Food-grade polyvinyl chloride film and calendaring process thereof

A technology of polyvinyl chloride and calendering process is applied in the field of food-grade polyvinyl chloride film and its calendering process, which can solve the problems of poor environmental protection and limited application of blown film, and achieve good hand feeling and visual effect and good mechanical strength. , the effect of reducing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

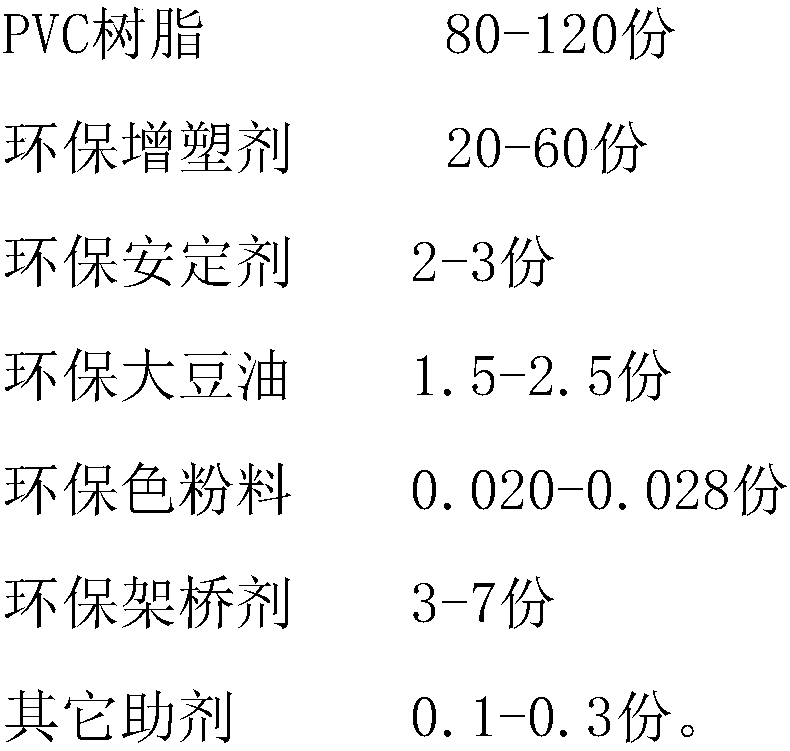

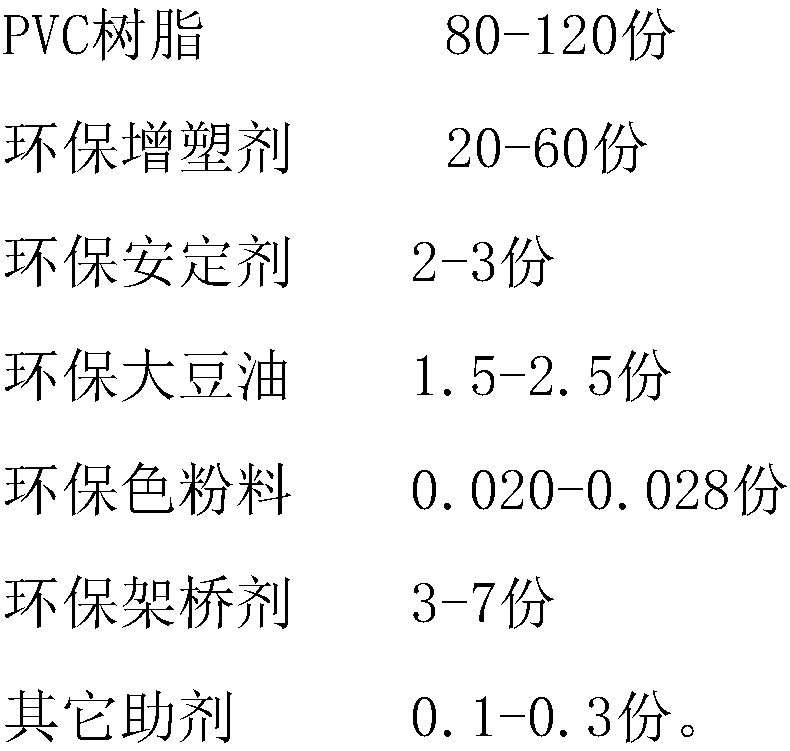

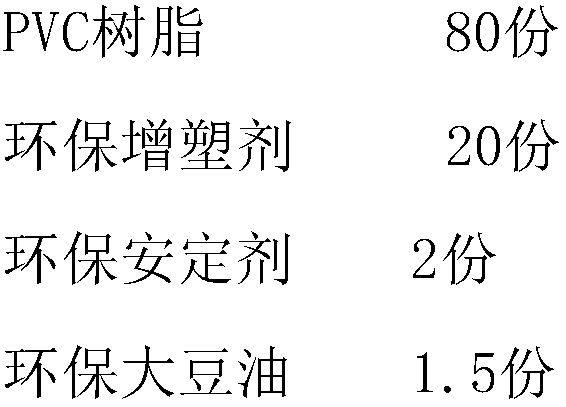

[0054] A kind of food grade polyvinyl chloride film, described food grade polyvinyl chloride film comprises the raw material of following weight portion:

[0055]

[0056]

[0057] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 1000.

[0058] The environment-friendly plasticizer is a mixture composed of synthetic vegetable ester, trioctyl trimellitate and diisononyl cyclohexane 1,2-dicarboxylate in a weight ratio of 1:0.5:1.

[0059] The environment-friendly stabilizer is a mixture composed of calcium stearate, barium stearate, zinc stearate and hydrotalcite in a weight ratio of 1:0.8:0.8:0.4.

[0060] The environmentally friendly soybean oil is epoxidized soybean oil with an epoxy value of 6.1%.

[0061] The environmentally friendly toner is a mixture of phthalocyanine blue and ultramarine toner in a weight ratio of 0.8:1.

[0062] The environment-friendly bridging agent is a vinyl chloride-vinyl acetate-butyl acrylate terpoly...

Embodiment 2

[0073] A kind of food grade polyvinyl chloride film, described food grade polyvinyl chloride film comprises the raw material of following weight portion:

[0074]

[0075] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 1200.

