber tensile element is weaved outside the polyester rubber isolation pad, and a tetrafluoroethylene-hexafluoropropylene copolymer sheath is arranged outside the aramid fiber tensile element. The high flexibility tensile corrosion resistant aluminum alloy aerial insulating cable has very high mechanical strength and superior chemical agent resistance and also has superior hydrolysis resistance, superior oil resistance and fuel resistance and the like.

Owner:JIANGSU KAIDA CABLE

Method for manufacturing automotive oil conveying pipe

The invention provides a method for manufacturing an automotive oil conveying pipe. The method comprises the following steps: A, sending an inner pipe sizing material component and an outer pipe sizing material component into an internal mixer for mixing; B, performing quick detection test on the mixed inner pipe sizing material and outer pipe sizing material; C, putting the inner pipe sizing material and outer pipe sizing material subjected to the quick detection test into two feeding holes of a 90 extruder respectively, adopting the straight-form handpiece of the 90 extruder to extrude an inner pipe rubber layer, and adopting a laser diameter measuring instrument to automatically detect the size of the extruded inner pipe rubber layer; D, selecting a 12-stitch knitting machine to knit a fiber linear enhancement layer on the extruded inner pipe rubber layer; E, adopting the T-shaped handpiece of the 90 extruder to directly extrude an outer pipe rubber layer on the inner pipe rubber layer knitted with the fiber linear enhancement layer to produce a semi-finished siphonula; F, cutting off the siphonula, penetrating the cut siphonula into a die, and sending the siphonula into a vulcanizer for vulcanization. According to the method, the automotive oil conveying pipe is simple in production technology, low in cost, high in efficiency, excellent in fuel oil resistance, and wide in thermal resistance range.

Owner:鲁一军

Fluororubber base sealant composition and fluororubber base sealant

InactiveUS7199198B2Excellent fuel oil resistance and freeze resistanceGood fuel resistanceOther chemical processesVinyl etherHexafluoropropylene

Owner:NOK CORP

Fluororubber and epichlorophdrin rubber formula

ActiveCN100532447CHigh electronegativityGood fuel resistanceSynthetic resin layered productsPolymer scienceLead(II,IV) oxide

The invention relates to a formula of fluorine rubber and epichlorohydrin rubber. The components of the inner layer of fluorine rubber include fluorine rubber, thermal black N990, 2,5-dimethyl-2,5-dihexane, triallyl cyanurate, carnauba wax; the middle layer and the outer layer The components of the layer epichloride rubber include epichloride rubber C, epichloride rubber H, quick extruded carbon black N550, anti-aging agent NBC, processing aid R-300, stearic acid, plasticizer RS-107, trioxide Lead, ethylenethiourea NA-22, plasticizer W-305ELS, anti-scorch agent CTP-80. By adopting the rubber hose whose inner layer is fluorine rubber and outer layer is chloroether rubber, the problems of high temperature resistance, heat oil resistance, ozone resistance, and fuel oil permeation requirements of the fuel hose are improved.

