Special rubber alloy elastomer for sealing members and preparation method thereof

A technology for special rubber and seals, applied in the field of special rubber alloy elastomers for seals and their preparation, can solve the problems of poor processability, poor cold resistance, and high price of fluororubber, and achieve high self-lubrication and significantly reduced friction coefficient. , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

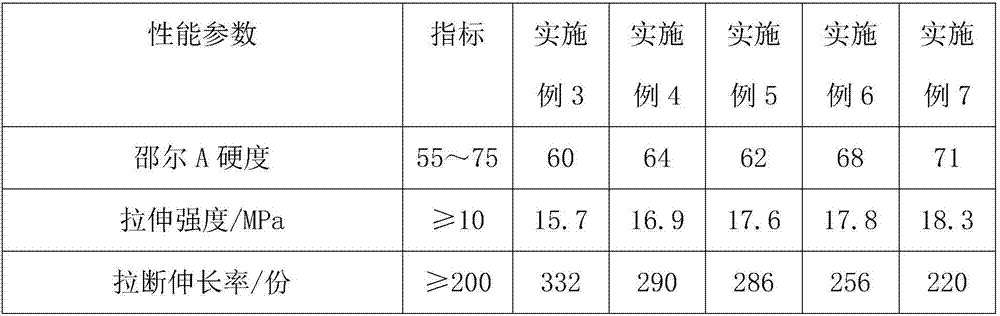

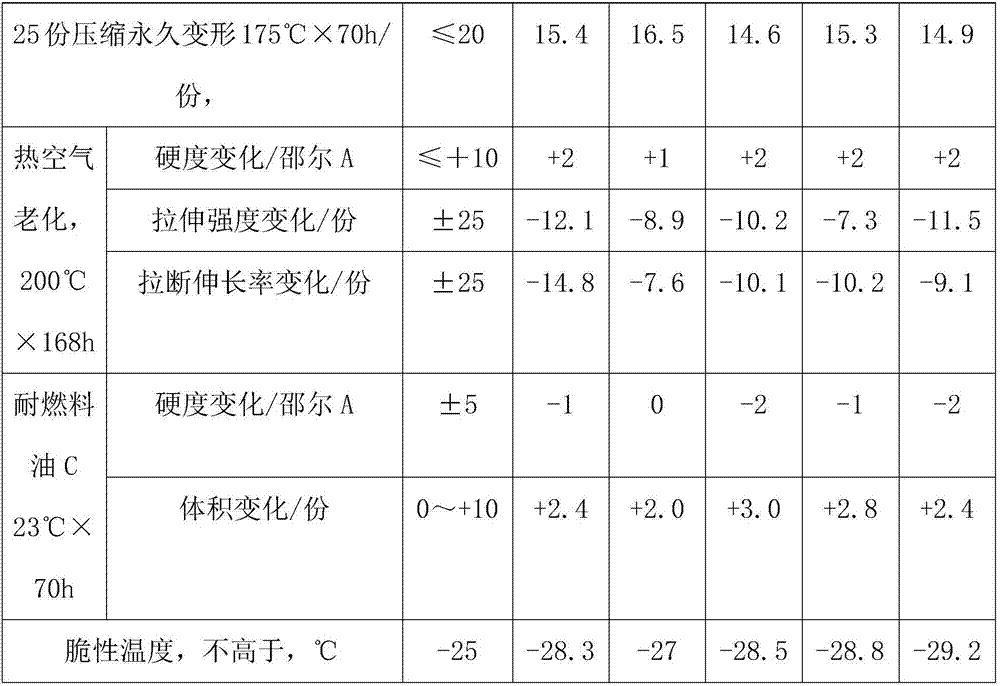

Examples

Embodiment 1

[0025] A kind of special rubber alloy elastic body for seal that the present invention proposes, its raw material comprises by weight: 40 parts of fluorine rubber raw rubber, 10 parts of hydrogenated nitrile rubber raw rubber, 6 parts of thermal cracking carbon black, 5 parts of calcium sulfate , 0.5 parts of carbon fiber, 0.2 parts of graphene, 0.5 parts of chromium oxide green, 0.3 parts of polyperfluoroisopropyl ether oil, 1 part of zinc oxide, 0.8 parts of 1,3-bis(tert-butylperoxyisopropyl)benzene, 0.8 parts of three 0.5 parts of allyl isocyanurate, 0.7 parts of lubricant.

[0026] The present invention also proposes a method for preparing a special rubber alloy elastomer for a seal, comprising the steps of:

[0027] S1. Preparation of synthetic rubber: mix fluorine rubber raw rubber and hydrogenated nitrile rubber raw rubber evenly, then add filler reinforcing agent, polyperfluoroisopropyl ether oil, zinc oxide and lubricant, banbury after mixing, Then add organic peroxi...

Embodiment 2

[0031] A kind of special rubber alloy elastic body for seal that the present invention proposes, its raw material comprises by weight: 60 parts of fluorine rubber raw rubber, 16.5 parts of hydrogenated nitrile rubber raw rubber, 20 parts of thermal cracking carbon black, active calcium silicate 15 parts, 10 parts of magnesium silicate, 2 parts of carbon fiber, 1 part of graphene, 1 part of iron oxide yellow, 1 part of titanium dioxide, 2 parts of polyperfluoroisopropyl ether oil, 3 parts of zinc oxide, 2,5-dimethyl -1 part of 2,5-bis(tert-butylperoxy)hexane, 0.4 part of dicumyl peroxide, 2.5 parts of triallyl isocyanurate, and 1 part of lubricant.

[0032] The present invention also proposes a method for preparing a special rubber alloy elastomer for a seal, comprising the steps of:

[0033] S1. Preparation of synthetic rubber: Mix fluorine rubber raw rubber and hydrogenated nitrile rubber raw rubber evenly, then add thermal cracking carbon black, activated calcium silicate, m...

Embodiment 3

[0037]A kind of special rubber alloy elastic body for seal that the present invention proposes, its raw material comprises by weight: 45 parts of fluorine rubber raw rubber, 10 parts of hydrogenated nitrile rubber raw rubber, 8 parts of active calcium silicate, 5 parts of calcium oxide, 0.03 parts of graphene, 1.5 parts of polyperfluoroisopropyl ether oil, 2 parts of zinc oxide, 0.6 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane, triallyl isopropyl 1.8 parts of cyanurate, 0.5 parts of lubricant, and 0.8 parts of iron oxide red.

[0038] The present invention also proposes a method for preparing a special rubber alloy elastomer for a seal, comprising the steps of:

[0039] S1. Preparation of synthetic rubber: Put fluororubber raw rubber and hydrogenated nitrile rubber raw rubber into an open mill and mix them evenly to obtain material A, then mix material A with active calcium silicate, calcium oxide, graphene, polyperfluoroisocyanate Propyl ether oil, zinc oxide, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com