Fluororubber and epichlorophdrin rubber formula

A chloroether rubber and fluororubber technology, applied in the field of fluororubber and chloroether rubber formulation, can solve problems such as poor ozone resistance and fuel penetration requirements of fuel hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

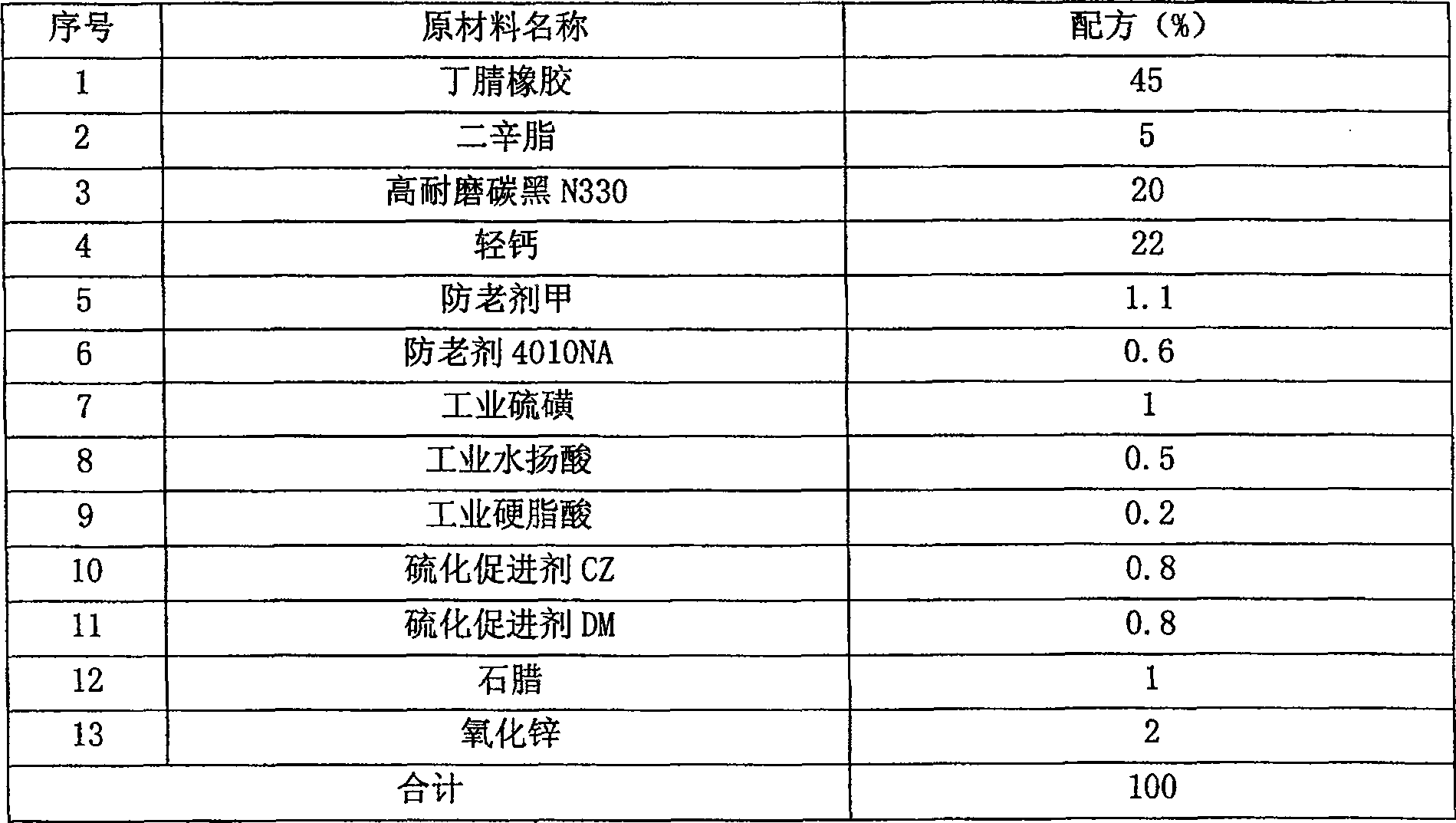

[0016] The content is calculated as a percentage by weight

[0017]

