Polyvinyl chloride multi-color phoenix tail vein sheet material and calendaring process thereof

A polyvinyl chloride and calendering process technology, applied in the field of polyvinyl chloride colorful phoenix-tail pattern sheet and its calendering process, can solve the problems of small ornamental, poor mechanical and physical properties, etc., and achieves good thermal stabilization effect and easy processing. , the effect of good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

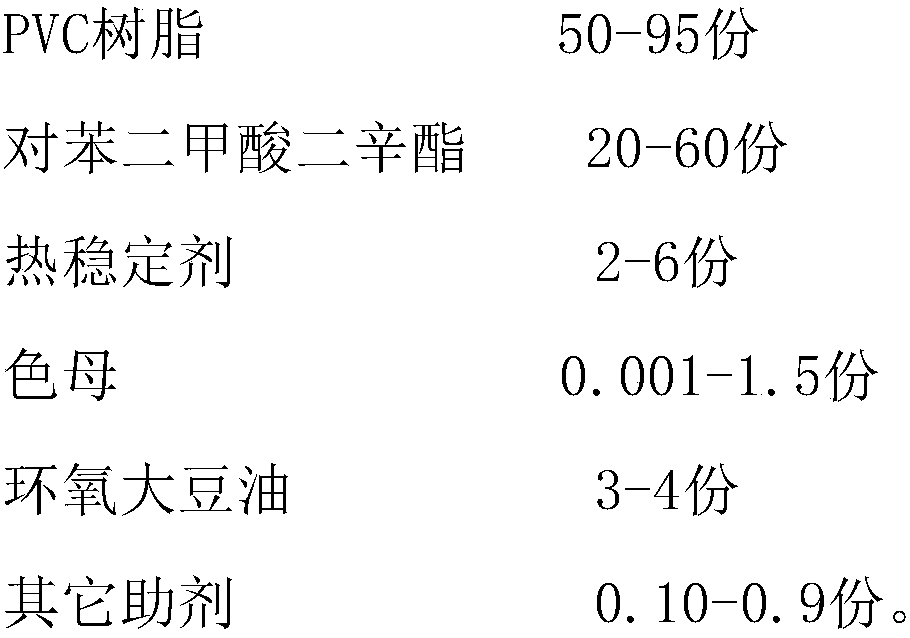

[0055] A polyvinyl chloride colorful phoenix-tailed sheet, the polyvinyl chloride colorful phoenix-tailed sheet includes the following raw materials in parts by weight:

[0056]

[0057] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 1000.

[0058] The heat stabilizer is a mixture of calcium stearate, barium stearate, zinc stearate and hydrotalcite in a weight ratio of 1:0.8:0.8:0.4.

[0059] The polyvinyl chloride colorful phoenix-tail pattern sheet of the color masterbatch includes the following raw materials in parts by weight: 20 parts of ethylene-vinyl acetate copolymer, 10 parts of titanium dioxide, 10 parts of polyacrylate, 15 parts of heavy calcium carbonate and oxidized 20 parts of polyethylene wax.

[0060] The titanium dioxide is surface-treated, and its preparation method is: stir the rutile-type titanium dioxide at a high speed at 100°C for 15 minutes to remove the absorbed water, then add it into the styrene and silic...

Embodiment 2

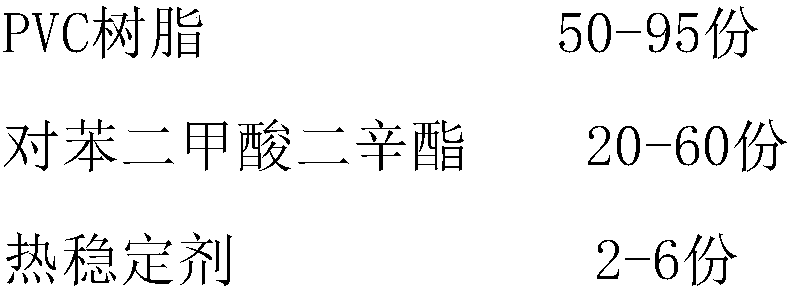

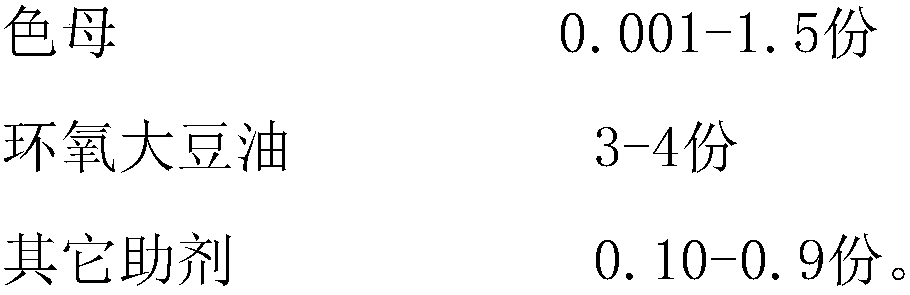

[0074] A polyvinyl chloride colorful phoenix-tailed sheet, the polyvinyl chloride colorful phoenix-tailed sheet includes the following raw materials in parts by weight:

[0075]

[0076] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 1200.

[0077] The heat stabilizer is a mixture of calcium stearate, barium stearate, zinc stearate and hydrotalcite in a weight ratio of 1:0.9:0.9:0.5.

[0078] The polyvinyl chloride colorful phoenix-tail pattern sheet of the color masterbatch includes the following raw materials in parts by weight: 30 parts of ethylene-vinyl acetate copolymer, 20 parts of titanium dioxide, 15 parts of polyacrylate, 20 parts of heavy calcium carbonate and oxidized 25 parts of polyethylene wax.

[0079] The titanium dioxide is surface-treated, and its preparation method is: stir the rutile-type titanium dioxide at a high speed of 105°C for 18 minutes to remove the absorbed water, then add it into the styrene and silic...

Embodiment 3

[0093] A polyvinyl chloride colorful phoenix-tailed sheet, the polyvinyl chloride colorful phoenix-tailed sheet includes the following raw materials in parts by weight:

[0094]

[0095]

[0096] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 1500.

[0097] The heat stabilizer is a mixture of calcium stearate, barium stearate, zinc stearate and hydrotalcite in a weight ratio of 1:1:1:0.6.

[0098] The polyvinyl chloride colorful phoenix-tail pattern sheet of the color masterbatch includes the following raw materials in parts by weight: 40 parts of ethylene-vinyl acetate copolymer, 30 parts of titanium dioxide, 20 parts of polyacrylate, 25 parts of heavy calcium carbonate and oxidized 30 parts of polyethylene wax.

[0099] The titanium dioxide is surface-treated, and its preparation method is: stir the rutile-type titanium dioxide at a high speed of 110°C for 20 minutes to remove the absorbed water, then add it to the styrene and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com