Owner:TIANJIN PENGYI GRP CO LTD

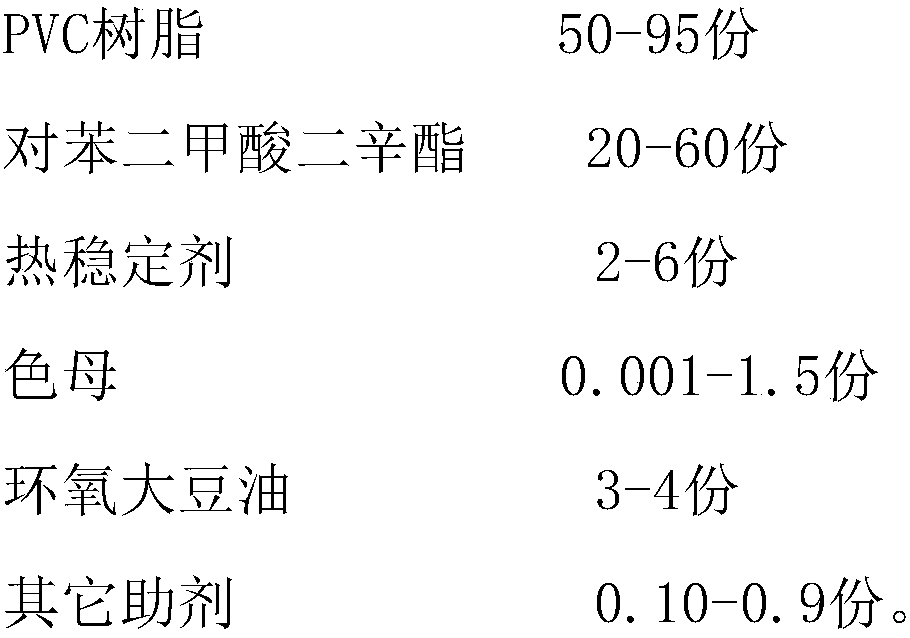

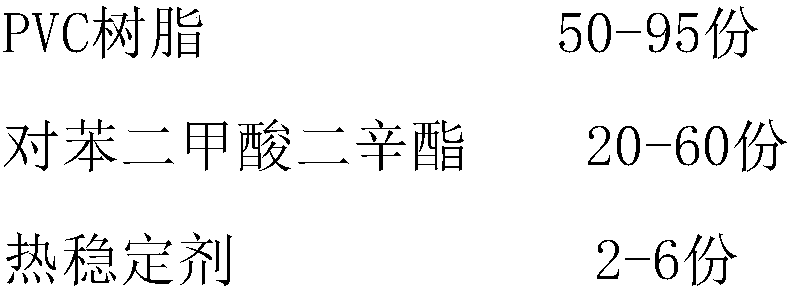

Polyvinyl chloride multi-color phoenix tail vein sheet material and calendaring process thereof

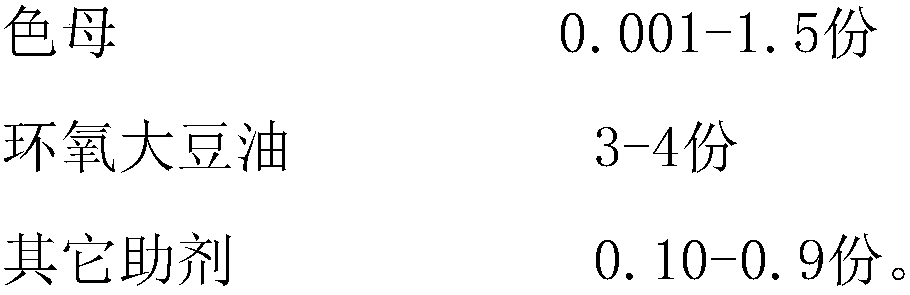

InactiveCN107841061AImprove the three-dimensional effectSoft and comfortableFlat articlesMasterbatchDioctyl terephthalate

The invention relates to the technical field of a sheet material, in particular to a polyvinyl chloride multi-color phoenix tail vein sheet material and a calendaring process thereof. The polyvinyl chloride multi-color phoenix tail vein sheet material is prepared from the following raw materials in parts by weight: 50 to 95 parts of PVC (polyvinyl chloride) resin, 20 to 60 parts of dioctyl terephthalate, 2 to 6 parts of thermal stabilizers, 0.001 to 1.5 parts of color masterbatch, 3 to 4 parts of epoxidized soybean oil and 0.10 to 0.9 part of other auxiliary agents. The polyvinyl chloride multi-color phoenix tail vein sheet material has good three-dimensional steric effects and soft and comfortable hand feelings; good chemical stability, fire resistance, insulation, acid and alkali resistance, waterproof and dampproof performance, anti-corrosion performance, tensile resistance, anti-aging performance, anti-static performance and the like; the comprehensive performance is excellent.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com