Novel insulated sealing material for chemical pump

An insulating sealing and chemical pump technology, which is applied in the field of new insulating sealing materials for chemical pumps, can solve the problem that the breakdown voltage cannot meet the requirements of chemical pump performance indicators, and achieves the effect of reducing production costs and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

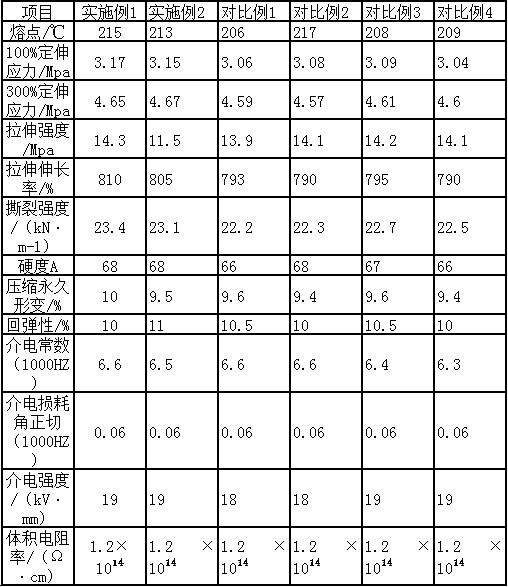

Examples

Embodiment 1

[0017] A new type of insulating and sealing material for chemical pumps, the raw material components and their parts by weight are: 110 parts of organic fluorothermoplastic elastomer, 10 parts of Al2O3, 50.8 parts of polymethylsiloxane, and 46 parts of polypropylene , 20 parts of barium sulfate, 0.1 part of tetraethylenepentamine, 0.1 part of hexafluorobisphenol A, and 0.1 part of sulfonated-1,3-dibenzyl-2-methylimidazole.

[0018] The preparation method of a novel insulating and sealing material for chemical pumps comprises the following steps:

[0019] Step 1. Add organic fluorothermoplastic elastomer, Al2O3, polymethylsiloxane, polypropylene, barium sulfate, tetraethylenepentamine, hexafluorobisphenol A and sulfonated-1,3-dibenzyl in the following order -2-methylimidazole is mixed on an open mill to obtain a rubber compound;

[0020] Step 2: Dry and store the mixed rubber obtained in Step 1 at a low temperature, and then carry out a re-milling on an open mill before moldin...

Embodiment 2

[0023] A new type of insulating and sealing material for chemical pumps, the raw material components and their parts by weight are: 106 parts of organic fluorothermoplastic elastomer, 12 parts of Al2O3, 51.3 parts of polymethylsiloxane, and 48.5 parts of polypropylene , 25 parts of barium sulfate, 0.1 parts of tetraethylenepentamine, 0.15 parts of hexafluorobisphenol A, and 0.1 parts of sulfonated-1,3-dibenzyl-2-methylimidazole.

[0024] The preparation method of a novel insulating and sealing material for chemical pumps comprises the following steps:

[0025] Step 1. Add organic fluorothermoplastic elastomer, Al2O3, polymethylsiloxane, polypropylene, barium sulfate, tetraethylenepentamine, hexafluorobisphenol A and sulfonated-1,3-dibenzyl in the following order -2-methylimidazole is mixed on an open mill to obtain a rubber compound;

[0026] Step 2: Dry and store the mixed rubber obtained in Step 1 at a low temperature, and then carry out a re-milling on an open mill before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com