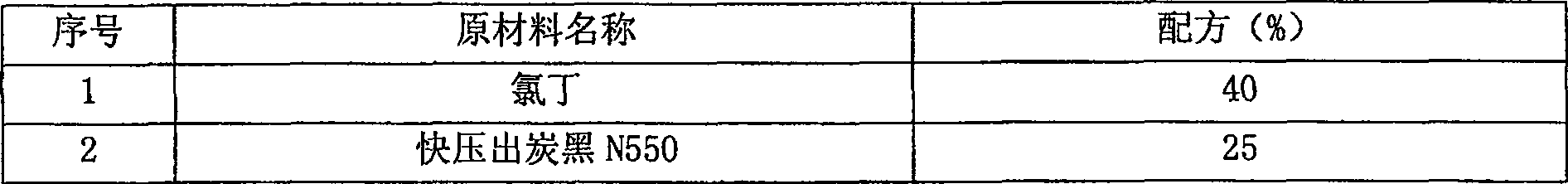

[0018] Implementation of the middle and outer layers of chloroether:

[0019] The content is calculated as a percentage by weight

[0020]

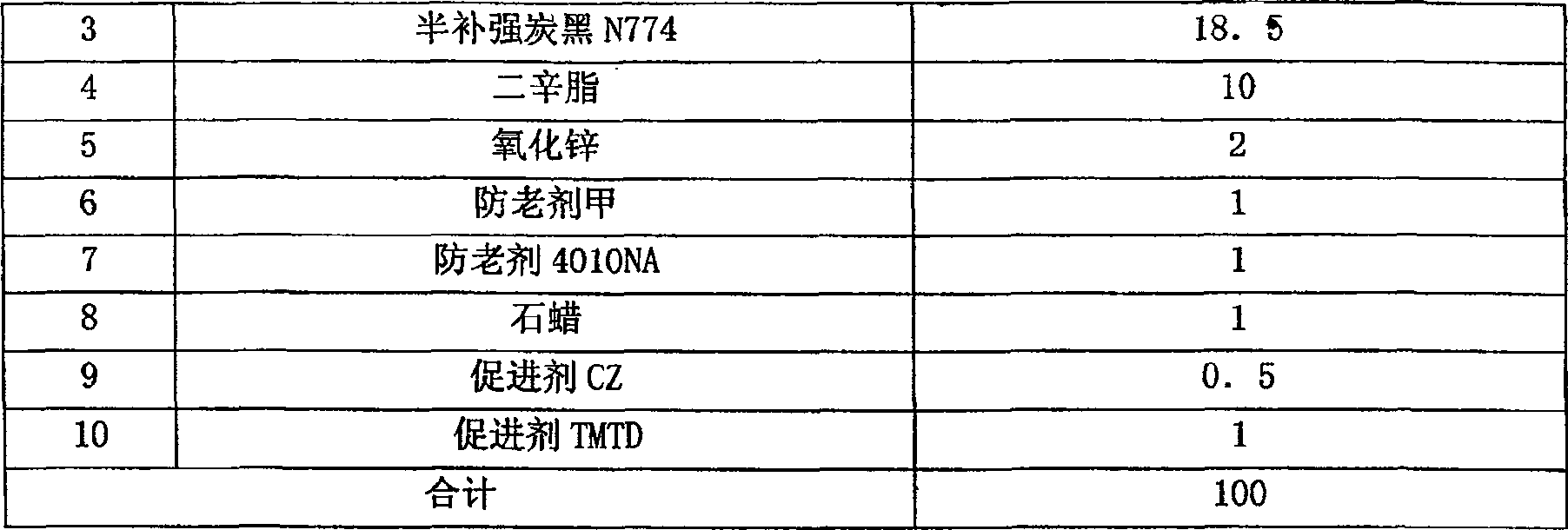

[0021] The following is a comparison of the performance of the inner layer of fluorine rubber and nitrile rubber.

[0022] Serial number Test conditions Internal technical requirements Measured value of fluorine rubber Measured value of nitrile 1 Hardness Shore A 1.1 Availability 80±5 78 77 1.2 After heat-resistant storage 70h / 135℃ 0~+6 +4 fracture

[0023] 1.3 After storage of fuel-resistant FAM2, 168h / 23℃ 0~-12 -8 -18 1.4 The fuel-resistant FAM2 is dried immediately after storage for 22h / 150℃ 0~+6 +2 +10 1.5 After storage of rapeseed oil methyl ester 94h / 100℃ ±6 +4 +10 504h / 100℃ ±10 +3 +14 1.6 Resistant to rapeseed oil methyl ester storage, press and dry 22h / 80℃ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com