[0076] The environment-friendly plasticizer is a mixture composed of synthetic vegetable ester, trioctyl trimellitate and diisononyl cyclohexane 1,2-dicarboxylate in a weight ratio of 1.2:0.8:1.

[0077] The environment-friendly stabilizer is a mixture composed of calcium stearate, barium stearate, zinc stearate and hydrotalcite in a weight ratio of 1:0.9:0.9:0.5.

[0078] The environmentally friendly soybean oil is epoxidized soybean oil with an epoxy value of 6.2%.

[0079] The environmentally friendly toner is a mixture of phthalocyanine blue and ultramarine toner in a weight ratio of 0.9:1.

[0080] The environment-friendly bridging agent is a vinyl chloride-vinyl acetate-butyl acrylate terpolymer with a...

Embodiment 3

[0091] A kind of food grade polyvinyl chloride film, described food grade polyvinyl chloride film comprises the raw material of following weight portion:

[0092]

[0093] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 1500.

[0094] The environment-friendly plasticizer is a mixture composed of synthetic vegetable ester, trioctyl trimellitate and diisononyl cyclohexane 1,2-dicarboxylate in a weight ratio of 1.5:1:1.

[0095] The environment-friendly stabilizer is a mixture composed of calcium stearate, barium stearate, zinc stearate and hydrotalcite in a weight ratio of 1:1:1:0.6.

[0096] The environmentally friendly soybean oil is epoxidized soybean oil with an epoxy value of 6.3%.

[0097] The environmentally friendly toner is a mixture of phthalocyanine blue and ultramarine toner in a weight ratio of 1:1.

[0098] The environment-friendly bridging agent is a vinyl chloride-vinyl acetate-butyl acrylate terpolymer with a vinyl c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com